ASTM F1308-98(2003)

(Test Method)Standard Test Method for Quantitating Volatile Extractables in Microwave Susceptors Used for Food Products

Standard Test Method for Quantitating Volatile Extractables in Microwave Susceptors Used for Food Products

SIGNIFICANCE AND USE

This test method is intended to measure volatile extractables that may be emitted from a microwave susceptor material during use. It may be a useful procedure to assist in minimizing the amount of volatile extractables either through susceptor design or manufacturing processes.

Modification of this procedure by utilizing appropriate qualitative GC detection such as a mass spectrometer in place of the flame ionization detector may provide identification of volatile extractables of unknown identity.

SCOPE

1.1 This test method covers complete microwave susceptors.

1.2 This test method covers a procedure for quantitating volatile compounds whose identity has been established and which are evolved when a microwave susceptor sample is tested under simulated use conditions.

1.3 This test method was collaboratively evaluated with a variety of volatile compounds (see statistical evaluation). For compounds other than those evaluated, the analyst should determine the sensitivity and reproducibility of the method by carrying out appropriate spike and recovery studies. The analyst is referred to Practice E 260 for guidance.

1.4 For purposes of verifying the identity of or identifying unknown volatile compounds, the analyst is encouraged to incorporate techniques such as gas chromatography/mass spectroscopy, gas chromatography/infrared spectroscopy, or other techniques in conjunction with this test method.

1.5 A sensitivity level of approximately 0.025 g/in. is achievable for the compounds studied in . Where other compounds are being quantitated and uncertainty exists over method sensitivity, the analyst is referred to Practice E 260 for procedures on determining sensitivity of chromatographic methods.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific safety hazards warnings are given in 10.2, 11.1, and 11.6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1308–98 (Reapproved 2003)

Standard Test Method for

Quantitating Volatile Extractables in Microwave Susceptors

Used for Food Products

This standard is issued under the fixed designation F 1308; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

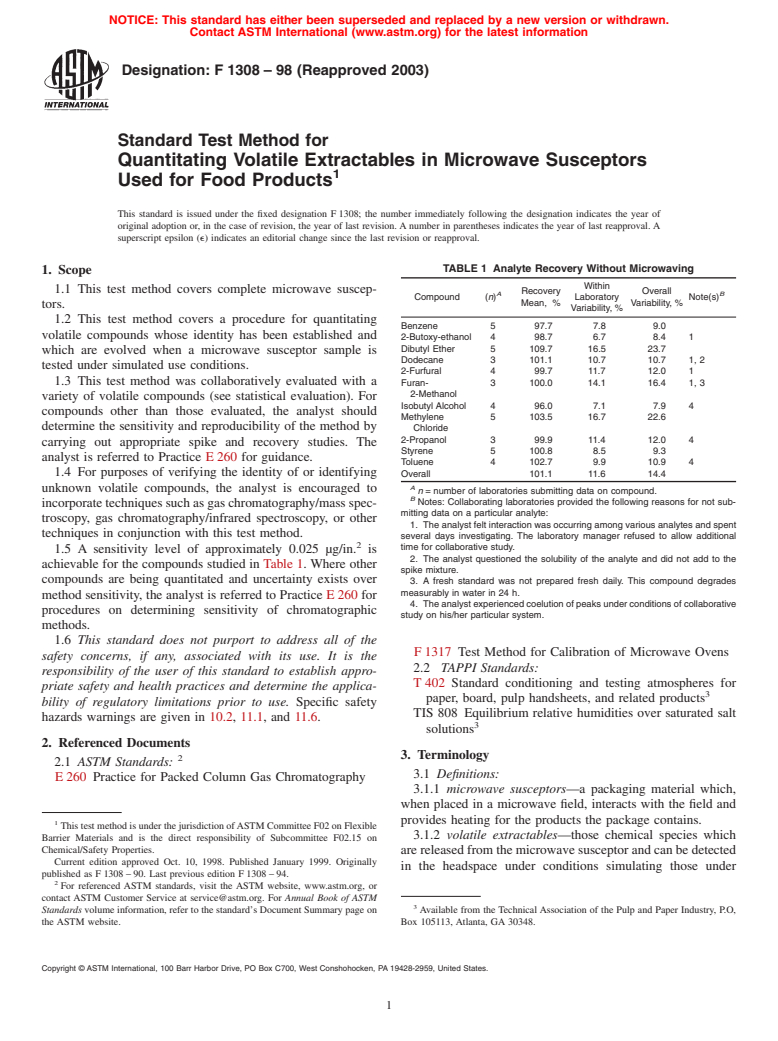

TABLE 1 Analyte Recovery Without Microwaving

1. Scope

Within

1.1 This test method covers complete microwave suscep-

Recovery Overall

A B

Compound (n) Laboratory Note(s)

Mean, % Variability, %

tors.

Variability, %

1.2 This test method covers a procedure for quantitating

Benzene 5 97.7 7.8 9.0

volatile compounds whose identity has been established and

2-Butoxy-ethanol 4 98.7 6.7 8.4 1

Dibutyl Ether 5 109.7 16.5 23.7

which are evolved when a microwave susceptor sample is

Dodecane 3 101.1 10.7 10.7 1, 2

tested under simulated use conditions.

2-Furfural 4 99.7 11.7 12.0 1

1.3 This test method was collaboratively evaluated with a

Furan- 3 100.0 14.1 16.4 1, 3

2-Methanol

variety of volatile compounds (see statistical evaluation). For

Isobutyl Alcohol 4 96.0 7.1 7.9 4

compounds other than those evaluated, the analyst should

Methylene 5 103.5 16.7 22.6

determine the sensitivity and reproducibility of the method by Chloride

2-Propanol 3 99.9 11.4 12.0 4

carrying out appropriate spike and recovery studies. The

Styrene 5 100.8 8.5 9.3

analyst is referred to Practice E 260 for guidance.

Toluene 4 102.7 9.9 10.9 4

1.4 For purposes of verifying the identity of or identifying

Overall 101.1 11.6 14.4

A

unknown volatile compounds, the analyst is encouraged to

n = number of laboratories submitting data on compound.

B

Notes: Collaborating laboratories provided the following reasons for not sub-

incorporate techniques such as gas chromatography/mass spec-

mitting data on a particular analyte:

troscopy, gas chromatography/infrared spectroscopy, or other

1. The analyst felt interaction was occurring among various analytes and spent

techniques in conjunction with this test method.

several days investigating. The laboratory manager refused to allow additional

time for collaborative study.

1.5 A sensitivity level of approximately 0.025 µg/in. is

2. The analyst questioned the solubility of the analyte and did not add to the

achievable for the compounds studied in Table 1. Where other

spike mixture.

compounds are being quantitated and uncertainty exists over 3. A fresh standard was not prepared fresh daily. This compound degrades

measurably in water in 24 h.

method sensitivity, the analyst is referred to Practice E 260 for

4. The analyst experienced coelution of peaks under conditions of collaborative

procedures on determining sensitivity of chromatographic

study on his/her particular system.

methods.

1.6 This standard does not purport to address all of the

F 1317 Test Method for Calibration of Microwave Ovens

safety concerns, if any, associated with its use. It is the

2.2 TAPPI Standards:

responsibility of the user of this standard to establish appro-

T 402 Standard conditioning and testing atmospheres for

priate safety and health practices and determine the applica-

paper, board, pulp handsheets, and related products

bility of regulatory limitations prior to use. Specific safety

TIS 808 Equilibrium relative humidities over saturated salt

hazards warnings are given in 10.2, 11.1, and 11.6.

solutions

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 Definitions:

E 260 Practice for Packed Column Gas Chromatography

3.1.1 microwave susceptors—a packaging material which,

when placed in a microwave field, interacts with the field and

provides heating for the products the package contains.

This test method is under the jurisdiction ofASTM Committee F02 on Flexible

3.1.2 volatile extractables—those chemical species which

Barrier Materials and is the direct responsibility of Subcommittee F02.15 on

Chemical/Safety Properties.

are released from the microwave susceptor and can be detected

Current edition approved Oct. 10, 1998. Published January 1999. Originally

in the headspace under conditions simulating those under

published as F 1308 – 90. Last previous edition F 1308 – 94.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from the Technical Association of the Pulp and Paper Industry, P.O,

the ASTM website. Box 105113, Atlanta, GA 30348.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1308–98 (2003)

which the susceptor is used. Extractability does not necessarily 7.2.1 Requirements for constant temperature-humidity

mean migration of the extractable species to the product being chambers and equilibrium relative humidities over saturated

heated on the susceptors. saltsolutionsareoutlinedinTAPPIMethodsT 402-om-88,and

TIS 808-03.

7.3 Vials, headspace, 20 mL (actual volume 21.5 mL). To

4. Summary of Test Method

ensure against extraneous peaks in the gas chromatographic

4.1 Volatile extractables are determined by subjecting a

traces, wash vials thoroughly and dry in a 125°C air oven for

sample of the susceptor material to microwave heating, fol-

a minimum of 4 h before using.

lowed by headspace sampling and gas chromatography. Quali-

7.4 Vial Crimp Caps.

tative analysis may be carried out on a gas chromatograph

7.5 Septa, Polytetrafluoroethylene (PTFE)/silicone. To en-

(GC) coupled to an appropriate detector capable of compound

sure that the septa are free of volatiles, cover the bottom of a

identification. Volatile extractables are quantitated by compari-

15-cm petri dish with septa, PTFE-polymer side up. Micro-

son with standards of known concentration.

wave at full power for 10 min. Place microwaved septa into a

vacuum (greater than 29 in.) oven at 130°C for 16 h.

5. Significance and Use

7.6 Crimping Tool for vials.

5.1 This test method is intended to measure volatile extract-

7.7 Syringe, 2 mL, gas-tight with valve. Store syringe in

ablesthatmaybeemittedfromamicrowavesusceptormaterial

90°C oven between uses.

duringuse.Itmaybeausefulproceduretoassistinminimizing

7.8 Gas Chromatograph equipped as follows:

the amount of volatile extractables either through susceptor

7.8.1 FID Detector, compatible with capillary columns.

design or manufacturing processes.

7.8.2 Injector, split/splitless compatible with capillary col-

5.2 Modification of this procedure by utilizing appropriate

umns.

qualitative GC detection such as a mass spectrometer in place

7.8.3 Automated Headspace Sampler, Optional.

of the flame ionization detector may provide identification of

7.8.4 Column, DB-5, 30 m, 0.25-mm inside diameter, 1-µm

volatile extractables of unknown identity.

13 14

film thickness, or 0.32 mm. (A short piece of deactivated

0.25-mm fused silica column may be placed between the

6. Interferences

injector and the column to serve as a guard column.)

6.1 Gas Chromatography—Because of the potentially large

7.8.5 Peak-Area Integration System compatible with GC

number of chemical species that can be analyzed using this

system.Alternatively,achartrecorderandhandintegrationcan

methodology, not all species will be resolved from one another

be used.

on a particular GC column under a given set of conditions. 15

7.9 Fluoroptic Thermometry System.

Techniques available to the analyst to verify the identity of the

7.10 Temperature Probes, high temperature.

species being quantitated include retention time comparisons

7.11 Beaker, 600 mL.

using alternate GC conditions or using an alternate GC column

7.12 Oven, hot air, set for 90°C.

to verify identification. Good judgement of chromatographic

7.13 Stopwatch.

4,5,6

results is always important. Refer to Practice E 260 for 17

7.14 4-Heptanone.

guidance.

7.15 Standard Solutions—Regular Method:

6.2 Apparatus—Because this test method is designed for

trace volatiles, and is highly sensitive, contaminants on vials,

septa, syringes, etc. can lead to misinterpretation of results.

Preparing apparatus properly and carrying out blank determi-

Vials from Shamrock Glass Co., 200 N. Delaware Ave., Seaford, DE 302

629-5500 (Catalog No. 667601) or from Chemical Research Supplies, P. O. Box

nations as specified in the procedure is essential to minimize

888, Addison, IL 60101 or equivalent vials have been found suitable for this

this possibility.

purpose.

Vial crimp caps from Shamrock Glass Co., Catalog No. 778704 or from

Hewlett Packard Computer Supplies Operation, PO Box 62124, San Francisco, CA

7. Apparatus and Reagents

94162, Catalog No. 07675-120625 or equivalent have been found suitable for this

7.1 Microwave Oven—Calibrated, 7006 35 W, no turn-

purpose.

table. See Test Method F 1317. Septa from Shamrock Glass Co., Catalog No. 778173A or Hewlett-Packard

Computer Supplies Operation, Catalog No. 5080-8726 or equivalent have been

7.2 Humidity Chambers, operated at 50 % RH and 23°C.

found suitable for this purpose.

Crimping tools from Supelco Inc., Belefonte, PA 16823, Catalog No. 33280.

Syringes fromAlltech, 2051 Waukegan Rd., Deerfield, IL 60015, Catalog No.

050034 or equivalent have been found suitable for this purpose.

4 12

McCown, S. M., and Radenheimer, P., “An Equilibrium Headspace Gas The Hewlett-Packard Model No. 19395A or equivalent has been found

Chromatographic Method for the Determination of Volatile Residues in Vegetable suitable for this purpose.

Oils and Fats,” LC/GC, Vol 7, No. 11, 1989, pp. 918–924. Columns from J and W Scientific, 91 Blue Ravine Rd., Folsom, CA

McNeal, T. P., and Breder, C. V., “Headspace Gas Chromatographic Determi- 95630-4714, Catalog No. 122-5033 or equivalent has been found suitable for this

nation of Residual 1,3-Butadiene in Rubber-Modified Plastics and Its Migration purpose.

from Plastic Containers Into Selected Foods,” Journal of the Association of Catalog No. 123-5033 from J and W Scientific.

Analytical Chemists, Vol 70, No. 1, 1987, pp. 18–21. Luxtron Model 750 available from Luxtron Inc., 106 Terra Bella Ave.,

McNeal, T. P., and Breder, C. V., “Headspace Sampling and Gas-Solid Mountain View, CA 90403, or equivalent has been found suitable for this purpose.

Chromatographic Determination of Residual Acrylonitrile in Acrylonitrile Copoly- Luxtron Model MIH or equivalent has been found suitable for this purpose.

mer Solutions,” Journal of the Association of Offıcial Analytical Chemists, Vol 64, 4-Heptanone from Aldrich, 940 West St. Paul Ave., Milwaukee, WI 53233,

No. 2, 1981, pp. 270–275. Catalog No. 10, 174-5 or equivalent has been found suitable for this purpose.

F1308–98 (2003)

7.15.1 Internal Standard Solution (245 µg/mL 8.1.4 Place 250 mLof room-temperature distilled water into

4-Heptanone)—To approximately 950 mL of distilled water in a 600-mL beaker. Place the beaker in the center rear of the

a 1-L volumetric flask add 300 µL of 4-heptanone. Mix well microwave oven.

2 2

and dilute to volume with water. 8.1.5 Cut a 10 by 65-mm (6.5-cm = 1-in. ) portion from the

susceptor sample to be tested. Insert carefully into the 20-mL

7.15.2 Standard Solution 1: (Prepare fresh daily.)—To ap-

proximately 475 mL of internal standard solution in a 500-mL headspace vial.

8.1.6 Using a 13-gage syringe needle, pierce a hole into a

volumetric flask, add 50 µL of each of the compounds to be

quantitated. Mix well, and dilute to volume with internal headspace vial septum. Place the septum on the vial and crimp.

8.1.7 Insert one temperature probe (7.10) through the sep-

standard solution. If difficulty is experienced with dissolution

of analyte, alternate standard solution procedure may over- tum hole into the vial and manipulate it until it is in contact

come this difficulty. with the active face of the susceptor material. Place the vial on

7.15.3 Standard Solution 2—Repeat 7.14.2 using 25 µL of its side in the center of microwave oven, crimp end toward

right of the oven, and susceptor with active face up.

each compound.

8.1.8 Microwave at full power, recording the probe tem-

7.15.4 Standard Solution 3—Repeat 7.14.2 using 10 µL of

perature, preferably at 5-s intervals, but at intervals not to

each compound.

exceed 15 s.

7.16 Standard Solutions—Alternate Method:

8.1.9 Plotthetemperaturesfrom8.1.3and8.1.8onthesame

7.16.1 Alternate Internal Standard Solution (1225 µg/mL

graph.

4-Heptanone)—To approximately 150 mL of helium-sparged

8.1.10 Compare the plots. If the trace from 8.1.8 closely

orthodichlorobenzene (ODCB) in a 200-mL volumetric flask

approximates or is slightly higher than the plot from 8.1.3 then

add300µLof4-heptanone.Mixwellanddilutetovolumewith

the test time will be equal to the maximum product cook time

ODCB.

of the product in that oven. If the trace is substantially higher

7.16.2 Alternate Standard Solution 1— To approximately

or lower than that of the susceptor with product, then adjust the

75 mL of alternate internal standard solution in a 100-mL

mass or surface area, or both, (by changing container size) of

volumetric flask, add 50 µL of each of the compounds to be

the water (using a fresh sample of room temperature distilled

quantitated. Mix well, and dilute to volume with alternate

water) as necessary to achieve a similar profile. Record the

internal standard solution.

mass of water and type of container that gives the best

7.16.3 Alternate Standard Solution 2— Repeat 7.15.2 using

agreementbetweenthetestsampleandtheproducttemperature

25 µL of each compound.

profiles.

7.16.4 Alternate Standard Solution 3— Repeat 7.15.2 using

8.2 Set up the gas chromatographic system to meet the

10 µL of each compound.

following criteria.

7.17 Susceptor Blank—Obtain a representative sample of

8.2.1 Injector Temperature—250°C.

susceptor material to be tested. Bake in an air oven overnight

8.2.2 Detector Temperature—250°C.

at 100°C or higher to remove any volatile materials present.

8.2.3 Column Temperature:

Store blank susceptor strips in humidity chamber 1 at 50 % RH

8.2.3.1 Initial—40°C for 4 min.

and 23°C until equilibrium moisture content is reached. An

8.2.3.2 Program—Adjust to give a retention window of:

exposure time of 24 h is generally adequate for most paper-

(1) At least 15 min for volatile compounds bracketed by

based products. Strips should remain in the conditioning

2-propanol and dichlorobenzene, retention time for 2-propanol

environment until needed for analysis.

of approximately 3 min and retention time for dichlorobenzene

7.18 Syri

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.