ASTM E1543-00(2011)

(Test Method)Standard Test Method for Noise Equivalent Temperature Difference of Thermal Imaging Systems

Standard Test Method for Noise Equivalent Temperature Difference of Thermal Imaging Systems

SIGNIFICANCE AND USE

This test method gives an objective measure of the temperature sensitivity of a thermal imaging system (relative to a standard reference filter) exclusive of a monitor, with emphasis on the detector(s) and preamplifier.

Note 1—Test values obtained under idealized laboratory conditions may or may not correlate directly with service performance.

This test method affords a convenient means for periodically monitoring the performance of a given thermal imaging system.

NETD relates to minimum resolvable temperature difference as described in Test Method E1213. Thus, an increase in NETD may be manifest as a loss of detail in imagery.

Intercomparisons based solely on NETD figures may be misleading.

Note 2—NETD depends on various factors such as spectral bandwidth and background temperature.

SCOPE

1.1 This test method covers the determination of the noise equivalent temperature difference (NETD; NEΔT) of thermal imaging systems of the conventional forward-looking infrared (FLIR) or other types that utilize an optical-mechanical scanner; it does not include charge-coupled devices or pyroelectric vidicons.

1.2 Parts of this test method have been formulated under the assumption of a photonic detector(s) at a standard background temperature of 295°K (22°C). Besides nonuniformity, tests made at other background temperatures may result in impairment of precision and bias.

1.3 The values stated in SI units are to be regarded as standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1543 −00(Reapproved 2011)

Standard Test Method for

Noise Equivalent Temperature Difference of Thermal

Imaging Systems

This standard is issued under the fixed designation E1543; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope body (surface with emissivity of 1.0), usually a cavity or a flat

plate with a structured or coated surface having a stable and

1.1 This test method covers the determination of the noise

uniform temperature.

equivalent temperature difference (NETD; NE∆T) of thermal

3.1.2 dwell time—the time spent, during one frame, in

imaging systems of the conventional forward-looking infrared

scanning one angular dimension of a single pixel (picture

(FLIR) or other types that utilize an optical-mechanical scan-

element) of the image within the instantaneous field of view

ner; it does not include charge-coupled devices or pyroelectric

(IFOV) of a detector. Thus, for example, if a single pixel is

vidicons.

scanned n times during one frame, the dwell time is given by

1.2 Parts of this test method have been formulated under the

n times the duration of a single scan of the pixel.

assumption of a photonic detector(s) at a standard background

3.1.3 FLIR—an acronym for forward-looking infrared,

temperature of 295°K (22°C). Besides nonuniformity, tests

originally implying airborne, now denoting any fast-frame

made at other background temperatures may result in impair-

thermal imaging system comparable to that of television and

ment of precision and bias.

yielding real-time displays. Generally, these systems employ

1.3 The values stated in SI units are to be regarded as

optical-mechanical scanning mechanisms.

standard.

3.1.4 See also Section J: Infrared Examination, of Termi-

1.4 This standard does not purport to address all of the

nology E1316.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 4. Summary of Test Method

priate safety and health practices and determine the applica-

4.1 The target is a blackbody source of uniform temperature

bility of regulatory limitations prior to use.

that is viewed by the infrared thermal imaging system through

an aperture of prescribed size. A specified temperature differ-

2. Referenced Documents

ence is established between the target and its background.

2.1 ASTM Standards: Measurements are made of the peak-to-peak signal voltage

from the target and the RMS noise voltage from the

E1213 Test Method for Minimum Resolvable Temperature

background, both across a standard reference filter, and of the

Difference for Thermal Imaging Systems

target and background temperatures. From these measured

E1316 Terminology for Nondestructive Examinations

values, the NETD is calculated.

3. Terminology

5. Significance and Use

3.1 Definitions:

5.1 This test method gives an objective measure of the

3.1.1 blackbody simulator—a device that produces an emis-

temperaturesensitivityofathermalimagingsystem(relativeto

sion spectrum closely approximating that emitted by a black-

a standard reference filter) exclusive of a monitor, with

emphasis on the detector(s) and preamplifier.

NOTE 1—Test values obtained under idealized laboratory conditions

This test method is under the jurisdiction of ASTM Committee E07 on

may or may not correlate directly with service performance.

Nondestructive Testing and is the direct responsibility of Subcommittee E07.10 on

Specialized NDT Methods.

5.2 This test method affords a convenient means for peri-

Current edition approved Dec. 1, 2011. Published March 2012. Originally

odically monitoring the performance of a given thermal imag-

approved in 1993. Last previous edition approved in 2006 as E1543 - 00(2006).

ing system.

DOI: 10.1520/E1543-00R11.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.3 NETD relates to minimum resolvable temperature dif-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ference as described in Test Method E1213. Thus, an increase

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. in NETD may be manifest as a loss of detail in imagery.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1543−00 (2011)

5.4 Intercomparisons based solely on NETD figures may be

misleading.

NOTE 2—NETD depends on various factors such as spectral bandwidth

and background temperature.

6. Apparatus

6.1 The apparatus, as shown in Fig. 1, consists of the

following:

6.1.1 Blackbody Simulator, temporally stable and control-

lable to within 0.1°C.

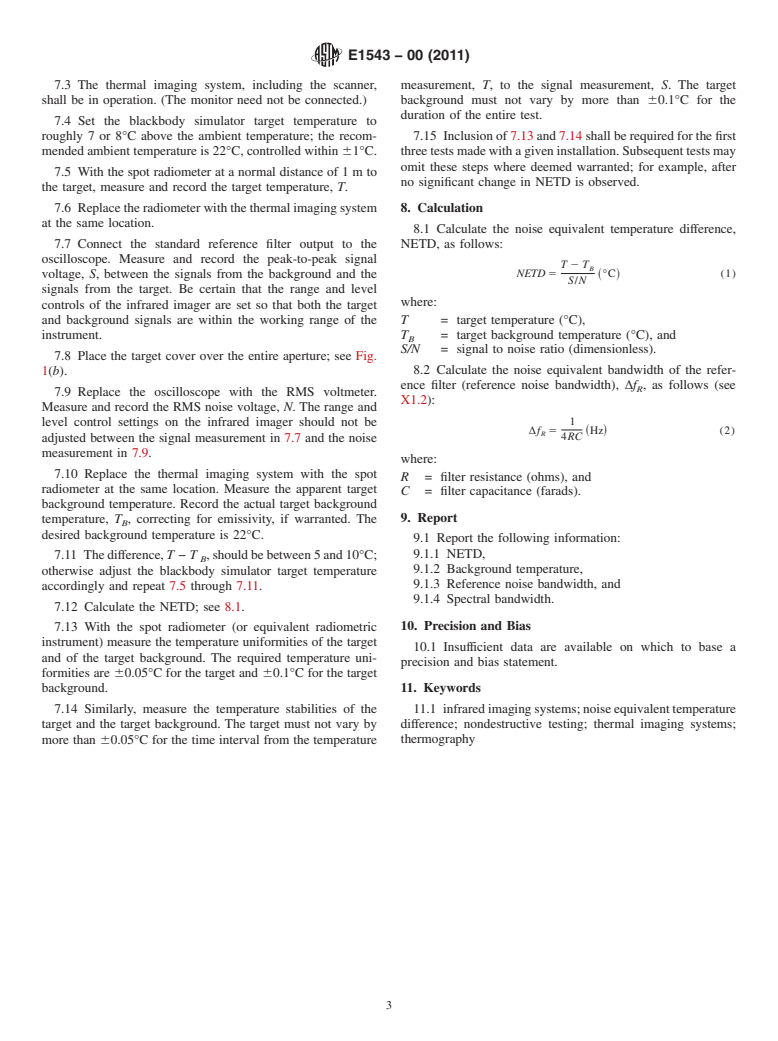

FIG. 2 Circuit Diagram of Standard Reference Filter

6.1.2 Target Plate, containing an aperture several times

larger dimensionally than the IFOV. The target plate should be

NOTE 4—The purpose of the filter is to standardize and define a

at least ten times the dimension of the aperture in both the

reference noise bandwidth, upon which the noise measurement depends in

part.

height and width. (The plate forms the target background; the

NOTE 5—If convenient, the filter may be a self-contained unit for

aperture, in effect, becomes the target as the blackbody

external connection.

simulator is viewed through it.) The material and surface

6.1.5 Infrared Spot Radiometer or equivalent radiometric

conditions of the target plate must be carefully considered. It is

instrument, calibrated with the aid of a blackbody source to an

helpful for the back side of the target plate to be a highly

accuracy within 0.1°C.

reflective metallic surface to minimize the influence of the

6.1.6 Digital Oscilloscope.

blackbody simulator on the temperature of the target back-

6.1.7 Digital True RMS Voltmeter, with high crest factor

ground. The front surface of the target plate should appear to

(peak voltage/RMS voltage) so as not to attenuate any noise

the infrared imaging system to have a high emissivity. One

peaks, and bandwidth from approximately zero to at least

possibility would be to coat the viewed surface with a high

1.6/RC. See 6.1.4 and X1.1.

emissivity paint

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.