ASTM E1486M-14(2022)

(Test Method)Standard Test Method for Determining Floor Tolerances Using Waviness, Wheel Path and Levelness Criteria (Metric)

Standard Test Method for Determining Floor Tolerances Using Waviness, Wheel Path and Levelness Criteria (Metric)

SIGNIFICANCE AND USE

5.1 This test method provides statistical and graphical information concerning floor surface profiles.

5.2 Results of this test method are for the purpose of the following:

5.2.1 Establishing compliance of random or fixed-path trafficked floor surfaces with specified tolerances;

5.2.2 Evaluating the effect of different construction methods on the waviness of the resulting floor surface;

5.2.3 Investigating the curling and deflection of concrete floor surfaces;

5.2.4 Establishing, evaluating, and investigating the profile characteristics of other surfaces; and

5.2.5 Establishing, evaluating, and investigating the levelness characteristics of surfaces.

5.3 Application:

5.3.1 Random Traffic—When the traffic patterns across a floor are not fixed, two sets of survey lines approximately equally spaced and at right angles to each other shall be used. The survey lines shall be spaced across the test section to produce lines of approximately equal total length, both parallel to and perpendicular to the longest test section boundary. Limits are specified in 7.2.2 and 7.3.2.

5.3.2 Defined Wheel Path Traffic—For surfaces primarily intended for defined wheel path traffic, only two wheel paths and the initial transverse elevation difference (“side-to-side”) between wheels shall be surveyed.

5.3.3 Time of Measurement—For new concrete floor construction, the elevation measurements shall be made within 72 h of final concrete finishing. For existing structures, measurements shall be taken as appropriate.

5.3.4 Elevation Conformance—Use is restricted to shored, suspended surfaces.

5.3.5 RMS Levelness—Use is unrestricted, except that it is excluded from use with cambered surfaces and unshored, elevated surfaces.

SCOPE

1.1 This test method covers data collection and analysis procedures to determine surface flatness and levelness by calculating waviness indices for survey lines and surfaces, elevation differences of defined wheel paths, and levelness indices using SI units.

Note 1: This test method is the companion to inch-pound Test Method E1486.

Note 2: This test method was not developed for, and does not apply to clay or concrete paver units.

1.1.1 The purpose of this test method is to provide the user with floor tolerance estimates as follows:

1.1.1.1 Local survey line waviness and overall surface waviness indices for floors based on deviations from the midpoints of imaginary chords as they are moved along a floor elevation profile survey line. End points of the chords are always in contact with the surface. The imaginary chords cut through any points in the concrete surface higher than the chords.

1.1.1.2 Defined wheel path criteria based on transverse and longitudinal elevation differences, change in elevation difference, and root mean square (RMS) elevation difference.

1.1.1.3 Levelness criteria for surfaces characterized by either of the following methods: the conformance of elevation data to the test section elevation data mean; or by the conformance of the RMS slope of each survey line to a specified slope for each survey line.

1.1.2 The averages used throughout these calculations are the root mean squares, RMS (that is, the quadratic means). This test method gives equal importance to humps and dips, measured up (+) and down (−), respectively, from the imaginary chords.

1.1.3 Appendix X1 is a commentary on this test method. Appendix X2 provides a computer program for waviness index calculations based on this test method.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use....

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E1486M − 14 (Reapproved 2022)

Standard Test Method for

Determining Floor Tolerances Using Waviness, Wheel Path

and Levelness Criteria (Metric)

This standard is issued under the fixed designation E1486M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

1.1 This test method covers data collection and analysis

standard.

procedures to determine surface flatness and levelness by

1.3 This standard does not purport to address all of the

calculating waviness indices for survey lines and surfaces,

safety concerns, if any, associated with its use. It is the

elevation differences of defined wheel paths, and levelness

responsibility of the user of this standard to establish appro-

indices using SI units.

priate safety, health, and environmental practices and deter-

NOTE1—Thistestmethodisthecompaniontoinch-poundTestMethod

mine the applicability of regulatory limitations prior to use.

E1486.

1.4 This international standard was developed in accor-

NOTE2—Thistestmethodwasnotdevelopedfor,anddoesnotapplyto

dance with internationally recognized principles on standard-

clay or concrete paver units.

ization established in the Decision on Principles for the

1.1.1 The purpose of this test method is to provide the user

Development of International Standards, Guides and Recom-

with floor tolerance estimates as follows:

mendations issued by the World Trade Organization Technical

1.1.1.1 Local survey line waviness and overall surface

Barriers to Trade (TBT) Committee.

waviness indices for floors based on deviations from the

midpoints of imaginary chords as they are moved along a floor

2. Referenced Document

elevation profile survey line. End points of the chords are

2.1 ASTM Standard:

always in contact with the surface. The imaginary chords cut

E1486Test Method for Determining FloorTolerances Using

through any points in the concrete surface higher than the

Waviness, Wheel Path and Levelness Criteria

chords.

1.1.1.2 Defined wheel path criteria based on transverse and

3. Terminology

longitudinal elevation differences, change in elevation

3.1 Definitions of Terms Specific to This Standard:

difference, and root mean square (RMS) elevation difference.

3.1.1 defined wheel path traffıc—traffic on surfaces, or

1.1.1.3 Levelness criteria for surfaces characterized by ei-

specifically identifiable portions thereof, intended for defined

ther of the following methods: the conformance of elevation

linear traffic by vehicles with two primary axles and four

data to the test section elevation data mean; or by the

primary load wheel contact points on the floor and with

conformance of the RMS slope of each survey line to a

corresponding front and rear primary wheels in approximately

specified slope for each survey line.

the same wheel paths.

1.1.2 The averages used throughout these calculations are

therootmeansquares,RMS(thatis,thequadraticmeans).This

3.1.2 levelness—describedintwoways:theconformanceof

test method gives equal importance to humps and dips,

surface elevation data to the mean elevation of a test section,

measured up (+) and down (−), respectively, from the imagi-

elevation conformance; and as the conformance of survey line

nary chords.

slope to a specified slope, RMS levelness.

1.1.3 Appendix X1 is a commentary on this test method.

3.1.2.1 elevation conformance—the percentage of surface

AppendixX2providesacomputerprogramforwavinessindex

elevation data, h, that lie within the tolerance specified from

i

calculations based on this test method.

themeanelevationofatestsectionfromthemeanelevationof

alldatawithinatestsection.Theabsolutevalueofthedistance

ofallpoints,h,fromthetestsectiondatameanistestedagainst

i

This test method is under the jurisdiction of ASTM Committee E06 on

Performance of Buildings and is the direct responsibility of Subcommittee E06.21

on Serviceability. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2022. Published October 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1994. Last previous edition approved in 2014 as E1486M–14. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E1486M-14R22. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1486M − 14 (2022)

EC = percentage compliance of each survey line to a

L

specified maximum deviation, dmax, from the

mean of all elevation data points within a test

section.

h = elevation of the points along the survey line,

i

mm.

ha = elevation of the points along the survey line of

i

the left wheel path of defined wheel path

traffic, mm.

hb = elevation of the points along the survey line of

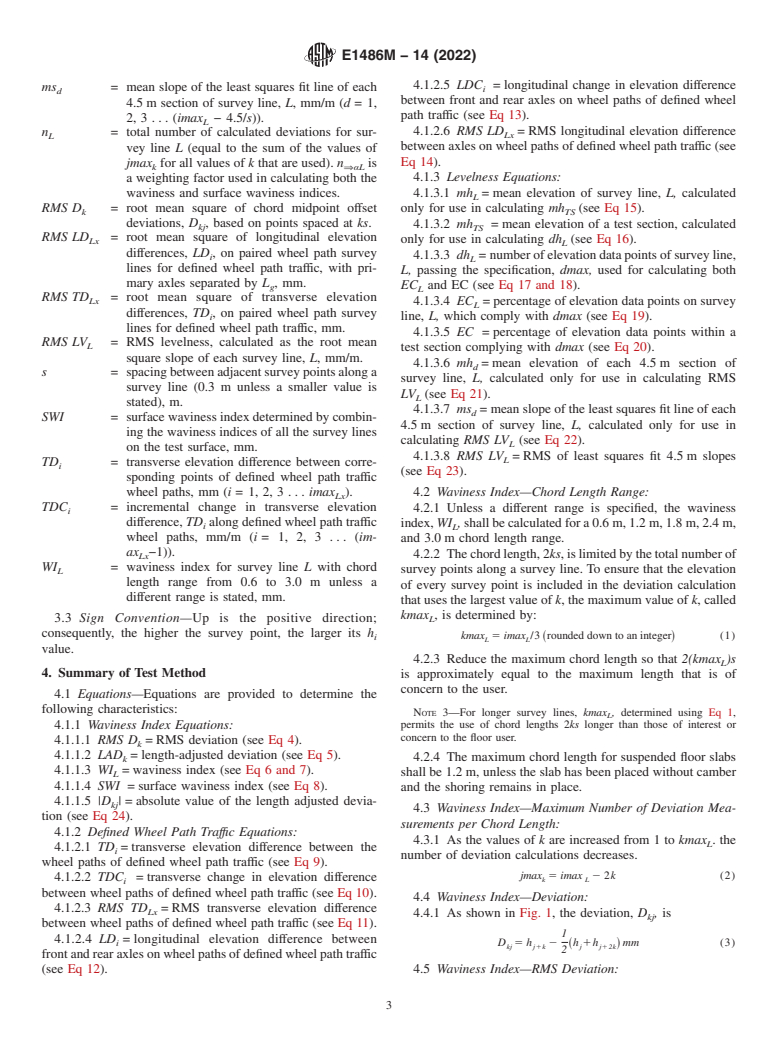

FIG. 1 Explanation of Symbols

i

the right wheel path of defined wheel path

traffic, mm.

the specification, dmax. Passing values are counted, and that i = designation of the location of survey points

total is divided by the aggregate quantity of elevation data

along a survey line (i=1, 2, 3 . imax ).

L

imax = total number of survey points along a survey

points for the test section, and percent passing is reported.

L

line.

3.1.2.2 RMS levelness—directionally dependent calculation

imax = total number of survey points along one of the

Lx

of the RMS of the slopes of the least squares fit line through

pair of survey lines, Lx, representing the wheel

successive 4.5m long sections of a survey line, L. The RMS

paths of defined wheel path traffic.

LV is compared to the specified surface slope and specified

L

j = designation of the location of the survey point

maximum deviation to determine compliance.

which is the initial point for a deviation calcu-

3.1.3 Waviness Index Terms:

lation (j=1, 2, 3 . jmax ).

k

3.1.3.1 chord length—the length of an imaginary straight-

jmax = total number of deviation calculations with a

k

edge (chord) joining the two end points at j andj+2k. This

chord length 2ks along a survey line.

length is equal to 2ks (see Fig. 1) where the survey spacing, s,

k = number of spaces of length s between the

is equal to 0.3 m, and where k is equal to 1, 2, 3, 4, and 5 to

survey points used for deviation calculations.

define chord lengths of 0.6m, 1.2m, 1.8m, 2.4m, and 3.0 m,

kmax = maximum number (rounded down to an inte-

L

respectively, unless values for s and for k are otherwise stated.

ger) of spaces of length s that can be used for

deviation calculations for imax survey points

3.1.3.2 deviation (D )—the vertical distance between the L

kj

(kmax =5 unless otherwise specified).

surfaceandthemidpoint,j+ks,ofachordoflength2kswhose L

L = designation of survey lines (L=1, 2, 3 .

end points are in contact with the surface.

Lmax).

3.1.3.3 length adjusted RMS deviation (LAD )—calculated

k

LAD = length-adjustedRMSdeviationbasedonpoints

k

for a reference length L of 3 m, unless otherwise stated, in

r

spaced at ks and a reference length of L .

r

order to obtain deviations that are independent of the various

Lg = totalnumberofsurveyspacesbetweenprimary

chord lengths, 2ks.

axles of a vehicle used as the basis for longi-

3.1.3.4 waviness—therelativedegreetowhichasurveyline

tudinal analysis of each pair of survey lines

deviates from a straight line.

representing the wheel paths of defined wheel

path traffic. Lg equals the integer result of the

3.2 Symbols:

primary axle spacing, in metres divided by s.

A = area of test section, m . Lmax = number of survey lines on the test surface.

d = pointi,ofthe(4.5/s+1)pointsubsetofi=1to

L = referencelengthof3m,thelengthtowhichthe

r

imax, where d is a point within the (4.5/s+1) RMS deviations, RMS D , from chord lengths

k

point subset, used to evaluate RMS levelness.

other than 3 m are adjusted.

dh = number of elevation data points of survey line, LD = longitudinal elevation difference between cor-

L i

L, which lie within the maximum allowable responding pairs of points separated by Lg of

deviation from the test section elevation data defined wheel paths, mm (i= 1, 2, 3 .

mean, dmax. (imax −Lg)).

L

D = deviation from chord midpoint,j+k, to the LDC = incremental change in longitudinal elevation

kj i

survey line, mm. difference, LD alongdefinedwheelpathtraffic

i

dmax = specified maximum allowable deviation from wheel paths, mm/m (i= 1, 2, 3 . (im-

the test section elevation data mean.

ax −Lg−1)).

L

EC = percentage of elevation data within a test

Lx = designation of the pair of survey lines used for

section complying to a specified maximum

defined wheel path traffic analysis.

deviation,dmax,fromthemeanofallelevation mh = meanelevationofeach4.5msectionofsurvey

d

data points within a test section. line, L,mm(d= 1, 2, 3 . (imax − 4.5/s)).

L

E1486M − 14 (2022)

4.1.2.5 LDC =longitudinal change in elevation difference

ms = mean slope of the least squares fit line of each

i

d

between front and rear axles on wheel paths of defined wheel

4.5m section of survey line, L, mm/m (d= 1,

path traffic (see Eq 13).

2,3.(imax − 4.5/s)).

L

4.1.2.6 RMS LD =RMS longitudinal elevation difference

n = total number of calculated deviations for sur-

Lx

L

vey line L (equal to the sum of the values of betweenaxlesonwheelpathsofdefinedwheelpathtraffic(see

Eq 14).

jmax for all values of k that are used). n is

k ⇒αL

a weighting factor used in calculating both the 4.1.3 Levelness Equations:

waviness and surface waviness indices. 4.1.3.1 mh =mean elevation of survey line, L, calculated

L

RMS D = root mean square of chord midpoint offset only for use in calculating mh (see Eq 15).

k TS

deviations, D , based on points spaced at ks.

4.1.3.2 mh =mean elevation of a test section, calculated

kj

TS

RMS LD = root mean square of longitudinal elevation

only for use in calculating dh (see Eq 16).

Lx

L

differences, LD, on paired wheel path survey

4.1.3.3 dh =numberofelevationdatapointsofsurveyline,

i

L

lines for defined wheel path traffic, with pri-

L, passing the specification, dmax, used for calculating both

mary axles separated by L , mm.

EC and EC (see Eq 17 and 18).

g

L

RMS TD = root mean square of transverse elevation

Lx

4.1.3.4 EC =percentage of elevation data points on survey

L

differences, TD, on paired wheel path survey

i line, L, which comply with dmax (see Eq 19).

lines for defined wheel path traffic, mm.

4.1.3.5 EC =percentage of elevation data points within a

RMS LV = RMS levelness, calculated as the root mean

L

test section complying with dmax (see Eq 20).

square slope of each survey line, L, mm/m.

4.1.3.6 mh =mean elevation of each 4.5m section of

d

s = spacingbetweenadjacentsurveypointsalonga

survey line, L, calculated only for use in calculating RMS

survey line (0.3 m unless a smaller value is

LV (see Eq 21).

L

stated), m.

4.1.3.7 ms =meanslopeoftheleastsquaresfitlineofeach

d

SWI = surfacewavinessindexdeterminedbycombin-

4.5m section of survey line, L, calculated only for use in

ing the waviness indices of all the survey lines

calculating RMS LV (see Eq 22).

L

on the test surface, mm.

4.1.3.8 RMS LV =RMS of least squares fit 4.5m slopes

L

TD = transverse elevation difference between corre-

i

(see Eq 23).

sponding points of defined wheel path traffic

wheel paths, mm (i= 1, 2, 3 . imax ). 4.2 Waviness Index—Chord Length Range:

Lx

TDC = incremental change in transverse elevation

4.2.1 Unless a different range is specified, the waviness

i

difference, TD alongdefinedwheelpathtraffic

index,WI ,shallbecalculatedfora0.6m,1.2m,1.8m,2.4m,

i L

wheel paths, mm/m (i= 1, 2, 3 . (im-

and 3.0m chord length range.

ax −1)).

4.2.2 Thechordlength,2ks,islimitedbythetotalnumberof

Lx

WI = waviness index for survey line L with chord

L survey points along a survey line. To ensure that the elevation

length range from 0.6 to 3.0 m unless a

of every survey point is included in the deviation calculation

different range is stated, mm.

thatusesthelargestvalueof k,themaximumvalueof k,called

kmax , is determined by:

3.3 Sign Convention—Up is the positive direction; L

consequently, the higher the survey point, the larger its h

i kmax 5 imax /3 ~roundeddowntoaninteger! (1)

L L

value.

4.2.3 Reduce the maximum chord length so that 2(kmax )s

L

4. Summary of Test Method

is approximately equal to the maximum length that is of

concern to the user.

4.1 Equations—Equations are provided to determine the

following characteristics:

NOTE 3—For longer survey lines, kmax , determined using Eq 1,

L

permits the use of chord lengths 2ks longer than those of interest or

4.1.1 Waviness Index Equations:

concern to the floor user.

4.1.1.1 RMS D =RMS deviation (see Eq 4).

k

4.1.1.2 LAD =length-adjusted deviation (see Eq 5).

4.2.4 The maximum chord length for suspended floor slabs

k

4.1.1.3 WI =waviness index (see Eq 6 and 7).

shall be 1.2 m, unless the slab has been placed without camber

L

4.1.1.4 SWI =surface waviness index (see Eq 8).

and the shoring remains in place.

4.1.1.5 |D |=absolute value of the length adjusted devia-

kj

4.3 Waviness Index—Maximum Number of Deviation Mea-

tion (see Eq 24).

surements per Chord Length:

4.1.2 Defined Wheel Path Traffıc Equations:

4.3.1 As the values of k are increased from 1 to kmax . the

L

4.1.2.1 TD =transverse elevation difference between the

i

number of deviation calculations decreases.

wheel paths of defined wheel path traffic (see Eq 9).

jmax 5 imax 2 2k (2)

4.1.2.2 TDC =transverse change in elevation difference

k L

i

between wheel paths of defined wheel path traffic (see Eq 10).

4.4 Waviness Index—Deviation:

4.1.2.3 RMS TD =RMS transverse elevation difference

Lx

4.4.1 As shown in Fig. 1, the deviation, D , is

kj

between wheel paths of defined wheel path traffic (see Eq 11).

4.1.2.4 LD = longitudinal elevation difference between

i

D 5 h 2 ~h 1h !mm (3)

kj j1k j j12k

frontandrearaxlesonwheelpathsofdefinedwheelpathtraffic

(see Eq 12). 4.5 Waviness Index—RMS Deviation:

E1486M − 14 (2022)

4.5.1 RMS D is calculated for each chord length using all ha 1hb ha 1hb

i1Lg i1Lg i i

k

LD 5 2 mm (12)

SS D S DD

i

points along the survey line. 2 2

jmax

k 4.9.5 Longitudinal Change in Elevation Difference—LDC

i

D

( kj is calculated for a pair of wheel path survey lines, using Eq 13

j51

RMSD 5 mm (4)

!

k (i= 1, 2, 3 . (imax −Lg− 1)).

jmax Lx

k

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.