ASTM E1221-23

(Test Method)Standard Test Method for Determining Plane-Strain Crack-Arrest Fracture Toughness, KIa, of Ferritic Steels

Standard Test Method for Determining Plane-Strain Crack-Arrest Fracture Toughness, <emph type="bdit">K<inf>Ia</inf></emph>, of Ferritic Steels

SIGNIFICANCE AND USE

5.1 In structures containing gradients in either toughness or stress, a crack may initiate in a region of either low toughness or high stress, or both, and arrest in another region of either higher toughness or lower stress, or both. The value of the stress intensity factor during the short time interval in which a fast-running crack arrests is a measure of the ability of the material to arrest such a crack. Values of the stress intensity factor of this kind, which are determined using dynamic methods of analysis, provide a value for the crack-arrest fracture toughness which will be termed KA in this discussion. Static methods of analysis, which are much less complex, can often be used to determine K at a short time (1 to 2 ms) after crack arrest. The estimate of the crack-arrest fracture toughness obtained in this fashion is termed K a. When macroscopic dynamic effects are relatively small, the difference between KA and Ka is also small (1-4). For cracks propagating under conditions of crack-front plane-strain, in situations where the dynamic effects are also known to be small, KIa determinations using laboratory-sized specimens have been used successfully to estimate whether, and at what point, a crack will arrest in a structure (5, 6). Depending upon component design, loading compliance, and the crack jump length, a dynamic analysis of a fast-running crack propagation event may be necessary in order to predict whether crack arrest will occur and the arrest position. In such cases, values of K Ia determined by this test method can be used to identify those values of K below which the crack speed is zero. More details on the use of dynamic analyses can be found in Ref (4).

5.2 This test method can serve at least the following additional purposes:

5.2.1 In materials research and development, to establish in quantitative terms significant to service performance, the effects of metallurgical variables (such as composition or heat treatment) or fabrication o...

SCOPE

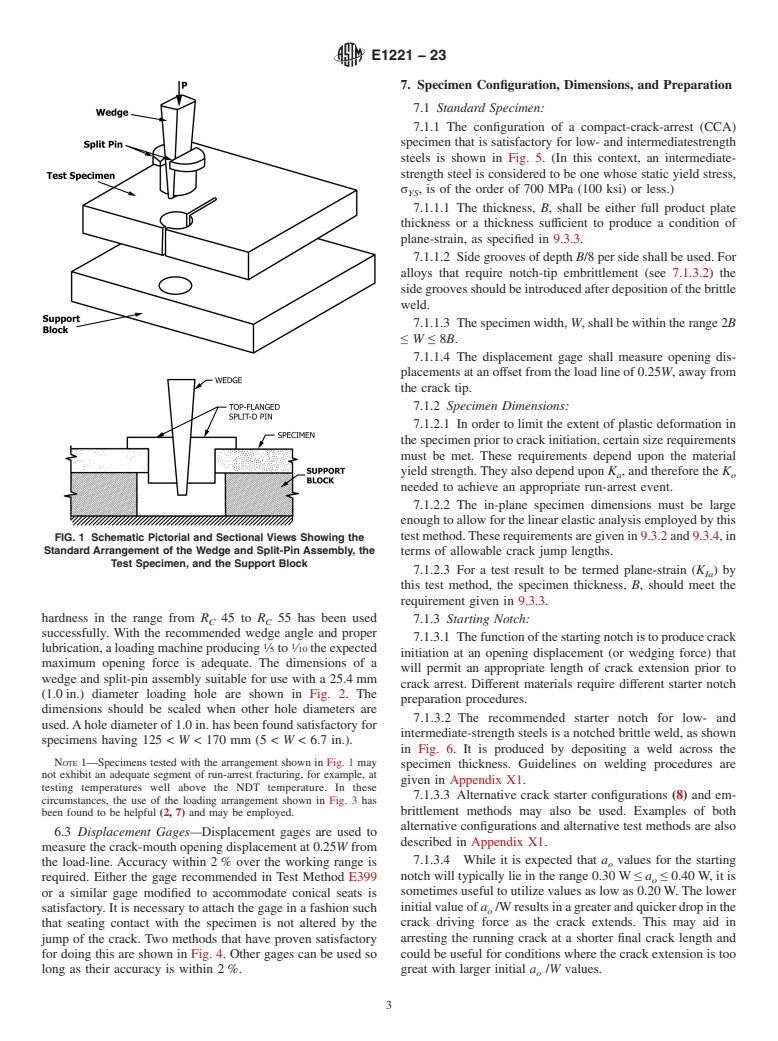

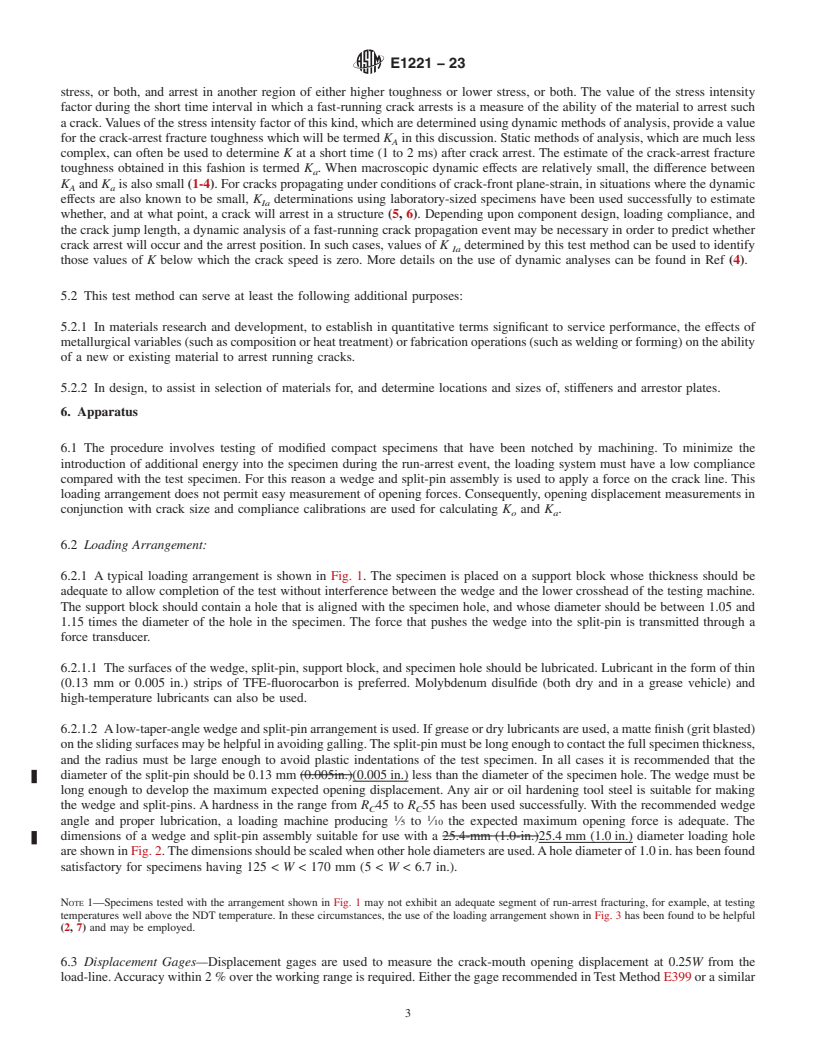

1.1 This test method employs a side-grooved, crack-line-wedge-loaded specimen to obtain a rapid run-arrest segment of flat-tensile separation with a nearly straight crack front. This test method provides a static analysis determination of the stress intensity factor at a short time after crack arrest. The estimate is denoted Ka. When certain size requirements are met, the test result provides an estimate, termed KIa, of the plane-strain crack-arrest toughness of the material.

1.2 The specimen size requirements, discussed later, provide for in-plane dimensions large enough to allow the specimen to be modeled by linear elastic analysis. For conditions of plane-strain, a minimum specimen thickness is also required. Both requirements depend upon the crack arrest toughness and the yield strength of the material. A range of specimen sizes may therefore be needed, as specified in this test method.

1.3 If the specimen does not exhibit rapid crack propagation and arrest, Ka cannot be determined.

1.4 The values stated in SI units are to be regarded as the standards. The values given in parentheses are provided for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E1221 − 23

Standard Test Method for

Determining Plane-Strain Crack-Arrest Fracture Toughness,

1

K , of Ferritic Steels

Ia

This standard is issued under the fixed designation E1221; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This test method employs a side-grooved, crack-line-

E8/E8M Test Methods for Tension Testing of Metallic Ma-

wedge-loaded specimen to obtain a rapid run-arrest segment of

terials

flat-tensile separation with a nearly straight crack front. This

E23 Test Methods for Notched Bar Impact Testing of Me-

test method provides a static analysis determination of the

tallic Materials

stress intensity factor at a short time after crack arrest. The

E208 Test Method for Conducting Drop-Weight Test to

estimate is denoted K . When certain size requirements are

a

Determine Nil-Ductility Transition Temperature of Fer-

met, the test result provides an estimate, termed K , of the

Ia

ritic Steels

plane-strain crack-arrest toughness of the material.

E399 Test Method for Linear-Elastic Plane-Strain Fracture

Toughness of Metallic Materials

1.2 The specimen size requirements, discussed later, pro-

E1304 Test Method for Plane-Strain (Chevron-Notch) Frac-

vide for in-plane dimensions large enough to allow the speci-

ture Toughness of Metallic Materials

men to be modeled by linear elastic analysis. For conditions of

E1823 Terminology Relating to Fatigue and Fracture Testing

plane-strain, a minimum specimen thickness is also required.

Both requirements depend upon the crack arrest toughness and

3. Terminology

the yield strength of the material. A range of specimen sizes

3.1 Definitions:

may therefore be needed, as specified in this test method.

3.1.1 Definitions in Terminology E1823 are applicable to

1.3 If the specimen does not exhibit rapid crack propagation this test method.

and arrest, K cannot be determined. 3.2 Definitions of Terms Specific to This Standard:

a

3.2.1 conditional value of the plane-strain crack-arrest

1.4 The values stated in SI units are to be regarded as the

−3/2

fracture toughness, K (FL ) —the conditional value of K

Qa Ia

standards. The values given in parentheses are provided for

calculated from the test results and subject to the validity

information only.

criteria specified in this test method.

3.2.1.1 Discussion—In this test method, side-grooved speci-

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the mens are used. The calculation of K is based upon measure-

Qa

ments of both the arrested crack size and of the crack-mouth

responsibility of the user of this standard to establish appro-

opening displacement prior to initiation of a fast-running crack

priate safety, health, and environmental practices and deter-

and shortly after crack arrest.

mine the applicability of regulatory limitations prior to use.

−3/2

3.2.2 crack-arrest fracture toughness, K (FL )—the

1.6 This international standard was developed in accor- A

value of the stress intensity factor shortly after crack arrest as

dance with internationally recognized principles on standard-

determined from dynamic methods of analysis.

ization established in the Decision on Principles for the

3.2.2.1 Discussion—The in-plane specimen dimensions

Development of International Standards, Guides and Recom-

must be large enough for adequate enclosure of the crack-tip

mendations issued by the World Trade Organization Technical

plastic zone by a linear-elastic stress field.

Barriers to Trade (TBT) Committee.

−3/2

3.2.3 crack-arrest fracture toughness, K (FL )—the

a

value of the stress intensity factor shortly after crack arrest, as

determined from static methods of analysis.

1

This test method is under the jurisdiction of ASTM Committee E08 on Fatigue

and Fracture and is the direct responsibility of Subcommittee E08.07 on Fracture

2

Mechanics. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2023. Published December 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ɛ1

approved in 1988. Last previous edition approved in 2018 as E1221 – 18 . DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E1221-23. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-295

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: E1221 − 12a (Reapproved 2018) E1221 − 23

Standard Test Method for

Determining Plane-Strain Crack-Arrest Fracture Toughness,

1

K , of Ferritic Steels

Ia

This standard is issued under the fixed designation E1221; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Editorial changes were made throughout in May 2020.

1. Scope

1.1 This test method employs a side-grooved, crack-line-wedge-loaded specimen to obtain a rapid run-arrest segment of

flat-tensile separation with a nearly straight crack front. This test method provides a static analysis determination of the stress

intensity factor at a short time after crack arrest. The estimate is denoted K . When certain size requirements are met, the test result

a

provides an estimate, termed K , of the plane-strain crack-arrest toughness of the material.

Ia

1.2 The specimen size requirements, discussed later, provide for in-plane dimensions large enough to allow the specimen to be

modeled by linear elastic analysis. For conditions of plane-strain, a minimum specimen thickness is also required. Both

requirements depend upon the crack arrest toughness and the yield strength of the material. A range of specimen sizes may

therefore be needed, as specified in this test method.

1.3 If the specimen does not exhibit rapid crack propagation and arrest, K cannot be determined.

a

1.4 The values stated in SI units are to be regarded as the standards. The values given in parentheses are provided for information

only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E8/E8M Test Methods for Tension Testing of Metallic Materials

E23 Test Methods for Notched Bar Impact Testing of Metallic Materials

E208 Test Method for Conducting Drop-Weight Test to Determine Nil-Ductility Transition Temperature of Ferritic Steels

1

This test method is under the jurisdiction of ASTM Committee E08 on Fatigue and Fracture and is the direct responsibility of Subcommittee E08.07 on Fracture

Mechanics.

Current edition approved Nov. 1, 2018Nov. 1, 2023. Published December 2018December 2023. Originally approved in 1988. Last previous edition approved in 20122018

ɛ1

as E1221 – 12a.E1221 – 18 . DOI: 10.1520/E1221-12AR18E01.10.1520/E1221-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1221 − 23

E399 Test Method for Linear-Elastic Plane-Strain Fracture Toughness of Metallic Materials

3

E616 Terminology Relating to Fracture Testing (Withdrawn 1996)

E1304 Test Method for Plane-Strain (Chevron-Notch) Fracture Toughness of Metallic Materials

E1823 Terminology Relating to Fatigue and Fracture Testing

3. Terminology

3.1 Definitions:

3.1.1 Definitions in Terminology E1823 are applicable to this test method.

3.2 Definitions of Terms Specific to This Standard:

−3/2

3.2.1 conditional value of the plane-strain crack-arrest fracture toughness, K (FL ) —the conditional value of K calculated

Qa Ia

from the test results and subject to the validity criteria specified in this test method.

3.2.1.1 Discussion—

In this test method, side-grooved specimens are used. The calculation of K is based upon measurements of both the arrested

Qa

crack size and of the crack-mouth opening displacement prior to initiation of a fast-running crack and shortly after crack arrest.

−3/2

3.2.2 crack-arrest fracture toughness, K (FL )—the value of the stress intensity facto

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.