ASTM F1349-08(2014)

(Test Method)Standard Test Method for Nonvolatile Ultraviolet (UV) Absorbing Extractables from Microwave Susceptors

Standard Test Method for Nonvolatile Ultraviolet (UV) Absorbing Extractables from Microwave Susceptors

ABSTRACT

This test method establishes the apparatuses required, the standard procedures, and associated calculations involved in the determination of relatively polar nonvolatile ultraviolet (UV) absorbing extractable components that may migrate from microwave susceptor packaging into food simulants, such as corn oil and Miglyol 812. This test method has been collaboratively studied using bilaminate susceptors constructed of paperboard, adhesive, and a layer of polyethylene terephthalate polymer (PETE) susceptor.

SCOPE

1.1 This test method covers the determination of nonpolar and relatively polar ultraviolet (UV) absorbing components that may migrate from microwave susceptor packaging into food simulants, such as corn oil and Miglyol 812.

1.2 This test method has been collaboratively studied using bilaminate susceptors constructed of paperboard, adhesive, and a layer of polyethylene terephthalate polymer (PETE) susceptor. Adhesive and PETE related compounds were quantitated using this test method.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warning statements are given in 4.3.2.3.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1349 −08 (Reapproved 2014)

Standard Test Method for

Nonvolatile Ultraviolet (UV) Absorbing Extractables from

Microwave Susceptors

This standard is issued under the fixed designation F1349; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 High-Pressure Liquid Chromatograph (HPLC), consist-

ing of:

1.1 This test method covers the determination of nonpolar

3.2.1 Pump, capable of 1.5 mL/min with flow precision

and relatively polar ultraviolet (UV) absorbing components

62%.

that may migrate from microwave susceptor packaging into

3.2.2 Injector, loop-type, equipped with 20-µL loop.

food simulants, such as corn oil and Miglyol 812.

3.2.3 Guard Column, C , 5 µm.

1.2 This test method has been collaboratively studied using

3.2.4 Analytical Column, C , 5 µm, 250 by 4.6 mm.

bilaminatesusceptorsconstructedofpaperboard,adhesive,and

3.2.5 Detector-UV Absorbance, set for 254 nm. Adjust

a layer of polyethylene terephthalate polymer (PETE) suscep-

sensitivity to give a 70 to 100 % of full scale peak for the 5-

tor. Adhesive and PETE related compounds were quantitated

ppm dimethylterephthalate DMT standard.

using this test method.

3.2.6 Gradient Program, 4 to 60 % Mobile Phase B in 8

min; 60 to 70 % B in 9 min; 70 to 100 % B in 7 min; 100 % B

1.3 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this for 11 min; 100 to 4 % B in 5 min; 4 % B for minimum of 5

min. Where Mobile Phase A (v/v) is 85 + 15 + 0.25 %

standard.

water:acetonitrile:acetic acid, and Mobile Phase B (v/v)is

1.4 This standard does not purport to address all of the

15 + 85 % water:acetonitrile.

safety concerns, if any, associated with its use. It is the

3.2.7 Peak Area Integration System—Initialize data acqui-

responsibility of the user of this standard to establish appro-

sition or integration system, or both, from 5 to 35 min during

priate safety and health practices and determine the applica-

the separation.

bility of regulatory limitations prior to use. Specific warning

statements are given in 4.3.2.3.

3.3 Hexane, LC/UV grade.

3.4 Acetonitrile, LC/UV grade.

2. Referenced Documents

3.5 Corn Oil—Obtain corn oil that is as pure and fresh as

2.1 ASTM Standards:

possible to minimize peaks in nonvolatiles extractables chro-

F874 Test Method for Temperature Measurement and Pro-

matogram. Alternatively, Miglyol 812 (a fractionated coconut

filing for Microwave Susceptors

oil)orsyntheticfatsimulantHB307canbeusedasasubstitute

F1317 Test Method for Calibration of Microwave Ovens

for corn oil.

3. Apparatus and Reagents

3.6 Dimethylacetamide (DMAC), LC/UV grade.

3.1 Microwave Oven, 700 6 35 W, calibrated. Refer to Test

3.7 Conical Bottom Test Tubes, 50 mL, graduated.

Method F1317.

3.8 Bishydroxyethyleneterephthalate (BHET).

3.9 Diethylterephthalate (DET).

This test method is under the jurisdiction ofASTM Committee F02 on Flexible

Barrier Packaging and is the direct responsibility of Subcommittee F02.15 on

3.10 Dimethylterephthalate (DMT).

Chemical/Safety Properties.

Current edition approved April 1, 2014. Published April 2014. Originally 3.11 Fluoroptic Thermometry System.

approved in 1991. Last previous edition approved in 2008 as F1349 – 08. DOI:

3.12 Temperature Probes, four, high temperature.

10.1520/F1349-08R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.13 Glass Beads, 3 to 4 mm, clean thoroughly by rinsing

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

with methylene chloride followed by soaking for 30 min in

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. acetonitrile. Dry thoroughly before using.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1349−08 (2014)

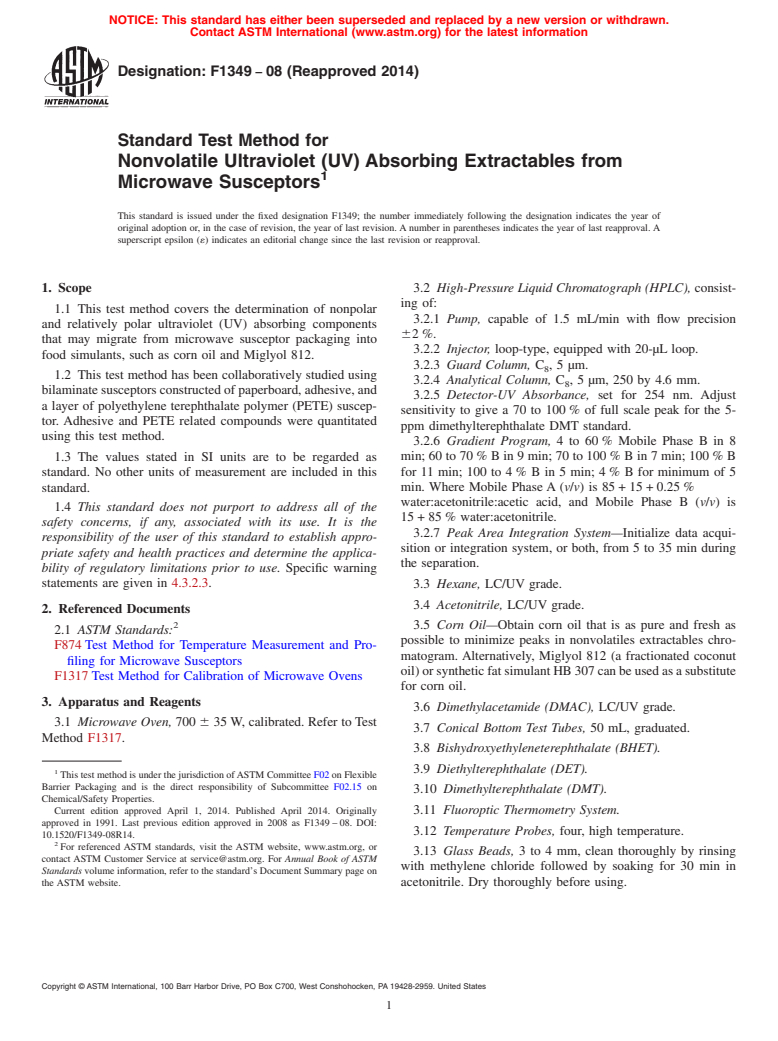

NOTE 1—The ⁄16-in. (1.6-mm) diameter hole is for a Luxtron MIW

temperature sensing probe. Number of holes and location may vary by

application.

FIG. 1Collar Section of Waldorf Polytetrafluoroethylene Micro-

wave Nonvolatile Extraction Cell

NOTE 1—Relieve thread at bottom. Collar must seal to bottom of cap.

FIG. 2Cap Section of Waldorf Polytetrafluorethylene Nonvolatile

Extraction Cell

F1349−08 (2014)

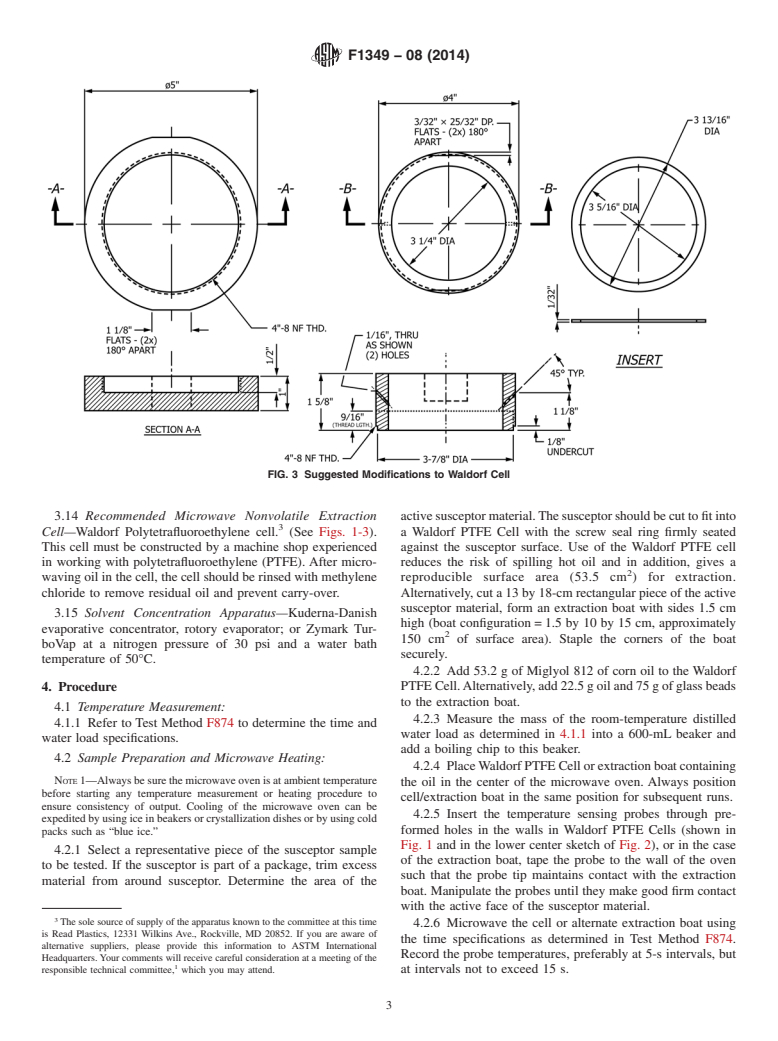

FIG. 3 Suggested Modifications to Waldorf Cell

3.14 Recommended Microwave Nonvolatile Extraction activesusceptormaterial.Thesusceptorshouldbecuttofitinto

Cell—Waldorf Polytetrafluoroethylene cell. (See Figs. 1-3). a Waldorf PTFE Cell with the screw seal ring firmly seated

This cell must be constructed by a machine shop experienced against the susceptor surface. Use of the Waldorf PTFE cell

in working with polytetrafluoroethylene (PTFE). After micro- reduces the risk of spilling hot oil and in addition, gives a

waving oil in the cell, the cell should be rinsed with methylene reproducible surface area (53.5 cm ) for extraction.

chloride to remove residual oil and prevent carry-over. Alternatively, cut a 13 by 18-cm rectangular piece of the active

susceptor material, form an extraction boat with sides 1.5 cm

3.15 Solvent Concentration Apparatus—Kuderna-Danish

high (boat configuration = 1.5 by 10 by 15 cm, approximately

evaporative concentrator, rotory evaporator; or Zymark Tur-

150 cm of surface area). Staple the corners of the boat

boVap at a nitrogen pressure of 30 psi and a water bath

securely.

temperature of 50°C.

4.2.2 Add 53.2 g of Miglyol 812 of corn oil to the Waldorf

4. Procedure PTFECell.Alternatively,add22.5goiland75gofglassbeads

to the extraction boat.

4.1 Temperature Measurement:

4.2.3 Measure the mass of the room-temperature distilled

4.1.1 Refer to Test Method F874 to determine the time and

water load as determined in 4.1.1 into a 600-mL beaker and

water load specifications.

add a boiling chip to this beaker.

4.2 Sample Preparation and Microwave Heating:

4.2.4 PlaceWaldorfPTFECellorextractionboatcontaining

NOTE1—Alwaysbesurethemicrowaveovenisatambienttemperature

the oil in the center of the microwave oven. Always position

before starting any temperature measurement or heating procedure to

cell/extraction boat in the same position for subsequent runs.

ensure consistency of output. Cooling of the microwave oven can be

4.2.5 Insert the temperature sensing probes through pre-

expeditedbyusingiceinbeakersorcrystallizationdishesorbyusingcold

formed holes in the walls in Waldorf PTFE Cells (shown in

packs such as “blue ice.”

Fig. 1 and in the lower center sketch of Fig. 2), or in the case

4.2.1 Select a representative piece of the susceptor sample

of the extraction boat, tape the probe to the wall of the oven

to be tested. If the susceptor is part of a package, trim excess

such that the probe tip maintains contact with the extraction

material from around susceptor. Determine the area of the

boat. Manipulate the probes until they make good firm contact

with the active face of the susceptor material.

The sole source of supply of the apparatus known to the committee at this time

4.2.6 Microwave the cell or alternate extraction boat using

is Read Plastics, 12331 Wilkins Ave., Rockville, MD 20852. If you are aware of

the time specifications as determined in Test Method F874.

alternative suppliers, please provide this information to ASTM International

Record the probe temperatures, preferably at 5-s intervals, but

Headquarters.Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. at intervals not to exceed 15 s.

F1349−08 (2014)

4.3 Quantitative Analysis:

cyclic trimer = 2.8

tetramer = 5.2

4.3.1 Standard Curve:

pentamer = 6.8

hexamer = 7.8

4.3.1.1 Prepare a standard mixture of 10 ppm (w/v) each of

heptamer = 8.8

BHET, DMT, DET, and any other identified UV components

octamer = 9.8

(see appendix) of the susceptor in DMAC. Proceed to generate

nonamer = 10.2

chromatograms using high pressure liquid chromatography in

4.3.2.11 Subtract blank oil peak contributions from the

accordance with 3.2.5, 3.2.6, and 4.3.2.8. Retention times for

sample chromatograms. Sum all the remaining peak areas in

BHET, DMT, and DET will be approximately 7.6, 16.6, and

the sample chromatogram.

21.5 min respectively.

4.3.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.