ASTM C1247-20

(Test Method)Standard Test Method for Durability of Sealants Exposed to Continuous Immersion in Liquids

Standard Test Method for Durability of Sealants Exposed to Continuous Immersion in Liquids

SIGNIFICANCE AND USE

5.1 This test method uses elevated temperature in an attempt to accelerate the degradation of a sealant and its adhesion to a substrate. This test method is an accelerated method and will only be a predictor of long-term durability if the actual service temperature is significantly lower than the elevated test temperature.

5.2 This test method can be used as an indicator of longevity but direct correlation to actual use will be difficult for many applications.

5.3 The correlation of data from this test method to applications where the sealant joint will have wet and dry cycles will be difficult since, with some sealants on some substrates, adhesion that is lost during wet periods is regained during dry periods.

5.4 This test method is performed in a hot liquid and may be considered an acceleration of deterioration of the sealant or the sealant's adhesion to a substrate. Compared to how the sealant will be used in some applications, in some cases, this test may be less severe than the actual application. The benefit from the use of this test method will depend on the comparison of the conditions of this test to the actual conditions of use (temperature, duration, nature of substrate, composition of the liquid).

5.5 To determine the ability of a sealant to perform in a given application; modification of this procedure will often be required and is permissible, as mutually agreed upon by interested parties.

SCOPE

1.1 This test method covers a laboratory procedure that assists in determining the durability of a sealant and its adhesion to a substrate while continuously immersed in a liquid. This method tests the influence of a liquid on the sealant and its adhesion to a substrate. It does not test the added influence of constant stress from hydrostatic pressure that is often present with sealants used in submerged and below-grade applications, nor does it test the added influence of stress from joint movement while immersed. This method also does not (in its standard form) test the added influence of acids or caustics or other materials that may be in the liquid, in many applications.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound given in parentheses are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1247 − 20

Standard Test Method for

Durability of Sealants Exposed to Continuous Immersion in

1

Liquids

This standard is issued under the fixed designation C1247; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

Specimens)

1.1 This test method covers a laboratory procedure that

C150 Specification for Portland Cement

assists in determining the durability of a sealant and its

C717 Terminology of Building Seals and Sealants

adhesion to a substrate while continuously immersed in a

C719 Test Method for Adhesion and Cohesion of Elasto-

liquid.This method tests the influence of a liquid on the sealant

meric Joint Sealants Under Cyclic Movement (Hockman

and its adhesion to a substrate. It does not test the added

Cycle)

influence of constant stress from hydrostatic pressure that is

3

2.2 ISO Standard:

often present with sealants used in submerged and below-grade

ISO 13638 Building Construction-Sealants-Determination

applications, nor does it test the added influence of stress from

of Resistance of Prolonged Exposure to Water

joint movement while immersed.This method also does not (in

its standard form) test the added influence of acids or caustics

3. Terminology

or other materials that may be in the liquid, in many applica-

3.1 Definitions:

tions.

3.1.1 Definitions of the following terms used in this test

1.2 The values stated in SI units are to be regarded as the

method are found in Terminology C717: adhesive failure;

standard.The inch-pound given in parentheses are provided for

cohesive failure; compound; cure; hydrostatic pressure; joints;

information only.

primer; sealant; self-leveling sealant; standard conditions; and

1.3 This standard does not purport to address all of the

substrate.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Test Method

priate safety, health, and environmental practices and deter-

4.1 Specimens are prepared and the sealant is cured. The

mine the applicability of regulatory limitations prior to use.

specimens are immersed in a hot liquid at 50 6 2°C (122 6

1.4 This international standard was developed in accor-

3.6°F) for six weeks. At the end of the six weeks, the

dance with internationally recognized principles on standard-

specimensareplacedintoacompression/extensionmachine,as

ization established in the Decision on Principles for the

described in Test Method C719, and cycled through the

Development of International Standards, Guides and Recom-

movement range appropriate to the test sealant or its

mendations issued by the World Trade Organization Technical

application, or both.

Barriers to Trade (TBT) Committee.

1

4.2 If after three movement cycles at 3.2 mm/h ( ⁄8 in./h) a

2. Referenced Documents

total adhesive or cohesive failure is not noted, the remaining

2

specimens are again placed in the hot liquid for an additional

2.1 ASTM Standards:

four weeks and then retested.

C33 Specification for Concrete Aggregates

C109/C109M Test Method for Compressive Strength of 4.3 The four weeks of immersion and subsequent extension

and compression testing is repeated as many times as required

for the application.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC24onBuilding

Seals and Sealantsand is the direct responsibility of Subcommittee C24.30 on

5. Significance and Use

Adhesion.

Current edition approved Jan. 1, 2020. Published February 2020. Originally

5.1 Thistestmethoduseselevatedtemperatureinanattempt

approved in 1993. Last previous edition approved in 2014 as C1247 – 14. DOI:

to accelerate the degradation of a sealant and its adhesion to a

10.1520/C1247-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute, 11 W. 42nd Street, 13th

the ASTM website. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1247 − 20

test with the sealant sample.

substrate. This test method is an accelerated method and will

only be a predictor of long-term durability if the actual service

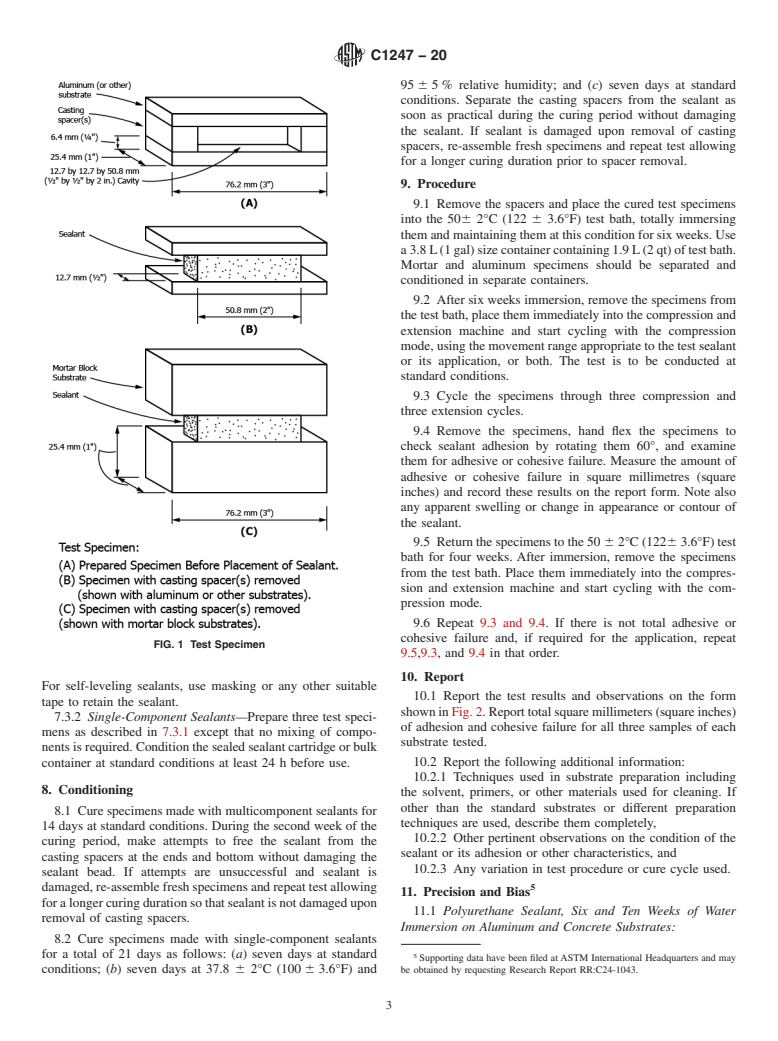

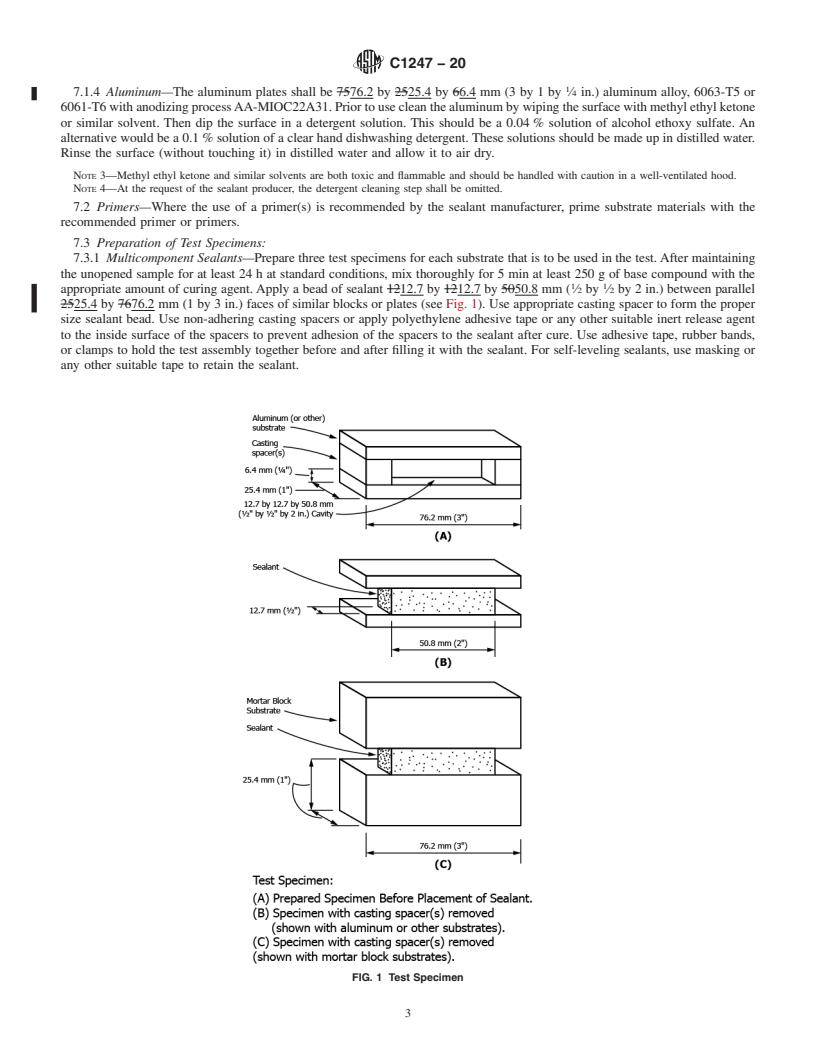

7.1.1 Mortar Block—Prepare ce

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1247 − 14 C1247 − 20

Standard Test Method for

Durability of Sealants Exposed to Continuous Immersion in

1

Liquids

This standard is issued under the fixed designation C1247; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a laboratory procedure that assists in determining the durability of a sealant and its adhesion to a

substrate while continuously immersed in a liquid. This test method tests the influence of a liquid on the sealant and its adhesion

to a substrate. It does not test the added influence of constant stress from hydrostatic pressure that is often present with sealants

used in submerged and below-grade applications, nor does it test the added influence of stress from joint movement while

immersed. This test method also does not (in its standard form) test the added influence of acids or caustics or other materials that

may be in the liquid, in many applications.

1.2 The values stated in SI units are to be regarded as the standard. The inch-pound given in parentheses are provided for

information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C33 Specification for Concrete Aggregates

C109/C109M Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens)

C150 Specification for Portland Cement

C717 Terminology of Building Seals and Sealants

C719 Test Method for Adhesion and Cohesion of Elastomeric Joint Sealants Under Cyclic Movement (Hockman Cycle)

3

2.2 ISO StandardsStandard:

ISO 13638 Building Construction-Sealants-Determination of Resistance of Prolonged Exposure to Water

3. Terminology

3.1 Definitions:

3.1.1 Definitions of the following terms used in this test method are found in Terminology C717: adhesive failure; cohesive

failure; compound; cure; hydrostatic pressure; joints; primer; sealant; self-leveling sealant; standard conditions; and substrate.

4. Summary of Test Method

4.1 Specimens are prepared and the sealant is cured. The specimens are immersed in a hot liquid at 50 6 2°C (122 6 3.6°F)

for six weeks. At the end of the six weeks, the specimens are placed into a compression/extension machine, as described in Test

Method C719, and cycled through the movement range appropriate to the test sealant or its application, or both.

1

This test method is under the jurisdiction of ASTM Committee C24 on Building Seals and Sealantsand is the direct responsibility of Subcommittee C24.30 on Adhesion.

Current edition approved Jan. 1, 2014Jan. 1, 2020. Published February 2014February 2020. Originally approved in 1993. Last previous edition approved in 20092014 as

C1247 – 09.C1247 – 14. DOI: 10.1520/C1247-14.10.1520/C1247-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute, 11 W. 42nd Street, 13th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1247 − 20

1

4.2 If after three movement cycles at 3.2 mm/h ( ⁄8 in./h) a total adhesive or cohesive failure is not noted, the remaining

specimens are again placed in the hot liquid for an additional four weeks and then retested.

4.3 This test method consists of six weeks of immersion followed by three extension and compression cycles. This can be

followed by four weeks of further immersion and a repeat of the three extension and compression cycles. The four week

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.