ASTM F1577-05(2012)

(Test Method)Standard Test Methods for Detention Locks for Swinging Doors

Standard Test Methods for Detention Locks for Swinging Doors

SIGNIFICANCE AND USE

A major concern for detention and correctional administrative officials is the reliable operation of locks used in their facilities. These test methods aid in assigning a level of physical security and performance to locks for swinging door assemblies.

These test methods evaluate the resistance of a lock to attacks using battering devices, prying devices, and fire. These test methods also evaluate the performance of a lock under simulated operating conditions. These test methods do not provide a measure of the resistance or performance of a lock subjected to attack by chemical agents, ballistics, explosives, or other extreme methods of attack. These test methods do not measure the resistance or performance of the device when subjected to environmental elements such as rain, snow, or wind-carried dust or sand. Where such elements may be a factor, the manufacturer should be consulted for proper application.

The primary purpose of these test methods is to approximate the levels of abuse and operating conditions to which locks are subjected in detention and correctional institutions. The desired result of these test methods will provide a measure of assurance of protection to the correctional personnel, public, and inmates.

It is recommended that the detention/correctional facility administration provide adequate training, supervision, and preventative maintenance programs to enable door assemblies to function as intended throughout the expected service life.

SCOPE

1.1 These test methods cover the apparatus, procedures, and acceptance conditions for evaluating the normal operational performance and the performance characteristics under assault conditions of locks used in swinging door assemblies in detention and correctional institutions. Thus, they give only an indication of the performance characteristics of locks in actual service. Such variables as installation and maintenance conditions are not considered.

1.2 It is the intent of these test methods to help ensure that detention locks perform at or above minimum acceptable levels to control passage to unauthorized or secure areas, to confine inmates, and to delay and frustrate escape attempts and resist vandalism. It is recognized that in order to meet the intent of these test methods, door and frame assemblies must be compatible with the level of performance required by Test Methods F1450.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1577 − 05 (Reapproved 2012)

Standard Test Methods for

Detention Locks for Swinging Doors

This standard is issued under the fixed designation F1577; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F1592Test Methods for Detention Hollow Metal Vision

Systems

1.1 Thesetestmethodscovertheapparatus,procedures,and

F1643Test Methods for Detention Sliding Door Locking

acceptance conditions for evaluating the normal operational

Device Assembly

performance and the performance characteristics under assault

F1758 Test Methods for Detention Hinges Used on

conditions of locks used in swinging door assemblies in

Detention-Grade Swinging Doors

detention and correctional institutions.Thus, they give only an

F1915Test Methods for Glazing for Detention Facilities

indication of the performance characteristics of locks in actual

2.2 ANSI Standard:

service. Such variables as installation and maintenance condi-

ANSI A156.5Auxiliary Locks and Associated Products

tions are not considered.

2.3 UL Standards:

1.2 It is the intent of these test methods to help ensure that

UL-437Standard for Key Locks

detentionlocksperformatoraboveminimumacceptablelevels

UL-1034Standard for Burglary Resistant Electric Locking

to control passage to unauthorized or secure areas, to confine

Mechanisms

inmates, and to delay and frustrate escape attempts and resist

vandalism. It is recognized that in order to meet the intent of

3. Terminology

these test methods, door and frame assemblies must be

3.1 Definitions:

compatible with the level of performance required by Test

3.1.1 Bolts:

Methods F1450.

3.1.1.1 bolt projections, n—distance the lock bolt extends

1.3 The values stated in inch-pound units are to be regarded

from the lock case measured with the lock bolt in an extended

as the standard. The values in parentheses are for information

position.

only.

3.1.1.2 dead bolt, n—lock component having an end that

1.4 This standard does not purport to address all of the protrudes from or is withdrawn into the lock front by action of

safety concerns, if any, associated with its use. It is the the lock mechanism by rotating the key or thumb turn. When

responsibility of the user of this standard to establish appro-

the door is closed and the dead bolt is thrown, it extends into

priate safety and health practices and determine the applica- a hole provided in the strike, locking the door, and will not

bility of regulatory limitations prior to use.

return with end pressure.

3.1.1.3 deadlocking latch bolt, adj—component that, when

2. Referenced Documents

actuated, automatically locks the projected latch bolt against

2.1 ASTM Standards: return by end pressure. Also referred to as an auxiliary latch

E152TestMethodforFireTestsOfDoorAssemblies(With- bolt or roller bolt.

drawn 1995) 3.1.1.4 latch bolt, n—lock component having a beveled end

F1450Test Methods for Hollow Metal Swinging Door that projects from the lock front in its extended position but

Assemblies for Detention and Correctional Facilities may be forced back into the lock case by end pressure or

drawingbackbyactionofthelockmechanism.Whenthedoor

is closed, the latch bolt projects into a hole provided in the

These test methods are under the jurisdiction of ASTM Committee F33 on

strike, holding the door in a closed position. Sometimes

Detention and Correctional Facilities and are the direct responsibility of Subcom-

mittee F33.04 on Detention Hardware.

referred to as a snapbolt.

Current edition approved June 1, 2012. Published August 2012. Originally

3.1.2 bolt throw, n—distance the lock bolt travels from a

approved in 1995. Last previous edition approved in 2005 as F1577–05. DOI:

retracted to a fully extended position.

10.1520/F1577-05R12.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

3 5

The last approved version of this historical standard is referenced on Available from Underwriters Laboratories (UL), Corporate Progress, 333

www.astm.org. Pfingsten Rd., Northbrook, IL 60062.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1577 − 05 (2012)

3.1.3 cylinder, n—subassembly of a lock containing a plug 4. Significance and Use

with a key slot and tumbler mechanism.

4.1 A major concern for detention and correctional admin-

3.1.3.1 builders hardware cylinder, adj—key cylinder of istrative officials is the reliable operation of locks used in their

similar design to the mogul cylinder except smaller (1 ⁄32 in. facilities. These test methods aid in assigning a level of

(40 mm) in diameter), with keys and internal parts at least half physical security and performance to locks for swinging door

the size of mogul cylinders. Also known as commercial assemblies.

cylinders and mortise cylinders. See ANSI A156.5, 6.9.

4.2 These test methods evaluate the resistance of a lock to

3.1.3.2 mogul cylinder, adj—pin tumbler cylinder approxi- attacks using battering devices, prying devices, and fire.These

test methods also evaluate the performance of a lock under

mately 2 in. (51 mm) in diameter, 2 in. long.

simulated operating conditions. These test methods do not

3.1.3.3 mogul key, adj—oversized key designed to fit the

provide a measure of the resistance or performance of a lock

1 5

mogulcylinder,whichisapproximately1 ⁄2in.(38mm)by3 ⁄8

subjected to attack by chemical agents, ballistics, explosives,

in. (92 mm).

or other extreme methods of attack. These test methods do not

3.1.3.4 paracentric cylinder, commonly referred to as a

measure the resistance or performance of the device when

lever tumbler cylinder, adj—key cylinder consisting of a

subjected to environmental elements such as rain, snow, or

cylinder that is an integral part of the lock.

wind-carried dust or sand. Where such elements may be a

factor, the manufacturer should be consulted for proper appli-

3.1.3.5 paracentric key, commonly referred to as a lever

cation.

tumbler key, adj—paracentrickeysarebetween4in.(102mm)

and 5 in. (153 mm) long, with large ends or bows, which may

4.3 Theprimarypurposeofthesetestmethodsistoapproxi-

be as large as 2 ⁄2 in. (63 mm) wide.

mate the levels of abuse and operating conditions to which

locks are subjected in detention and correctional institutions.

3.1.4 detention security, adj—assurance of the restriction of

Thedesiredresultofthesetestmethodswillprovideameasure

mobilityofinmatestodesignatedareaswithinacorrectionalor

ofassuranceofprotectiontothecorrectionalpersonnel,public,

detention facility.

and inmates.

3.1.5 hand tools, n—items permitted for use in disengaging

4.4 It is recommended that the detention/correctional facil-

a lock when it fails to disengage, either remotely or manually;

ity administration provide adequate training, supervision, and

suchitemsaretoolscommonlycarriedinacorrectionalfacility

preventative maintenance programs to enable door assemblies

maintenance tool kit: hand screwdrivers (various sizes and tip

to function as intended throughout the expected service life.

configurations including tips for coverplate security screws),

claw hammer, ball peen hammer, chisel, pliers (any common

5. Sample Selection, Construction, and Size

size), and vise grips.

5.1 Sample locks shall be randomly selected and shall be

3.1.6 hinged door, adj—door equipped with hinges that

representative of the types and styles intended for use in the

permit it to swing about the hinge axis.

application of these test methods.

3.1.7 hollow metal, n—term used in reference to such items

5.2 The manufacturer shall permanently mark the test

asdoors,frames,partitions,enclosures,andotheritemsthatare

sample and retain them at the manufacturing facility for future

fabricated from sheet metal. These products are internally

reference. Instead of test samples, the manufacturer shall

reinforced but hollow, hence the term hollow metal.

provide a certified procedure for the construction of tested

3.1.8 locks, n—fastening device that secures a door or

assemblies.

window assembly against unauthorized use. A lock generally

5.3 The test assembly shall be certified by an independent,

includes the cylinder, bolt, strike, knobs, or levers.

third-party testing and certification agency; any change of

3.1.9 manufacturer, n—party responsible for the fabrication

components or assembly methods or processes shall be certi-

of the lock.

fied in writing by the testing certification agency. The agency

shall have the sole authority to decide the extent and scope of

3.1.10 performance characteristics, n—response attributes

retesting required.

of the lock in any one of the tests described.

5.4 Test reports shall include complete details and photo-

3.1.11 strike or strike plate, n—metal plate attached to or

graphs of the test specimen, the testing apparatus, and instal-

mortised into the door or frame to receive and hold a projected

lation instructions including templates for all items of hard-

latch bolt or dead bolt, or both, in order to secure the door to

ware.

the jamb.

3.1.12 strike box, n—housing used in the back of the strike 6. Test Methods

to enclose the bolt or bolt opening.

6.1 A test sample shall consist of a minimum of one lock.

3.1.13 testing laboratory, n—independent testing laboratory Thetestmethodsthatfollowmayconsistofindependentsetups

not associated with the manufacturer.

and procedures.

3.1.14 trim, n—trim shall include knobs or lever handles 6.2 Impact Test—Locks shall comply with the following.

used to retract the latch bolt or to act as a pull when the latch 6.2.1 Scope—This test method is designed to evaluate the

bolt is inoperative. capability of a detention lock to resist repeated impact forces.

F1577 − 05 (2012)

TABLE 1 Impact Test Criteria

6.2.2 Significance and Use—This test method is intended to

A

closely simulate a sustained battering ram-style attack and Security Grade Number of Impacts Element of Time

provide an evaluation of the capability of the lock to prevent, 1 600 60 min

2 400 40 min

delay, or frustrate escape or access to unauthorized areas, or

3 200 20 min

combination thereof. The test results are intended to aid in

4 100 10 min

assigning a level of physical security to various configurations

A

Element of time is based on the assumption that sustained manpower can

of detention locks.An impact test of this design performed on

deliver 400 blows of 200 ft·lb (271.2 J) each in 40 min. Since 400 blows is the

number of impacts a Grade 2 lock must absorb and still be operational, in

a detention lock evaluates the impact strength of the lock and

accordance with in 6.2.5, it is assumed failure of the Grade 2 lock will occur after

its components as well as the quality of fabrication techniques.

40 min.The element of time assigned to the various grades of locks is adjusted to

6.2.3 Apparatus: achieve more manageable time periods than actual calculations provide. The

element of time is hypothetical and is offered solely as a design suggestion.

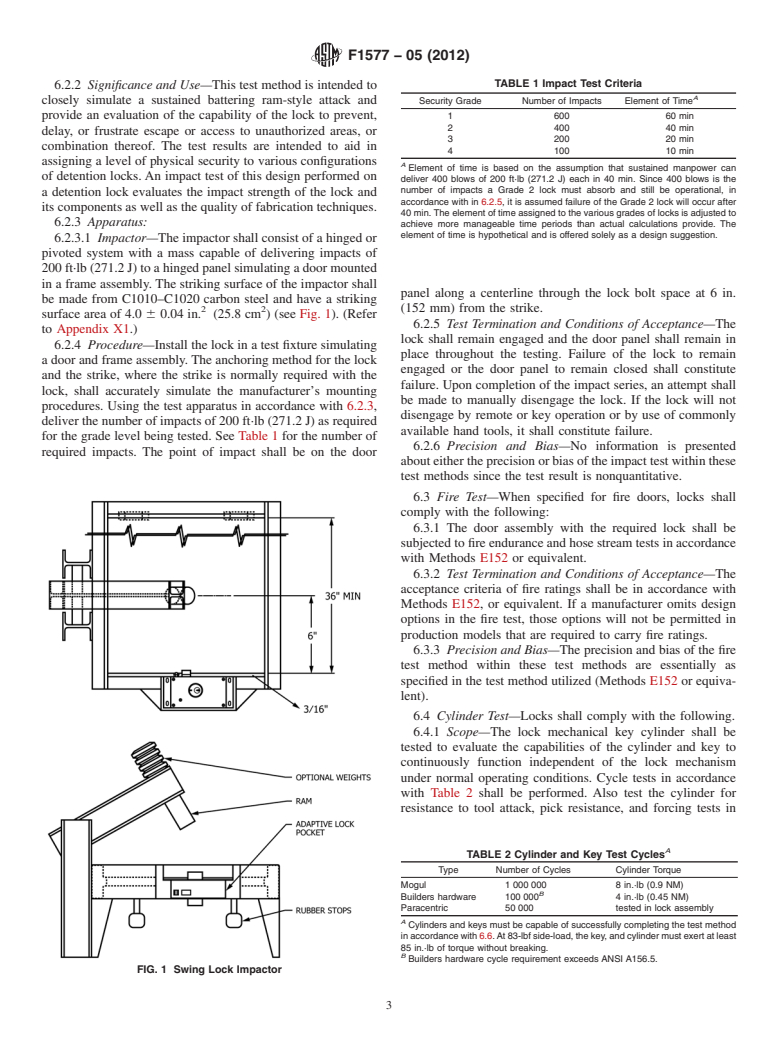

6.2.3.1 Impactor—The impactor shall consist of a hinged or

pivoted system with a mass capable of delivering impacts of

200ft·lb(271.2J)toahingedpanelsimulatingadoormounted

in a frame assembly.The striking surface of the impactor shall

panel along a centerline through the lock bolt space at 6 in.

be made from C1010–C1020 carbon steel and have a striking

2 2 (152 mm) from the strike.

surface area of 4.0 6 0.04 in. (25.8 cm ) (see Fig. 1). (Refer

6.2.5 Test Termination and Conditions of Acceptance—The

to Appendix X1.)

lock shall remain engaged and the door panel shall remain in

6.2.4 Procedure—Install the lock in a test fixture simulating

place throughout the testing. Failure of the lock to remain

a door and frame assembly.The anchoring method for the lock

engaged or the door panel to remain closed shall constitute

and the strike, where the strike is normally required with the

failure. Upon completion of the impact series, an attempt shall

lock, shall accurately simulate the manufacturer’s mounting

be made to manually disengage the lock. If the lock will not

procedures. Using the test apparatus in accordance with 6.2.3,

disengage by remote or key operation or by use of commonly

deliverthenumberofimpactsof200ft·lb(271.2J)asrequired

available hand tools, it shall constitute failure.

for the grade level being tested. See Table 1 for the number of

6.2.6 Precision and Bias—No information is presented

required impacts. The point of impact shall be on the door

abouteithertheprecisionorbiasoftheimpacttestwithinthese

test methods since the test result is nonquantitative.

6.3 Fire Test—When specified for fire doors, locks shall

comply with the following:

6.3.1 The door assembly with the required lock shall be

subjectedtofireenduranceandhosestreamtestsinaccordance

with Methods E152 or equivalent.

6.3.2 Test Termination and Conditions of Acceptance—The

acceptance criteria of fire ratings shall be in accordance with

Methods E152, or equivalent. If a manufacturer omits design

options in the fire test, those options will not be permitted in

production models that are required to carry fire ratings.

6.3.3 Precision and Bias—The precision and bias of the fire

test method within these test methods are essentially as

specified in the test method utilized (Methods E152 or equiva-

lent).

6.4 Cylinder Test—Locks shall comply with the following.

6.4.1 Scope—The lock mechanical key cylinder shall be

tested to evaluate the capabilities of the cylinder and key to

continuously function independent of the lock mechanism

under normal operating conditions. Cycle tests in accordance

with Table 2 shall be performed. Also test the cylinder for

resistance to tool attack, pick resistance, and forcing tests in

A

TABLE 2 Cylinder and Key Test Cycles

Type Number of Cycles Cylinder Torque

Mogul 1 000 000 8 in.·lb (0.9 NM)

B

Builders hardware 100 000 4 in.·lb (0.45 NM)

Paracentric 50 000 tested in lock assembly

A

Cylinders and keys must be capable of successfully completing the test method

inaccordancewith6.6.At83-lbfside-load,thekey,andcylindermustexertatleast

85 in.·lb of torque without breaking.

B

Builders hardware cycle requirement exceeds ANSI A156.5.

FIG. 1 Swing Lock Impactor

F1577 − 05 (2012)

acc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.