ASTM C719-93(2005)

(Test Method)Standard Test Method for Adhesion and Cohesion of Elastomeric Joint Sealants Under Cyclic Movement (Hockman Cycle)

Standard Test Method for Adhesion and Cohesion of Elastomeric Joint Sealants Under Cyclic Movement (Hockman Cycle)

SIGNIFICANCE AND USE

The failure of a building sealant in an active joint is usually manifested by cohesive failure in the sealant or adhesive failure between the sealant and the substrate, or both. The method described in this test method relates only to the performance of the sealant when properly installed with recommended primers, and does not evaluate sealant failures caused by improper joint design, excessive joint movement, improper application practices, and other factors known to cause sealant failure in buildings and building areas.

SCOPE

1.1 This test method is an accelerated laboratory procedure for evaluating the performance of a building sealant in a test configuration that is subjected to water immersion, cyclic movement, and temperature change.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C719 – 93 (Reapproved 2005)

Standard Test Method for

Adhesion and Cohesion of Elastomeric Joint Sealants

,

1 2

Under Cyclic Movement (Hockman Cycle)

This standard is issued under the fixed designation C719; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 4. Summary of Test Method

1.1 This test method is an accelerated laboratory procedure 4.1 This test method consists of subjecting standard joint

for evaluating the performance of a building sealant in a test specimens to a series of treatments as follows: (a) immersion

configuration that is subjected to water immersion, cyclic inwaterforsevendays;(b)exposureinanovenforsevendays

movement, and temperature change. while under compression; (c) automatic compression and

1.2 The values stated in inch-pound units are to be regarded extension cycling at room temperature at a specified rate and

as the standard. The values in parentheses are for information amount of joint movement; and (d) alternate compression and

only. extension of the joint at high and low temperatures, respec-

1.3 This standard does not purport to address all of the tively, under specified conditions described herein.

safety concerns, if any, associated with its use. It is the 4.2 The effects of the test shall be evaluated by visual

responsibility of the user of this standard to establish appro- inspectionforcohesiveandadhesivefailures,sealantdeforma-

priate safety and health practices and determine the applica- tion, and bubble formation within the sealant.

bility of regulatory limitations prior to use. 4.3 This test method is applicable to any joint movement.

The most common test movements are 612.5 and 625% as

2. Referenced Documents

used in the examples.

2.1 ASTM Standards:

5. Significance and Use

C33 Specification for Concrete Aggregates

C109/C109M Test Method for Compressive Strength of 5.1 The failure of a building sealant in an active joint is

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube usually manifested by cohesive failure in the sealant or

Specimens) adhesive failure between the sealant and the substrate, or both.

C150 Specification for Portland Cement The method described in this test method relates only to the

C717 Terminology of Building Seals and Sealants performance of the sealant when properly installed with

recommended primers, and does not evaluate sealant failures

3. Terminology

caused by improper joint design, excessive joint movement,

3.1 Definitions—For definitions of terms used in this test

improper application practices, and other factors known to

method, refer to Terminology C717. cause sealant failure in buildings and building areas.

6. Apparatus

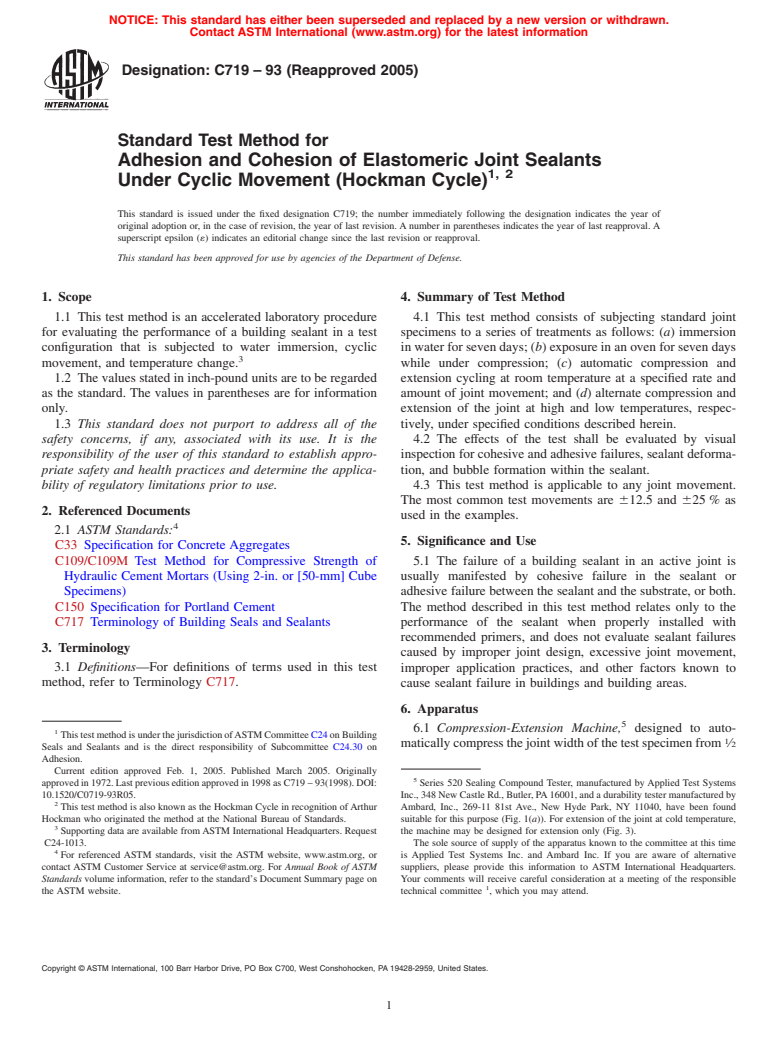

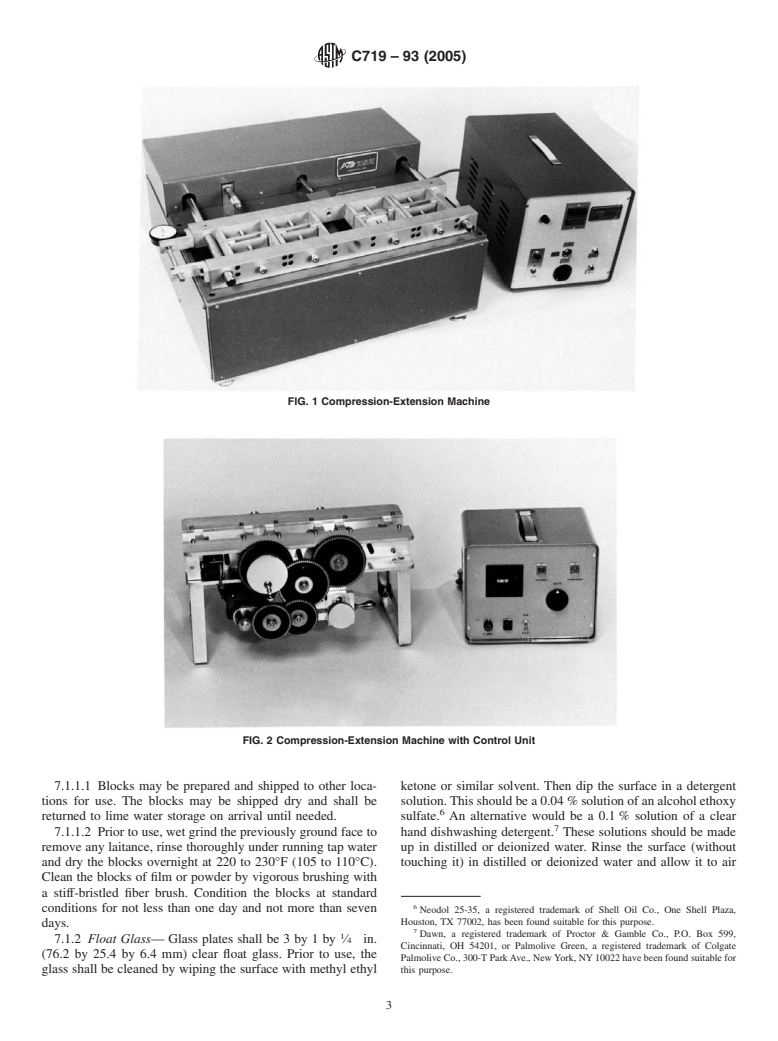

6.1 Compression-Extension Machine, designed to auto-

ThistestmethodisunderthejurisdictionofASTMCommitteeC24onBuilding

maticallycompressthejointwidthofthetestspecimenfrom ⁄2

Seals and Sealants and is the direct responsibility of Subcommittee C24.30 on

Adhesion.

Current edition approved Feb. 1, 2005. Published March 2005. Originally

approvedin1972.Lastpreviouseditionapprovedin1998asC719–93(1998).DOI: Series 520 Sealing Compound Tester, manufactured by Applied Test Systems

10.1520/C0719-93R05. Inc.,348NewCastleRd.,Butler,PA16001,andadurabilitytestermanufacturedby

This test method is also known as the Hockman Cycle in recognition ofArthur Ambard, Inc., 269-11 81st Ave., New Hyde Park, NY 11040, have been found

Hockman who originated the method at the National Bureau of Standards. suitable for this purpose (Fig. 1(a)). For extension of the joint at cold temperature,

Supporting data are available fromASTM International Headquarters. Request the machine may be designed for extension only (Fig. 3).

C24-1013. The sole source of supply of the apparatus known to the committee at this time

For referenced ASTM standards, visit the ASTM website, www.astm.org, or is Applied Test Systems Inc. and Ambard Inc. If you are aware of alternative

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM suppliers, please provide this information to ASTM International Headquarters.

Standards volume information, refer to the standard’s Document Summary page on Your comments will receive careful consideration at a meeting of the responsible

the ASTM website. technical committee , which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C719 – 93 (2005)

in. (12.7 mm) to the minimum dimension desired (Table 1, 7. Test Specimens

Column C) and extend the specimen from ⁄2 in. to the

7.1 The standard substrate used in the test shall be portland

maximum extension desired (Table 1, Column E) at a constant

cement mortar, float glass, and aluminum alloy.

rateof ⁄8in./h(3.2mm/h).Themachineshallbeequippedwith

NOTE 1—When requested, only one or two of the standard materials

grips of sufficient strength to withstand, without bending, the

may be tested with the sample. Likewise other substrates such as brick,

resistance of high tensile strength sealants (see Figs. 1-3).

FIG. 4 A Motor-Driven Machine That Can be Used for Extension of Specimens at − 15°F (−26.11°C)

marble, wood, etc., may be specified by the purchaser in place of or in

6.2 Cold Box or Chamber,maintainedat−15 63°F(−26.1

addition to the standard substrate for test with the sealant sample.

6 1.7°C).

6.3 Forced-Draft Oven, controlled at 158 6 3.6°F (70 6 7.1.1 Mortar Block—Preparecementmortarblocks,each3

2°C).

by 1 by 1 in. (75 by 25 by 25 mm) in size, using one part of

high early strength portland cement conforming to Type III of

6.4 C-clamps, or other device for maintaining the specimen

Specification C150 to two parts by weight of clean uniformly

under compression.

graded, concrete fine aggregate (sand) conforming to Specifi-

6.5 Spacer Blocks.

cationC33.Usesufficientwatertoproduceaflowof10065%

6.6 Room or Chamber,maintainedatstandardconditionsof

when tested in accordance with the procedure for the determi-

73.4 6 3.6°F (23 6 2°C), 50 6 5% relative humidity.

nation of consistency of cement mortar described in Test

Method C109/C109M. After curing one day in moist air and

six days in saturated lime water at 73 6 3°F (23 6 2°C),

TABLE 1 Examples of Dimensions in Compression and

prepare the surface of one face, 1 by 3 in. (25 by 75 mm), of

Extension

each block by wet grinding either with a belt sander using No.

Dimension

60aluminumcarbidesandingbeltorusinganironlapwithNo.

Class C—Width of Joint in E—Width of Joint in

Compression, in. (mm) Extension, in. (mm)

60 silicon carbide (or aluminum oxide) grain until the aggre-

7 9

12.5 ⁄16 (11.1) ⁄16 (14.3)

gate is uniformly exposed. Return blocks to saturated lime

3 5

25 ⁄8 (9.5) ⁄8 (15.9)

water storage until needed.

C719 – 93 (2005)

FIG. 1 Compression-Extension Machine

FIG. 2 Compression-Extension Machine with Control Unit

7.1.1.1 Blocks may be prepared and shipped to other loca- ketone or similar solvent. Then dip the surface in a detergent

tions for use. The blocks may be shipped dry and shall be solution.Thisshouldbea0.04%solutionofanalcoholethoxy

returned to lime water storage on arrival until needed. sulfate. An alternative would be a 0.1% solution of a clear

7.1.1.2 Prior to use, wet grind the previously ground face to hand dishwashing detergent. These solutions should be made

remove any laitance, rinse thoroughly under running tap water up in distilled or deionized water. Rinse the surface (without

and dry the blocks overnight at 220 to 230°F (105 to 110°C). touching it) in distilled or deionized water and allow it to air

Clean the blocks of film or powder by vigorous brushing with

a stiff-bristled fiber brush. Condition the blocks at standard

conditions for not less than one day and not more than seven

Neodol 25-35, a registered trademark of Shell Oil Co., One Shell Plaza,

Houston, TX 77002, has been found suitable for this purpose.

days.

Dawn, a registered trademark of Proctor & Gamble Co., P.O. Box 599,

7.1.2 Float Glass— Glass plates shall be 3 by 1 by ⁄4 in.

Cincinnati, OH 54201, or Palmolive Green, a registered trademark of Colgate

(76.2 by 25.4 by 6.4 mm) clear float glass. Prior to use, the

PalmoliveCo.,300-TParkAve.,NewYork,NY10022havebeenfoundsuitablefor

glass shall be cleaned by wiping the surface with methyl ethyl this purpose.

C719 – 93 (2005)

FIG. 3 Top View of Machine in Fig. 2 Showing Three Specimens Ready for Automatic Cycling

dry.Thefloatglassrequiresreinforcementtosurvivetherigors compound with the appropriate amount of curing agent.Apply

1 1

of the subsequent testing procedures. This must be done prior

a bead of sealant ⁄2 by ⁄2 by 2 in. (12.7 by 12.7 by 50.8 mm)

to the compression-extension cycling performed in 9.4. Rein- between parallel 1 by 3-in. (

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.