ASTM D4970-99

(Test Method)Standard Test Method for Pilling Resistance and Other Related Surface Changes of Textiles Fabrics (Martindale Pressure Tester Method)

Standard Test Method for Pilling Resistance and Other Related Surface Changes of Textiles Fabrics (Martindale Pressure Tester Method)

SCOPE

1.1 This test method covers the determination of resistance to the formation of pills and other related surface changes on textile fabrics under light pressure. The method utilizes the Martindale tester. The procedure is generally applicable to all types of fabrics, being particularly suitable for woven fabrics.

1.2 This method is not suitable for fabrics thicker than 3 mm ( 1/8 in.), since such fabrics cannot be mounted in the specimen holder.

1.3 The values stated in inch-pound units are to be regarded as standard; the values in SI units are provided as information only.

1.4 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Note 2 and Note A1.1 Note 1-For other methods of testing the pilling resistance of textiles, refer to the following ASTM methods: Test Method D3511 for Pilling Resistance and Other Related Surface Changes of Textile Fabrics: Brush Pilling Tester Method, Test Method D3512 for Pilling Resistance and Other Related Surface Changes of Textile Fabrics: Random Tumble Pilling Tester Method, and Test Method D3514 for Resistance of Apparel Fabrics to Pilling (Elastomeric Pad Method). For directions covering the measurement of resistance to pilling by the Appearance Retention Tester, refer to Method D1375. For directions covering the measurement of resistance to pilling by the Inflated Diaphragm Tester, and the Reciprocating Table Tester, refer to Method D1375. 2. Referenced Documents ASTM Standards:

D 123* Terminology Relating to Textiles

D 1776* Practice for Conditioning Textiles for Testing

General Information

Relations

Standards Content (Sample)

Designation: D 4970 – 99

Standard Test Method for

Pilling Resistance and Other Related Surface Changes of

1

Textile Fabrics: Martindale Tester

This standard is issued under the fixed designation D 4970; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope in this test method, refer to Terminology D 123.

3.2 Description of Terms Specific to This Standard:

1.1 This test method covers the determination of the resis-

3.2.1 cycle, n—in the Martindale tester, the sixteen move-

tance to the formation of pills and other related surface changes

ments required to complete one Lissajous figure.

on textile fabrics using the Martindale tester. The procedure

3.2.2 fuzz, n—tangled fiber ends that protrude from the

generally is applicable to all types of fabrics, being particularly

surface of a yarn or fabric.

suitable for woven fabrics.

3.2.3 movement, n—one rotation of the outer gearing of the

NOTE 1—For other methods, if testing the pilling resistance of textiles,

Martindale tester.

refer to Test Methods D 3511, D 3512, and D 3514.

3.2.4 pilling resistance, n—resistance to formation of pills

1.2 This test method is not suitable for fabrics thicker than

on the surface of a textile fabric.

3 mm (0.125 in.) because such fabrics cannot be mounted in

3.2.5 pills, n—bunches or balls of tangled fibers, which are

the specimen holder.

held to the surface of a fabric by one or more fibers.

1.3 The fabric may be laundered or dry cleaned before

4. Summary of Test Method

testing.

1.4 The values stated in SI units are to be regarded as the

4.1 Pilling and other changes in the surface appearance,

standard. The values given in parentheses are provided for

such as fuzzing, that occur in normal wear are simulated on a

information only.

laboratory testing machine. Fabrics are mounted on the Mar-

1.5 This standard does not purport to address all of the

tindale Tester, and the face of the test specimen is rubbed

safety concerns, if any, associated with its use. It is the

against the face of the same mounted fabric in the form of a

responsibility of the user of this standard to establish appro-

geometric figure, that is, a straight line, which becomes a

priate safety and health practices and determine the applica-

gradually widening ellipse, until it forms another straight line

bility of regulatory limitations prior to use.

in the opposite direction and traces the same figure again under

light pressure for a specific number of movements. The degree

2. Referenced Documents

of fabric pilling or surface appearance change produced by this

2.1 ASTM Standards:

action is evaluated by comparison of the tested specimen with

2

D 123 Terminology Relating to Textiles

visual standards that may be actual fabrics, or photographs of

2

D 1776 Practice for Conditioning Textiles for Testing

fabrics, showing a range of pilling resistance. The observed

D 3511 Test Method for Pilling Resistance and Other Re-

resistance to pilling is reported using an arbitrary rating scale.

lated Surface Changes of Textile Fabrics: Brush Pilling

3

5. Significance and Use

Tester

D 3512 Test Method for Pilling Resistance and Other Re-

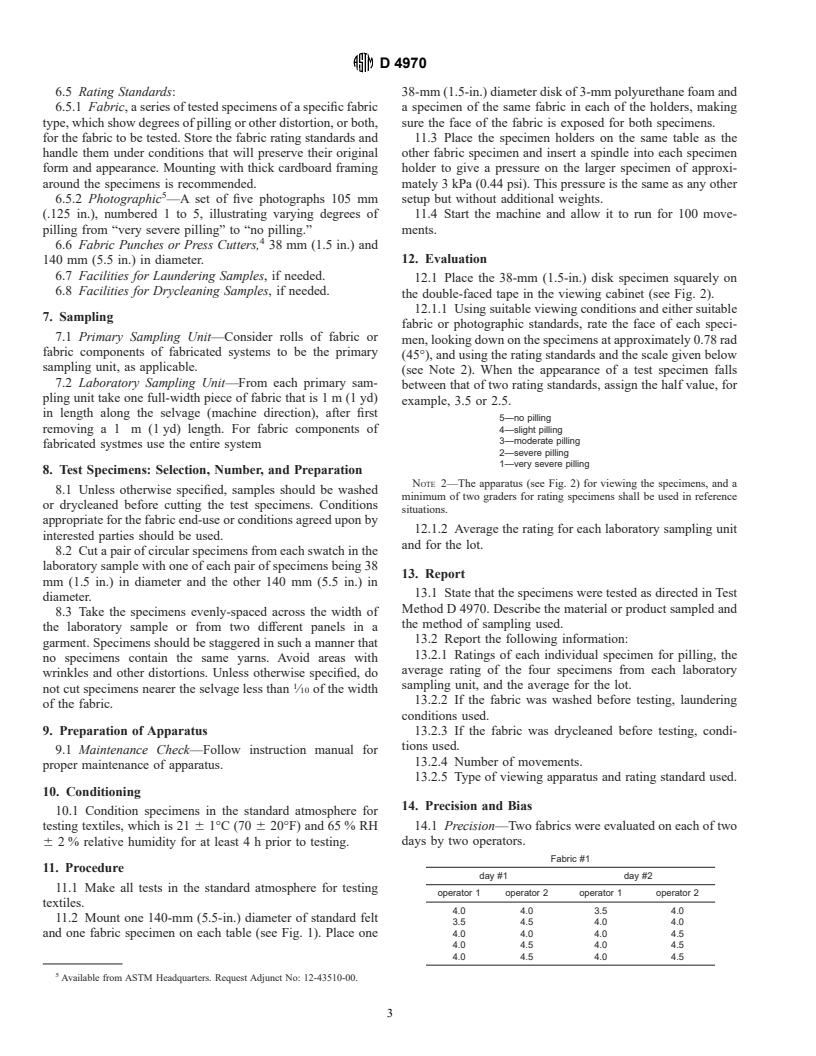

5.1 Acceptance Testing—This test method for resistance to

lated Surface Changes of Textile Fabrics: Random Tumble

pilling for fabrics is not recommended for acceptance testing.

3

Pilling Tester Method

If it is used for acceptance testing, it should be used with

D 3514 Test Method for Resistance of Apparel Fabrics to

caution because interlaboratory data are not available. In some

3

Pilling (Elastomeric Pad Method)

cases the purchaser or supplier may have to test a commercial

shipment of one or more specific materials by the best available

3. Terminology

method even though the method has not been recommended for

3.1 Definitions—For definitions of other textile terms used

acceptance testing. Although this test method is not recom-

mended for acceptance testing, it is useful because it is used

1

This test method is under the jurisdiction of ASTM Committee D-13 on Textiles widely outside the United States.

and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods,

5.2 If there is a disagreement arising from differences in

Specific.

values reported by the purchaser and the supplier when using

Current edition approved Sept. 10, 1999. Published December 1999. Last

this test method, the statistical bias, if any, between the

previous edition D 4970 – 98.

2

Annual Book of ASTM Standards, Vol 07.01.

laboratory of the purchaser and the laboratory of the supplier

3

Discontinued 1995, Annual Book of ASTM Standards, Vol 07.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 4970

fabric finishing treatmen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.