ASTM E740/E740M-23

(Practice)Standard Practice for Fracture Testing with Surface-Crack Tension Specimens

Standard Practice for Fracture Testing with Surface-Crack Tension Specimens

SIGNIFICANCE AND USE

4.1 The surface-crack tension (SCT) test is used to estimate the load-carrying capacity of simple sheet- or plate-like structural components having a type of flaw likely to occur in service. The test is also used for research purposes to investigate failure mechanisms of cracks under service conditions.

4.2 The residual strength of an SCT specimen is a function of the crack depth and length and the specimen thickness as well as the characteristics of the material. This relationship is extremely complex and cannot be completely described or characterized at present.

4.2.1 The results of the SCT test are suitable for direct application to design only when the service conditions exactly parallel the test conditions. Some methods for further analysis are suggested in Appendix X1.

4.3 In order that SCT test data can be comparable and reproducible and can be correlated among laboratories, it is essential that uniform SCT testing practices be established.

4.4 The specimen configuration, preparation, and instrumentation described in this practice are generally suitable for cyclic- or sustained-force testing as well. However, certain constraints are peculiar to each of these tests. These are beyond the scope of this practice but are discussed in Ref. (1).

SCOPE

1.1 This practice covers the design, preparation, and testing of surface-crack tension (SCT) specimens. It relates specifically to testing under continuously increasing force and excludes cyclic and sustained loadings. The quantity determined is the residual strength of a specimen having a semielliptical or circular-segment fatigue crack in one surface. This value depends on the crack dimensions and the specimen thickness as well as the characteristics of the material.

1.2 Metallic materials that can be tested are not limited by strength, thickness, or toughness. However, tests of thick specimens of tough materials may require a tension test machine of extremely high capacity. The applicability of this practice to nonmetallic materials has not been determined.

1.3 This practice is limited to specimens having a uniform rectangular cross section in the test section. The test section width and length must be large with respect to the crack length. Crack depth and length should be chosen to suit the ultimate purpose of the test.

1.4 Residual strength may depend strongly upon temperature within a certain range depending upon the characteristics of the material. This practice is suitable for tests at any appropriate temperature.

1.5 Residual strength is believed to be relatively insensitive to loading rate within the range normally used in conventional tension tests. When very low or very high rates of loading are expected in service, the effect of loading rate should be investigated using special procedures that are beyond the scope of this practice.

Note 1: Further information on background and need for this type of test is given in the report of ASTM Task Group E24.01.05 on Part-Through-Crack Testing (1).2

1.6 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to T...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E740/E740M − 23

Standard Practice for

1

Fracture Testing with Surface-Crack Tension Specimens

This standard is issued under the fixed designation E740/E740M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining

1.1 This practice covers the design, preparation, and testing

values from the two systems may result in non-conformance

of surface-crack tension (SCT) specimens. It relates specifi-

with the standard.

cally to testing under continuously increasing force and ex-

1.7 This standard does not purport to address all of the

cludes cyclic and sustained loadings. The quantity determined

safety concerns, if any, associated with its use. It is the

is the residual strength of a specimen having a semielliptical or

responsibility of the user of this standard to establish appro-

circular-segment fatigue crack in one surface. This value

priate safety, health, and environmental practices and deter-

depends on the crack dimensions and the specimen thickness as

mine the applicability of regulatory limitations prior to use.

well as the characteristics of the material.

1.8 This international standard was developed in accor-

1.2 Metallic materials that can be tested are not limited by

dance with internationally recognized principles on standard-

strength, thickness, or toughness. However, tests of thick

ization established in the Decision on Principles for the

specimens of tough materials may require a tension test

Development of International Standards, Guides and Recom-

machine of extremely high capacity. The applicability of this

mendations issued by the World Trade Organization Technical

practice to nonmetallic materials has not been determined.

Barriers to Trade (TBT) Committee.

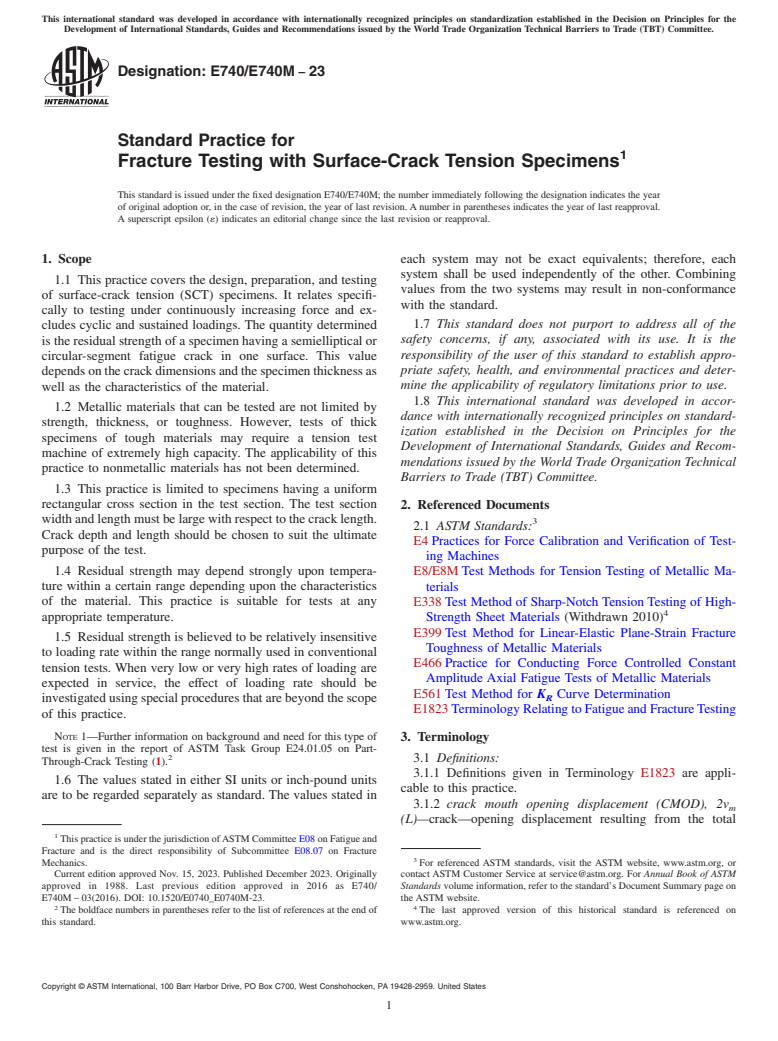

1.3 This practice is limited to specimens having a uniform

rectangular cross section in the test section. The test section

2. Referenced Documents

width and length must be large with respect to the crack length. 3

2.1 ASTM Standards:

Crack depth and length should be chosen to suit the ultimate

E4 Practices for Force Calibration and Verification of Test-

purpose of the test.

ing Machines

1.4 Residual strength may depend strongly upon tempera-

E8/E8M Test Methods for Tension Testing of Metallic Ma-

ture within a certain range depending upon the characteristics terials

of the material. This practice is suitable for tests at any

E338 Test Method of Sharp-Notch Tension Testing of High-

4

appropriate temperature.

Strength Sheet Materials (Withdrawn 2010)

E399 Test Method for Linear-Elastic Plane-Strain Fracture

1.5 Residual strength is believed to be relatively insensitive

Toughness of Metallic Materials

to loading rate within the range normally used in conventional

E466 Practice for Conducting Force Controlled Constant

tension tests. When very low or very high rates of loading are

Amplitude Axial Fatigue Tests of Metallic Materials

expected in service, the effect of loading rate should be

E561 Test Method for K Curve Determination

R

investigated using special procedures that are beyond the scope

E1823 Terminology Relating to Fatigue and Fracture Testing

of this practice.

NOTE 1—Further information on background and need for this type of

3. Terminology

test is given in the report of ASTM Task Group E24.01.05 on Part-

2

3.1 Definitions:

Through-Crack Testing (1).

3.1.1 Definitions given in Terminology E1823 are appli-

1.6 The values stated in either SI units or inch-pound units

cable to this practice.

are to be regarded separately as standard. The values stated in

3.1.2 crack mouth opening displacement (CMOD), 2v

m

(L)—crack—opening displacement resulting from the total

1

This practice is under the jurisdiction of ASTM Committee E08 on Fatigue and

Fracture and is the direct responsibility of Subcommittee E08.07 on Fracture

3

Mechanics. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 15, 2023. Published December 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1988. Last previous edition approved in 2016 as E740/ Standards volume information, refer to the standard’s Document Summary page on

E740M – 03(2016). DOI: 10.1520/E0740_E0740M-23. the ASTM website.

2 4

The boldface numbers in parentheses refer to the list of references at the end of The last appr

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E740/E740M − 03 (Reapproved 2016) E740/E740M − 23

Standard Practice for

1

Fracture Testing with Surface-Crack Tension Specimens

This standard is issued under the fixed designation E740/E740M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the design, preparation, and testing of surface-crack tension (SCT) specimens. It relates specifically to

testing under continuously increasing force and excludes cyclic and sustained loadings. The quantity determined is the residual

strength of a specimen having a semielliptical or circular-segment fatigue crack in one surface. This value depends on the crack

dimensions and the specimen thickness as well as the characteristics of the material.

1.2 Metallic materials that can be tested are not limited by strength, thickness, or toughness. However, tests of thick specimens

of tough materials may require a tension test machine of extremely high capacity. The applicability of this practice to nonmetallic

materials has not been determined.

1.3 This practice is limited to specimens having a uniform rectangular cross section in the test section. The test section width and

length must be large with respect to the crack length. Crack depth and length should be chosen to suit the ultimate purpose of the

test.

1.4 Residual strength may depend strongly upon temperature within a certain range depending upon the characteristics of the

material. This practice is suitable for tests at any appropriate temperature.

1.5 Residual strength is believed to be relatively insensitive to loading rate within the range normally used in conventional tension

tests. When very low or very high rates of loading are expected in service, the effect of loading rate should be investigated using

special procedures that are beyond the scope of this practice.

NOTE 1—Further information on background and need for this type of test is given in the report of ASTM Task Group E24.01.05 on Part-Through-Crack

2

Testing (1).

1.6 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and healthsafety, health, and environmental practices and determine

the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This practice is under the jurisdiction of ASTM Committee E08 on Fatigue and Fracture and is the direct responsibility of Subcommittee E08.07 on Fracture Mechanics.

Current edition approved Oct. 1, 2016Nov. 15, 2023. Published October 2016December 2023. Originally approved in 1988. Last previous edition approved in 20102016

ɛ2

as E740/E740M – 03(2010)(2016). . DOI: 10.1520/E0740_E0740M-03R16.10.1520/E0740_E0740M-23.

2

The boldface numbers in parentheses refer to the list of references at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E740/E740M − 23

2. Referenced Documents

3

2.1 ASTM Standards:

E4 Practices for Force Calibration and Verification of Testing Machines

E8/E8M Test Methods for Tension Testing of Metallic Materials

4

E338 Test Method of Sharp-Notch Tension Testing of High-Strength Sheet Materials (Withdrawn 2010)

E399 Test Method for Linear-Elastic Plane-Strain Fracture Toughness of Metallic Materials

E466 Practice for Conducting Force Controlled Constant Amplitude Axial Fatigue Tests of Metallic Materials

E561 Test Method for K Curve Determination

R

E1823 Terminology Relating to Fatigue and Fracture Testing

3. Terminology

3.1 Definitions:

3.1.1 Definitions given in

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.