ASTM B673-05(2016)

(Specification)Standard Specification for UNS N08925, UNS N08354, and UNS N08926 Welded Pipe

Standard Specification for UNS N08925, UNS N08354, and UNS N08926 Welded Pipe

ABSTRACT

This specification covers UNS N08925, UNS 8354, and UNS N08926 welded pipes of specific dimensions for general corrosion applications. The pipe shall be made from flat-rolled alloy by an automatic welding process with no addition of filler material. Class 1 and Class 2 material shall be cold worked either in both weld and base metal or in weld metal only, subsequent to welding and before final solution treatment. The tensile strength, yield strength, and elongation requirements shall conform to specified values. The pipes shall be subjected to random flattening, leak, and electric tests.

SCOPE

1.1 This specification covers UNS N08925, UNS N08354, and UNS N089262 welded pipe for general corrosion applications.

1.2 This specification covers pipe sizes in schedules shown in Table 1. (A) Schedule 5S and 10S wall thicknesses do not permit threading in accordance with ANSI B2.1.(B) These do not conform to ANSI B31.10.(C) These do not conform to ANSI for Welded and Seamless Wrought Steel Pipe (ANSI B36.10).

1.3 ASTM International has adopted definitions whereby some grades, such as UNS N08904, previously in this specification were recognized as stainless steels, because those grades have iron as the largest element by mass percent. Such grades are under the oversight of ASTM Committee A01 and its subcommittees. The products of N08904 previously covered in this specification are now covered by Specification A312/A312M.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Safety Data Sheet (SDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B673 −05(Reapproved 2016)

Standard Specification for

1

UNS N08925, UNS N08354, and UNS N08926 Welded Pipe

This standard is issued under the fixed designation B673; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B775 Specification for General Requirements for Nickel and

Nickel Alloy Welded Pipe

1.1 This specification covers UNS N08925, UNS N08354,

2 E527 Practice for Numbering Metals and Alloys in the

and UNS N08926 welded pipe for general corrosion applica-

Unified Numbering System (UNS)

tions.

4

2.2 ANSI Standards:

1.2 This specification covers pipe sizes in schedules shown

B2.1 Pipe Threads

in Table 1.

B31.10 Power Piping

1.3 ASTM International has adopted definitions whereby B36.10 Welded and Seamless Wrought Steel Pipe

4

some grades, such as UNS N08904, previously in this speci- B36.19 Stainless Steel Pipe

fication were recognized as stainless steels, because those

3. Classification

grades have iron as the largest element by mass percent. Such

grades are under the oversight of ASTM Committee A01 and

3.1 Class 1—Welded, cold worked, solution treated, and

itssubcommittees.TheproductsofN08904previouslycovered

nondestructively tested in accordance with 8.3.1.

in this specification are now covered by Specification A312/

3.2 Class 2—Welded, cold worked, solution treated, and

A312M.

nondestructively tested in accordance with 8.3.2.

1.4 The values stated in inch-pound units are to be regarded

3.3 Class 3—As welded, solution treated, and nondestruc-

as standard. The values given in parentheses are mathematical

tively tested in accordance with 8.3.1.

conversions to SI units that are provided for information only

and are not considered standard.

4. General Requirement

1.5 This standard does not purport to address all of the

4.1 Material furnished under this specification shall con-

safety concerns, if any, associated with its use. It is the

form to the applicable requirements of Specification B775

responsibility of the user of this standard to become familiar

unless otherwise provided herein.

with all hazards including those identified in the appropriate

Safety Data Sheet (SDS) for this product/material as provided

5. Ordering Information

by the manufacturer, to establish appropriate safety and health

5.1 Orders for material under this specification should

practices, and determine the applicability of regulatory limi-

include the following information:

tations prior to use.

5.1.1 Alloy name or UNS number,

5.1.2 Class,

2. Referenced Documents

5.1.3 Quantity (feet or number of lengths),

3

2.1 ASTM Standards:

5.1.4 Size (nominal size or outside diameter and schedule

A312/A312M Specification for Seamless, Welded, and

number or average wall thickness),

Heavily Cold Worked Austenitic Stainless Steel Pipes

5.1.5 Length—Specify cut length or random,

5.1.6 Certification—State if certification or a report of test

results is required,

1

This specification is under the jurisdiction of ASTM Committee B02 on

5.1.7 Purchaser Inspection—State which tests or inspec-

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

tions are to be witnessed,

B02.07 on Refined Nickel and Cobalt and Their Alloys.

Current edition approved June 1, 2016. Published June 2016. Originally 5.1.8 Ends—Plain ends cut and deburred will be furnished,

ε1

approved in 1980. Last previous edition approved in 2011 as B673 – 05 (2011) .

unless otherwise specified, and

DOI: 10.1520/B0673-05R16.

5.1.9 Samples for Product (Check) Analysis—State whether

2

New designation established in accordance with ASTM E527 and SAE J1086,

samples shall be furnished.

Practice for Numbering Metals and Alloys (UNS).

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B673−05(2016)

TABLE 1 Dimensions of Welded Pipe

NOTE 1—The following table is a partial reprint of Table 1 of ANSI B36.19.

NOTE 2—The decimal thicknesses listed for the respective pipe sizes represent their nominal wall dimensions.

NOTE 3—1 in. = 25.4 mm.

Nominal Nominal Wall Thickness, in.

Pipe Size, Outside Diameter A A

Schedule 5S Schedule 10S Schedule 40S Schedule 80S Schedule 160S

in.

1

⁄

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: B673 − 05 (Reapproved 2011) B673 − 05 (Reapproved 2016)

Standard Specification for

1

UNS N08925, UNS N08354, and UNS N08926 Welded Pipe

This standard is issued under the fixed designation B673; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Table 3 heading for Tensile Strength and Yield Strength was editorially corrected from psi to ksi in May 2012.

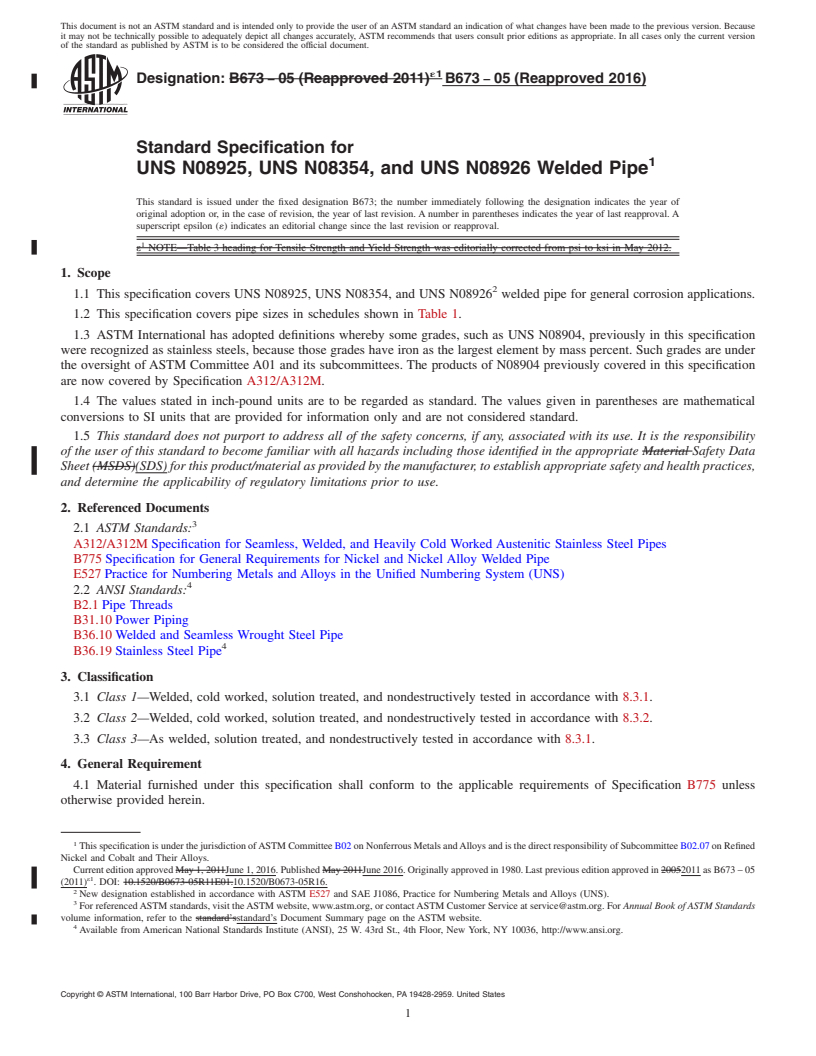

1. Scope

2

1.1 This specification covers UNS N08925, UNS N08354, and UNS N08926 welded pipe for general corrosion applications.

1.2 This specification covers pipe sizes in schedules shown in Table 1.

1.3 ASTM International has adopted definitions whereby some grades, such as UNS N08904, previously in this specification

were recognized as stainless steels, because those grades have iron as the largest element by mass percent. Such grades are under

the oversight of ASTM Committee A01 and its subcommittees. The products of N08904 previously covered in this specification

are now covered by Specification A312/A312M.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data

Sheet (MSDS)(SDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices,

and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

3

2.1 ASTM Standards:

A312/A312M Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes

B775 Specification for General Requirements for Nickel and Nickel Alloy Welded Pipe

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

4

2.2 ANSI Standards:

B2.1 Pipe Threads

B31.10 Power Piping

B36.10 Welded and Seamless Wrought Steel Pipe

4

B36.19 Stainless Steel Pipe

3. Classification

3.1 Class 1—Welded, cold worked, solution treated, and nondestructively tested in accordance with 8.3.1.

3.2 Class 2—Welded, cold worked, solution treated, and nondestructively tested in accordance with 8.3.2.

3.3 Class 3—As welded, solution treated, and nondestructively tested in accordance with 8.3.1.

4. General Requirement

4.1 Material furnished under this specification shall conform to the applicable requirements of Specification B775 unless

otherwise provided herein.

1

This specification is under the jurisdiction of ASTM Committee B02 on Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee B02.07 on Refined

Nickel and Cobalt and Their Alloys.

Current edition approved May 1, 2011June 1, 2016. Published May 2011June 2016. Originally approved in 1980. Last previous edition approved in 20052011 as B673 – 05

ε1

(2011) . DOI: 10.1520/B0673-05R11E01.10.1520/B0673-05R16.

2

New designation established in accordance with ASTM E527 and SAE J1086, Practice for Numbering Metals and Alloys (UNS).

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

4

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

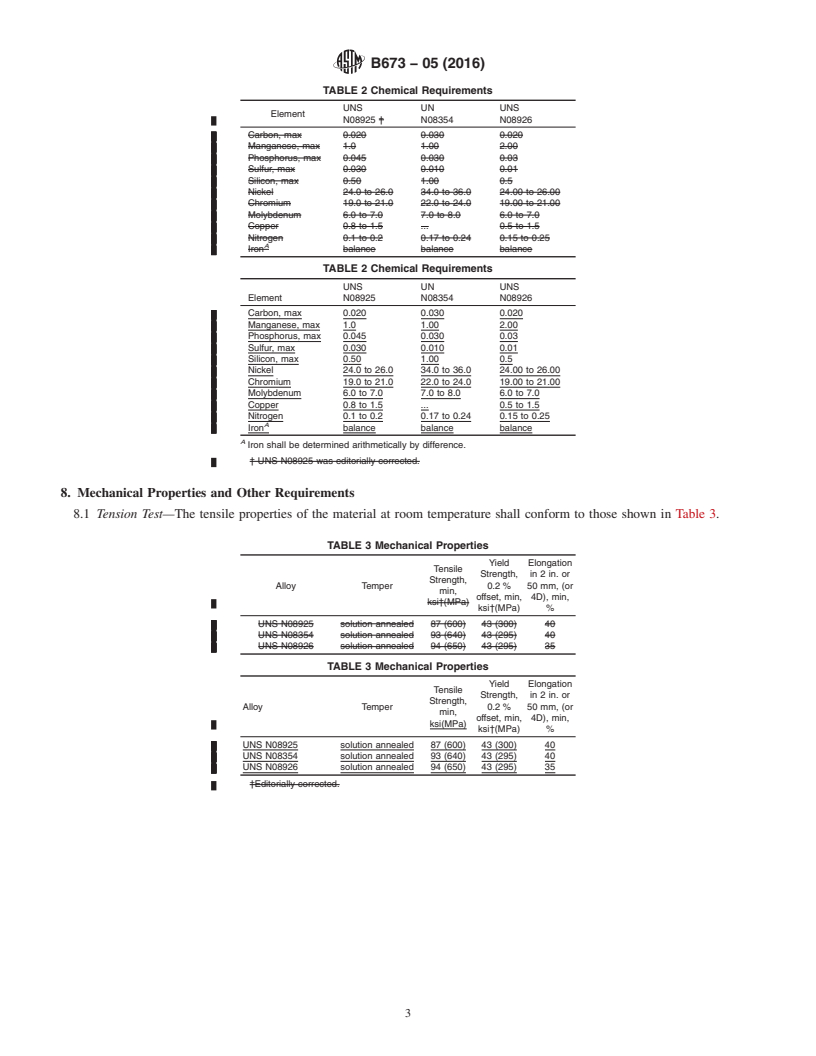

B673 − 05 (2016)

TABLE 1 Dimensions of Welded Pipe

NOTE 1—The following table is a partial reprint of Table 1 of ANSI B36.19.

NOTE 2—The decimal thicknesses listed for the respective pipe sizes represent their nominal wall dimensions.

NOTE 3—1 in. = 25.4 mm.

Nominal Nominal Wall Thickness, in.

Pipe Size, Outside Diameter A A

Schedule 5S Schedule 10S Schedule 40S Schedule 80S Schedule 160S

in.

1

⁄8 0.405 10.29 . . 0.049 1.25 0.068 1.73 0.095 2.41 . .

1

⁄4 0.540 13.72 . . 0.065 1.65 0.088 2.24 0.119 3.02 . .

3

⁄8 0.675 17.15 . . 0.065 1.65 0.091 2.31

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.