ASTM B294-92(2001)

(Test Method)Standard Test Method for Hardness Testing of Cemented Carbides

Standard Test Method for Hardness Testing of Cemented Carbides

SCOPE

1.1 This test method covers the hardness testing of cemented carbides by use of the Rockwell hardness tester with the Rockwell A scale (diamond indenter and 588.4 N (60 kgf) load) in the range of Rockwell A80 and above. Also covered are the procedures for the testing and selection of diamond indenters, the management and traceability of the four levels of standard test blocks, the acquisition of secondary standard test blocks, and the making and calibration of working standard test blocks.

1.2 The Rockwell hardness tester is a convenient and reliable means of measuring the hardness of cemented carbides. A hardness value is obtained easily, but it is subject to considerable error unless certain precautions are observed.

1.3 Test Methods E18 shall be followed except where otherwise indicated in this test method.

1.4 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B294–92(Reapproved 2001)

Standard Test Method for

Hardness Testing of Cemented Carbides

This standard is issued under the fixed designation B 294; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Part 2, Preparation and calibration of standard test blocks

1.1 This test method covers the hardness testing of ce-

3. Significance and Use

mented carbides by use of the Rockwell hardness tester with

3.1 Rockwell hardness is one of the more important prop-

the Rockwell A scale (diamond indenter and 588.4 N (60 kgf)

erties used to evaluate cemented carbides. For compositional

load) in the range of Rockwell A80 and above. Also covered

groups of cemented carbides, hardness is an indication of wear

are the procedures for the testing and selection of diamond

resistance and toughness. Lower hardness grades usually

indenters, the management and traceability of the four levels of

indicate less wear resistance but greater toughness. For a

standard test blocks, the acquisition of secondary standard test

specific grade of cemented carbide, hardness is an indication of

blocks,andthemakingandcalibrationofworkingstandardtest

the metallurgical quality of the material. In no case is hardness

blocks.

the only property to be considered in evaluating cemented

1.2 The Rockwell hardness tester is a convenient and

carbides.

reliable means of measuring the hardness of cemented car-

bides. A hardness value is obtained easily, but it is subject to

4. Apparatus

considerable error unless certain precautions are observed.

4.1 Scale—All hardness tests shall be made on the regular

1.3 Test Methods E 18 shall be followed except where

(asopposedtosuperficial)Rockwelltester,usinga588.4N(60

otherwise indicated in this test method.

kgf) load (Rockwell A scale).

1.4 The values stated in SI units are to be regarded as

4.2 Effect of Vibration—The Rockwell hardness tester

standard. The values given in parentheses are for information

should be located in a vibration-free area in order to avoid

only.

erroneous results. If this is not possible, the tester shall be

1.5 This standard does not purport to address all of the

mounted so as to minimize vibrations, since vibrations tend to

safety concerns, if any, associated with its use. It is the

cause erratic readings.

responsibility of the user of this standard to establish appro-

4.3 Indenter—The standard indenter shall be selected, in

priate safety and health practices and determine the applica-

accordance with the Annex to this test method, from diamond

bility of regulatory limitations prior to use.

cone indenters specified for Rockwell A scale use and in

2. Referenced Documents conformance with Test Methods E 18.

4.3.1 The indenter, and an indentation made with it, in

2.1 ASTM Standards:

hardened steel or cemented carbide should be examined

E 18 Test Methods for Rockwell Hardness and Rockwell

2 optically at approximately 50-diameter magnification for de-

Superficial Hardness of Metallic Materials

fects, conformance to shape, and mounting of the diamond.

E 29 Practice for Using Significant Digits in Test Data to

3 Examination should be made when selecting an indenter,

Determine Conformance with Specifications

occasionally during use, and whenever some event may be

2.2 ISO Standard:

suspected of having damaged the diamond or its mounting.

3738-2 Hardmetals—Rockwell hardness test (Scale A)—

4.4 Anvils—Select an anvil suitable for the specimen to be

tested. The shoulder of the screw and the mating surface of the

anvil should be clean. Seat the anvil securely. For the best

accuracy, flat test pieces should be tested on a flat anvil of

This test method is under the jurisdiction of ASTM Committee B09 on Metal 1

approximately 6-mm ( ⁄4-in.) diameter. The bearing surface of

Powders and Metal Powder Products and is the direct responsibility of Subcom-

this anvil, with a Rockwell C hardness of at least 60, shall be

mittee B09.06 on Cemented Carbides.

Current edition approved Jan. 15, 1992. Published March 1992. Originally

published as B 294 – 54 T. Last previous edition B 294 – 86.

2 4

Annual Book of ASTM Standards, Vol 03.01. AvailablefromAmericanNationalStandardsInstitute,25W.43rdSt.,4thfloor,

Annual Book of ASTM Standards, Vol 14.02. New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B294

polished smooth and be free of pits and heavy scratches. The 6.3 Limit the speed of applying the major load so that the

test piece should be supported suitably, with the test surface movement of the weights is completed in 4 to 6 s, with no test

perpendicular to the line of travel of the indenter. Dust, dirt, piece on the testing equipment and with the machine set to

grease, or scale should not be allowed to accumulate on any apply a major load of 60 Kg. Verification should be by direct

part of the apparatus, as this will affect the results. observation of the weight motion, if visible.

4.5 Test Blocks—Secondary standard test blocks or working 6.4 Do not permit the time of maintaining the major load

standard test blocks that have been prepared and calibrated in after the motion of the needle or the changing of the digital

accordance with the Annex to this test method shall be used. readout has ceased to exceed 2 s. Removal of the major load

should be gradual by operating lever in manual machines or by

5. Test Specimens motor in automatic machines, and should not exceed two

additional seconds. On manual machines, abrupt actuation of

5.1 Size of Specimens—A minimum thickness of 1.6 mm

the major load trip lever may affect the hardness value

( ⁄16 in.) is recommended. With thinner specimens, breakage

obtained.Abrupt actuation of the major load removal lever will

may occur, resulting in damage to the anvil, the indenter, or

significantly affect the hardness value obtained.

both. Specimens that have enough overhang to cause imbal-

6.5 The Rockwell A hardness value is read after the major

ance shall be supported properly. The 6-mm ( ⁄4-in.) anvil will

load has been removed and while the minor load is still

support flat test specimens up to approximately 113 g ( ⁄4 lb)

applied.

and will also support the standard test blocks recommended

6.6 The distance between the centers of any two adjacent

previously.

indentations, and the distance between the center of any

5.2 Preparation of Test Specimens—The finish of the test

indentationandtheedgeofatestspecimen,shallbeatleast1.5

surface is of major importance. The surface to be tested should

mm (0.06 in.).

be prepared to obtain a roughness of Ra#0.2 µm (8 µin.) A

6.7 Hardness should be read or estimated to the nearest 0.1

coarser finish will provide a wider range of readings. Prepara-

HRA. Calculations should be carried to two decimal places.

tion shall be conducted in such a way that alteration of the

6.8 Make two trial determinations of the hardness of the test

surface due to heat or cold-working is minimized. A 220-grit

specimen. This action also reassures that the indenter is seated

medium hardness resinoid bond diamond wheel, downfed 0.01

properly.

mm(0.0005in.)perpasswithabundantflowofcoolant,should

6.8.1 Select the standard test block having a value closest to

providethedesiredsurface.Thethicknessofthelayerremoved

the trial hardness of the test specimen. Determine the Rockwell

from an as-sintered surface to be tested shall be not less than

A hardness at three points on the block.

0.2 mm (0.008 in.).

6.8.2 If the arithmetic mean of the three determinations

5.3 The surfaces of the test specimen shall be flat and

differs from the certified hardness value of the standard test

parallel within one part per hundred parts in general practice,

block by more than 60.5 HRA, check the diamond indenter

but within one part per thousand parts when critical compari-

and the testing equipment, and eliminate the cause of the error.

sonsarebeingmade.Thesurfaceincontactwiththeanvilshall

Repeat the determinations.

be free of any irregularity (for example, a previous hardness

6.8.3 If the arithmetic mean of the three determinations

indentation). Taper that results in the test surface not being

differs from the certified hardness value of the standard test

normal to the axis of the indenter, or irregularity that causes

block by 60.5 HRA or less, record the difference, giving due

instability during the test, will result in error.

regard to the algebraic sign. This difference will be used to

5.4 When determining the hardness of a test specimen with

correct the arithmetic mean of the hardness of the test

a curved surface, the radius of curvature shall not be less than

specimens.

9 1

15mm( ⁄16in.).Ifless,thenaflatsurfaceatleast3-mm( ⁄8-in.)

6.8.4 Determine the Rockwell A hardness of the test speci-

wide shall be prepared on which to conduct the test, and there

men, with determinations at three or more locations chosen at

shall be an opposite flat surface such that the specimen

random, or as dictated by the purpose of the test.

conforms to the requirements of 5.2 and 5.3. If the test surface

6.8.5 Calculate the arithmetic mean of the hardness deter-

is curved or the opposite surface must be supported in a

minations. Apply the correction determined as in 6.8.3, giving

V-anvil, the repeatability and reproducibility limits of 8.2 and

due regard to the algebraic sign.

8.3 may not apply.

6.8.6 Report the corrected arithmetic mean of the hardness

5.5 Preparation of Mounted Carbides—Remove mounted

determinations, rounded in accordance with Practice E 29 to

carbides from the steel body by heating or some other

the nearest 0.1 HRA.

convenient method. All braze metal or other bond material

shall be removed from both the test surface and the opposite

7. Report

face.The specimen should then be prepared as described in 5.1

7.1 Report the following information:

through 5.4.

6. Procedure

When the second decimal place is less than 0.05, leave the first decimal place

6.1 Procedures that are not described in this test method

unchanged. When the second decimal place is more than 0.05, increase the first

shall conform to those of Test Methods E 18.

decimal place by 0.1. When the second decimal place is exactly 5 and the first

6.2 Disregard the first two readings after an indenter has

decimal place is odd, increase the first decimal by 0.1. If the first decimal place is

been newly mounted. even, leave it unchanged.

B294

7.1.1 All details necessary for identification of the test results obtained in the same laboratory on the same test

specimen, specimen will be expected to exceed 0.3 HRA only approxi-

7.1.2 The corrected mean hardness, mately 5 % of the time. The repeatability standard deviation

7.1.3 The range of hardness determinations, (S ) is 0.1 HRA.

r

7.1.4 The number of hardness determinations, 8.3 The reproducibility limit (R) between or among labora-

7.1.5 The smallest division of readout or graduation of the tories is 0.4 HRA when each has calibrated its machine,

hardness test machine and whether it is digital or analog, indenter, and operator system with a standard test block that

7.1.6 The identification and original source of calibration has itself been calibrated to the same superior test block used

for the standard test blocks used, to calibrate the test blocks of the other laboratories. On the

7.1.7 A reference to this test method, and basis of test error alone, the difference in absolute value of the

7.1.8 Details of any deviations from this test method, of test results obtained in different laboratories on the same test

optional procedures used, and of any conditions and occur- specimen will be expected to exceed 0.4 HRA only approxi-

rences that may have affected the results. mately 5 % of the time. The reproducibility standard deviation

(S ) is 0.14 HRA.

R

8. Precision and Bias

8.4 Neither the data of the interlaboratory study nor theo-

8.1 Thefollowingstatementsregardingtherepeatabilityand

retical considerations suggest a bias in this test procedure.

reproducibility of hardness (HRA) measurements of cemented

8.5 If the test specimens are of a hardness substantially

carbide test specimens shall apply only within the hardness

outside the hardness ranges of the standard test blocks on

range established for the indenter in accordance withA1.8.2 or

which the indenter has been performance tested, and if inter-

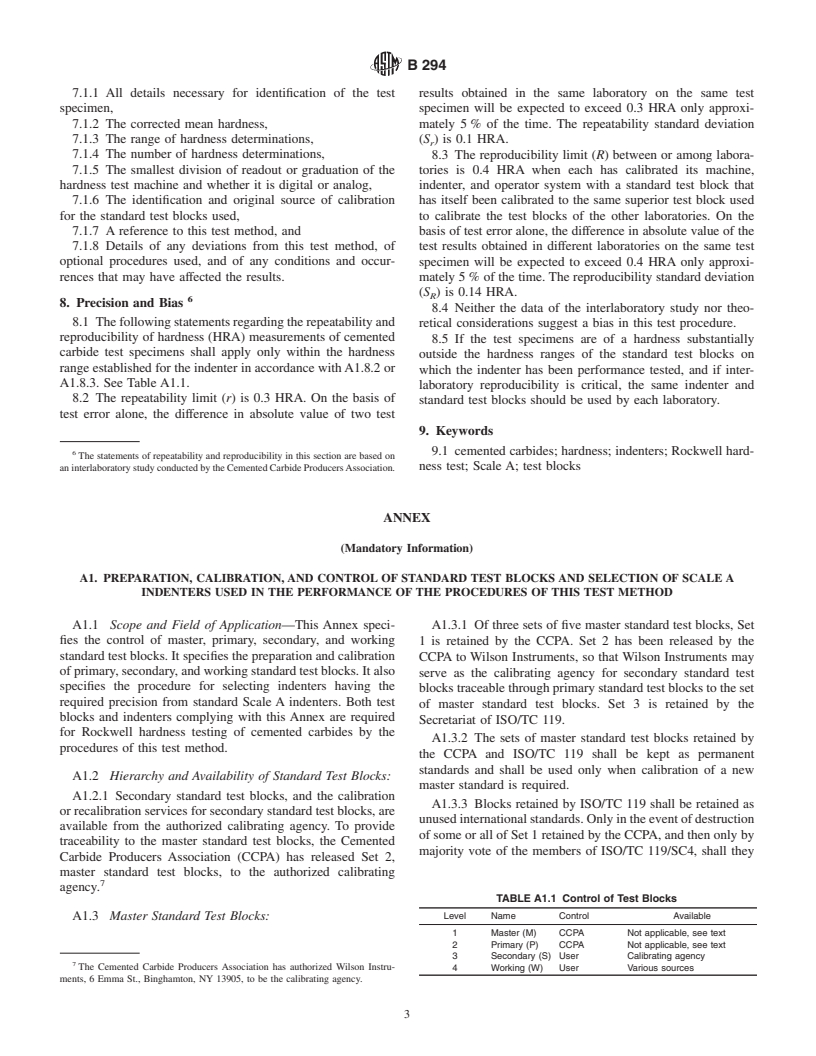

A1.8.3. See Table A1.1.

laboratory reproducibility is critical, the same indenter and

8.2 The repeatability limit (r) is 0.3 HRA. On the basis of

standard test blocks should be used by each laboratory.

test error alone, the difference in absolute value of two test

9. Keywords

9.1 cemented carbides; hardness; indenters; Rockwell hard-

The statements of repeatability and reproducibility in this section are based on

aninterlaboratorystudyconductedbytheCementedCarbideProducersAssociation. ness test; Scale A; test blocks

ANNEX

(Mandatory Information)

A1. PREPARATION, CALIBRATION, AND CONTROL OF STANDARD TEST BLOCKS AND SELECTION OF SCALE A

INDENTERS USED IN THE PERFORMANCE OF THE PROCEDURES OF THIS TEST METHOD

A1.1 Scope and Field of Application—This Annex speci- A1.3.1 Of three sets of five master standard test blocks, Set

fies the control of master, primary, secondary, and working 1 is retained by the CCPA. Set 2 has been released by the

standard test blocks. It specifies the preparation and calibration

CCPA to Wilson Instruments, so that Wilson Instruments may

of primary, secondary, and working standard test blocks. It also

serve as the calibrating agency for secondary standard test

specifies the procedure for selecting indenters having the

blocks traceable through primary standard test blocks to the set

required precision from standard Scale A indenters. Both test

of master standard test blocks. Set 3 is retained by the

blocks and indenters complying with this Annex are required

Secretariat of ISO/TC 119.

for Rockwell hardness testing of cemented carbides by the

A1.3.2 The sets of master standard test blocks retained by

procedures of this test method.

the CCPA and ISO/TC 119 shall be kept as permanent

standards and shall be used only when calibration of a new

A1.2 Hierarchy and Availability of Standard Test Blocks:

master standard is required.

A1.2.1 Secondary standard test blocks, and the calibration

A1.3.3 Blocks retained by ISO/TC 119 shall be retained as

or recalibration services for secondary standard test blocks, are

unusedinternationalstandards.Onlyintheeventofdestruction

available from the authori

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.