ASTM D545-99

(Test Method)Standard Test Methods for Preformed Expansion Joint Fillers for Concrete Construction (Nonextruding and Resilient Types)

Standard Test Methods for Preformed Expansion Joint Fillers for Concrete Construction (Nonextruding and Resilient Types)

SCOPE

1.1 These test methods cover the physical properties associated with preformed expansion joint fillers. The test methods include: Property Section Asphalt content 7.5 Boiling in hydrochloric acid 7.4 Compression 7.2 Density 7.7 Expansion in boiling water 7.1 Extrusion 7.3 Recovery 7.2 Water absorption 7.6

1.2 The values stated in inch-pound are to be regarded as standard. Note 1-Specific test methods are applicable only to certain types of joint fillers, as stated herein.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.>

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D545–99

Standard Test Methods for

Preformed Expansion Joint Fillers for Concrete

Construction (Nonextruding and Resilient Types)

This standard is issued under the fixed designation D545; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope joint and thereby prevent damage that might otherwise occur

during thermal expansion. The asphalt content is a measure of

1.1 These test methods cover the physical properties asso-

thefiber-typejointfiller’sdurabilityandlifeexpectancy.Inthe

ciated with preformed expansion joint fillers.The test methods

case of cork-type fillers, the resistance to water absorption and

include:

resistance to boiling hydrochloric acid are relative measures of

Property Section

durability and life expectancy.

Asphalt content 7.5

Boiling in hydrochloric acid 7.4

Compression 7.2

4. Apparatus

Density 7.7

4.1 Balance, for weighing joint fillers capable of weighing

Expansion in boiling water 7.1

Extrusion 7.3

test specimens within 0.01 g.

Recovery 7.2

4.2 Mechanical Convection Oven, capable of maintaining

Water absorption 7.6

220 6 5.0°F [104 6 3°C].

1.2 The values stated in inch-pound are to be regarded as

4.3 Desiccator, of sufficient size to accommodate the test

standard.

specimens.

4.4 Vernier Caliper, for measuring length and width of

NOTE 1—Specific test methods are applicable only to certain types of

joint fillers, as stated herein. specimens with accuracy within 60.01 in. [0.25 mm].

4.5 Dial Micrometer, or other measuring device, graduated

1.3 This standard does not purport to address all of the

to read in 0.001-in. [0.02-mm] units.

safety concerns, if any, associated with its use. It is the

4.6 Extrusion Mold— Three-sided steel mold to confine

responsibility of the user of this standard to consult and

lateral movement of specimens under compression to one side

establish appropriate safety and health practices and deter-

only. Interior dimensions shall be 4 by 4 in. [102 by 102 mm]

mine the applicability of regulatory limitations prior to use.

with permissible variations in length and width of 60.015 in.

2. Referenced Documents [0.38 mm]. Mold sides shall be of such height as to extend at

least 0.5 in. [13 mm] above the test specimens.Atypical mold

2.1 ASTM Standards:

can be made from a steel base ⁄2by4by4 6 0.015 in. [13 by

D147 Methods ofTesting Bituminous Mastics, Grouts, and

2 102 by 102 6 0.3 mm] and three bolted steel side plates ⁄4 in.

Like Mixtures

[6.35 mm] thick, extending approximately 1 ⁄2 in. [38 mm]

D1037 Methods for Evaluating the Properties of Wood-

3 above the base plate, thus forming a three-sided open-top box.

Base Fiber and Particle Panel Materials

4.7 Template—One steel template 4 by 4 in. [102 by 102

3. Significance and Use mm], machined from ⁄2-in. [6.4-mm] steel plate to fit the

extrusion mold. The template shall fit the mold within−0.005

3.1 The compression resistance perpendicular to the faces,

in. [0.13 mm] in length and width.

the resistance to the extrusion during compression, and the

1 1

4.8 Metal Plate,4 ⁄2 by 4 ⁄2 in. 6 0.1 in. [114 by 114 6 2.5

ability to recover after release of the load are indicative of a

mm] with parallel faces machined from ⁄2-in. [6.4-mm] steel

joint filler’s ability to fill continuously a concrete expansion

plate.

4.9 Compression Tester, either hydraulic- or screw-type

These methods are under the jurisdiction of ASTM Committee D-4 on Road

equipment with sufficient opening between upper- and lower-

and Paving Materials and are the direct responsibility of Subcommittee D04.34 on

bearing surfaces to permit the use of verifying apparatus. The

Preformed Joint Fillers and Sealers.

load applied to the test specimen shall be indicated with an

Current edition approved June 10, 1999. Published July 1999. Originally

{1

accuracy of 61.0%. The upper-bearing device shall be a

published as D545–39T. Last previous edition D545–84 (1993) .

Discontinued, See 1989 Annual Book of ASTM Standards, Vol 04.04.

spherically seated, hardened metal block firmly attached at the

Annual Book of ASTM Standards, Vol 04.10.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D545

center of the upper head of the machine. The center of the in.[0.03mm].Immersethespecimensinboilingwaterfor1h;

sphere shall lie at the center of the surface of the block in remove and allow to cool to room temperature for 15 min.

contactwiththespecimen.Theblockshallbecloselyheldinits Measure the final thickness of each specimen to the nearest

spherical seat, but free to tilt in any direction. Load shall be 0.001 in. Calculate the expansion as follows:

applied without shock at 0.05 in. [1.3 mm] per minute.

A

Expansion,%,oforiginalthickness 5 3100 (1)

4.10 Extractor Apparatus, similar to Fig. 1 of Methods

B

D147 with thermostatically controlled heating element.

where:

5. Sampling A 5 thickness in inches after boiling in water and

B 5 thickness in inches before boiling in water.

2 2

5.1 One representative sample approximately 2 ft /1000 ft

7.1.2 Prepare the test specimens for testing as described in

of joint filler shall be obtained and properly packaged for safe

6.2.

transporting to the testing agency.

7.2 Recovery and Compression:

5.2 For self-expanding cork joint filler, a minimum of five

1 1

4 ⁄2-by4 ⁄2-in. (114- by 114-mm) square specimens properly

7.2.1 Test Specimen—For these tests use one of the speci-

banded and plastic wrapped at point of manufacture shall be

mens prepared and described in 6.1 and 6.2. For the cork,

submitted for testing.

sponge rubber, bituminous cork, and fiber joint fillers make

these tests on material as received. If the cork filler fails to

6. Preparation of Test Specimens

meet the specified requirements, make check tests on speci-

6.1 For the joint fillers made of cork, sponge rubber, mens that have been immersed in water for 24 h and then

air-driedatambientconditionsfor24h.Acceptanceisbasedon

bituminouscork,orfiber,cutfivespecimens4by4in.[102by

102 mm]. Each specimen shall be freshly and squarely cut the results of the check tests.

using a metal plate as a cutting template, as described in 4.7.

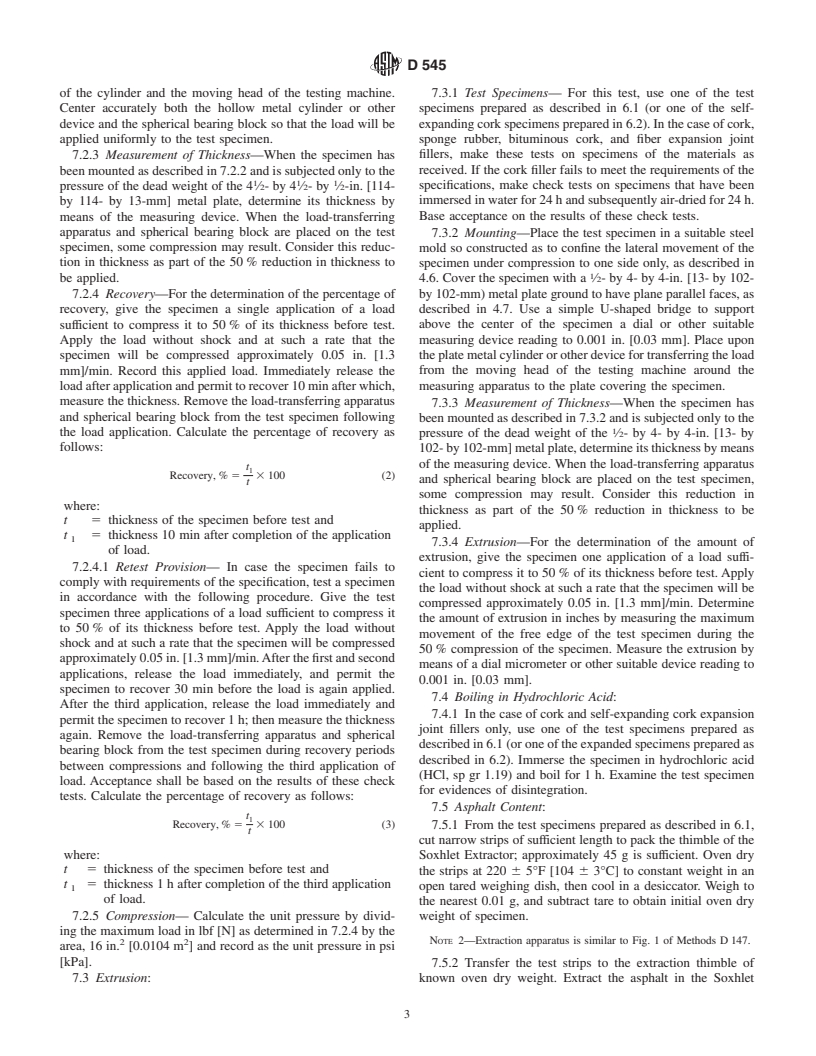

7.2.2 Mounting—Place the test specimen on a flat metal

1 1

6.2 For self-expanding cork only, after boiling the speci-

plate and center a 4- by 4 ⁄2-by ⁄2-in. [114- by 114- by 13-

mens in water as described in 7.1.1, air dry in ambient air 24

mm]metalplate,groundtohaveplaneparallelfaces,onthetop

h. Then cut specimens to the size described in 6.1.

surface of the specimen. Use a simple U-shaped bridge to

6.3 Determine the thickness of each specimen to the nearest

support a dial gage or other suitable measuring device reading

0.001 in. [0.03 mm].

to the nearest 0.001 in. [0.03 mm] above the center of the

specimen. Place a hollow metal load transfer cylinder with

7. Procedures

slots for inserting the U-shape bridge and an opening for

7.1 Expansion in Boiling Water: reading the measuring device between the moving head of the

7.1.1 Forself-expandingcorkjointfilleronly,usefiveofthe testing machine and the plate covering the specimen.Atypical

testspecimenssuppliedbythemanufactureasdescribedin5.2. mounting is shown in Fig. 1, but other suitable devices may be

Determine the thickness of each specimen to the nearest 0.001 used. Mount a spherical bearing block between the upper end

1—Flat Metal Plate. 5—Measuring Device.

2—Specimen. 6—Hollow Cylinder.

1 1 1

3—Metal Plate 4 ⁄2 by 4 ⁄2 by ⁄2 in. (102 by 102 by 13 mm). 7—Spherical Bearing Block.

4—U-Shape Bridge.

FIG. 1 Typical Mounting of the Specimen for Recovery and Compression Tests

D545

of the cylinder and the moving head of the testing machine. 7.3.1 Test Specimens— For this test, use one of the test

Center accurately both the hollow metal cylinder or other specimens prepared as described in 6.1 (or one of the self-

device and the spherical bearing block so that the load will be expandingcorkspecimenspreparedin6.2).Inthecaseofcork,

applied uniformly to the test specimen. sponge rubber, bituminous cork, and fiber expansion joint

fillers, make these tests on specimens of the materials as

7.2.3 Measurement of Thickness—When the specimen has

received. If the cork filler fails to meet the requirements of the

beenmountedasdescribedin7.2.2andissubjectedonlytothe

1 1 1

specifications, make check tests on specimens that have been

pressure of the dead weight of the 4 ⁄2-by4 ⁄2-by ⁄2-in. [114-

by 114- by 13-mm] metal plate, determine its thickness by immersedinwaterfor24handsubsequentlyair-driedfor24h.

Base acceptance on the results of these chec

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.