ASTM D5389-93(2019)

(Test Method)Standard Test Method for Open-Channel Flow Measurement by Acoustic Velocity Meter Systems

Standard Test Method for Open-Channel Flow Measurement by Acoustic Velocity Meter Systems

SIGNIFICANCE AND USE

5.1 This test method is used where high accuracy of velocity or continuous discharge measurement over a long period of time is required and other test methods of measurement are not feasible due to low velocities in the channel, variable stage-discharge relations, complex stage-discharge relations, or the presence of marine traffic. It has the additional advantages of requiring no moving parts, introducing no head loss, and providing virtually instantaneous readings (1 to 100 readings per second).

5.2 The test method may require a relatively large amount of site work and survey effort and is therefore most suitable for permanent or semi-permanent installations.

SCOPE

1.1 This test method covers the measurement of flow rate of water in open channels, streams, and closed conduits with a free water surface.

1.2 The test method covers the use of acoustic transmissions to measure the average water velocity along a line between one or more opposing sets of transducers—by the time difference or frequency difference techniques.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 6.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5389 − 93 (Reapproved 2019)

Standard Test Method for

Open-Channel Flow Measurement by Acoustic Velocity

Meter Systems

This standard is issued under the fixed designation D5389; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3858 Test Method for Open-Channel Flow Measurement

of Water by Velocity-Area Method

1.1 This test method covers the measurement of flow rate of

water in open channels, streams, and closed conduits with a 2.2 ISO Standard:

free water surface. ISO 6416 Liquid Flow Measurements in Open Channels—

Measurement of Discharge by the Ultrasonic (Acoustic)

1.2 Thetestmethodcoverstheuseofacoustictransmissions

Method

tomeasuretheaveragewatervelocityalongalinebetweenone

or more opposing sets of transducers—by the time difference

3. Terminology

or frequency difference techniques.

3.1 Definitions:

1.3 The values stated in SI units are to be regarded as the

3.1.1 For definitions of terms used in this standard, refer to

standard.

Terminology D1129.

1.4 This standard does not purport to address all of the

3.2 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the

3.2.1 acoustic path, n—the straight line between the centers

responsibility of the user of this standard to establish appro-

of two acoustic transducers.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

3.2.2 acoustic path length, n—the face-to-face distance

Specific precautionary statements are given in Section 6.

between transducers on an acoustic path.

1.5 This international standard was developed in accor-

3.2.3 acoustic transducer, n—a device that is used to gen-

dance with internationally recognized principles on standard-

erate acoustic signals when driven by an electric voltage, and

ization established in the Decision on Principles for the

conversely, a device that is used to generate an electric voltage

Development of International Standards, Guides and Recom-

when excited by an acoustic signal.

mendations issued by the World Trade Organization Technical

3.2.4 acoustic travel time, n—the time required for an

Barriers to Trade (TBT) Committee.

acoustic signal to propagate along an acoustic path, either

upstream or downstream.

2. Referenced Documents

3.2.5 discharge, n—the rate of flow expressed in units of

2.1 ASTM Standards:

volume of water per unit of time. The discharge includes any

D1129 Terminology Relating to Water

sediment or other materials that may be dissolved or mixed

D2777 Practice for Determination of Precision and Bias of

with it.

Applicable Test Methods of Committee D19 on Water

D3850 Test Method for RapidThermal Degradation of Solid

3.2.6 line velocity, n—the downstream component of water

Electrical Insulating Materials By Thermogravimetric

velocity averaged over an acoustic path.

Method (TGA)

3.2.7 measurement plane, n—the plane formed by two or

more parallel acoustic paths of different elevations.

3.2.8 path velocity, n—the water velocity averaged over the

This test method is under the jurisdiction of ASTM Committee D19 on Water

acoustic path.

and is the direct responsibility of Subcommittee D19.07 on Sediments,

Geomorphology, and Open-Channel Flow.

3.2.9 stage, n—the height of a water surface above an

Current edition approved Nov. 1, 2019. Published January 2020. Originally

established (or arbitrary) datum plane; also gage height.

approved in 1993. Last previous edition approved in 2013 as D5389 – 93 (2013).

DOI: 10.1520/D5389-93R19.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5389 − 93 (2019)

FIG. 1 Velocity Component Used in Developing Travel-Time

Equations

FIG. 3 Example of Acoustic Velocity/Flow Measuring System

principle that the point-to-point upstream traveltime of an

acoustic pulse is longer than the downstream traveltime and

that this difference in travel time can be accurately measured

by electronic devices.

4.2 Most commercial AVM systems that measure stream-

flow use the time-of-travel method to determine velocity along

an acoustic path set diagonal to the flow. This test method

describes the general formula for determining line velocity

defined as (Fig. 1 and Fig. 2):

1 1

B

t t

F G

CA AC

V 5 2 (1)

L

2cosθ

where:

V = line velocity, or the average water velocity at the

L

FIG. 2 Voltage Representation of Transmit and Receive Pulses at

depth of the acoustic path,

Upstream and Downstream Transducers

θ = angle of departure between streamflow and the acous-

tic path,

t

AC = traveltime from A to C (upstream),

3.2.10 velocity sampling, n—meansofobtaininglineveloci-

t

CA = traveltime from C to A (downstream), and

ties in a measurement plane that are suitable for determining

B = length of the acoustic path from A to C.

flow rate by a velocity-area integration.

4. Summary of Test Method

4.1 Acoustic velocity meter (AVM) systems, also known as

Laenen, A., and Smith, W., “Acoustic Systems for the Measurement of

ultrasonic velocity meter (UVM) systems, operate on the Streamflow,” U.S. Geological Survey Water Supply Paper 2213, 1983.

D5389 − 93 (2019)

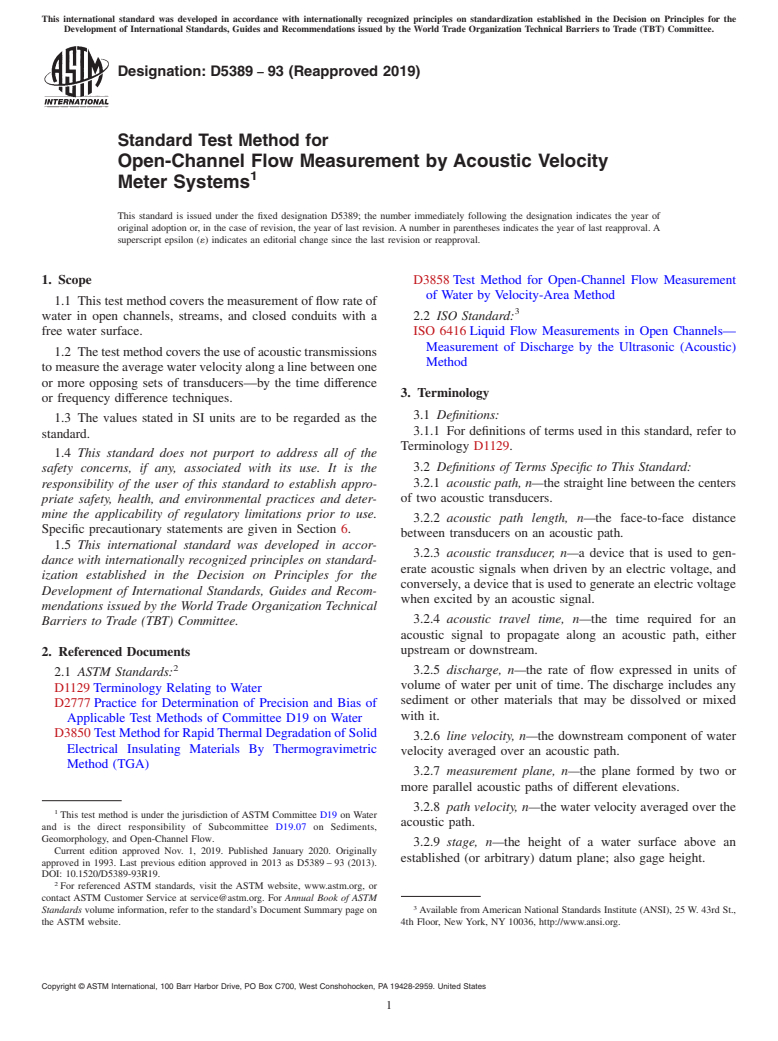

FIG. 4 Signal Bending Caused by Different Density Gradients

4.3 The discharge measurement or volume flow rate deter- requiring no moving parts, introducing no head loss, and

mination made with anAVM relies on a calibrated or theoreti- providing virtually instantaneous readings (1 to 100 readings

cal relation between the line velocity as measured by theAVM per second).

and mean velocity in the flow segment being measured.Taking

5.2 The test method may require a relatively large amount

morelinevelocitymeasurementsacrossthechannelatdifferent

of site work and survey effort and is therefore most suitable for

elevations in the acoustic plane and performing a numerical

permanent or semi-permanent installations.

integration or weighted summation of the measured velocities

and areas of flow can be used to better define the volume flow

6. Interferences

rate. The spacing between acoustic paths, the spacing between

6.1 Refraction—Thepathtakenbyanacousticsignalwillbe

thetoppathandtheliquidsurface,andthespacingbetweenthe

bent if the medium through which it is propagating varies

lowest path and the bottom are determined on the basis of

significantly in temperature or density. This condition, known

stream cross-section geometry or estimates of the vertical-

as ray bending, is most severe in slow moving streams with

velocity distribution and by the required measurement accu-

poor vertical mixing or tidal (estuaries) with variable salinity.

racy. In addition to several line velocity measurements, it is

In extreme conditions the signal may be lost. Examples of ray

necessary to provide water level (stage) and cross-sectional

bending are shown in Fig. 4. Beam deflection for various

area information for calculation of the volume flow rate (see

temperatures and specific conductivities are shown in Fig. 5

Fig. 3).

and Fig. 6.

5. Significance and Use

6.2 Reflection—Acoustic signals may be reflected by the

5.1 Thistestmethodisusedwherehighaccuracyofvelocity water surface or streambed. Reflected signals can interfere

or continuous discharge measurement over a long period of with, or cancel, signals propagated along the measurement

time is required and other test methods of measurement are not plane. When thermal or density gradients are present, the

feasible due to low velocities in the channel, variable stage- placement of transducers with respect to boundaries is most

discharge relations, complex stage-discharge relations, or the critical. This condition is most critical in shallow streams. A

presence of marine traffic. It has the additional advantages of general rule of thumb to prevent reflection interference is to

D5389 − 93 (2019)

NOTE 1—Transducer directivity or beam width determined at the 30-dB level of the transmitted signal pattern. The signal is propagated beyond the

beam width but at a weak level. In the shaded area the detection is so great that signals cannot be received directly for any transducer beam width.

FIG. 5 Beam Deflection From Linear Temperature Gradients for Different Path Lengths

NOTE 1—Transducer directivity or beam width determined at the 30-dB level of the transmitted signal pattern. The signal is propagated beyond the

beam width but at a weak level. In the shaded area the deflection is so great that signals cannot be received directly for any transducer beam width.

FIG. 6 Beam Deflection From Linear Conductivity Gradients for Different Path Lengths

maintain a minimum stream depth to path length ratio of 1 to bubbles,sediment,orotherparticleoraquaticmaterialspresent

100 for path lengths greater than 50 m.

in the water column. Table 1 presents tolerable sediment

concentrations.

6.3 Attenuation—Acoustic signals are attenuated by

absorption, spreading, or scattering. Absorption involves the

6.4 Mechanical Obstructions—Marine growth or water-

conversion of acoustic energy into heat. Spreading loss is

borne debris may build up on transducers or weed growth,

signal weakening as it spreads outward geometrically from its

boats, or other channel obstructions may degrade propagation

source. Scattering losses are the dominant attenuation factors

and timing of acoustic signals.

in streamflow applications. These losses are caused by air

D5389 − 93 (2019)

TABLE 1 Estimates of Tolerable Sediment Concentrations for

7.1.5 Display/Recorder—Generally, the output of the sys-

AVM System Operation Based on Attenuation From Spherical

tem is a display or a recorder, or both. The recorder normally

Spreading and From Scattering From the Most Critical Particle

includes calendar data, time, flow rate, stage, and any other

Size

information deemed desirable, such as error messages. Equip-

NOTE 1—Sediment concentrations in milligrams per litre.

ment of this type is often connected to other output devices,

Selected Path distance (m)

such as telemetry equipment.

Trans-

ducer 7.2 Acoustic Transducers—Transducers may be active (con-

Fre-

taining Transmitter and first stage of amplification) or passive

quency 5 20 50 100 200 300 500 1000

(no amplification) depending on path length and presence of

(kHz)

electromagnetic interference EMI. Acoustic transducers must

1000 6300 1200 400 — — — — —

500 — 3500 1200 530 230 — — —

be rigidly mounted in the channel wall or bottom. Means must

300 — 7900 2800 1300 560 350 — —

be provided for precise determination of acoustic path

200 — 11 000 4000 1800 830 520 280 —

elevation, length, and angle to flow. The transducers and

100 — — 10 000 4600 2200 1400 770 350

30 — — — — 8800 5700 3200 1500

cabling must be sufficiently rugged to withstand the handling

and operational environment into which they will be placed.

Additionally, provision shall be made for simple replacement

of transducer or cable, or both, in the event of failure or

damage.

6.5 Electrical Obstructions—Nearby radio transmitters,

electrical machinery, faulty electrical insulators, or other

7.3 StageMeasuringDevice—Thereareseveralmethodsfor

sources of electromagnetic interference (EMI) can cause fail-

measuring stage and inputting this information to the system.

ure or sporadic operation of AVMs.

The actual method used depends on the particular installation

requirements. Some examples include visual measurement/

7. Apparatus

manual keyboard entry, float/counterweight or bubbler systems

with servo manometers connected to analog conversion equip-

7.1 The instrumentation used to measure open-channel flow

ment or digital encoders, upward looking acoustic transducers,

by acoustic means consists of a complex and integrated

or other electronic pressure sensors.

electronic system known as an acoustic velocity meter (AVM).

Three or four companies presently market AVM systems

7.4 Power Supply—Several venders currently offer battery-

suitable for measurement of open-channel flow. System con-

powdered AVMs as well as systems operating on 110 V ac

figurations range from simple single-path to complex-multi-

standard commercial electric power. Availability of electricity

path systems. Internal computation, transmission, and record-

should be considered during site evaluation prior to equipment

ing systems vary depending on local requirements. MostAVM

selection.

systemsmustincludethecapabilitytocomputeanacousticline

7.5 Cabling—All interconnected cabling to and from trans-

velocity from one or more path velocities together with stage

ducers shall be armored or protected, or both, to minimize

(waterlevel)andotherinformationrelatedtochannelgeometry

damage during installation and operation.

necessarytocalculateaflowrateperunitoftime,usuallycubic

3 3

7.6 Responders—A responder is an electronic device that

millimetres per second (m /s) or cubic feet per second (ft /s).

receives an acoustic signal and then retransmits it back across

7.1.1 Electronics Equipment—There are several methods

the stream after a predetermined time interval. A responder is

that are currently being used to implement the electro-acoustic

used where direct wire connection is impractical. A typical

functions and mathematical manipulations required to obtain a

responder system is shown in Fig. 7.

line-velocity measurement. Whatever method is used must

includeinternalautomaticmeansforcontinuouslycheckingthe

8. Sampling

accuracy. In addition, provision must be included to prevent

8.1 Sampling, as defined in Terminology D1129,isnot

erroneous readings during acoustic interruptions caused by

rivertraffic,aquaticlife,orgradualdegradationofcomponents. applicable to this test method.

7.1.2 Flow Readout Equipment—This equipment is func-

9. Preparation of Apparatus

tionally separated into three subsystems. These subsystems

may or may not be physically separable but are discussed 9.1 Site Selections:

separately for cl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.