ASTM C1197-14a

(Test Method)Standard Test Method for In Situ Measurement of Masonry Deformability Properties Using the Flatjack Method

Standard Test Method for In Situ Measurement of Masonry Deformability Properties Using the Flatjack Method

SIGNIFICANCE AND USE

5.1 Deformation and strength properties are measured only on the masonry between flatjacks. Boundary effects of the collar joint behind the wythe tested and adjacent masonry are neglected. In the case of multi-wythe masonry, deformability is estimated only in the wythe in which the flatjack is inserted. Deformability of other wythes may be different.

SCOPE

1.1 This test method describes an in situ method for determining the deformation properties of existing unreinforced solid-unit masonry. (See Note 1.) This test method concerns the measurement of in-situ masonry deformability properties in existing masonry by use of thin, bladder-like flatjack devices that are installed in cut mortar joints in the masonry wall. This test method provides a relatively non-destructive means of determining masonry properties.

Note 1: Solid-unit masonry is that built with stone, concrete, or clay units whose net area is equal to or greater than 75 % of the gross area.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1197 −14a

Standard Test Method for

In Situ Measurement of Masonry Deformability Properties

1

Using the Flatjack Method

This standard is issued under the fixed designation C1197; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3.1.1.1 Discussion—The use of shims may be necessary

during testing to achieve a tight fit of the flatjack in the slot and

1.1 This test method describes an in situ method for

to ensure uniform transfer of pressure (stress) to the masonry

determining the deformation properties of existing unrein-

overthecompleteareaoftheflatjack.SeeAnnexA1forfurther

forced solid-unit masonry. (See Note 1.) This test method

discussion on allowable types of shims.

concerns the measurement of in-situ masonry deformability

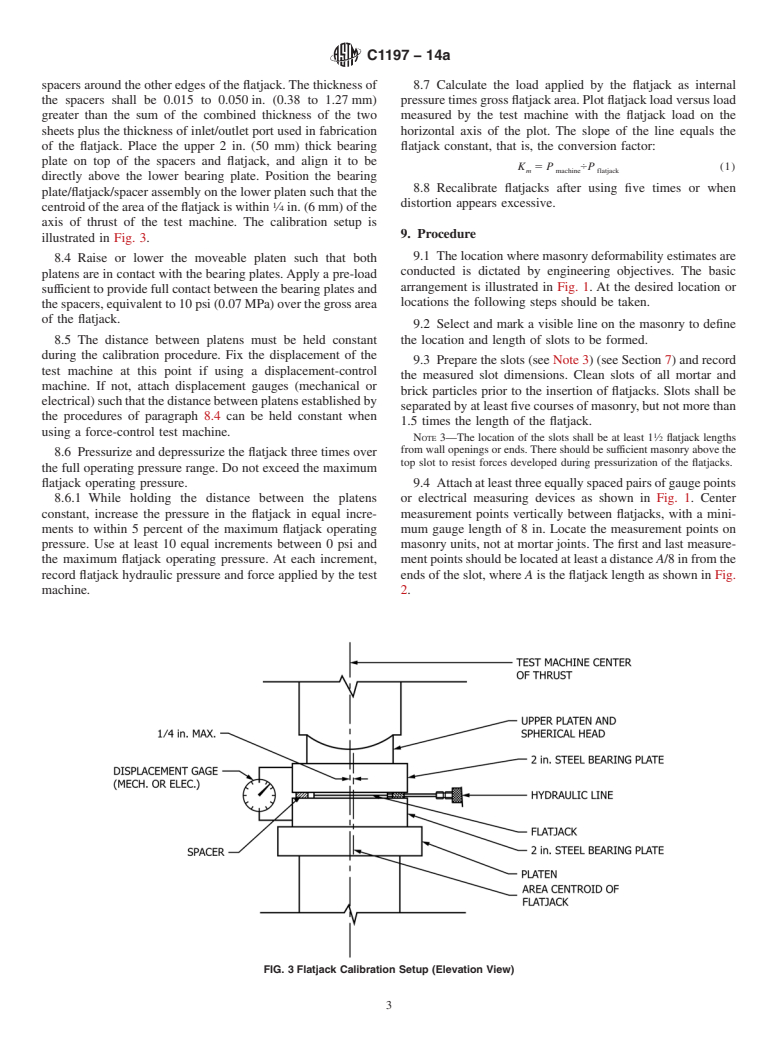

3.1.2 spacer, n—metal plate used in the calibration process

properties in existing masonry by use of thin, bladder-like

to control flatjack thickness.

flatjack devices that are installed in cut mortar joints in the

masonry wall. This test method provides a relatively non-

3.2 For definitions of other terms used in this test method

destructive means of determining masonry properties.

refer to Terminology C1180 for mortar and grout and Termi-

NOTE 1—Solid-unit masonry is that built with stone, concrete, or clay

nology C1232 for masonry.

units whose net area is equal to or greater than 75 % of the gross area.

1.2 The values stated in inch-pound units are to be regarded 4. Summary of Test Method

as standard. The values given in parentheses are mathematical

4.1 Two flatjacks inserted into parallel slots, one above the

conversions to SI units that are provided for information only

other, in a solid-unit masonry wall are pressurized thus

and are not considered standard.

inducing compressive stress on the masonry between them.

1.3 This standard does not purport to address all of the

The installation is shown in Fig. 1. By gradually increasing the

safety concerns, if any, associated with its use. It is the

flatjack pressure and measuring the deformation of the ma-

responsibility of the user of this standard to establish appro-

sonry between the flatjacks, load-deformation (stress-strain)

priate safety and health practices and determine the applica-

properties may be obtained. Maximum compressive strengths

bility of regulatory limitations prior to use.

may be measured in certain cases.

2. Referenced Documents 5. Significance and Use

2

2.1 ASTM Standards: 5.1 Deformation and strength properties are measured only

C1180 Terminology of Mortar and Grout for Unit Masonry on the masonry between flatjacks. Boundary effects of the

C1232 Terminology of Masonry collar joint behind the wythe tested and adjacent masonry are

E74 Practice of Calibration of Force-Measuring Instruments neglected.Inthecaseofmulti-wythemasonry,deformabilityis

for Verifying the Force Indication of Testing Machines estimated only in the wythe in which the flatjack is inserted.

Deformability of other wythes may be different.

3. Terminology

6. Apparatus

3.1 Definitions of Terms Specific to This Standard:

6.1 Flatjack:

3.1.1 shim, n—item inserted into a flatjack slot prior to

6.1.1 Aflatjackisathinenvelope-likebladderwithinletand

testing to minimize the inflation of the test flatjack.

outlet ports which may be pressurized with hydraulic fluid.

Flatjacks may be of any shape in plan, and are designed to be

1

This test method is under the jurisdiction of ASTM Committee C15 on

compatible with the masonry being tested. For determining

Manufactured Masonry Units and is the direct responsibility of Subcommittee

load-deformation properties of masonry, flatjacks are typically

C15.04 on Research.

rectangular or semi-rectangular as shown in Fig. 2.

Current edition approved Dec. 1, 2014. Published December 2014. Originally

6.1.2 For determination of the state of compressive stress,

approved in 1992. Last previous edition approved in 2014 as C1197 – 14. DOI:

10.1520/C1197-14A.

dimension A should be equal to or greater than the length of a

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

single masonry unit, but not less than 8 in. (200 mm).

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Dimension B should be equal to or greater than the thickness

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ofonewytheandnotlessthan3in.(75mm).Theradius, R,for

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

----------

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1197 − 14 C1197 − 14a

Standard Test Method for

In Situ Measurement of Masonry Deformability Properties

1

Using the Flatjack Method

This standard is issued under the fixed designation C1197; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method describes an in situ method for determining the deformation properties of existing unreinforced solid-unit

masonry. (See Note 1.) This test method concerns the measurement of in-situ masonry deformability properties in existing masonry

by use of thin, bladder-like flatjack devices that are installed in cut mortar joints in the masonry wall. This test method provides

a relatively non-destructive means of determining masonry properties.

NOTE 1—Solid-unit masonry is that built with stone, concrete, or clay units whose net area is equal to or greater than 75 % of the gross area.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C1180 Terminology of Mortar and Grout for Unit Masonry

C1232 Terminology of Masonry

E74 Practice of Calibration of Force-Measuring Instruments for Verifying the Force Indication of Testing Machines

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 shim, n—item inserted into a flatjack slot prior to testing to minimize the inflation of the test flatjack.

1

This test method is under the jurisdiction of ASTM Committee C15 on Manufactured Masonry Units and is the direct responsibility of Subcommittee C15.04 on Research.

Current edition approved July 1, 2014Dec. 1, 2014. Published August 2014December 2014. Originally approved in 1992. Last previous edition approved in 20092014 as

C1197 – 09.C1197 – 14. DOI: 10.1520/C1197-14.10.1520/C1197-14A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.1.1.1 Discussion—

The use of shims may be necessary during testing to achieve a tight fit of the flatjack in the slot and to ensure uniform transfer

of pressure (stress) to the masonry over the complete area of the flatjack. See Annex A1 for further discussion on allowable types

of shims.

3.1.2 spacer, n—metal plate used in the calibration process to control flatjack thickness.

3.2 For definitions of other terms used in this test method refer to Terminology C1180 for mortar and grout and Terminology

C1232 for masonry.

4. Summary of Test Method

4.1 Two flatjacks inserted into parallel slots, one above the other, in a solid-unit masonry wall are pressurized thus inducing

compressive stress on the masonry between them. The installation is shown in Fig. 1. By gradually increasing the flatjack pressure

and measuring the deformation of the masonry between the flatjacks, load-deformation (stress-strain) properties may be obtained.

Maximum compressive strengths may be measured in certain cases.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1197 − 14a

FIG. 1 Deformation Properties Using Two Flatjacks

5. Significance and Use

5.1 Deformation and strength properties are measured only on the masonry between flatjacks. Boundary effects of the collar

joint behind the wythe tested and adjacent masonry are neglected. In the case of multi-wythe masonry, deformability is estimated

only in the wythe in which the flatjack is inserted. Deformability of other wythes may be different.

6. Apparatus

6.1 Flatjack:

6.1.1 A flatjack is a thin envelope-like bladder with inlet and outlet ports which may be pressurized with hydraulic fluid.

Flatjacks may be of any shape in plan, and are designe

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.