ASTM D4440-08

(Practice)Standard Test Method for Plastics: Dynamic Mechanical Properties Melt Rheology

Standard Test Method for Plastics: Dynamic Mechanical Properties Melt Rheology

SIGNIFICANCE AND USE

This test method provides a simple means of characterizing the important rheological properties and viscosity of thermoplastic polymers using very small amounts of material (approximately 25 to 50 mm in diameter by 1 to 3 mm in thickness ... approximately 3 to 5 g). Data may be used for quality control, research and development, and establishment of optimum processing conditions.

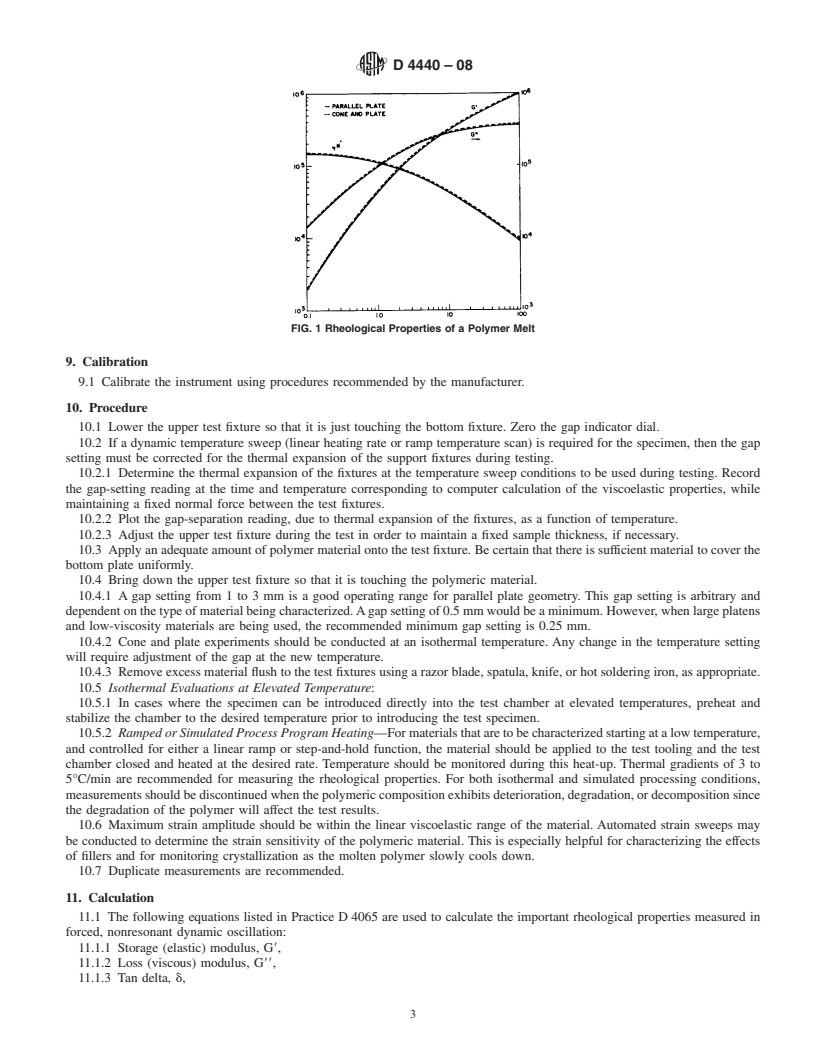

Dynamic mechanical testing provides a sensitive method for determining molten polymer properties by measuring the elastic and loss moduli as a function of frequency, strain, temperature, or time. Plots of viscosity, storage, and loss moduli, and tan delta as a function of the aforementioned process parameters provide graphical representation indicative of molecular weight, molecular weight distribution, effects of chain branching, and melt-processability for specified conditions.

Values obtained in this test method can be used to assess the following:

Complex viscosity of the polymer melt as a function of dynamic oscillation,

Processing viscosity, minimum as well as changes in viscosity as a function of experimental parameters,

Effects of processing treatment,

Relative polymer behavioral properties, including viscosity and damping, and

Effects of formulation additives that might affect processability or performance.

Before proceeding with this test method, reference should be made to the specification of the material being tested. Any test specimen preparation, conditioning, dimensions, or testing parameters, or combination thereof, covered in the relevant ASTM materials specification shall take precedence over those mentioned in the test method. If there are no relevant ASTM material specifications, then the default conditions apply.

SCOPE

1.1 This test method outlines the use of dynamic mechanical instrumentation in determining and reporting the rheological properties of thermoplastic resins and other types of molten polymers. It may be used as a method for determining the complex viscosity and other significant viscoelastic characteristics of such materials as a function of frequency, strain amplitude, temperature, and time. Such properties may be influenced by fillers and other additives.

1.2 It incorporates a laboratory test method for determining the relevant rheological properties of a polymer melt subjected to various oscillatory deformations on an instrument of the type commonly referred to as a mechanical or dynamic spectrometer.

1.3 This test method is intended to provide a means of determining the rheological properties of molten polymers, such as thermoplastics and thermoplastic elastomers over a range of temperatures by nonresonant, forced-vibration techniques. Plots of modulus, viscosity, and tan delta as a function of dynamic oscillation (frequency), strain amplitude, temperature, and time are indicative of the viscoelastic properties of a molten polymer.

1.4 This test method is valid for a wide range of frequencies, typically from 0.01 to 100 Hz.

1.5 This test method is intended for homogenous and heterogeneous molten polymeric systems and composite formulations containing chemical additives, including fillers, reinforcements, stabilizers, plasticizers, flame retardants, impact modifiers, processing aids, and other important chemical additives often incorporated into a polymeric system for specific functional properties, and which could affect the processability and functional performance. These polymeric material systems have molten viscosities typically less than 106 Pa·s (107 poise).

1.6 Apparent discrepancies may arise in results obtained under differing experimental conditions. Without changing the observed data, reporting in full (as described in this test method) the conditions under which the data was obtained may enable apparent differences observed in another study to be reconciled.

1.7 Test data obtained by this test method are relevant and appropriate for u...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4440 − 08

StandardTest Method for

1

Plastics: Dynamic Mechanical Properties Melt Rheology

This standard is issued under the fixed designation D4440; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* observed data, reporting in full (as described in this test

method) the conditions under which the data was obtained may

1.1 Thistestmethodoutlinestheuseofdynamicmechanical

enable apparent differences observed in another study to be

instrumentation in determining and reporting the rheological

reconciled.

properties of thermoplastic resins and other types of molten

polymers. It may be used as a method for determining the

1.7 Test data obtained by this test method are relevant and

complex viscosity and other significant viscoelastic character-

appropriate for use in engineering design.

istics of such materials as a function of frequency, strain

1.8 The values stated in SI units are to be regarded as the

amplitude, temperature, and time. Such properties may be

standard. The values given in parentheses are for information

influenced by fillers and other additives.

only.

1.2 It incorporates a laboratory test method for determining

1.9 This standard does not purport to address all of the

the relevant rheological properties of a polymer melt subjected

safety concerns, if any, associated with its use. It is the

tovariousoscillatorydeformationsonaninstrumentofthetype

responsibility of the user of this standard to establish appro-

commonly referred to as a mechanical or dynamic spectrom-

priate safety and health practices and determine the applica-

eter.

bility of regulatory limitations prior to use.

1.3 This test method is intended to provide a means of

NOTE 1—This test method is equivalent to ISO 6721, Part 10.

determining the rheological properties of molten polymers,

such as thermoplastics and thermoplastic elastomers over a

2. Referenced Documents

range of temperatures by nonresonant, forced-vibration tech-

2

niques. Plots of modulus, viscosity, and tan delta as a function

2.1 ASTM Standards:

of dynamic oscillation (frequency), strain amplitude,

D4000 Classification System for Specifying Plastic Materi-

temperature, and time are indicative of the viscoelastic prop-

als

erties of a molten polymer.

D4065 Practice for Plastics: Dynamic Mechanical Proper-

ties: Determination and Report of Procedures

1.4 Thistestmethodisvalidforawiderangeoffrequencies,

D4092 Terminology for Plastics: Dynamic Mechanical

typically from 0.01 to 100 Hz.

Properties

1.5 This test method is intended for homogenous and

E691 Practice for Conducting an Interlaboratory Study to

heterogeneous molten polymeric systems and composite for-

Determine the Precision of a Test Method

mulations containing chemical additives, including fillers,

3

2.2 ISO Standard:

reinforcements, stabilizers, plasticizers, flame retardants, im-

ISO 6721, Part 10 Plastics— Determination of Dynamic

pact modifiers, processing aids, and other important chemical

Mechanical Properties, Part 10, Complex Shear Viscosity

additives often incorporated into a polymeric system for

Using a Parallel-Plate Oscillatory Rheometer

specific functional properties, and which could affect the

processability and functional performance. These polymeric

6

3. Terminology

materialsystemshavemoltenviscositiestypicallylessthan10

7

Pa·s (10 poise).

3.1 Definitions—Definitions are in accordance with Termi-

nology Standard D4092.

1.6 Apparent discrepancies may arise in results obtained

under differing experimental conditions. Without changing the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Aug. 1, 2008. Published September 2008. Originally the ASTM website.

3

approved in 1984. Last previous edition approved in 2007 as D4440 - 07. DOI: Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/D4440-08. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4440 − 08

4. Summary of Test Method 7. Apparatus

4.1 A known amount of thermoplastic polymer (molten 7.1 The fu

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4440–07 Designation:D4440–08

Standard Test Method for

1

Plastics: Dynamic Mechanical Properties Melt Rheology

This standard is issued under the fixed designation D 4440; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method outlines the use of dynamic mechanical instrumentation in determining and reporting the rheological

properties of thermoplastic resins and other types of molten polymers. It may be used as a method for determining the complex

viscosity and other significant viscoelastic characteristics of such materials as a function of frequency, strain amplitude,

temperature, and time. Such properties may be influenced by fillers and other additives.

1.2 It incorporates a laboratory test method for determining the relevant rheological properties of a polymer melt subjected to

various oscillatory deformations on an instrument of the type commonly referred to as a mechanical or dynamic spectrometer.

1.3 This test method is intended to provide a means of determining the rheological properties of molten polymers, such as

thermoplastics and thermoplastic elastomers over a range of temperatures by nonresonant, forced-vibration techniques. Plots of

modulus, viscosity, and tan delta as a function of dynamic oscillation (frequency), strain amplitude, temperature, and time are

indicative of the viscoelastic properties of a molten polymer.

1.4 This test method is valid for a wide range of frequencies, typically from 0.01 to 100 Hz.

1.5 This test method is intended for homogenous and heterogeneous molten polymeric systems and composite formulations

containing chemical additives, including fillers, reinforcements, stabilizers, plasticizers, flame retardants, impact modifiers,

processing aids, and other important chemical additives often incorporated into a polymeric system for specific functional

properties, and which could affect the processability and functional performance. These polymeric material systems have molten

6 7

viscosities typically less than 10 Pa·s (10 poise).

1.6 Apparent discrepancies may arise in results obtained under differing experimental conditions. Without changing the

observed data, reporting in full (as described in this test method) the conditions under which the data was obtained may enable

apparent differences observed in another study to be reconciled.

1.7 Test data obtained by this test method are relevant and appropriate for use in engineering design.

1.8 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE 1—This test method is equivalent to ISO 6721, Part 10.

2. Referenced Documents

2

2.1 ASTM Standards:

D 4000 Classification System for Specifying Plastic Materials

D 4065 Practice for Plastics: Dynamic Mechanical Properties: Determination and Report of Procedures

D 4092Terminology for Plastics: Dynamic Mechanical Properties Terminology for Plastics: Dynamic Mechanical Properties

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3

2.2 ISO Standard:

ISO 6721, Part 10 Plastics— Determination of Dynamic Mechanical Properties, Part 10, Complex Shear Viscosity Using a

Parallel-Plate Oscillatory Rheometer

3. Terminology

3.1 Definitions: Definitions are in accordance with Terminology Standard D 4092.

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties .

Current edition approved MarchAug. 1, 2007.2008. Published March 2007.September 2008. Originally approved in 1984. Last previous edition approved in 20012007

as D 4440 - 017.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, h

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.