ASTM D2268-93(2013)

(Test Method)Standard Test Method for Analysis of High-Purity n-Heptane and Isooctane by Capillary Gas Chromatography

Standard Test Method for Analysis of High-Purity <emph type="ital">n</emph>-Heptane and <emph type="ital">Iso</emph>octane by Capillary Gas Chromatography

SIGNIFICANCE AND USE

3.1 This test method is used for specification analysis of high-purity n-heptane and isooctane, which are used as ASTM Knock Test Reference Fuels. Hydrocarbon impurities or contaminants, which can adversely affect the octane number of these fuels, are precisely determined by this method.

SCOPE

1.1 This test method covers and provides for the analysis of high-purity (greater than 99.5 % by volume) n -heptane and isooctane (2,2,4-trimethylpentane), which are used as primary reference standards in determining the octane number of a fuel. Individual compounds present in concentrations of less than 0.01 % can be detected. Columns specified by this test method may not allow separation of all impurities in reference fuels.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2268 − 93 (Reapproved 2013)

Standard Test Method for

Analysis of High-Purity n-Heptane and Isooctane by

Capillary Gas Chromatography

This standard is issued under the fixed designation D2268; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

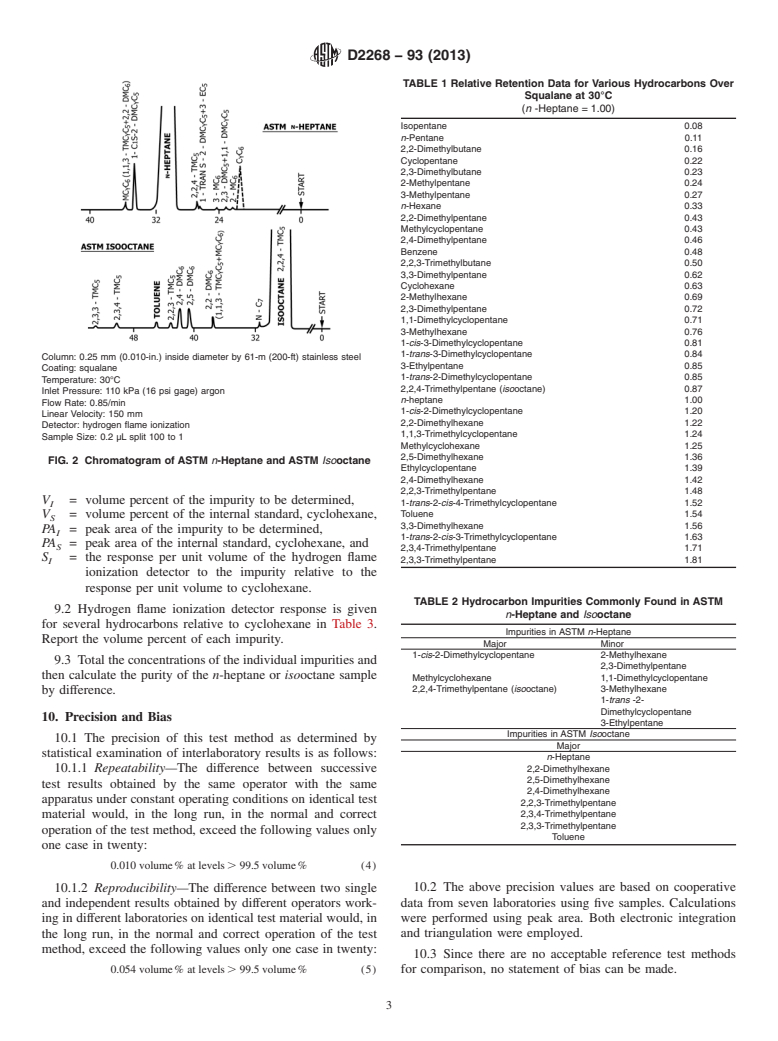

1. Scope Knock Test Reference Fuels. Hydrocarbon impurities or

contaminants, which can adversely affect the octane number of

1.1 This test method covers and provides for the analysis of

these fuels, are precisely determined by this method.

high-purity (greater than 99.5 % by volume) n -heptane and

isooctane (2,2,4-trimethylpentane), which are used as primary

4. Apparatus

reference standards in determining the octane number of a fuel.

4.1 Chromatograph—Gas chromatograph should be

Individual compounds present in concentrations of less than

equipped with a split-stream inlet device for introducing

0.01 % can be detected. Columns specified by this test method

minute quantities of sample without fractionation, a capillary

may not allow separation of all impurities in reference fuels.

column, and a hydrogen flame ionization detector. An elec-

1.2 The values stated in SI units are to be regarded as the

trometertoamplifythelowoutputsignalofthehydrogenflame

standard. The values given in parentheses are for information

ionization detector, and a strip-chart recorder for recording the

only.

detector signal are needed. The time constant of neither the

1.3 This standard does not purport to address all of the electrometernortherecordershouldexceed1s.Aballanddisk

integrator or electronic integrator for peak area measurements

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- should be used. The detection system must have sufficient

sensitivity to produce a recorder deflection for cyclohexane of

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. at least 8 divisions on a standard 0–100 scale chart using 0.10

volume percent of cyclohexane in n-heptane as defined in 7.1.

2. Summary of Test Method

4.2 Microsyringe—A microsyringe is needed for injecting

2.1 The sample is injected into a capillary gas chromato-

the sample into the split-stream inlet device.

graphic column consisting of at least 61 m (200 ft) of stainless

4.3 Volumetric Pipet, 0.1-mL capacity.

steel tubing (0.25-mm (0.010-in.) inside diameter), the inner

walls of which are coated with a thin film of stationary liquid.

4.4 Analytical Balance, 200-g capacity.

An inert gas transports the sample through the column, in

5. Reagents and Materials

which it is partitioned into its individual components. As each

component is eluted from the column, it is detected with a

5.1 Carrier Gas—Argon, Nitrogen, or Helium; 99.99% or

hydrogen flame ionization detector and recorded on a conven-

greater purity. (Warning—Compressed gases under high pres-

tional strip-chart recording potentiometer. The detector re-

sure.)

sponse from each impurity is then compared with that of a

5.2 Fuel Gas—Hydrogen; 99.99% or greater purity.

known quantity of an internal standard. After determining the

(Warning—Compressed gas under high pressure. Extremely

total impurity concentration, the n-heptane, or isooctane purity

flammable gas.)

is obtained by difference.

5.3 Oxidant Gas—Air; 99.99% or greater purity.

3. Significance and Use

(Warning—Compressed gases under high pressure.)

3.1 This test method is used for specification analysis of

5.4 Cyclohexane—At least 99 mol % pure, to be used as

high-purity n-heptane and isooctane, which are used asASTM

internalstandard.(Warning—Flammableliquidandharmfulif

ingested or inhaled.)

This test method is under the jurisdiction of ASTM Committee D02 on

5.5 n-Pentane—Commercial grade. (Warning—Volatile

Petroleum Products, Liquid Fuels, and Lubricantsand is the direct responsibility of

Subcommittee D02.04.0L on Gas Chromatography Methods. and flammable liquid, and harmful if ingested or inhaled.)

Current edition approved Oct. 1, 2013. Published October 2013. Originally

5.6 Isooctane (2,2,4-trimethylpentane)— (Warning—

approved in 1964. Last previous edition approved in 2008 as D2268 – 93(2008).

DOI: 10.1520/D2268-93R13. Flammable liquid and harmful if ingested or inhaled.)

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2268 − 93 (2013)

5.7 Squalane—Liquid phase for gas chromatographic col- Resolution (R), using the above equation, must exceed a

umns. value of 10.

5.8 Tubing—Type 316, 321, or 347 stainless steel; 0.25 mm

7. Sample Preparation

(0.010 in.) inside diameter.

7.1 Place 20 to 30 mL of the reference fuel (n-heptane or

6. Preparation of Resolving Column

isooctane) into a 100-mL volumetric flask which has been

NOTE 1—There are many different procedures for coating capillary

previously weighed.

columns.Asuitable procedure is given in 6.1 through 6.3. Other columns

may be used provided they meet resolution and repeatability requirements

7.2 Weigh the sample. Using a 0.10-mL volumetric pipet,

of the method.

add 0.10 mL of the internal standard cyclohexane (99 mol %,

6.1 Connect a 229 mm (9-in.) section of stainless steel

min) and reweigh. Dilute to the mark with the n-heptane or

tubing 6.4 mm ( ⁄4-in.) outside diameter, total volume of

isooctane sample and weigh. Use a 200-g analytical balance

approximately 5 mL) to a high-pressure cylinder of argon,

accurate to 60.0002 g. From these weights (masses) and the

helium, or nitrogen through a pressure regulator. Connect at

relative density (specific gravities) of cyclohexane and

least 61 m (200 ft) of Type 316, 321, or 347 stainless steel

n-heptane or isooctane, calculate the volume percent of the

tubing (0.25-mm (0.010-in.) inside diameter) to the 229-mm

cyclohexane internal standard to the nearest 0.001 volume

section of 64 mm tubing which is to be used as a reservoir for

percent. (Relative density (specific gravity) of cyclohexane at

the coating solution. The capillary column is generally coiled

20°C = 0.7786; n-heptane = 0.6838, and 2,2,4-trimethylpen-

on a suitable mandrel before coating. To the other end of the

tane = 0.6919.)

capillary column, connect an additional 30 to 9 to 12 m (40 ft)

Cyclohexane, volume% 5 wt cyclohexane/rel dens cyclohexane (2)

of capillary tubing through a 1.6 mm ( ⁄16-in.) Swagelok union.

6.2 Clean the tubing by passing 25 to 30 mL (5 to 6 ÷ ~wt reference fuel/rel dens reference fuel! 3100

reservoir volumes) of n-pentane through the tubing with about

1.7 to 2.1 MPa ( 250 to 300 psig gage) of inert gas. After the 8. Procedure

column has been cleaned, disconnect the upstream end of the

8.1 Adjust the operating variables to optimum conditions.

reservoir tube and allow the pressure in the tubing to return to

Temperatures should be as follows: Injection port and splitter

atmospheric.

150 to 250°C, column at optimum temperature and detector

6.3 Prepare a solution containing 6 volume percent of

greater than 100°C. Adjust the excess gas flow through the

squalane in n-pentane. Fill the reservoir tube with the coating

splitter to provide a proper sample size to the column.

solution and promptly connect to the gas cylinder. Pass the

8.2 Usingthemicrosyringe,injectsufficientsamplecontain-

coating solution through the column at 500 psig (3.5 MPa

ing the internal standard. Both the sample volume and the split

gage) until the solution begins issuing from the end of the

ratio must be considered in choosing the correct volume of

capillary tubing; gradually reduce the inlet pressure in order to

sample to inject. Volumes entering the column in the range of

keep the flow of the solution at a relatively even rate of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.