ASTM B226-95(2003)

(Specification)Standard Specification for Cored, Annular, Concentric-Lay-Stranded Copper Conductors

Standard Specification for Cored, Annular, Concentric-Lay-Stranded Copper Conductors

SCOPE

1.1 This specification covers cored, annular, concentric-lay-stranded conductors made from round soft copper wires, either uncoated or coated with tin, lead, or lead alloy for use as electrical conductors (Explanatory Note 1 and Note 2).

1.2 The constructions prescribed herein are suitable for bare conductors, or for conductors to be covered with weather-resistant (weather-proof) material, or for conductors to be insulated with rubber, varnished cloth, or impregnated paper, except types such as "oil-filled" or "gas-filled" (Explanatory Note 0).

1.3 Cored, annular conductor constructions not included in this specification shall be specifically agreed upon between the manufacturer and the purchaser when placing the order.

1.4 These constructions are not recommended for use as electric furnace leads where great flexibility is required and special conductor designs are indicated in consideration of the particular service requirements.

1.5 The SI values for density are regarded as the standard. For all other properties the inch-pound values are to be regarded as standard and the SI units may be approximate.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 226 – 95 (Reapproved 2003)

Standard Specification for

Cored, Annular, Concentric-Lay-Stranded Copper

Conductors

This standard is issued under the fixed designation B 226; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope ductors Having Bunch-Stranded Members, for Electrical

Conductors

1.1 This specification covers cored, annular, concentric-lay-

B 173 Specification for Rope-Lay-Stranded Copper Con-

stranded conductors made from round soft copper wires, either

ductors Having Concentric-Stranded Members, for Elec-

uncoated or coated with tin, lead, or lead alloy for use as

trical Conductors

electrical conductors (Explanatory Note 1 and Note 2).

B 174 Specification for Bunch-Stranded Copper Conduc-

1.2 The constructions prescribed herein are suitable for bare

tors for Electrical Conductors

conductors, or for conductors to be covered with weather-

B 189 Specification for Lead-Coated and Lead-Alloy-

resistant (weather-proof) material, or for conductors to be

Coated Soft Copper Wire for Electrical Purposes

insulated with rubber, varnished cloth, or impregnated paper,

B 263 Test Method for Determination of Cross-Sectional

except types such as “oil-filled” or “gas-filled” (Explanatory

Area of Stranded Conductors

Note 3).

B 354 Terminology Relating to Uninsulated Metallic Elec-

1.3 Cored, annular conductor constructions not included in

trical Conductors

this specification shall be specifically agreed upon between the

2.2 American National Standard:

manufacturer and the purchaser when placing the order.

ANSI C42.35 Definitions of Electrical Terms

1.4 These constructions are not recommended for use as

2.3 NIST:

electric furnace leads where great flexibility is required and

NBS Handbook 100—Copper Wire Tables

special conductor designs are indicated in consideration of the

particular service requirements.

3. Ordering Information

1.5 The SI values for density are regarded as the standard.

3.1 Orders for material under this specification shall include

For all other properties the inch-pound values are to be

the following information:

regarded as standard and the SI units may be approximate.

3.1.1 Quantity of each size,

2. Referenced Documents 3.1.2 Conductor size: circular-mil area (Section 7 and Table

1),

The following documents of the issue in effect at the time of

3.1.3 Whether coated or uncoated; if coated, designate type

reference form a part of these methods to the extent referenced

of coating (Section 11),

herein:

3.1.4 Specific kind and treatment of core material (Section

2.1 ASTM Standards:

2 4),

B 3 Specification for Soft or Annealed Copper Wire

3.1.5 Details of special-purpose lays, if required (see 6.1

B 8 Specification for Concentric-Lay-Stranded Copper

2 and 6.2 and Explanatory Note 3),

Conductors, Hard, Medium-Hard, or Soft

3.1.6 Package size (Section 14),

B 33 Specification for Tinned Soft or Annealed Copper

3.1.7 Lagging, if required (see 14.2),

Wire for Electrical Purposes

3.1.8 Special package marking, if required (Section 14), and

B 172 Specification for Rope-Lay-Stranded Copper Con-

3.1.9 Place of inspection (Section 13).

This specification is under the jurisdiction of ASTM Committee B01 on

Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

Conductors of Copper and Copper Alloys. 4th Floor, New York, NY 10036.

Current edition approved October 1, 2003. Published October 2003. Originally NBS Handbook 100, available from National Technical Information Service

approved in 1948. Last previous edition approved in 1995 as B 226 – 95. (NTIS), U.S. Department of Commerce, 5285 Port Royal Rd., Springfield, VA

Annual Book of ASTM Standards, Vol 02.03. 22161.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 226 – 95 (2003)

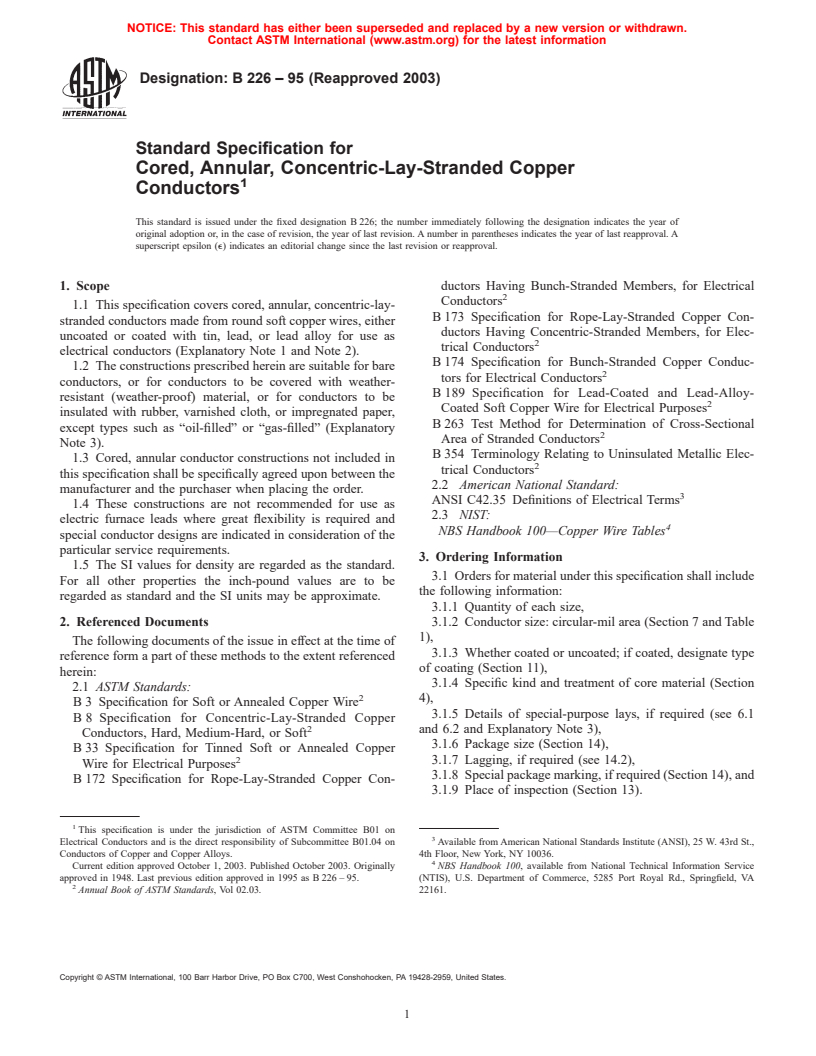

TABLE 1 Construction of Cored, Annular, Concentric-Lay-Stranded Copper Conductors

Nominal Area of Number of Strands in Layers

Approximate Calculated Area of Maximum

Copper Diameter of

A

Diameter of Copper, Cross Outside Diameter,

Cross Wires, in.

Core, in. Section, cmils in.

1st 2nd 3rd Total

Section, cmils

5 000 000 2.875 0.1620 57 63 69 189 4 960 116 3.897

4 500 000 2.500 0.1620 50 56 62 168 4 408 992 3.517

4 000 000 2.250 0.1620 45 51 57 153 4 015 332 3.262

3 500 000 2.000 0.1620 40 45 52 137 3 595 428 3.007

3 000 000 1.625 0.1620 33 38 45 116 3 044 304 2.627

2 500 000 1.500 0.1440 34 40 46 120 2 488 320 2.394

2 000 000 1.313 0.1284 34 40 46 120 1 978 387 2.114

1 750 000 1.125 0.1280 30 35 42 107 1 753 088 1.923

1 500 000 1.000 0.1255 26 32 38 96 1 512 024 1.783

1 250 000 0.750 0.1255 21 26 33 80 1 260 020 1.533

1 000 000 0.563 0.1255 16 21 28 65 1 023 766 1.346

900 000 0.500 0.1172 16 22 28 66 906 565 1.234

800 000 0.468 0.1110 16 21 28 65 800 865 1.164

750 000 0.375 0.1172 12 18 24 54 741 735 1.108

A

The following plus tolerances are included in the calculation of maximum outside diameters:

Nominal Area, Plus Tolerance Included,

cmils mils

5 000 000 to 4 500 001 50

4 500 000 to 4 000 001 45

4 000 000 to 3 500 001 40

3 500 000 to 3 000 001 35

3 000 000 to 750 000 30

4. Core 6.2 The direction of lay of the outer layer of wires shall be

left hand, unless specified otherwise by the purchaser (Ex-

4.1 The core may be of any material or materials suitable for

planatory Note 3).

the purpose as agreed upon by the manufacturer and the

6.3 The direction of lay shall be reversed in successive

purchaser when placing the order.

layers (Explanatory Note 3).

4.2 The size of the core and its surface firmness as a base for

the overlaid wires shall be adequate to prevent the forcing or

7. Construction

dropping of any wire out of its layer position (Explanatory

7.1 The nominal conductor size, number of layers of wires,

Note 4).

number, diameter, lay-up of wires, approximate core diameter,

4.3 If a specific kind of fibrous core is required by the

and maximum conductor diameter shall conform to the require-

purchaser (such as manila rope, sisal, asbestos, and so forth) it

ments prescribed in Table 1 (Explanatory Note 4).

shall be specified by him when placing the order (Explanatory

Note 4).

8. Physical and Electrical Tests

4.4 The proper treatment of the fibrous core, if any treat-

8.1 Tests for the electrical properties of wires composing

ment be required, shall be left to the discretion of the

conductors made from soft or annealed copper wire, bare or

manufacturer unless other arrangements are made at the time of

coated, shall be made before stranding.

purchase.

8.2 Tests for the physical properties of soft or annealed

4.5 If a metal supporting type of core is required, special

copper wire, bare or coated, may be made upon the wires

arrangements will be necessary between the manufacturer and

before stranding or upon wires removed from the completed

the purchaser.

stranded conductor, but need not be made upon both. Care shall

5. Joints

be taken to avoid mechanical injury to wire removed from the

conductor for the purpose of testing.

5.1 No splice shall be made in the conductor as a whole.

8.3 The physical properties of wire when tested before

Welds or brazes may be made in the finished individual wires.

stranding shall conform to the applicable requirements of 11.2.

Not more than one of the wires in any given layer shall be

8.4 The physical properties of wires removed from the

spliced in any 1-ft length of that layer.

completed stranded conductor shall be permitted to vary from

5.2 All joints shall be made in a workmanlike manner and

the applicable requirements of 11.2 by the following amounts

shall be approximately the diameter of the unjointed wire.

(Explanatory Note 5):

6. Lay

8.4.1 Average of Results Obtained on All Wires Tested—The

6.1 The length of lay of the respective layers of wires shall minimum elongation required shall be reduced in numerical

be at the option of the manufacturer unless otherwise agreed value 5 (for example, from 30 to 25 %) from the numerical

upon with the purchaser (Explanatory Note 3). requirements for the wire before stranding.

B 226 – 95 (2003)

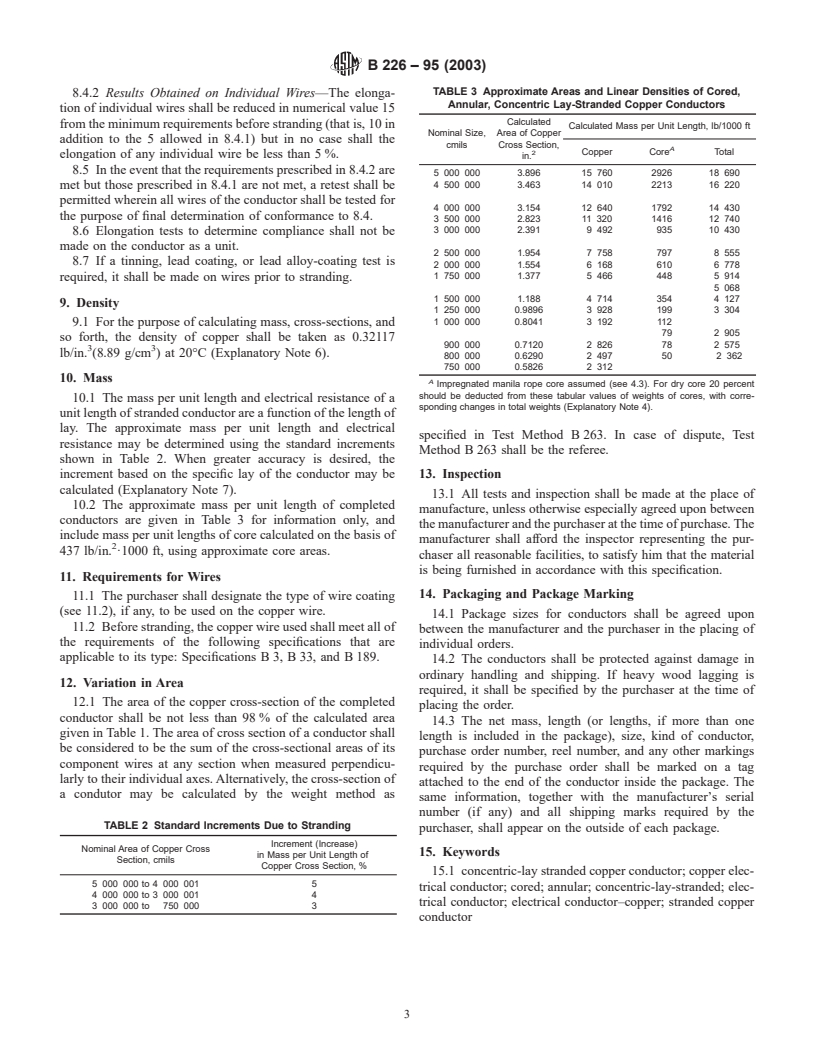

TABLE 3 Approximate Areas and Linear Densities of Cored,

8.4.2 Results Obtained on Individual Wires—The elonga-

Annular, Concentric Lay-Stranded Copper Conductors

tion of individual wires shall be reduced in numerical value 15

Calculated

from the minimum requirements before stranding (that is, 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.