ASTM F874-98(2019)

(Test Method)Standard Test Method for Temperature Measurement and Profiling for Microwave Susceptors (Withdrawn 2024)

Standard Test Method for Temperature Measurement and Profiling for Microwave Susceptors (Withdrawn 2024)

ABSTRACT

This test method covers the standard procedures for measuring and profiling surface temperatures attained by microwave interactive packaging and cooking aids (that is, susceptors). This procedure is useful for measuring susceptor/food interface temperatures during microwave preparation of foods with susceptor-based packaging, heating pads, and crisping sleeves, etc. It may also be used in the temperature profiling of susceptors exposed in vials used for volatile extractives testing, or in liquid (PTFE-fluorocarbon polymer) extraction cells used for nonvolatile extractives testing. The latter procedures are performed to establish test conditions for conducting extraction and migration studies using temperature versus time profiles approximating those for actual microwave preparation of the product.

SCOPE

1.1 This is a test method for measuring surface temperatures attained by microwave interactive packaging and cooking aids (that is, susceptors). It is useful for measuring susceptor/food interface temperatures during microwave preparation of foods with susceptor-based packaging, heating pads, and crisping sleeves, etc. It may also be used to measure the temperature of a susceptor exposed to extractives testing or in a liquid extraction cell to be used for nonvolatile extractives testing. The latter procedures are performed to establish test conditions for conducting extraction and migration studies using temperature versus time profiles approximating those for actual microwave preparation of the product.

1.1.1 Several of the steps of this test method are taken directly from Test Method F1308 which gives extraction testing procedures for susceptors.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

WITHDRAWN RATIONALE

This was a test method for measuring surface temperatures attained by microwave interactive packaging and cooking aids (that is, susceptors). It was useful for measuring susceptor/food interface temperatures during microwave preparation of foods with susceptor-based packaging, heating pads, and crisping sleeves, etc. It may have also been used to measure the temperature of a susceptor exposed to extractives testing or in a liquid extraction cell to be used for nonvolatile extractives testing. The latter procedures were performed to establish test conditions for conducting extraction and migration studies using temperature versus time profiles approximating those for actual microwave preparation of the product.

Formerly under the jurisdiction of Committee F02 on Primary Barrier Packaging, this test method was withdrawn in April 2024. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F874 −98 (Reapproved 2019)

Standard Test Method for

Temperature Measurement and Profiling for Microwave

Susceptors

ThisstandardisissuedunderthefixeddesignationF874;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 Thisisatestmethodformeasuringsurfacetemperatures

F1308 Test Method for Quantitating Volatile Extractables in

attained by microwave interactive packaging and cooking aids

Microwave Susceptors Used for Food Products

(that is, susceptors). It is useful for measuring susceptor/food

F1317 Test Method for Calibration of Microwave Ovens

interface temperatures during microwave preparation of foods

F1349 Test Method for Nonvolatile Ultraviolet (UV) Ab-

with susceptor-based packaging, heating pads, and crisping

sorbing Extractables from Microwave Susceptors

sleeves, etc. It may also be used to measure the temperature of

F1500 Test Method for Quantitating Non-UV-Absorbing

a susceptor exposed to extractives testing or in a liquid

extraction cell to be used for nonvolatile extractives testing. Nonvolatile Extractables from Microwave Susceptors Uti-

lizing Solvents as Food Simulants

The latter procedures are performed to establish test conditions

for conducting extraction and migration studies using tempera-

3. Apparatus

ture versus time profiles approximating those for actual micro-

wave preparation of the product. 3.1 Microwave Oven, no turntable, unmodified except for

small holes to allow for probe lead access to the oven cavity.

1.1.1 Several of the steps of this test method are taken

The oven should be calibrated in accordance with Test Method

directly from Test Method F1308 which gives extraction

testing procedures for susceptors. F1317.

3.2 Fluoroptic Thermometry System.

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

3.3 Vials, headspace, 20 mL.

standard.

3.4 Septa,polytetrafluorethylene(PTFE)polymerfacedsili-

1.3 This standard does not purport to address all of the

cone rubber.

safety concerns, if any, associated with its use. It is the

3.5 Vial Crimp Caps.

responsibility of the user of this standard to establish appro-

3.6 Microwave Nonvolatile Extraction Cell—This cell must

priate safety, health, and environmental practices and deter-

be constructed of PTFE-fluorocarbon polymer. Additional

mine the applicability of regulatory limitations prior to use.

details on this cell may be found in Test Method F1349.

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

3.7 Beakers, 600 and 250 mL, or other sizes as appropriate.

ization established in the Decision on Principles for the

3.8 Aluminum Foil, household roll.

Development of International Standards, Guides and Recom-

3.9 Adhesive Tape, such as Kapton high-temperature tape,

mendations issued by the World Trade Organization Technical

vinyl tape, silicone tape, etc.

Barriers to Trade (TBT) Committee.

3.10 High-Vacuum Silicone Grease .

3.11 Syringe Needle, 13 gage diameter.

This test method is under the jurisdiction ofASTM Committee F02 on Primary

Barrier Packaging and is the direct responsibility of Subcommittee F02.15 on

Chemical/Safety Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 1, 2019. Published May 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approvedin1990.Lastpreviouseditionapprovedin2014asF874 – 98(2014).DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F0874-98R19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F874−98 (2019)

3.12 Corn Oil, Miglyol 812 (a fractionated coconut oil), or expands during cooking. If it has been demonstrated that the

synthetic fat simulant HB 307. See Test Method F1349 for outer bag surface and inner bag surface temperatures are

details. equivalent,thentapingtheprobestotheoutersurfacewouldbe

satisfactory.

3.13 Petri Dishes.

5.4 For products prepared on a susceptor board, such as

3.14 Fan, tabletop.

microwave pizza, the probe should be immobilized to the

3.15 Blue Ice.

susceptor board in parallel contact by applying a suitable

3.16 Vials, for alternative profile method, 40-mLclear vials. adhesive tape 0.5 in. behind the probe tip.

5.5 For products without free fat or oil at the food susceptor

3.17 Screw Caps.

interface, it is advisable to apply high-vacuum silicone grease

4. Procedure

to the tip of the probe to assure good thermal contact with the

susceptor.

4.1 General:

4.1.1 Start all tests with a cool microwave oven, that is,

5.6 Microwave at full power for the maximum directed

ambient temperature. Use a fan and blue ice to cool oven floor

cooking time of the product, recording the temperature of each

or any other reliable method to suitably return the oven to

probe, preferably at 5-s intervals, but at intervals not to exceed

ambient temperature between replicates.

15 s. It is suggested that readings be taken at 1-s intervals if

4.1.2 Test three replicates per variable.

possible, in order to generate a smoother curve. Calculate the

average of the replicate runs at each recorded time for each

5. Measurement of Food/Susceptor Interface

probe position. Do not use data if discontinuities appear in plot

Temperature During Microwave Cooking

(indicative of loss of susceptor/probe contact).

5.1 Place product in center of the microwave oven as a

6. Temperature Profiling of Susceptors in Vials Used for

consumer would. Mark the position of first replicate on oven

floor, and position subsequent replicates similarly. Volatile Extractives Testing

6.1 First determine the temperature versus time profile for

5.2 Position probes at food susceptor interface in such a

manner that good probe/susceptor contact is maintained during the product during microwave preparation in accordance with

cooking, disturbing the food load as little as possible. The Section 5.

2 2

analyst may wish to position multiple probes on different

6.2 Cut a 10 by 65-mm (6.5 cm or 1-in. ) portion from the

regions of the susceptor, such as the center and edge, as the

susceptor sample to be tested. Insert carefully into vial,

temperature attained at different locations may differ signifi-

positioning the sample on the vial side, with the active side

cantly.

facing into the vial.

5.2.1 If the nature of the product permits, the analyst may

6.3 Using a 13-gage syringe needle, pierce a hole into a

wish to determine whether probes positioned parallel to the

septum, place septum on vial and crimp.

susceptor surface, or abutted to the susceptor surface would

result in better temperature measurement as evidenced by

6.4 Insert one temperature–sensing probe through the sep-

better reproducibility between replicate runs and less tum hole into the vial and manipulate it until it is in contact

discontinuity, due to loss of contact, of temperature readings with the active face of the susceptor material.

versus time.

5.3 For in-package measurements for products such as

microwave popcorn, probe access into the package is achieved

by drilling approximately 0.1-in. holes through the package.

(SeeFig.1forprobeplacementinsideapopcornbag.)Itisalso

advisable to route the probes along the bottom of the package

to avoid disruption of probe/susceptor contact as the bag

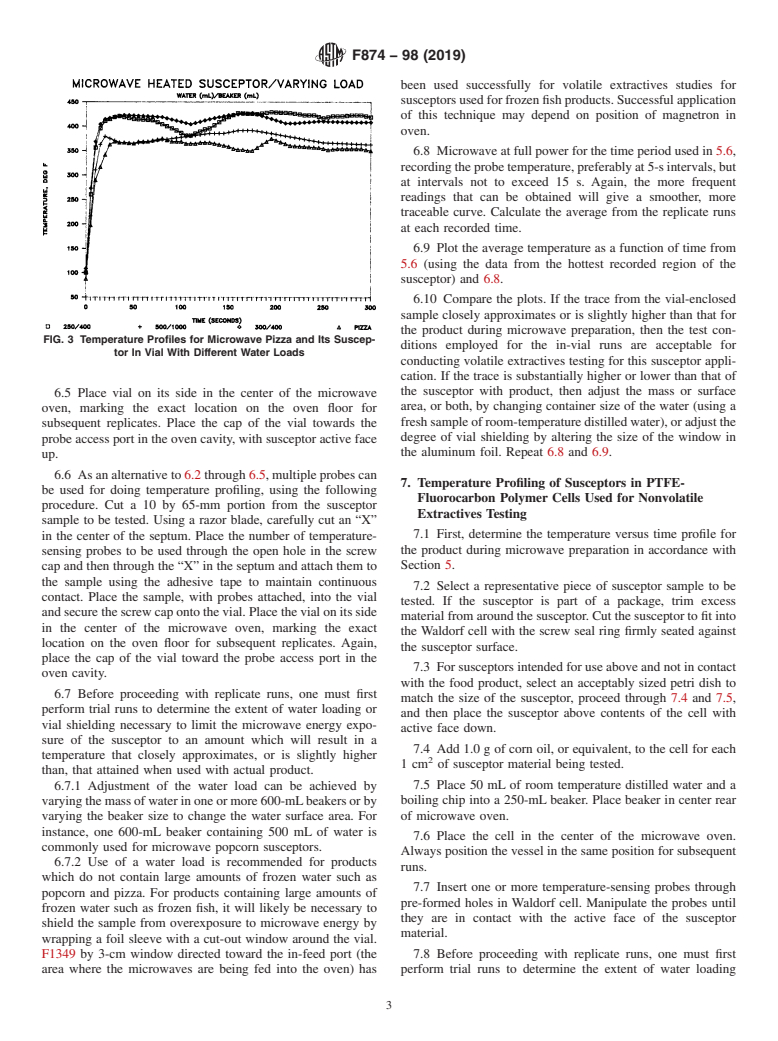

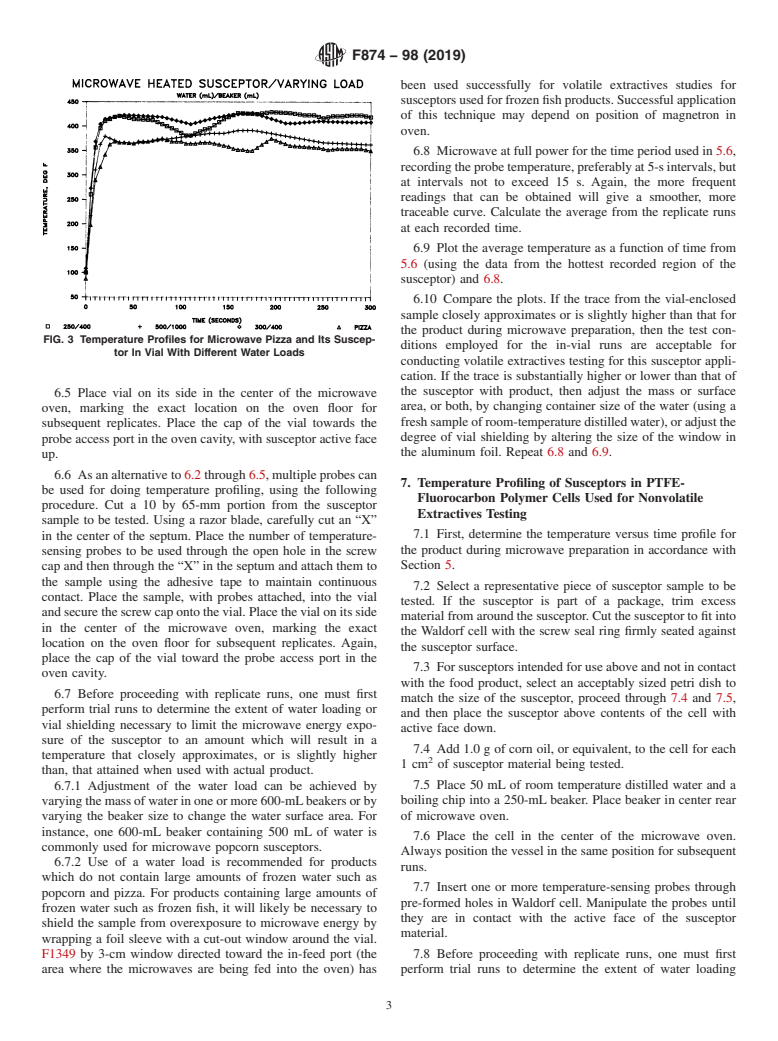

FIG. 1 Probe Configuration for Popcorn Bag Temperature Mea- FIG. 2 Effect of Foil Sleeve Window Size (cm ) on Temperature

surement Attained by Frozen Fish Product Susceptor

F874−98 (2019)

been used successfully for volatile extractives studies for

susceptorsusedforfrozenfishproducts.Successfulapplication

of this technique may depend on position of magnetron in

oven.

6.8 Microwave at full power for the time period used in 5.6,

recordingtheprobetemperature,preferablyat5-sintervals,but

at intervals not to exceed 15 s. Again, the more frequent

readings that can be obtained will give a smoother, more

traceable curve. Calculate the average from the replicate runs

at each recorded time.

6.9 Plot the average temperature as a function of time from

5.6 (using the data from the hottest recorded region of the

susceptor) and 6.8.

6.10 Compare the plots. If the trace from the vial-enclosed

sample closely approximates or is slightly higher than that for

the product during microwave preparation, then the test con-

FIG. 3 Temperature Profiles for Microwave Pizza and Its Suscep-

ditions employed for the in-vial runs are acceptable for

tor In

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F874 − 98 (Reapproved 2019)

Standard Test Method for

Temperature Measurement and Profiling for Microwave

Susceptors

This standard is issued under the fixed designation F874; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This is a test method for measuring surface temperatures 2.1 ASTM Standards:

attained by microwave interactive packaging and cooking aids F1308 Test Method for Quantitating Volatile Extractables in

(that is, susceptors). It is useful for measuring susceptor/food Microwave Susceptors Used for Food Products

interface temperatures during microwave preparation of foods F1317 Test Method for Calibration of Microwave Ovens

with susceptor-based packaging, heating pads, and crisping F1349 Test Method for Nonvolatile Ultraviolet (UV) Ab-

sleeves, etc. It may also be used to measure the temperature of sorbing Extractables from Microwave Susceptors

a susceptor exposed to extractives testing or in a liquid F1500 Test Method for Quantitating Non-UV-Absorbing

extraction cell to be used for nonvolatile extractives testing. Nonvolatile Extractables from Microwave Susceptors Uti-

The latter procedures are performed to establish test conditions lizing Solvents as Food Simulants

for conducting extraction and migration studies using tempera-

3. Apparatus

ture versus time profiles approximating those for actual micro-

3.1 Microwave Oven, no turntable, unmodified except for

wave preparation of the product.

small holes to allow for probe lead access to the oven cavity.

1.1.1 Several of the steps of this test method are taken

The oven should be calibrated in accordance with Test Method

directly from Test Method F1308 which gives extraction

F1317.

testing procedures for susceptors.

3.2 Fluoroptic Thermometry System.

1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

3.3 Vials, headspace, 20 mL.

standard.

3.4 Septa, polytetrafluorethylene (PTFE) polymer faced sili-

1.3 This standard does not purport to address all of the

cone rubber.

safety concerns, if any, associated with its use. It is the

3.5 Vial Crimp Caps.

responsibility of the user of this standard to establish appro-

3.6 Microwave Nonvolatile Extraction Cell—This cell must

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. be constructed of PTFE-fluorocarbon polymer. Additional

details on this cell may be found in Test Method F1349.

1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

3.7 Beakers, 600 and 250 mL, or other sizes as appropriate.

ization established in the Decision on Principles for the

3.8 Aluminum Foil, household roll.

Development of International Standards, Guides and Recom-

3.9 Adhesive Tape, such as Kapton high-temperature tape,

mendations issued by the World Trade Organization Technical

vinyl tape, silicone tape, etc.

Barriers to Trade (TBT) Committee.

3.10 High-Vacuum Silicone Grease .

3.11 Syringe Needle, 13 gage diameter.

This test method is under the jurisdiction of ASTM Committee F02 on Primary

Barrier Packaging and is the direct responsibility of Subcommittee F02.15 on

Chemical/Safety Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 1, 2019. Published May 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1990. Last previous edition approved in 2014 as F874 – 98(2014). DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F0874-98R19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F874 − 98 (2019)

3.12 Corn Oil, Miglyol 812 (a fractionated coconut oil), or expands during cooking. If it has been demonstrated that the

synthetic fat simulant HB 307. See Test Method F1349 for outer bag surface and inner bag surface temperatures are

details. equivalent, then taping the probes to the outer surface would be

satisfactory.

3.13 Petri Dishes.

5.4 For products prepared on a susceptor board, such as

3.14 Fan, tabletop.

microwave pizza, the probe should be immobilized to the

3.15 Blue Ice.

susceptor board in parallel contact by applying a suitable

adhesive tape 0.5 in. behind the probe tip.

3.16 Vials, for alternative profile method, 40-mL clear vials.

3.17 Screw Caps. 5.5 For products without free fat or oil at the food susceptor

interface, it is advisable to apply high-vacuum silicone grease

4. Procedure

to the tip of the probe to assure good thermal contact with the

susceptor.

4.1 General:

4.1.1 Start all tests with a cool microwave oven, that is,

5.6 Microwave at full power for the maximum directed

ambient temperature. Use a fan and blue ice to cool oven floor

cooking time of the product, recording the temperature of each

or any other reliable method to suitably return the oven to

probe, preferably at 5-s intervals, but at intervals not to exceed

ambient temperature between replicates.

15 s. It is suggested that readings be taken at 1-s intervals if

4.1.2 Test three replicates per variable.

possible, in order to generate a smoother curve. Calculate the

average of the replicate runs at each recorded time for each

5. Measurement of Food/Susceptor Interface

probe position. Do not use data if discontinuities appear in plot

Temperature During Microwave Cooking

(indicative of loss of susceptor/probe contact).

5.1 Place product in center of the microwave oven as a

consumer would. Mark the position of first replicate on oven 6. Temperature Profiling of Susceptors in Vials Used for

Volatile Extractives Testing

floor, and position subsequent replicates similarly.

5.2 Position probes at food susceptor interface in such a 6.1 First determine the temperature versus time profile for

manner that good probe/susceptor contact is maintained during the product during microwave preparation in accordance with

cooking, disturbing the food load as little as possible. The Section 5.

analyst may wish to position multiple probes on different 2 2

6.2 Cut a 10 by 65-mm (6.5 cm or 1-in. ) portion from the

regions of the susceptor, such as the center and edge, as the

susceptor sample to be tested. Insert carefully into vial,

temperature attained at different locations may differ signifi-

positioning the sample on the vial side, with the active side

cantly.

facing into the vial.

5.2.1 If the nature of the product permits, the analyst may

6.3 Using a 13-gage syringe needle, pierce a hole into a

wish to determine whether probes positioned parallel to the

septum, place septum on vial and crimp.

susceptor surface, or abutted to the susceptor surface would

result in better temperature measurement as evidenced by 6.4 Insert one temperature–sensing probe through the sep-

better reproducibility between replicate runs and less

tum hole into the vial and manipulate it until it is in contact

discontinuity, due to loss of contact, of temperature readings with the active face of the susceptor material.

versus time.

5.3 For in-package measurements for products such as

microwave popcorn, probe access into the package is achieved

by drilling approximately 0.1-in. holes through the package.

(See Fig. 1 for probe placement inside a popcorn bag.) It is also

advisable to route the probes along the bottom of the package

to avoid disruption of probe/susceptor contact as the bag

FIG. 1 Probe Configuration for Popcorn Bag Temperature Mea- FIG. 2 Effect of Foil Sleeve Window Size (cm ) on Temperature

surement Attained by Frozen Fish Product Susceptor

F874 − 98 (2019)

been used successfully for volatile extractives studies for

susceptors used for frozen fish products. Successful application

of this technique may depend on position of magnetron in

oven.

6.8 Microwave at full power for the time period used in 5.6,

recording the probe temperature, preferably at 5-s intervals, but

at intervals not to exceed 15 s. Again, the more frequent

readings that can be obtained will give a smoother, more

traceable curve. Calculate the average from the replicate runs

at each recorded time.

6.9 Plot the average temperature as a function of time from

5.6 (using the data from the hottest recorded region of the

susceptor) and 6.8.

6.10 Compare the plots. If the trace from the vial-enclosed

sample closely approximates or is slightly higher than that for

the product during microwave preparation, then the test con-

FIG. 3 Temperature Profiles for Microwave Pizza and Its Suscep-

ditions employed for the in-vial runs are acceptable for

tor In Vial With Different Water Loads

conducting volatile extractives testing f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.