ASTM D5242-92(2007)

(Test Method)Standard Test Method for Open-Channel Flow Measurement of Water with Thin-Plate Weirs

Standard Test Method for Open-Channel Flow Measurement of Water with Thin-Plate Weirs

SIGNIFICANCE AND USE

Thin-plate weirs are reliable and simple devices that have the potential for highly accurate flow measurements. With proper selection of the shape of the overflow section a wide range of discharges can be covered; the recommendations in this test method are based on experiments with flowrates from about 0.008 ft 3/s (0.00023 m 3/s) to about 50 ft 3/s (1.4 m 3/s).

Thin-plate weirs are particularly suitable for use in water and wastewater without significant amounts of solids and in locations where a head loss is affordable.

SCOPE

1.1 This test method covers measurement of the volumetric flowrate of water and wastewater in channels with thin-plate weirs. Information related to this test method can be found in Rantz (1) and Ackers (2).

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5242 − 92 (Reapproved2007)

Standard Test Method for

Open-Channel Flow Measurement of Water with Thin-Plate

Weirs

This standard is issued under the fixed designation D5242; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 For definitions of terms used in this test method, refer

to Terminology D1129.

1.1 This test method covers measurement of the volumetric

3.2 Definitions of Terms Specific to This Standard:

flowrate of water and wastewater in channels with thin-plate

3.2.1 crest—the bottom of the overflow section or notch of

weirs. Information related to this test method can be found in

a rectangular weir.

Rantz (1) and Ackers (2).

3.2.2 head—the height of a liquid above a specified point,

1.2 The values stated in inch-pound units are to be regarded

for example, the weir crest.

as the standard. The SI units given in parentheses are for

information only.

3.2.3 hydraulic jump—an abrupt transition from supercriti-

cal flow to subcritical or tranquil flow.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3.2.4 nappe—the curved sheet or jet of water overfalling the

responsibility of the user of this standard to establish appro-

weir.

priate safety and health practices and determine the applica-

3.2.5 notch—the overflow section of a triangular weir or of

bility of regulatory limitations prior to use.

a rectangular weir with side contractions.

2. Referenced Documents

3.2.6 primary instrument—the device (in this case the weir)

2.1 ASTM Standards: thatcreatesahydrodynamicconditionthatcanbesensedbythe

D1129 Terminology Relating to Water secondary instrument.

D2777 Practice for Determination of Precision and Bias of

3.2.7 scow float—an in-stream float for depth sensing,

Applicable Test Methods of Committee D19 on Water

usually mounted on a hinged cantilever.

D3858 Test Method for Open-Channel Flow Measurement

3.2.8 secondary instrument—in this case, a device that

of Water by Velocity-Area Method

measures the depth of flow (referenced to the crest) at an

2.2 ISO Standards:

appropriate location upstream of the weir plate. The secondary

ISO1438 FlowMeasurementinOpenChannelsUsingWeirs

instrument may also convert the measured depth to an indi-

and Venturi Flumes—Part 1: Thin-Plate Weirs

cated flowrate.

ISO 555 Liquid Flow Measurement in Open Channels,

Delusion Methods for Measurement of Steady Flow- 3.2.9 stilling well—a small free-surface reservoir connected

Constant Rate Injection Method through a constricted channel to the approach channel up-

stream of the weir so that a depth (head) measurement can be

3. Terminology

made under quiescent conditions.

3.1 Definitions:

3.2.10 subcritical flow—open channel flow in which the

average velocity is less than the square root of the product of

This test method is under the jurisdiction of ASTM Committee D19 on Water

the average depth and the acceleration due to gravity; some-

and is the direct responsibility of Subcommittee D19.07 on Sediments,

times called tranquil flow.

Geomorphology, and Open-Channel Flow.

Current edition approved June 15, 2007. Published July 2007. Originally

3.2.11 submergence—a condition where the water level on

approved in 1992. Last previous edition approved in 2001 as D5242 – 92 (2001).

the downstream side of the weir is at the same or at a higher

DOI: 10.1520/D5242-92R07.

The boldface numbers in parentheses refer to a list of references at the end of

elevation than the weir crest; depending on the percent of

the text.

submergence the flow over the weir and hence the head-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

discharge relation may be altered.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

3.2.12 supercritical flow—open channel flow in which the

the ASTM website.

4 average velocity exceeds the square root of the product of the

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. average depth and the acceleration due to gravity.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5242 − 92 (2007)

3.2.13 tailwater—the water level immediately downstream

of the weir.

4. Summary of Test Method

4.1 Thin-plate weirs are overflow structures of specified

geometries for which the volumetric flowrate is a unique

functionofasinglemeasureddepth(head)abovetheweircrest

or vertex, the other factors in the head-discharge relation

having been experimentally or analytically determined as

functions of the shape of the overflow section and approach

channel geometry.

5. Significance and Use

5.1 Thin-plate weirs are reliable and simple devices that

havethepotentialforhighlyaccurateflowmeasurements.With

proper selection of the shape of the overflow section a wide

range of discharges can be covered; the recommendations in

this test method are based on experiments with flowrates from

3 3 3 3

about 0.008 ft /s (0.00023 m /s) to about 50 ft /s (1.4 m /s).

5.2 Thin-plate weirs are particularly suitable for use in

waterandwastewaterwithoutsignificantamountsofsolidsand

in locations where a head loss is affordable.

6. Interferences

6.1 Because of the reduced velocities in the backwater

upstream of the weir, solids normally transported by the flow

will tend to deposit and ultimately affect the approach condi-

tions.

6.2 Weirs are applicable only to open channel flow and

become inoperative under pressurized-conduit conditions.

7. Apparatus

7.1 A weir measuring system consists of the weir plate and

its immediate channel (the primary) and a depth (head)

measuring device (the secondary). The secondary device can

range from a simple scale for manual readings to an instrument

that continuously senses the depth, converts it to a flowrate,

and displays or transmits a readout or record of the instanta-

neous flowrate or totalized flow, or both.

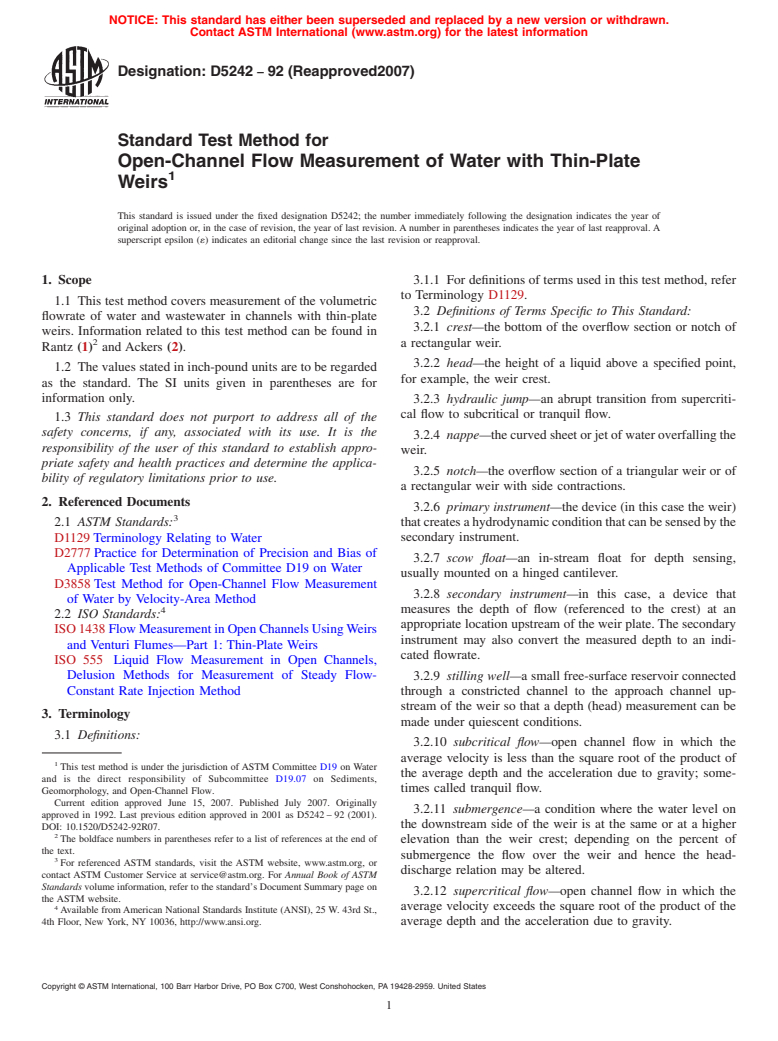

FIG. 1 Rectangular Weir

7.2 Thin-Plate Weir:

7.2.1 Shapes—The thin-plate weir provides a precisely

shaped overflow section symmetrically located in a (usually)

rectangular approach section, as in Fig. 1 and Fig. 2.Although

information is available in the literature (3) on a variety of

overflow-section or notch shapes (for example, rectangular,

triangular, trapezoidal, circular) only the rectangular and trian-

gular shapes are considered to have a data base sufficient for

promulgation as a standard method.

7.2.2 Weir Plate:

7.2.2.1 The plate thickness in the direction of flow must be

from 0.03 in 0.08 in. (about 1 to 2 mm); the lower limit is

prescribedtominimizepotentialdamage,andtheupperlimitis

FIG. 2 Crest-Length Adjustment, ∆

required to help avoid nappe clinging. See 7.2.5.4 and 7.2.6.3 L

for plates thicker than 0.08 in. (2 mm). The plate must be

fabricated of smooth metal or other material of equivalent

smoothness and sturdiness. Upstream corners of the overflow 7.2.2.2 The plane of the weir plate must be vertical and

section must be sharp and burr-free, and the edges must be flat, perpendicular to the channel walls. The overflow section must

smooth, and perpendicular to the weir face. be laterally symmetrical and its bisector must be vertical and

D5242 − 92 (2007)

located at the lateral midpoint of the approach channel. If the where g is the acceleration due to gravity in compatible

metal plate containing the overfall section does not form the units, H and L aretheeffectiveheadandeffectivecrestlength

e e

entire weir, it must be mounted on the remainder of the respectively, and C is a discharge coefficient. The effective

e

bulkhead so that the upstream face of the weir is flush and head, H , is related to the measured head, H, by:

e

smooth. (This requirement may be relaxed if the metal plate is

H 5 H1δH

e

large enough in itself to form full contractions. See 7.2.3.) The

where δH is an experimentally determined adjustment for

weir structure must be firmly mounted in the channel so that

the effects of viscosity and surface tension valid for water at

there is no leakage around it.

ordinarytemperatures(about4to30°C);itsvalueisconstantat

7.2.2.3 Additional plate requirements specific to rectangular

0.003 ft (0.001 m). The effective crest length, L , is related to

and triangular weirs are given in 7.2.5.4 and 7.2.6.3. e

the measured length, L, by:

7.2.3 WeirContractions—Whenthesidewallsandbottomof

the approach channel are far enough from the edges of the L 5 L1δL

e

notch for the contraction of the nappe to be unaffected by those

where the adjustment, δL, is a function of the crest length-

boundaries, the weir is termed “fully contracted.” With lesser

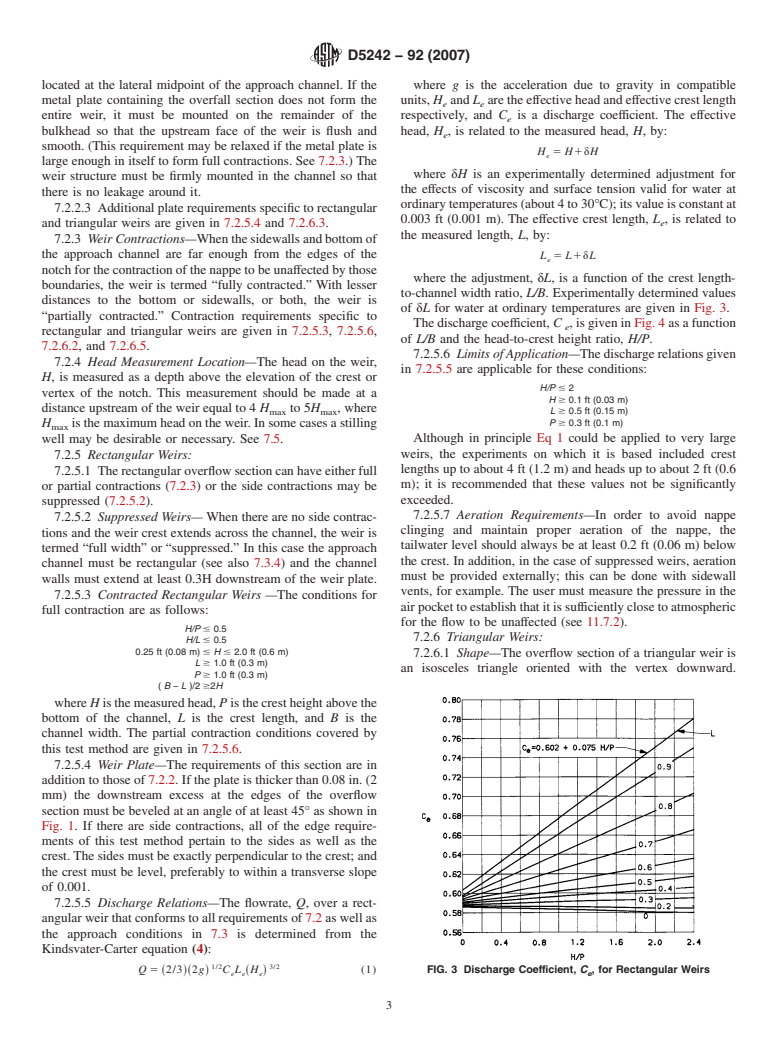

to-channel width ratio, L/B. Experimentally determined values

distances to the bottom or sidewalls, or both, the weir is

of δL for water at ordinary temperatures are given in Fig. 3.

“partially contracted.” Contraction requirements specific to

The discharge coefficient, C , is given in Fig. 4 as a function

e

rectangular and triangular weirs are given in 7.2.5.3, 7.2.5.6,

of L/B and the head-to-crest height ratio, H/P.

7.2.6.2, and 7.2.6.5.

7.2.5.6 Limits ofApplication—Thedischargerelationsgiven

7.2.4 Head Measurement Location—The head on the weir,

in 7.2.5.5 are applicable for these conditions:

H, is measured as a depth above the elevation of the crest or

H/P# 2

vertex of the notch. This measurement should be made at a

H$ 0.1 ft (0.03 m)

distance upstream of the weir equal to 4 H to 5H , where

max max L$ 0.5 ft (0.15 m)

P$ 0.3 ft (0.1 m)

H is the maximum head on the weir. In some cases a stilling

max

well may be desirable or necessary. See 7.5. Although in principle Eq 1 could be applied to very large

weirs, the experiments on which it is based included crest

7.2.5 Rectangular Weirs:

lengths up to about 4 ft (1.2 m) and heads up to about 2 ft (0.6

7.2.5.1 Therectangularoverflowsectioncanhaveeitherfull

m); it is recommended that these values not be significantly

or partial contractions (7.2.3) or the side contractions may be

exceeded.

suppressed (7.2.5.2).

7.2.5.7 Aeration Requirements—In order to avoid nappe

7.2.5.2 Suppressed Weirs— When there are no side contrac-

clinging and maintain proper aeration of the nappe, the

tions and the weir crest extends across the channel, the weir is

tailwater level should always be at least 0.2 ft (0.06 m) below

termed “full width” or “suppressed.” In this case the approach

the crest. In addition, in the case of suppressed weirs, aeration

channel must be rectangular (see also 7.3.4) and the channel

must be provided externally; this can be done with sidewall

walls must extend at least 0.3H downstream of the weir plate.

vents, for example. The user must measure the pressure in the

7.2.5.3 Contracted Rectangular Weirs —The conditions for

airpockettoestablishthatitissufficientlyclosetoatmospheric

full contraction are as follows:

for the flow to be unaffected (see 11.7.2).

H/P# 0.5

7.2.6 Triangular Weirs:

H/L# 0.5

0.25 ft (0.08 m)# H# 2.0 ft (0.6 m)

7.2.6.1 Shape—The overflow section of a triangular weir is

L$ 1.0 ft (0.3 m)

an isosceles triangle oriented with the vertex downward.

P$ 1.0 ft (0.3 m)

( B − L )/2$2H

where Histhemeasuredhead, Pisthecrestheightabovethe

bottom of the channel, L is the crest length, and B is the

channel width. The partial contraction conditions covered by

this test method are given in 7.2.5.6.

7.2.5.4 Weir Plate—The requirements of this section are in

addition to those of 7.2.2. If the plate is thicker than 0.08 in. (2

mm) the downstream excess at the edges of the overflow

section must be beveled at an angle of at least 45° as shown in

Fig. 1. If there are side contractions, all of the edge require-

ments of this test method pertain to the sides as well as the

crest. The sides must be exactly perpendicular to the crest; and

the crest must be level, preferably to within a transverse slope

of 0.001.

7.2.5.5 Discharge Relations—The flowrate, Q, over a rect-

angular weir that conforms to all requirements of 7.2 as well as

the approach conditions in 7.3 is determined from the

Kindsvater-Carter equation (4):

1/2 3/2

Q 5 2/3 2g C L H (1) FIG. 3 Discharge Coefficient, C , for Rectangular Weirs

~ !~ ! ~ !

e e e e

D5242 − 92 (2007)

where δ is an adjustment for the combined effects of

H

t

viscosityandsurfacetensionforwateratordinarytemperatures

(4 to 30°C) and is given as a function of notch angle in Fig. 5.

The discharge coefficient is given in Fig. 6 as a function of the

notch angle for fully contracted weirs only. For partially

contracted weirs the data base is considered adequate for 90°

notches only and these discharge coefficients are shown in Fig.

7.

7.2.6.5 Limits of Application—For 90° notches only, the

discharge relations given in 7.2.6.4 are valid for these partially

contracted conditions:

H/P# 1.2

H/B# 0.4

P$ 0.3 ft (0.1 m)

B$ 2ft(0.6m)

0.15 ft (0.05 m)# H# 2ft(0.6m)

Forotheranglesbetween20and100°thedischargerelations

are valid only for full contractions (see 7.2.6.2).

7.2.6.6 Aeration Requirements—In order to avoid nappe

clinging and maintain proper aeration of the nappe, the

tailwater level should always be at least 0.2 ft (0.05 m) below

the vertex of the triangular notch.

7.3 Approach Channel:

7.3.1 Weirs can be sensitive to the quality of the approach

flow. Therefore this flow should be tranquil and uniformly

distributed across the channel in order to closely approximate

the conditions of the experiments from which the discharge

relations were developed. For this purpose, uniform velocity

distribution can be defined as that associated with fully

developed flow in a long, straight, moderately smooth channel.

Unfortunately there are no universally accepted quantitative

guidelines for implementing these recommendations. One

standard (5) recommends a straight approach length of ten

FIG. 4 Triangular Weirs

channel widths when the weir length is greater than half the

channel width. However, the presence of upstream channel

Experimental results are available for notch angles, θ,of20to

bends or sudden enlargements would clearly lengthen this

100°. However, the most commonly used weirs are 90° (tan

approach requirement. Therefore the adequacy of the approach

θ/2 = 1),53.13°(tanθ/2 = 0.5)and28.07°(tanθ/2 = 0.25).See

flow generally must be demonstrated on a case-by-case basis

Fig. 2.

using velocity traverses, experience with similar situations, or

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.