ASTM D5030-89(1994)e1

(Test Method)Standard Test Method for Density of Soil and Rock in Place by the Water Replacement Method in a Test Pit (Withdrawn 2003)

Standard Test Method for Density of Soil and Rock in Place by the Water Replacement Method in a Test Pit (Withdrawn 2003)

SCOPE

1.1 This test method covers the determination of the in-place density and unit weight of soil and rock using water to fill a lined test pit to determine the volume of the test pit. The use of the word "rock" in this test method is used to imply that the material being tested will typically contain particles larger than 3 in. (75 mm).

1.2 This test method is best suited for test pits with a volume between approximately 3 and 100 ft3 (0.08 and 2.83 m 3). In general, the materials tested would have maximum particle sizes over 5 in. (125 mm). This test method may be used for larger sized excavations if desirable.

1.2.1 This procedure is usually performed using circular metal templates with inside diameters of 3 ft (0.9 m) or more. Other shapes or materials may be used providing they meet the requirements of this test method and the guidelines given in for the minimum volume of the test pit.

1.2.2 Test Method D4914 may be used as an alternative method. Its use, however, is usually only practical for volume determination of test pits between approximately 1 and 6 ft3 (0.03 and 0.17 m3).

1.2.3 Test Method D1556 or Test Method D2167 is usually used to determine the volume of test holes smaller than 1 ft3 (0.03 m3).

1.3 The two procedures are described as follows:

1.3.1 Procedure A--In-Place Density and Unit Weight of Total Material (Section 10).

1.3.2 Procedure B--In-Place Density and Unit Weight of Control Fraction (Section B).

1.4 Selection of Procedure

1.4.1 Procedure A is used when the in-place unit weight of total material is to be determined. Procedure A can also be used to determine percent compaction or percent relative density when the maximum particle size present in the in-place material being tested does not exceed the maximum particle size allowed in the laboratory compaction test (Test Methods D698, D1557, D4253, D4254, D4564). For Test Methods D698 and D1557 only, the unit weight determined in the laboratory compaction test may be corrected for larger particle sizes in accordance with, and subject to the limitations of, Practice D4718.

1.4.2 Procedure B is used when percent compaction or percent relative density is to be determined and the in-place material contains particles larger than the maximum particle size allowed in the laboratory compaction test or when Practice D4718 is not applicable for the laboratory compaction test. Then the material is considered to consist of two fractions, or portions. The material from the in-place unit weight test is physically divided into a control fraction and an oversize fraction based on a designated sieve size. The unit weight of the control fraction is calculated and compared with the unit weight(s) established by the laboratory compaction test(s).

1.4.2.1 Because of possible lower densities created when there is particle interference (see Practice D4718), the percent compaction of the control fraction should not be assumed to represent the percent compaction of the total material in the field.

1.4.3 Normally, the control fraction is the minus No. 4 sieve size material for cohesive or nonfree-draining materials and the minus 3-in. sieve size material for cohesionless, free-draining materials. While other sizes are used for the control fraction (3/ 8, 3/4-in.), this test method has been prepared using only the No. 4 and the 3-in. sieve sizes for clarity.

1.5 Any material can be tested, provided the material being tested has sufficient cohesion or particle attraction to maintain stable sides during excavation of the test pit and through completion of this test. It should also be firm enough not to deform or slough due to the minor pressures exerted in digging the hole and filling with water.

1.5.1 A very careful assessment must be made as to whether or not the volume determined is representative of the in-place condition when this test method is used for clean, relatively uniform-sized particles 3 in. (75 mm) and larger. The disturbance during exc...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: D 5030 – 89 (Reapproved 1994)

Standard Test Method for

Density of Soil and Rock in Place by the Water Replacement

Method in a Test Pit

This standard is issued under the fixed designation D 5030; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Section 16 was added editorially in March 1994.

1. Scope size allowed in the laboratory compaction test (Test Methods

D 698, D 1557, D 4253, D 4254, D 4564). For Test Methods

1.1 This test method covers the determination of the in-

D 698 and D 1557 only, the unit weight determined in the

place density and unit weight of soil and rock using water to fill

laboratory compaction test may be corrected for larger particle

a lined test pit to determine the volume of the test pit. The use

sizes in accordance with, and subject to the limitations of,

of the word “rock” in this test method is used to imply that the

Practice D 4718.

material being tested will typically contain particles larger than

1.4.2 Procedure B is used when percent compaction or

3 in. (75 mm).

percent relative density is to be determined and the in-place

1.2 This test method is best suited for test pits with a volume

3 3

material contains particles larger than the maximum particle

between approximately 3 and 100 ft (0.08 and 2.83 m ). In

size allowed in the laboratory compaction test or when Practice

general, the materials tested would have maximum particle

D 4718 is not applicable for the laboratory compaction test.

sizes over 5 in. (125 mm). This test method may be used for

Then the material is considered to consist of two fractions, or

larger sized excavations if desirable.

portions. The material from the in-place unit weight test is

1.2.1 This procedure is usually performed using circular

physically divided into a control fraction and an oversize

metal templates with inside diameters of 3 ft (0.9 m) or more.

fraction based on a designated sieve size. The unit weight of

Other shapes or materials may be used providing they meet the

the control fraction is calculated and compared with the unit

requirements of this test method and the guidelines given in

weight(s) established by the laboratory compaction test(s).

Annex A1 for the minimum volume of the test pit.

1.4.2.1 Because of possible lower densities created when

1.2.2 Test Method D 4914 may be used as an alternative

there is particle interference (see Practice D 4718), the percent

method. Its use, however, is usually only practical for volume

compaction of the control fraction should not be assumed to

determination of test pits between approximately 1 and 6 ft

represent the percent compaction of the total material in the

(0.03 and 0.17 m ).

field.

1.2.3 Test Method D 1556 or Test Method D 2167 is usually

1.4.3 Normally, the control fraction is the minus No. 4 sieve

used to determine the volume of test holes smaller than 1 ft

size material for cohesive or nonfree-draining materials and the

(0.03 m ).

minus 3-in. sieve size material for cohesionless, free-draining

1.3 The two procedures are described as follows:

materials. While other sizes are used for the control fraction

1.3.1 Procedure A—In-Place Density and Unit Weight of

3 3

( ⁄8, ⁄4-in.), this test method has been prepared using only the

Total Material (Section 10).

No. 4 and the 3-in. sieve sizes for clarity.

1.3.2 Procedure B—In-Place Density and Unit Weight of

1.5 Any material can be tested, provided the material being

Control Fraction (Section 11).

tested has sufficient cohesion or particle attraction to maintain

1.4 Selection of Procedure:

stable sides during excavation of the test pit and through

1.4.1 Procedure A is used when the in-place unit weight of

completion of this test. It should also be firm enough not to

total material is to be determined. Procedure A can also be used

deform or slough due to the minor pressures exerted in digging

to determine percent compaction or percent relative density

the hole and filling with water.

when the maximum particle size present in the in-place

1.5.1 A very careful assessment must be made as to whether

material being tested does not exceed the maximum particle

or not the volume determined is representative of the in-place

condition when this test method is used for clean, relatively

This test method is under the jurisdiction of ASTM Committee D-18 on Soil

uniform-sized particles 3 in. (75 mm) and larger. The distur-

and Rock and is the direct responsibility of Subcommittee D18.08 on Special and

bance during excavation, due to lack of cohesion, and the void

Construction Control Tests.

Current edition approved Dec. 29, 1989. Published February 1990.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

D 5030 – 89 (1994)

spaces between particles spanned by the liner may affect the Using a Vibratory Table

measurement of the volume of the test pit. D 4254 Test Methods for Minimum Index Density of Soils

1.6 This test method is generally limited to material in an and Calculation of Relative Density

unsaturated condition and is not recommended for materials D 4564 Test Method for Density of Soil in Place by the

that are soft or friable (crumble easily) or in a moisture Sleeve Method

condition such that water seeps into the excavated hole. The D 4718 Practice for Correction of Unit Weight and Water

accuracy of the test may be affected for materials that deform Content for Soils Containing Oversize Particles

easily or that may undergo volume change in the excavated D 4753 Specification for Evaluating, Selecting, and Speci-

hole from standing or walking near the hole during the test. fying Balances and Scales for Use in Soil and Rock

1.7 The values stated in inch-pound units are to be regarded Testing

as the standard. The values given in parentheses are for D 4914 Test Method for Density of Soils in Place by Sand

information only. Replacement Method in a Test Pit

1.7.1 In the engineering profession, it is customary practice E 1 Specification for ASTM Thermometers

to use, interchangeably, units representing both mass and force, E 11 Specification for Wire-Cloth Sieves for Testing Pur-

unless dynamic calculations (F = Ma) are involved. This im- poses

plicitly combines two separate systems of units, that is, the

3. Terminology

absolute system and the gravimetric system. It is scientifically

undesirable to combine the use of two separate systems within 3.1 Definitions—Except as follows in 3.2, all definitions are

a single standard. This test method has been written using in accordance with Terminology D 653.

inch-pound units (gravimetric system) where the pound (lbf) 3.2 Definitions of Terms Specific to This Standard:

represents a unit of force (weight); however, conversions are 3.2.1 control fraction—the portion of a soil sample consist-

given in the SI system. The use of balances or scales recording ing of particles smaller than a designated sieve size.

pounds of mass (lbm), or the recording of density in lbm/ft 3.2.1.1 Discussion—This fraction is used to compare in-

should not be regarded as nonconformance with this standard. place unit weights with unit weights obtained from standard

1.8 This standard does not purport to address all of the laboratory tests. The control sieve size depends on the labora-

safety concerns, if any, associated with its use. It is the tory test used.

responsibility of the user of this standard to establish appro- 3.2.2 oversize particles—the portion of a soil sample con-

priate safety and health practices and determine the applica- sisting of the particles larger than a designated sieve size.

bility of regulatory limitations prior to use. For a specific

4. Summary of Test Method

hazard statement, see Section 7.

4.1 The ground surface at the test location is prepared and a

2. Referenced Documents

template (metal ring) is placed and fixed into position. A liner

2.1 ASTM Standards: is laid in the template and the volume of the space between a

selected level within the template and the ground surface is

C 127 Test Method for Specific Gravity and Absorption of

Coarse Aggregate determined by filling the space with water. The mass or the

volume of the water required to fill the template to the selected

C 138 Test Method for Unit Weight, Yield, and Air Content

(Gravimetric) of Concrete level is determined and the water and liner removed. Material

from within the boundaries of the template is excavated,

C 566 Test Method for Total Moisture Content of Aggregate

forming a pit. A liner is placed in the test pit and template,

by Drying

water is poured into the pit and template up to the selected

D 653 Terminology Relating to Soil, Rock, and Contained

level; the mass or volume of the water within the pit and

Fluids

template and, subsequently, the volume of the hole are deter-

D 698 Test Methods for Moisture-Density Relations of

mined. The wet density of the in-place material is calculated

Soils and Soil-Aggregate Mixtures Using 5.5-lb (2.49-kg)

Rammer and 12-in. (305-mm) Drop from the mass of material removed and the measured volume

of the test pit. The moisture content is determined and the dry

D 1556 Test Method for Density of Soil in Place by the

Sand-Cone Method unit weight of the in-place material is calculated.

4.2 The unit weight of a fraction of the material can be

D 1557 Test Methods for Moisture-Density Relations of

Soils and Soil Aggregate Mixtures Using 10-lb (4.54-kg) determined by subtracting the mass and volume of any oversize

particles from the initial values and recalculating the unit

Rammer and 18-in. (457-mm) Drop

D 2167 Test Method for Density and Unit Weight of Soil weight.

In-Place by the Rubber Balloon Method

5. Significance and Use

D 2216 Method for Laboratory Determination of Water

5.1 This test method is used to determine the in-place unit

(Moisture) Content of Soil, Rock, and Soil-Aggregate

Mixtures weight of compacted materials in construction of earth em-

bankments, road fills, and structure backfill. For construction

D 4253 Test Methods for Maximum Index Density of Soils

control, it can be used as the basis for acceptance of material

Annual Book of ASTM Standards, Vol 04.02.

3 4

Annual Book of ASTM Standards, Vol 04.08. Annual Book of ASTM Standards, Vol 14.03.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

D 5030 – 89 (1994)

compacted to a specified unit weight or to a percentage of a top of the template, it is not necessary that the template be

maximum unit weight determined by a standard laboratory test level. The larger rings should be high enough to prevent any

method such as determined from Test Methods D 698 or loss of water due to wave action caused by wind.

D 1557, subject to the limitations discussed in 1.4. 6.7 Liners, approximately 4 to 6 mil thick. Two pieces, each

5.2 This test method can be used to determine in-place unit

large enough to line the test pit, with about 3 ft (1 m) extending

weight of natural soil deposits, aggregates, soil mixtures, or beyond the outside of the template. Any type of material,

other similar material.

plastic sheeting, etc. can be used as long as it is flexible enough

to conform to the ground surface.

6. Apparatus

6.8 Water-Measuring Device, including a storage container,

6.1 Balance or Scale, having a capacity and readability delivery hoses or piping, and a water meter, scale, or other

appropriate to the mass and procedural techniques for the

suitable measurement device. Water may be measured by mass

specific test pit dimensions within the range of 3 to 100 ft or by volume. The equipment must be capable of controlling

(0.08 to 2.83 m ) volume and meeting the requirements of

the delivery of the water so that any inaccuracies in filling and

Specification D 4753. measuring do not exceed 6 1 % of the total mass or volume

6.2 Balance or Scale—a balance (or scale) to determine

delivered.

moisture content of minus No. 4 material having a minimum 6.9 Water-Level Reference Indicator—A water-level refer-

capacity of about 1000 g and meeting the requirements of

ence must be established so that the water level in the template

Specification D 4753 for a balance of 0.1 g readability. is the same for the two determinations. A hook gage may be the

6.3 Drying Oven, thermostatically controlled, preferably of

simplest and most practical, although any device such as a rod

the forced-draft type, and capable of maintaining a uniform

with a pointed end that can be fastened to the template, a

temperature of 110 6 5°C throughout the drying chamber.

carpenter’s level and scale, a carpenter’s scale on a beam

6.4 Sieves, No. 4 sieve (4.75-mm) and 3-in. (75-mm),

across the template, or other similar arrangement or device

conforming to the requirements of Specification E 11.

may be used. Whichever method is employed, the device must

6.5 Thermometer, 0 to 50°C range, 0.5° graduations, con-

be able to be removed and replaced so that the reference water

forming to the requirements of Specification E 1.

level is measured at the exact same location. Some type of

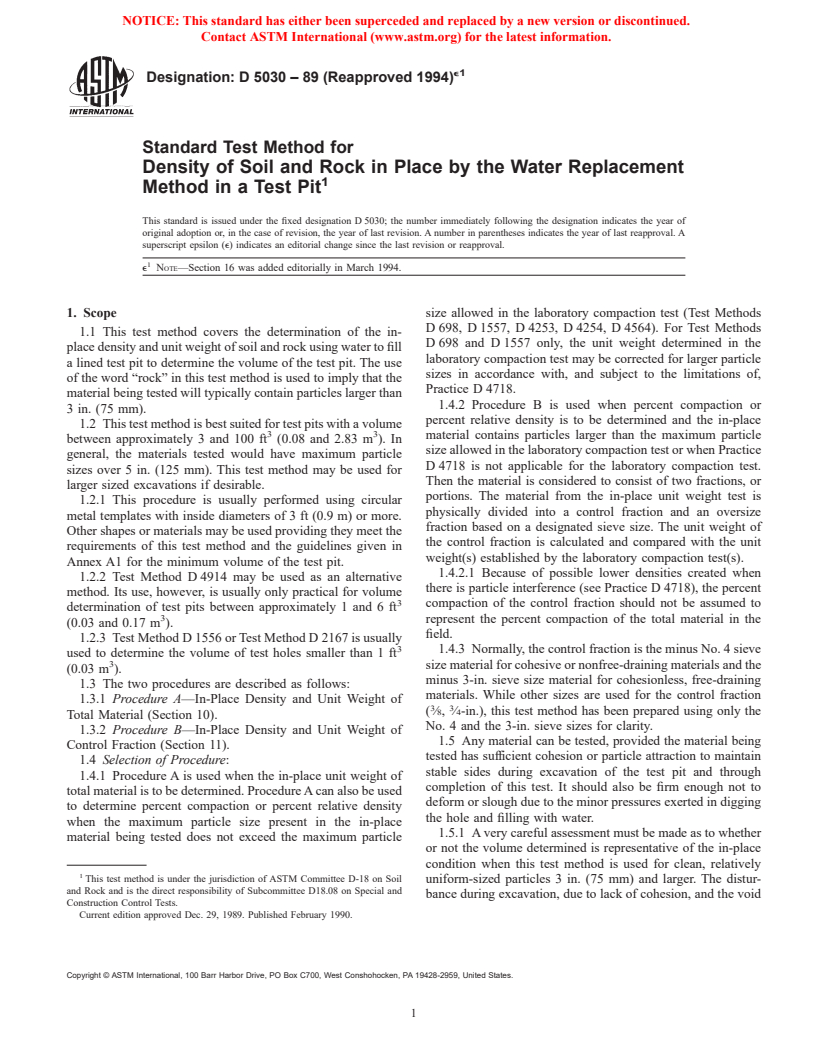

6.6 Metal Template—a circular template to serve as a

protection around the device may be necessary if the water

pattern for the excavation. Template dimensions, shapes, and

surface inside the template is not smooth.

material may vary according to the size of the test pit to be

6.10 Siphon Hose, Pump, Buckets, Hoses, or other suitable

excavated. The template must be rigid enough not to deflect or

equipment to move water to and from the template or pit, or

bend.

both, and any storage container or reservoir.

6.11 Miscellaneous Equipment, sandbags used to prevent

NOTE 1—The template shown in Fig. 1 represents a design that has

movement of the template during the test; shovels, picks,

been found suitable for this purpose.

chisels, bars, knives, and spoons for digging test pit; buckets or

6.6.1 Since it may be difficult to place the template exactly

seamless cans with lids, drums, barrels, or other suitable

level, particularly with 6-ft (1.8-m) and larger diameter rings,

containers for retaining the test specimen without moisture

the height of the template should accommodate a slope of

change; cloth for collecting excess soil; as

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.