ASTM C631-09(2014)

(Specification)Standard Specification for Bonding Compounds for Interior Gypsum Plastering

Standard Specification for Bonding Compounds for Interior Gypsum Plastering

ABSTRACT

This specification covers the minimum requirements for bonding compounds used in adhering interior gypsum plasters to structurally sound surfaces. The bonding compound should be a tinted film-forming material suitable for application by brush, roller, and spray. It shall have a non-oxidizing, non-toxic, and non-flammable composition, and have a smooth, homogeneous, and flexible consistency with no settling of the solids. It shall also be free of foreign matter, and shall not be noticeably affected by mild acid or alkali. The apparatus needed for the preparation of the compound are moist cabinet, forced drift type oven, freezer, balance, timing device, tamper, steel straight edge, metal-bladed spatula, paint brush, briquet testing machine, briquet molds, divider, and clips. Specimens shall be sampled, tested, and conform accordingly to the following performance requirements: bonding capability; degradation; high temperature stability; freeze-thaw stability, and bond strength.

SCOPE

1.1 This specification covers minimum requirements for bonding compounds for adhering interior gypsum plaster to structurally sound surfaces.

1.2 This specification also covers test methods for determining performance requirements and physical properties.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 The following safety hazards caveat pertains only to the test methods described in this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C631 −09 (Reapproved 2014)

Standard Specification for

1

Bonding Compounds for Interior Gypsum Plastering

This standard is issued under the fixed designation C631; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Physical Properties

1.1 This specification covers minimum requirements for 4.1 General—The bonding compound shall be a film

bonding compounds for adhering interior gypsum plaster to forming, non-oxidizing, non-toxic, non-flammable composi-

structurally sound surfaces. tion suitable for application by brush, roller, and spray. The

compound shall be tinted to show, by visual inspection, where

1.2 Thisspecificationalsocoverstestmethodsfordetermin-

ithasbeenapplied.Thetintingmaterialshallnotshowthrough

ing performance requirements and physical properties.

the material being bonded. The surfaces to which bonding

1.3 The values stated in inch-pound units are to be regarded

compounds are applied shall be relatively smooth, clean, and

as standard. The values given in parentheses are mathematical

dry. Surface coatings shall be removed if their nature indicates

conversions to SI units that are provided for information only

an unsatisfactory condition. Surfaces shall be prepared in

and are not considered standard.

accordance with the manufacturer’s directions.

1.4 The following safety hazards caveat pertains only to the

4.2 Consistency—The bonding compound shall be of a

testmethodsdescribedinthisspecification: This standard does

homogeneous nature with no settling of the solids. The

not purport to address all of the safety concerns, if any,

compound shall be free of foreign matter, and when applied in

associated with its use. It is the responsibility of the user of this

accordance with the manufacturer’s directions, shall cover

standard to establish appropriate safety and health practices

evenly.

and determine the applicability of regulatory limitations prior

4.3 Film Characteristics—A dry film of the bonding com-

to use.

pound shall be uniform and smooth and shall remain flexible.

Thefilmshallnotbenoticeablyaffectedbymildacidoralkali.

2. Referenced Documents

2

2.1 ASTM Standards:

5. Performance Requirements

C11Terminology Relating to Gypsum and Related Building

5.1 Bonding Capability—A dry film of bonding compound

Materials and Systems

shall be capable of bonding gypsum plaster immediately after

C28/C28MSpecification for Gypsum Plasters

drying and 10 days after drying when tested as specified in

C472Test Methods for Physical Testing of Gypsum, Gyp-

Section 12.

sum Plasters and Gypsum Concrete

5.2 Degradation—Bonding compound that separates shall

C511Specification for Mixing Rooms, Moist Cabinets,

beabletobere-mixedtoauniformconsistencywhentestedas

Moist Rooms, and Water Storage Tanks Used in the

specified in Section 10.

Testing of Hydraulic Cements and Concretes

5.3 High Temperature Stability—The bond strength shall be

3. Terminology

not less than 20 psi (138 kPa) when tested as specified in

3.1 Definitions—For definitions relating to gypsum and Section 9.

related building materials and systems, see Terminology C11.

5.4 Freeze-Thaw Stability—The bond strength shall be not

less than 20 psi (138 kPa) when tested as specified in Section

11.

1

This specification is under the jurisdiction of ASTM Committee C11 on

GypsumandRelatedBuildingMaterialsandSystemsandisthedirectresponsibility

5.5 Bond Strength—Bond strength of a fresh sample or a

of Subcommittee C11.02 on Specifications and Test Methods for Accessories and

30-day-oldsampleshallbenotlessthan20psi(138kPa)when

Related Products.

tested as specified in Section 12.

Current edition approved Sept. 1, 2014. Published October 2014. Originally

approved in 1988. Last previous edition approved in 2009 as C631–09. DOI:

6. Sampling

10.1520/C0631-09R14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.1 Take a sample of not less than 1 kg from each shipment

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

or consignment for analysis and tests. Except in special cases,

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. take the sample from not less than three separate containers,

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

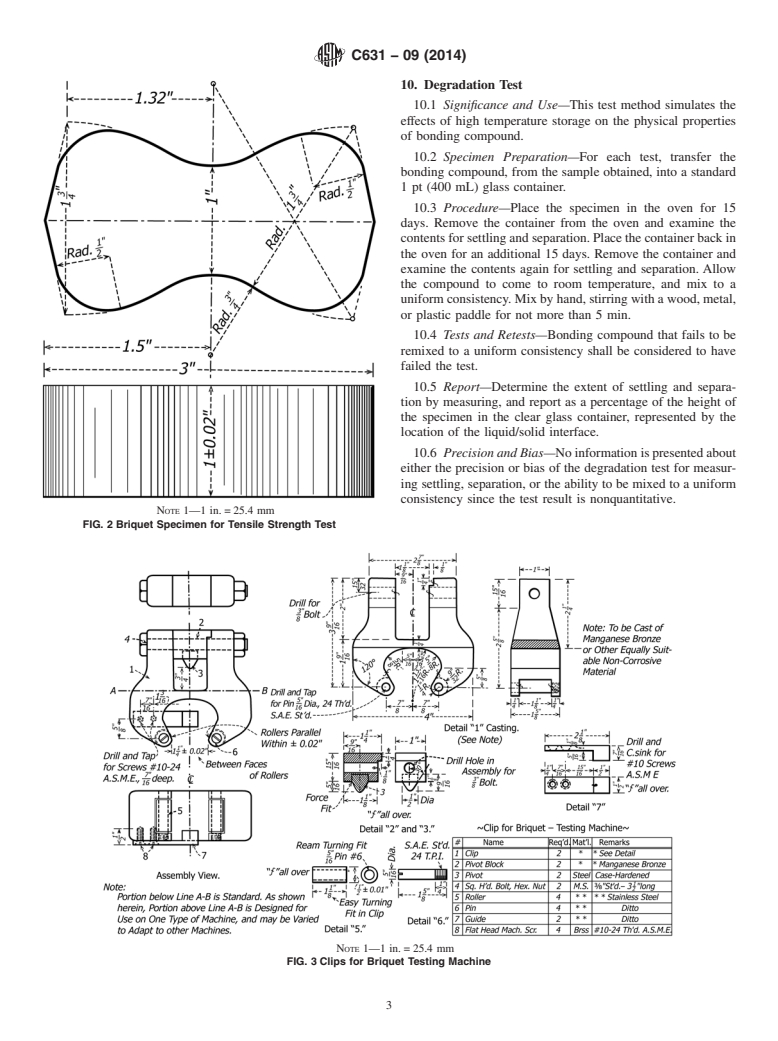

C631−09 (2014)

chosen at random. In addition, take samples from containers moldsmeasuredatthepointofgreatestthicknessoneitherside

that appear to be nonrepresentative, and test separately. Imme- of the mold at the waist

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C631 − 09 C631 − 09 (Reapproved 2014)

Standard Specification for

1

Bonding Compounds for Interior Gypsum Plastering

This standard is issued under the fixed designation C631; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*Scope

1.1 This specification covers minimum requirements for bonding compounds for adhering interior gypsum plaster to structurally

sound surfaces.

1.2 This specification also covers test methods for determining performance requirements and physical properties.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 The following safety hazards caveat pertains only to the test methods described in this specification:This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C11 Terminology Relating to Gypsum and Related Building Materials and Systems

C28/C28M Specification for Gypsum Plasters

C472 Test Methods for Physical Testing of Gypsum, Gypsum Plasters and Gypsum Concrete

C511 Specification for Mixing Rooms, Moist Cabinets, Moist Rooms, and Water Storage Tanks Used in the Testing of Hydraulic

Cements and Concretes

3. Terminology

3.1 Definitions—For definitions relating to gypsum and related building materials and systems, see Terminology C11.

4. Physical Properties

4.1 General—The bonding compound shall be a film forming, non-oxidizing, non-toxic, non-flammable composition suitable

for application by brush, roller, and spray. The compound shall be tinted to show, by visual inspection, where it has been applied.

The tinting material shall not show through the material being bonded. The surfaces to which bonding compounds are applied shall

be relatively smooth, clean, and dry. Surface coatings shall be removed if their nature indicates an unsatisfactory condition.

Surfaces shall be prepared in accordance with the manufacturer’s directions.

4.2 Consistency—The bonding compound shall be of a homogeneous nature with no settling of the solids. The compound shall

be free of foreign matter, and when applied in accordance with the manufacturer’s directions, shall cover evenly.

4.3 Film Characteristics—A dry film of the bonding compound shall be uniform and smooth and shall remain flexible. The film

shall not be noticeably affected by mild acid or alkali.

5. Performance Requirements

5.1 Bonding Capability—A dry film of bonding compound shall be capable of bonding gypsum plaster immediately after drying

and 10 days after drying when tested as specified in Section 12.

1

This specification is under the jurisdiction of ASTM Committee C11 on Gypsum and Related Building Materials and Systems and is the direct responsibility of

Subcommittee C11.02 on Specifications and Test Methods for Accessories and Related Products.

Current edition approved May 1, 2009Sept. 1, 2014. Published May 2009October 2014. Originally approved in 1988. Last previous edition approved in 20042009 as

C631 – 95aC631 – 09.(2004). DOI: 10.1520/C0631-09.10.1520/C0631-09R14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

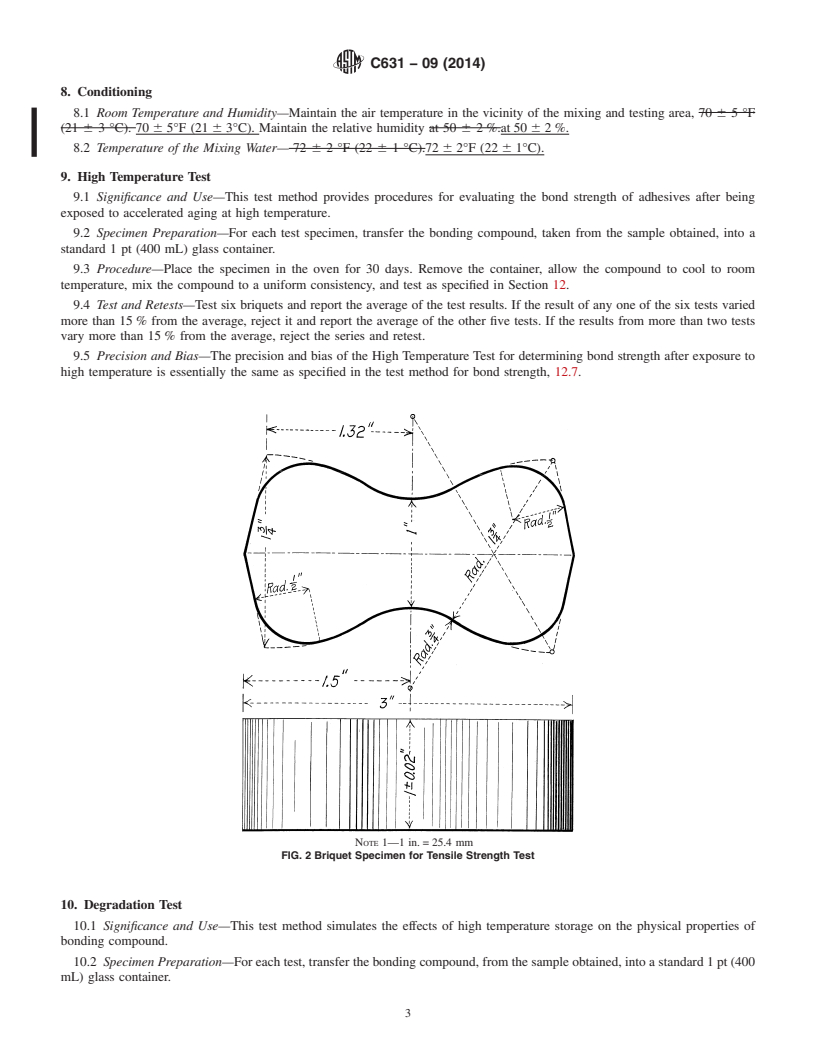

C631 − 09 (2014)

5.2 Degradation—Bonding compound that separates shall be able to be re-mixed to a uniform consistency when tested as

specified in Section 10.

5.3 High Temperature Stability—The bond strength shall be not less than 20 psi (138 kPa) when tested as specified in Section

9.

5.4 Freeze-Thaw Stability—The bond strength shall be not less than 20 psi (138 kPa) when tested as specified in Section 11.

5.5 Bond Strength—Bond strength of a fresh sample or a 30 day old

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.