ASTM D994/D994M-11(2022)

(Specification)Standard Specification for Preformed Expansion Joint Filler for Concrete (Bituminous Type)

Standard Specification for Preformed Expansion Joint Filler for Concrete (Bituminous Type)

ABSTRACT

This specification covers bituminous preformed expansion joint filler for use in concrete construction. This product shall consist of a bituminous (asphalt or tar) mastic composition, formed and encased between two layers of bituminous impregnated felt or two layers of glass-fiber felt. The mastic shall comprise mineral fillers and reinforcing fibers and may contain thin strips of reinforcing sheet material. Different test methods shall be performed in order to determine the following properties: distortion at 52°C, brittleness, water absorption, and compression.

SCOPE

1.1 This specification covers bituminous preformed expansion joint filler for use in concrete construction.

Note 1: Attention is called to ASTM Specifications D1751 and D1752.

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D994/D994M −11 (Reapproved 2022)

Standard Specification for

Preformed Expansion Joint Filler for Concrete (Bituminous

Type)

This standard is issued under the fixed designation D994/D994M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 3. Manufacture

1.1 This specification covers bituminous preformed expan- 3.1 This product shall consist of a bituminous (asphalt or

sion joint filler for use in concrete construction. tar) mastic composition, formed and encased between two

layers of bituminous impregnated felt or two layers of glass-

NOTE 1—Attention is called to ASTM Specifications D1751 and

fiber felt. The mastic shall comprise mineral fillers and

D1752.

reinforcing fibers and may contain thin strips of reinforcing

1.2 Units—The values stated in either SI units or inch-

sheet material.

pound units are to be regarded separately as standard. The

values stated in each system may not be exact equivalents; 4. General Requirements

therefore,eachsystemshallbeusedindependentlyoftheother.

4.1 Preformedstripsofexpansionjointfillershallbeofsuch

Combining values from the two systems may result in noncon-

character as not to be deformed or broken by ordinary handling

formance with the standard.

when exposed to atmospheric conditions and shall not become

1.3 This international standard was developed in accor-

brittle in cold weather. Pieces of the joint filler that have been

dance with internationally recognized principles on standard- damaged shall be rejected.

ization established in the Decision on Principles for the

5. Properties

Development of International Standards, Guides and Recom-

5.1 Distortion at 50 °C [125 °F]—The joint filler shall not

mendations issued by the World Trade Organization Technical

show a deflection of more than 1 in. [25 mm] when tested in

Barriers to Trade (TBT) Committee.

accordance with 8.2.1.

2. Referenced Documents

5.2 Brittleness—The joint filler shall not crack or shatter

2.1 ASTM Standards:

when tested in accordance with 8.2.2.

C670 Practice for Preparing Precision and Bias Statements

NOTE 2—Expansion joint filler having a nominal thickness of 5 mm

for Test Methods for Construction Materials

[ ⁄4 in.] or less shall not be subject to a requirement for brittleness.

D545 Test Methods for Preformed Expansion Joint Fillers

5.3 Water Absorption—The water absorption of the joint

for Concrete Construction (Nonextruding and Resilient

filler, when tested in accordance with 8.2.3, shall not exceed

Types)

the following values:

D1751 Specification for Preformed Expansion Joint Filler

Nominal Thickness of Absorption, max, weight %

for Concrete Paving and Structural Construction (Nonex-

Joint, min, mm [in.]

truding and Resilient Bituminous Types)

25 [1] 2.5

D1752 Specification for Preformed Sponge Rubber, Cork 20 [ ⁄4]3

15 [ ⁄2]4

and Recycled PVC Expansion Joint Fillers for Concrete

10 [ ⁄8]5

Paving and Structural Construction

NOTE 3—Expansion joint filler having a nominal thickness of less than

10 mm [ ⁄8 in.] shall not be subject to a requirement for water absorption.

This specification is under the jurisdiction of ASTM Committee D04 on Road

5.4 Compression—The load required to compress the test

and Paving Materials and is the direct responsibility of Subcommittee D04.34 on

specimen to 50 % of its thickness before test shall not be less

Preformed Joint Fillers, Sealers and Sealing Systems.

Current edition approved June 1, 2022. Published June 2022. Originally

than nor more than the following values when the joint filler is

approved in 1948. Last previous edition approved in 2016 as D994/D994M – 11

tested in accordance with 8.2.4.

(2016). DOI: 10.1520/D0994_D0994M-11R22.

Nominal Thickness of Joint, mm [in.] Load Requirements, min–max. kPa [psi]

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

25 [1] 700–5000 [100–754]

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

20 [ ⁄4 ] 700–6000 [100–841]

Standards volume information, refer to the standard’s Document Summary page on

15 [ ⁄2 ] 700–6500 [100–928]

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D994/D994M − 11 (2022)

A

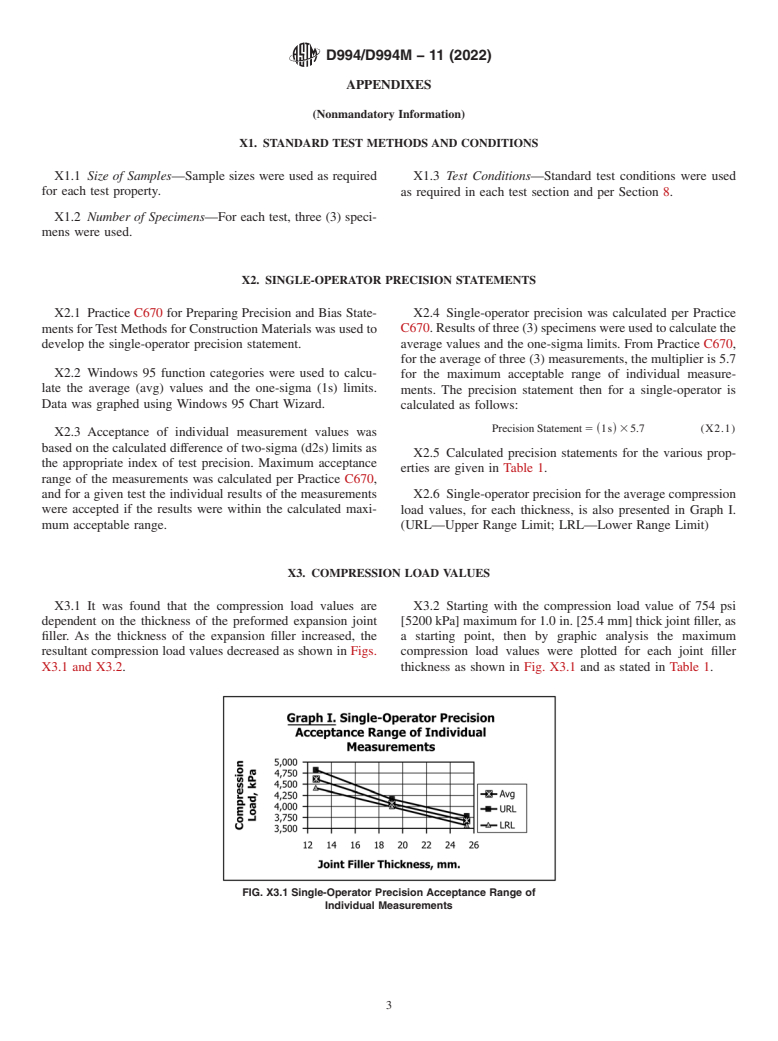

TABLE 1 Single-Operator Precision Statements SI Units Only

Property Property as a function of Nominal Thickness

Thickness, Nominal, mm. 25.4 19.1 12.7 9.5 6.4

Distortion, max. mm. 25.4 25.4 25.4 25.4 25.4

Precision, max.accept.range. 2.93 2.30 5.92 6.03 6.84

Brittleness Pass* Pass* Pass* Pass* ----

Precision, max.accept.range ** ** ** ** ----

Water Absorption, wt % max. 2.5 3 4 5 ----

Precision, max.accept.range. 0.057 0.087 0.400 1.187 ----

Compression, kPa, min-max. 690–5200 690–5800 690–6400 ---- ----

Precision, max.accept.range. 204.2 180.1 416.5 ---- ----

Note—Precision, max.accept.range. Per Practice C670, Maximum acceptable range between high and

low individual measurements.

Pass* Not crack or shatter.

** No precision statement is necessary for this attribute.

A

All precision data was derived using inch-pound units.

NOTE 4—Expansion joint filler having a nominal thickness of less than

temperature of 5 6 1 °C [39 to 43 °F] in water for at least 2 h

15 mm [ ⁄2 in.] shall not be subject to a requirement for compression.

before testing. Clamp the specimen between two boards so that

the expansion joint forms a cantilever of 90 mm [3 ⁄2 in.] in

6. Dimensions and Permissible Variations

length and hold in a horizontal position by a suitable rigid

6.1 The preformed strips shall conform to the dimensions

support. Suspend a spherical cast iron ball weighing 0.40 kg

specified or shown on the plans. Strips of the joint filler that do

[0.95 lb] and having a diameter of 50 mm [1 ⁄8 in.] by a cord

not conform to the specified dimensions within the permissible

tied to an eyelet fastened to the ball. For specimens having a

1 1

variations of 61mm[ ⁄16 in.] in thickness, 62mm[ ⁄8 in.] in

thickness of 15 mm [ ⁄16 in.] or less, suspend the ball 300 mm

depth, and 65mm[ ⁄4 in.] in length shall be rejected.

[1 ft] above the center of the projecting portion of the

specimen. For specimens over 15 mm [ ⁄16 in.] in thickness,

7. Sampling

suspendtheball600mm[2ft]abovethespecimen.Releasethe

7.1 Size of Sample—Each sample s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.