ASTM D537-85(1997)

(Specification)Standard Specification for Sodium Metasilicate (Withdrawn 2001)

Standard Specification for Sodium Metasilicate (Withdrawn 2001)

SCOPE

1.1 This specification for sodium metasilicate covers material suitable for various washing, cleaning, and scouring processes, with or without soap as conditions demand, and where a moderately strong alkaline material is desired.

1.2 This material may be hazardous if not properly managed.

1.3 Precautionary information for the safe use, storage, and disposal of this material should be preliminarily obtained from suppliers and others.

1.4 In case of personal accident with this material, apply appropriate first aid; telephone the nearest Poison Control Center for assistance, and get medical attention immediately.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 537 – 85 (Reapproved 1997)

Standard Specification for

Sodium Metasilicate

This standard is issued under the fixed designation D 537; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Therefore, the calculation of net weight shall be based upon a

product containing 98 % of sodium metasilicate calculated as

1.1 This specification for sodium metasilicate covers mate-

Na SiO ·5H O for Type I or 91.5 % of sodium metasilicate

2 3 2

rial suitable for various washing, cleaning, and scouring

calculated as Na SiO for Type II. The net weight of the

2 3

processes, with or without soap as conditions demand, and

material to be paid for shall be calculated as follows:

where a moderately strong alkaline material is desired.

1.2 This material may be hazardous if not properly man- W 5 ~R 3 T!/98 for Type I (1)

aged.

W 5 ~R 3 T!/91.5 for Type II (2)

1.3 Precautionary information for the safe use, storage, and

where:

disposal of this material should be preliminarily obtained from

W 5 net weight of the material to be paid for,

suppliers and others.

R 5 net weight of the material as received,

1.4 In case of personal accident with this material, apply

T 5 total sodium metasilicate calculated as Na SiO ·

appropriate first aid; telephone the nearest Poison Control 2 3

5H O, and

Center for assistance, and get medical attention immediately.

T8 5 total sodium metasilicate calculated as Na SiO .

2 3

2. Referenced Documents 4.2 In the event that the calculation under 4.1 results in a

figure greater than 100 %, the seller waives the right to invoice

2.1 ASTM Standards:

the purchaser for any amount in excess of 100 %.

D 501 Test Methods of Sampling and Chemical Analysis of

Alkaline Detergents

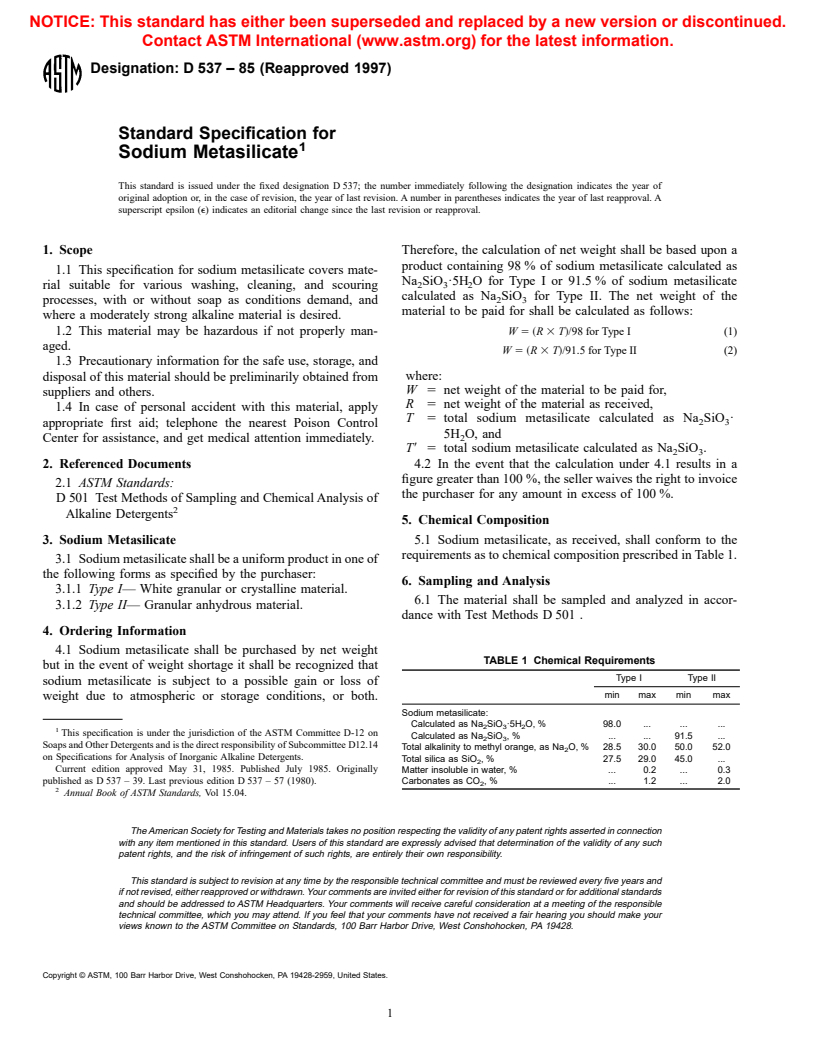

5. Chemical Composition

3. Sodium Metasilicate 5.1 Sodium metasilicate, as received, shall conform to the

requirements as to chemical composition prescribed in Table 1.

3.1 Sodium metasilicate shall be a uniform product in one of

the following forms as specified by the purchaser:

6. Sampling and Analysis

3.1.1 Type I— White granular or crystalline material.

6.1 The material shall be sampled and analyzed in accor-

3.1.2 Type II— Granular anhydrous material.

dance with Test Methods

...

This May Also Interest You

ABSTRACT

This guide details the standard procedures for the preparation of aqueous solutions of soaps and detergents and the determination of their pH. The required reagent for this procedure is distilled water or its equivalent, and the recommended electrodes for the determination of pH are the Fischer Accuphast combination electrode or Orion Ross Sure Flow electrode or their equivalents.

SCOPE

1.1 This guide covers the preparation of aqueous solutions of soaps and detergents and the determination of their pH.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Material Safety Data Sheets are available for reagents and materials. Review them for hazards prior to usage.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Guide2 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 The guide can be used to compare anti-redeposition performance of products; however, there is no confirmed basis for correlation of this controlled laboratory technique with consumers’ ranking of anti-redeposition performance.

SCOPE

1.1 This guide provides direction for measuring the ability of detergents to prevent the deposition of soils from detergent solutions onto fabrics. It is intended as a laboratory screening test to aid in the formulation of detergent products, for quality control, and as a basis between the purchaser and seller in standardizing specific products' performance.

1.2 The anti-soil deposition performance of detergent products will vary greatly depending on the type of soils and fabrics used in the test. Therefore, selection of the soils, fabrics, reference detergents, and test conditions shall be made by agreement between the interested parties on the basis of experience.

1.3 There is no single or combination of oily soils or particulate soils, or both, that will precisely predict overall the performance of a product or treatment with respect to anti-redeposition as perceived by a consumer. This guide is intended to assess or compare detergent performance with respect to the anti-redeposition performance for the specific soil chosen.

1.4 The values stated in either inch-pound or SI units are to be regarded separately as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Material safety data sheets are available for reagents and materials. Review them for hazards prior to usage.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Guide4 pagesEnglish languagesale 15% off

ABSTRACT

This test method covers the determination of the efficiency of ordinary commercial wetting agents using the skein test. It is applicable under limited and controlled conditions, but does not necessarily yield information correlating with specific end uses. The apparatus is comprised of a hook of standard weight depending on the concentration of the wetting agents and an anchor which shall be a flat, cylindrical, lead slug of specific dimensions. The reagents shall consist of water, acid and base test solutions, and wetting agent. The average of at least four determinations of the sinking time for each concentration of wetting agent shall be obtained and presented in plots with logarithmic coordinates. Standard deviation based on six replicate determinations shall also be calculated for precision.

SCOPE

1.1 This test method2,3 covers the determination of the efficiency of ordinary commercial wetting agents as defined in Terminology D459. This test method is applicable under limited and controlled conditions, but does not necessarily yield information correlating with specific end uses.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

5.1 The methods in this guide can be used for screening of fabric softener products or to evaluate their performance, through a single cycle or multiple accumulative cycles, relative to a designated reference product or a comparative product(s).

5.2 A single assessment of each of the product characteristics tested by these methods will not predict overall performance of the softener product. A single test run under specified fixed conditions cannot be expected to reflect the comparative performance under many other possible conditions of use.

SCOPE

1.1 This guide evaluates the performance characteristics of fabric softener products. It provides guidance for evaluating the on fabric efficacy of treatment chemicals dosed into the wash, rinse, or dryer cycle in a home laundry washer or dryer. This guide can be used for screening of fabric softener products, or to evaluate the products through multiple accumulative cycles.

1.2 The relative ranking of products assessed by these procedures may be affected by such factors as machine type and settings, fabric load composition, as well as by the washing and drying procedures used.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Guide7 pagesEnglish languagesale 15% off

ABSTRACT

These test methods cover procedures for the sampling and chemical analysis of inorganic alkaline detergents. These detergents include caustic soda, soda ash, modified soda (sequicarbonate type), sodium bicarbonate, sodium metasilicate, trisodium phosphate, tetrasodium pyrophosphate, borax, and sodium triphosphate. Different tests shall be conducted in order to determine the following properties of the detergents: total alkalinity, matter insoluble in water content, apparent density, ignition loss, pH level, turbidity, temperature rise, and particle size. Chemical analysis of the samples shall be performed by using either reverse-flow ion-exchange chromatography or paper chromatography.

SCOPE

1.1 These test methods cover procedures for the sampling and chemical analysis of inorganic alkaline detergents.

1.2 The procedures appear in the following order:

Sections

Caustic Soda:

Sampling

5

Total Alkalinity as Sodium Oxide (Na2O)

6 – 8

Sodium Hydroxide (NaOH)

9 – 11

Carbonate as Sodium Carbonate (Na2CO3)

12

Carbon Dioxide (CO2) by the Evolution Method

13 – 16

Soda Ash:

Sampling

17

Matter Volatile at 150 °C to 155 °C

18 and 19

Total Alkalinity as Sodium Carbonate (Na2CO3 )

20 – 22

Sodium Bicarbonate (NaHCO3)

23 – 25

Sodium Bicarbonate (NaHCO3) by Potentiometric Titration

26 – 28

Matter Insoluble in Water

29 and 30

Apparent Density

31 and 32

Modified Soda (Sequicarbonate Type):

Sampling

33

Total Alkalinity as Sodium Oxide (Na2O)

34 – 36

Sodium Bicarbonate (NaHCO3) and Sodium Carbonate (Na2CO3)

37 – 39

Matter Insoluble in Water

40

Sodium Bicarbonate:

Sampling

41

Sodium Bicarbonate, Sodium Carbonate, and Free Moisture

42 – 45

Matter Insoluble in Water

46

Sodium Metasilicate, Sodium Sesquisilicate and Sodium Orthosil- icate:

Sampling

47

Total Alkalinity as Sodium Oxide (Na2O)

48 – 50

Total Silica as SiO2

51 – 53

Sodium Metasilicate (Na2SiO3·5H2O)

54

Sodium Sesquisilicate (3Na2O·2SiO2·11H2O)

55

Matter Insoluble in Water

56 and 57

Loss on Ignition of Sodium Sesquisilicate (3Na2O·2SiO2 ·11H2O)

58 and 59

Sodium Orthosilicate (Na4SiO4)

60

Trisodium Phosphate:

Sampling

61

Trisodium Phosphate (Na3PO4) Content and Phosphorus Pentoxide (P2O5)

62 – 64

Trisodium Phosphate Calculated as Na3PO4·12H2O, Na3PO4· H2O, Na3PO4, and as P2O5

65 – 68

Total Alkalinity as Sodium Oxide (Na2O)

69 – 71

Matter Insoluble in Water

72 and 73

Tetrasodium Pyrophosphate:

Sampling

74

Tetrasodium Pyrophosphate

(Na4P2O7)

75 – 79

Matter Insoluble in Water

80 and 81

Loss on Ignition

82 and 83

Borax:

Sampling

84

Total Borate and Excess Alkalinity or Acidity

85 – 87

Matter Insoluble in Water

88 and 89

Sodium Triphosphate:

Sampling

90

Tritratable Na2O

91 – 94

Total P2O5:

Preferred Method

95 – 97

Alternative Method

98 – 101

pH Titration

102 – 107

Quantitative Separation and Measurement of Various Phosphates:

Reverse-Flow Ion-Exchange Chromatography (Preferred Method)

108 – 119

Paper Chromatographic Method

120 – 127

pH of 1 percent Solution

128

Turbidity

129

Temperature Rise

130 – 134

Sulfate

135 – 137

Ignition Loss

140 and 141

Matter Insoluble in Water

142 – 144

Particle Size

145

Orthophosphate

146 – 151

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of th...

- Standard27 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 The cloud point temperature is a reproducible characteristic of certain pure nonionic surfactants. It is also characteristic of certain nonionic surfactant formulated systems. This test method is appropriate for both systems.

Note 1: If the transition from a distinctly cloudy to a clear solution is not sharp, that is, if it does not take place within a range of 1 °C, this test method is not appropriate.

SCOPE

1.1 This test method covers a procedure to determine the “cloud point” of nonionic surfactants or detergent systems. Cloud Point is the temperature at which dissolved components (solids or liquids) are no longer completely soluble, precipating as a second phase giving the fluid a cloudy appearance. It is limited to those surfactants and detergent systems for which the visible solubility change occurs over a range of 1 °C or less at concentrations of 0.5 % to 1.0 % in DI water between 30 °C and 95 °C.

1.2 Chemical Limitations—Nonionic surfactants that exhibit a characteristic cloud point in general terms consist of a water-in-soluble moiety condensed with 50 % to 75 % by weight of ethylene oxide. If the level of ethoxylation is too low the surfactant may not be water soluble at temperatures less than 30 °C, and if it is too high no cloud point may exist.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard2 pagesEnglish languagesale 15% off

ABSTRACT

These test methods cover the sampling and chemical analysis of paste, powder, or liquid detergent fatty alkyl sulfates. The different procedure for sampling and chemical analysis of past, powder, or liquid detergent are presented and discussed in details. Distillation test, titration test, and gravimetric test shall be performed to meet the requirements prescribed. The calculations methods for chlorides as sodium chloride are presented in details.

SCOPE

1.1 These test methods cover the sampling and chemical analysis of paste, powder, or liquid detergent fatty alkyl sulfates.

1.2 The procedures for sampling and analysis appear in the following order:

Sections

Sampling:

Powders and Flakes Packed in Cans or Cartons

4

Powders and Flakes in Bulk

5

Liquids

6

Pastes

7

Preparation of Sample

8

Moisture by the Distillation Test Method

11 – 14

pH

15

Alkalinity

16 – 19

Alcohol-Soluble Matter

20 – 22

Alcohol-Insoluble Matter

23 and 24

Unsulfated Material

25 – 28

Combined Alcohols

29 – 32

Ester SO3:

Method A. Titration Test Method

36 and 37

Sections

Ester SO3:

Method B. Gravimetric Test Method

38 and 39

Sodium Sulfate

40 – 43

Chlorides Calculated as Sodium Chloride (NaCl)

44 – 47

1.3 The values stated in either inch-pound or SI units are to be regarded separately as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Material Safety Data Sheets are available for reagents and materials. Review them for hazards prior to usage.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard10 pagesEnglish languagesale 15% off

ABSTRACT

These test methods detail the standard procedures for the chemical analysis of soaps containing synthetic detergents. The analytical procedures include the determination of the following chemical properties and substances: moisture and other matter volatile at a specified temperature; free alkali or free acid; anhydrous, salt-free soda soap; alcohol-soluble matter; matter insoluble in water; total alkalinity of matter insoluble in alcohol (alkaline salts); sodium silicate; phosphates; phosphates by colorimetric method using molybdenum blue); unsaponified and unsaponifiable matter; free fatty matter; chlorides in alcohol-soluble matter; rosin by McNicoll method; synthetic detergent by difference; and neutral inorganic salts.

SCOPE

1.1 These test methods cover procedures for the chemical analysis of soaps containing synthetic detergents.

1.2 The analytical procedures appear in the following order:

Sections

Moisture and Other Matter Volatile at 105°C (Oven Method)

5 and 6

Free Alkali or Free Acid

7 and 8

Anhydrous, Salt-Free, Soda Soap

9 – 12

Alcohol-Soluble Matter

13 and 14

Matter Insoluble in Water

15 and 15

Total Alkalinity of Matter Insoluble in Alcohol (Alkaline Salts)

16 and 17

Sodium Silicate

18 – 20

Phosphates

21 – 28

Phosphate (Colorimetric Method Using Molybdenum Blue)

29 – 34

Unsaponified and Unsaponifiable Matter

35 – 39

Free Fatty Matter

40

Chlorides in Alcohol-Soluble Matter

41 – 43

Rosin (McNicoll Method)

44 – 47

Synthetic Detergent (by Difference)

48

Neutral, Inorganic Salts

49

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard10 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 This test method assures that the particle size of soaps and detergents conforms to specifications having to do with density and packaging, among others. It also offers a means of controlling the amount of potentially hazardous very low particle size material.

SCOPE

1.1 This test method covers the determination of the particle size of soaps and other detergents by hand sieving and machine sieving methods.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Material Safety Data Sheets are available for reagents and materials. Review them for hazards prior to usage.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard2 pagesEnglish languagesale 15% off

ABSTRACT

These test methods cover the chemical analysis of sulfonated and sulfated oils. Water by distillation with volatile solvent and moisture and volatile matter by hot-plate shall be tested to meet the requirements prescribed. Titration test, extraction-titration test, and ash-gravimetric test shall be performed to meet the requirements specified. Total desulfated fatty matter, total active ingredients, unsaponifiable non-volatile matter, inorganic salts, total alkalinity, and total ammonia shall be tested to meet the requirements prescribed. In the absence of ammonium or triethanolamine soaps test method, brine test method, and in the presence of ammonium or triethanolamine soaps test method shall be performed to meet the requirements prescribed. Water-immiscible organic solvents volatile with steam shall be tested to meet the requirements prescribed.

SCOPE

1.1 These test methods cover the chemical analysis of sulfonated and sulfated oils. The analytical procedures appear in the following order:

Section

Moisture:

Test Method A. Water by Distillation with Volatile Solvent

4 – 9

Test Method B. Moisture and Volatile Matter by Hot-Plate Method

10 – 14

Organically Combined Sulfuric Anhydride:

Test Method A. Titration Test

15 – 19

Test Method B. Extraction-Titration Test

20 – 24

Test Method C. Ash-Gravimetric Test (in the Presence of True

Sulfonates)

25 – 28

Total Desulfated Fatty Matter

29 – 32

Total Active Ingredients

33 – 36

Unsaponifiable Nonvolatile Matter

37 – 41

Inorganic Salts

42 – 46

Total Alkalinity

47 – 49

Total Ammonia

50 – 52

Acidity as Free Fatty Acids or Acid Number:

Test Method A. In the Absence of Ammonium or Triethanolamine Soaps

53 – 56

Test Method B. In the Presence of Dark Colored Oils but in the

Absence of Ammonium or Triethanolamine Soaps (Brine Test)

57 – 60

Test Method C. In the Presence of Ammonium or Triethanolamine Soaps

61 – 63

Water-Immiscible Organic Solvents Volatile with Steam

64 – 70

1.2 The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of inch-pound units may be approximate.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Material Safety Data Sheets are available for reagents and materials. Review them for hazards prior to usage.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard12 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.