ASTM C627-18(2024)

(Test Method)Standard Test Method for Evaluating Ceramic Floor Tile Installation Systems Using the Robinson-Type Floor Tester

Standard Test Method for Evaluating Ceramic Floor Tile Installation Systems Using the Robinson-Type Floor Tester

SIGNIFICANCE AND USE

4.1 This test method provides a standardized procedure for evaluating performance of ceramic floor tile installations under conditions similar to actual specific usages. It can be used to make comparisons between customary basic installation methods, to establish the influence of minor changes in a particular installation method, and to judge the merit of proposed novel methods.

SCOPE

1.1 This test method covers the evaluation of ceramic floor tile installation systems, using the Robinson2-type floor tester.

1.2 This test method is intended solely for evaluating complete ceramic floor tile installation systems for failure under dynamic loads and not for evaluating particular characteristics of ceramic tile, such as abrasion resistance. This test method does not claim to provide meaningful results for other than evaluating complete ceramic floor tile installation systems.

1.3 The values stated in inch-pound units are to be regarded as the standard. The metric (SI) units in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C627 − 18 (Reapproved 2024)

Standard Test Method for

Evaluating Ceramic Floor Tile Installation Systems Using

the Robinson-Type Floor Tester

This standard is issued under the fixed designation C627; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ASTM Adjuncts:

Robinson-type Floor Tester

1.1 This test method covers the evaluation of ceramic floor

2 Deflection Gauge

tile installation systems, using the Robinson -type floor tester.

1.2 This test method is intended solely for evaluating

3. Summary of Test Method

complete ceramic floor tile installation systems for failure

3.1 This test method consists of preparing test assemblies

under dynamic loads and not for evaluating particular charac-

that duplicate the type of installation under consideration,

teristics of ceramic tile, such as abrasion resistance. This test

subjecting them to one or more tests on the Robinson floor

method does not claim to provide meaningful results for other

tester, and evaluating the results in a prescribed manner.

than evaluating complete ceramic floor tile installation sys-

Description of the installation method must specifically include

tems.

all variables, for example, the type of materials and mixture

1.3 The values stated in inch-pound units are to be regarded

proportions of substratum, setting material, and tile grout; type

as the standard. The metric (SI) units in parentheses are for

of tile, installation technique, and cure.

information only.

4. Significance and Use

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 4.1 This test method provides a standardized procedure for

responsibility of the user of this standard to establish appro- evaluating performance of ceramic floor tile installations under

priate safety, health, and environmental practices and deter- conditions similar to actual specific usages. It can be used to

mine the applicability of regulatory limitations prior to use. make comparisons between customary basic installation

1.5 This international standard was developed in accor- methods, to establish the influence of minor changes in a

dance with internationally recognized principles on standard- particular installation method, and to judge the merit of

ization established in the Decision on Principles for the

proposed novel methods.

Development of International Standards, Guides and Recom-

5. Apparatus

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

5.1 Foundation for Tester—The foundation for the tester

shall consist of a minimum 4-ft by 4-ft (1220 mm by 1220 mm)

2. Referenced Documents

square and 1-ft (300 mm) thick cement slab. The testing

2.1 ASTM Standards: surface of this slab shall be smooth, level, and flat with the

maximum deviation from a true plane not to exceed ⁄32 in.

C144 Specification for Aggregate for Masonry Mortar

C150 Specification for Portland Cement (0.8 mm). The foundation may be equipped for a bottom or top

driven tester. Please see X1.1 for construction details for a

foundation using a bottom driven tester that has been known to

This test method is under the jurisdiction of ASTM Committee C21 on Ceramic meet the requirements of the test method.

Whitewares and Related Products and is the direct responsibility of Subcommittee

5.2 Tester—The tester itself shall be a 150-lbs 6 5-lbs

C21.06 on Ceramic Tile.

Current edition approved Feb. 1, 2024. Published February 2024. Originally (68.1 kg 6 2.3 kg) carriage in the shape of an equilateral

ɛ1

approved in 1970. Last previous edition approved in 2018 as C627 – 18 . DOI:

triangle. Three swivel caster wheels shall be equally spaced in

10.1520/C0627-18R24.

a circle with 15-in. (381 mm) radius from the center and

Detailed working drawings of the an apparatus known to meet the requirements

of this standard are available at a nominal cost from ASTM Headquarters. Order

Adjunct No. ADJC062701 or ADJC062701-E-PDF (digital version).

3 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Detailed working drawings for construction of a deflection gauge known to

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM meet the requirements of this standard are available at nominal cost from ASTM

Standards volume information, refer to the standard’s Document Summary page on Headquarters. Order Adjunct No. ADJC062702 or ADJC062702-E-PDF (digital

the ASTM website. version).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C627 − 18 (2024)

fastened to the underside of the carriage at the intersection of 5.5.1 One set of soft rubber wheels with a 78 6 3 Shore A

the bisector of each angle and the 15-in. (381 mm) radius durometer hardness,

circle. The carriage shall be capable of supporting 750 lbs 5.5.2 One set of hard rubber wheels with a 80 6 3 Shore D

(340.5 kg) of additional weight, 250 lbs (113.5 kg) of auxiliary durometer hardness, and

weights over each wheel. The auxiliary weight stacks shall be 5.5.3 One set of steel wheels with a steel surface. The

sufficiently secured to the carriage. Cutaway diagrams of a surface of the steel wheel shall be curved in such a way that the

bottom-driven apparatus and of a top-driven apparatus are radius in the center is greater than the radius on the edge by

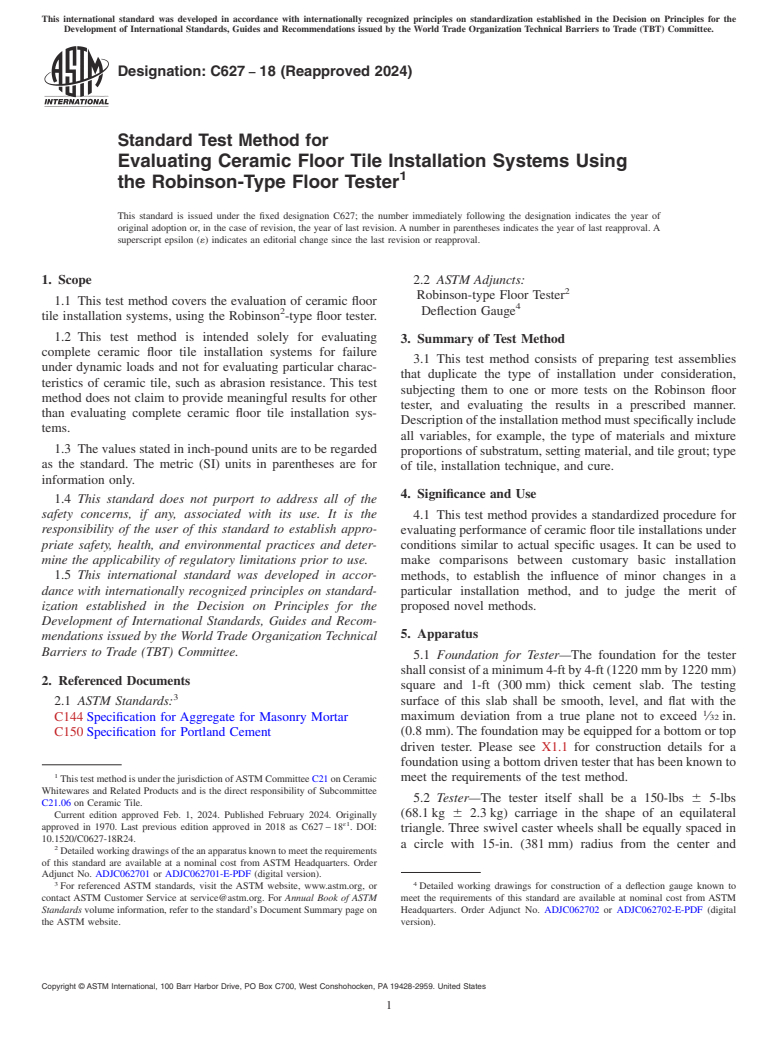

shown in Fig. 1. Please see X1.2 for construction details for approximately ⁄128 in. (0.6 mm). See Fig. 2.

one example of a tester known to meet the requirements of the

5.6 Weights—750-lbs (340 kg) of auxiliary weights are

test method.

required. Weights may be of any size or shape so long as they

5.3 Drive—The tester shall be driven by a motor and speed meet the requirements found in 5.2 and the loading schedule

reducer, variable speed drive, or equivalent, capable of rotating found in Table 1. Thirty 25-lb (11.5 kg) disk-shaped, 11-in.

the carriage at 15 rpm 6 0.5 rpm during testing. Drive trans- (280 mm) diameter bar bell weights have been known to work.

mittal shall be arranged in such a manner that the plane of Accuracy of the weights shall be 62 %.

travel and the elevation of the carriage are free to accommodate

5.7 Deflection Gauge (optional)—A gauge accurate to

various types of test assemblies. The drive shaft (whether top

0.001 in. (0.025 mm) which may be inserted between the upper

or bottom driven tester) shall be equipped with a universal joint

and lower sheet of a plywood base to measure the deflection of

between the driveshaft and carriage to allow contact between

the base under the path of the wheels.

the wheels and test panel at all times.

6. Test Panel Assemblies

5.4 Revolution Counter or Timer—A revolution counter,

capable of recording up to 1000 revolutions, or an automatic

6.1 The base upon which the tile are installed, the bonding

timing device which can be present to stop the tester.

medium, the type of tile mountings, the type of grout, and the

type of tile used may be varied with the requirements of the

5.5 Wheels—The wheels shall be attached to swivel casters

test.

with removable axles, equipped with grease fittings. All casters

shall be of ball bearing construction. The wheels shall be 4 in.

1 3 1

6 ⁄8 in. (102 mm 6 3 mm) in diameter and 1 ⁄8-in. 6 ⁄16-in.

The wheels must be conditioned at 73.4 °F 6 3.6 °F (23 °C 6 2 °C) for a

(35 mm 6 1.6 mm) in width. The wheels shall be equipped

minimum of 24 hours prior to measuring the durometer hardness. Shore A and Shore

with roller or ball bearings. Three sets of three wheels each are

D durometer hardness measurements shall be taken in the center of the wheel width

required, namely: prior to the wheel being placed into service on each test panel.

FIG. 1 Bottom- and Top-Driven Floor Tile Installations Systems Testers (Not to Scale)

C627 − 18 (2024)

FIG. 2 Steel Wheel Surface Profile

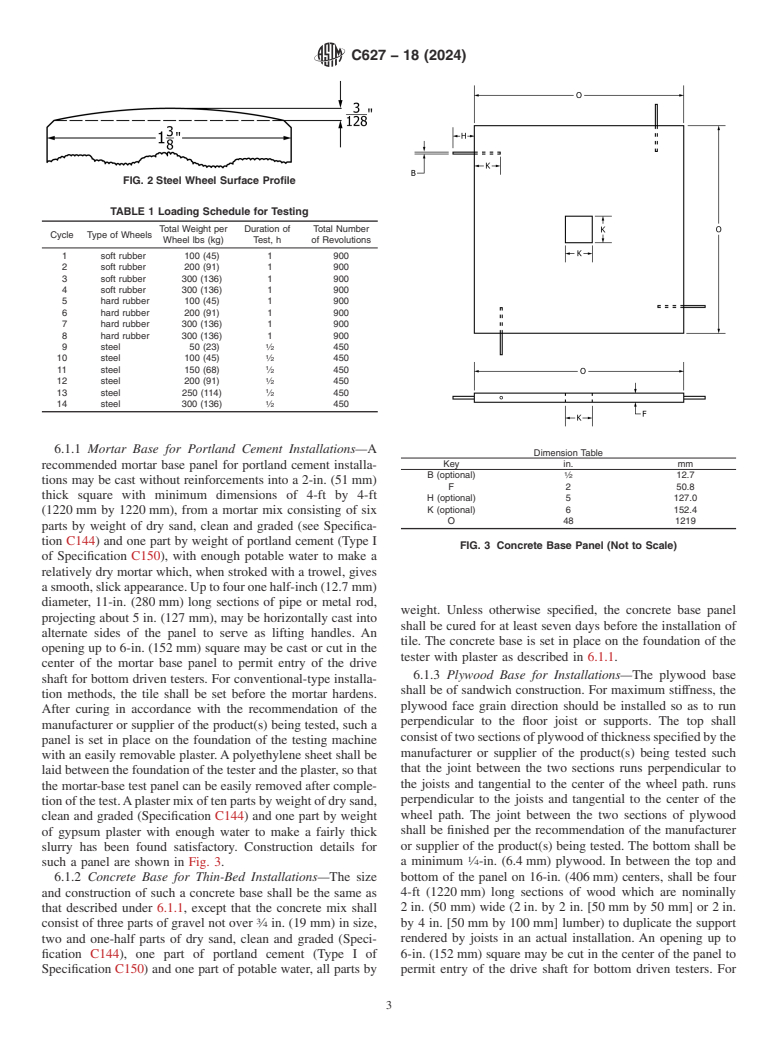

TABLE 1 Loading Schedule for Testing

Total Weight per Duration of Total Number

Cycle Type of Wheels

Wheel lbs (kg) Test, h of Revolutions

1 soft rubber 100 (45) 1 900

2 soft rubber 200 (91) 1 900

3 soft rubber 300 (136) 1 900

4 soft rubber 300 (136) 1 900

5 hard rubber 100 (45) 1 900

6 hard rubber 200 (91) 1 900

7 hard rubber 300 (136) 1 900

8 hard rubber 300 (136) 1 900

9 steel 50 (23) ⁄2 450

10 steel 100 (45) ⁄2 450

11 steel 150 (68) ⁄2 450

12 steel 200 (91) ⁄2 450

13 steel 250 (114) ⁄2 450

14 steel 300 (136) ⁄2 450

6.1.1 Mortar Base for Portland Cement Installations—A

Dimension Table

Key in. mm

recommended mortar base panel for portland cement installa-

B (optional) ⁄2 12.7

tions may be cast without reinforcements into a 2-in. (51 mm)

F 2 50.8

thick square with minimum dimensions of 4-ft by 4-ft

H (optional) 5 127.0

K (optional) 6 152.4

(1220 mm by 1220 mm), from a mortar mix consisting of six

O 48 1219

parts by weight of dry sand, clean and graded (see Specifica-

tion C144) and one part by weight of portland cement (Type I

FIG. 3 Concrete Base Panel (Not to Scale)

of Specification C150), with enough potable water to make a

relatively dry mortar which, when stroked with a trowel, gives

a smooth, slick appearance. Up to four one half-inch (12.7 mm)

diameter, 11-in. (280 mm) long sections of pipe or metal rod,

weight. Unless otherwise specified, the concrete base panel

projecting about 5 in. (127 mm), may be horizontally cast into

shall be cured for at least seven days before the installation of

alternate sides of the panel to serve as lifting handles. An

tile. The concrete base is set in place on the foundation of the

opening up to 6-in. (152 mm) square may be cast or cut in the

tester with plaster as described in 6.1.1.

center of the mortar base panel to permit entry of the drive

6.1.3 Plywood Base for Installations—The plywood base

shaft for bottom driven testers. For conventional-type installa-

shall be of sandwich construction. For maximum stiffness, the

tion methods, the tile shall be set before the mortar hardens.

plywood face grain direction should be installed so as to run

After curing in accordance with the recommendation of the

perpendicular to the floor joist or supports. The top shall

manufacturer or supplier of the product(s) being tested, such a

consist of two sections of plywood of thickness specified by the

panel is set in place on the foundation of the testing machine

manufacturer or supplier of the product(s) being tested such

with an easily removable plaster. A polyethylene sheet shall be

that the joint between the two sections runs perpendicular to

laid between the foundation of the tester and the plaster, so that

the joists and tangential to the center of the wheel path. runs

the mortar-base test panel can be easily removed after comple-

perpendicular to the joists and tangential to the center of the

tion of the test. A plaster mix of ten parts by weight of dry sand,

wheel path. The joint between the two sections of plywood

clean and graded (Specification C144) and one part by weight

shall be finished per the recommendation of the manufacturer

of gypsum plaster with enough water to make a fairly thick

or supplier of the product(s) being tested. The bottom shall be

slurry has been found satisfactory. Construction details for

a minimum ⁄4-in. (6.4 mm) plywood. In between the top and

such a panel are shown in Fig. 3.

6.1.2 Concrete Base for Thin-Bed Installations—The size bottom of the panel on 16-in. (406 mm) centers, shall be four

4-ft (1220 mm) long sections of wood which are nominally

and construction of such a concrete base shall be the same as

that described under 6.1.1, except that the concrete mix shall 2 in. (50 mm) wide (2 in. by 2 in. [50 mm by 50 mm] or 2 in.

by 4 in. [50 mm by 100 mm] lumber) to duplicate the support

consist of three parts of gravel not over ⁄4 in. (19 mm) in size,

two and one-half parts of dry sand, clean and graded (Speci- rendered by joists in an actual installation. An opening up to

fication C144), one part of portland cement (Type I of 6-in. (152 mm) square may be cut in the center of the panel to

Specification C150) and one part of potable water, all parts by permit entry of the drive shaft for bottom driven testers. For

C627 − 18 (2024)

details of construction of such a panel see Fig. 4. The panel 6.1.4 and install upon such a panel the type of floor tile by the

should be reasonably secured to not allow movement of the method that is to be evaluated. A minimum of four grout joints

panel during testing.

shall be within the wheel path for each installation to be

6.1.3.1 Plywood Base with Panel-Type or Sheet-Type

evaluated.

Underlayment—If a panel-type underlayment (for example,

7.2 After curing of the panel in accordance with the

backerboard) or a sheet-type underlayment (for example, sheet

recommendation of the manufacturer or supplier of the prod-

membrane) is to be installed atop the plywood base, it shall

uct(s) being tested, mount the test panel on the foundation of

consist of two sections such that the joint between the two

the testing machine in accordance with the instructions given

sections runs parallel to the joists and tangential to the center

for the type of panel used.

of the wheel path. The installation of the two sections of

underlayment atop the plywood base and the preparation of the

7.3 Install soft rubber wheels on the machine and place the

joint between the two sections of underlayment shall be

necessary weights over each wheel to obtain the weight per

finished in accordance with the recommendation of the manu-

wheel specified for each cycle as given in Table 1. Be sure to

facturer or supplier of the product(s) being tested. An opening

take into consideration that the weight of the 150-lbs (68.1 kg)

up to 6-in. (152 mm) square may be cut in the center of the

carriage is distributed so that each wheel is automatically

underlayment and plywood base to permit entry of the drive

loaded with 50 lbs (23 kg). Therefore, subtract 50 lbs from the

shaft for bottom driven testers. See Fig. 5 for an illustration.

weight specified in the column, “Total Weight per Wheel.”

6.1.4 Composition Base for Installations—The construction

7.3.1 Inspect the wheels for deterioration after each cycle

of the composition base panel shall be identical to that of the

and replace as necessary.

pl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.