ASTM A341/A341M-00(2005)e1

(Test Method)Standard Test Method for Direct Current Magnetic Properties of Materials Using D-C Permeameters and the Ballistic Test Methods

Standard Test Method for Direct Current Magnetic Properties of Materials Using D-C Permeameters and the Ballistic Test Methods

SIGNIFICANCE AND USE

Permeameters require the use of yokes to complete the magnetic circuit and are therefore inherently less accurate than ring test methods. Refer to Test Method A 596/A 596M for further details on ring test methods. However, when testing certain shapes as bars or when magnetic field strength in excess of 200 Oe [15.9 or more kA/m] are required, permeameters are the only practical means of measuring magnetic properties.

This test method is suitable for specification acceptance, service evaluation, research and development and design.

When the test specimen is fabricated from a larger sample and is in the same condition as the larger sample, it may not exhibit magnetic properties representative of the original sample. In such instances the test results, when viewed in context of past performance history, will be useful for judging the suitability of the material for the intended application.

SCOPE

1.1 This test method provides dc permeameter tests for the basic magnetic properties of materials in the form of bars, rods, wire, or strip specimens which may be cut, machined, or ground from cast, compacted, sintered, forged, extruded, rolled, or other fabricated materials. It includes tests for determination of the normal induction under symmetrically cyclically magnetized (SCM) conditions and the hysteresis loop (B-H loop) taken under conditions of rapidly changing or steep wavefront reversals of the direct current magnetic field strength.

1.2 This test method shall be used in conjunction with Practice A 34/A 34M.

1.3 This test method covers a range of magnetic field strength in the specimen from about 0.05 Oe [4 A/m] up to above 5000 Oe [400 kA/M] through the use of several permeameters. The separate permeameters cover this test region in several overlapping ranges.

1.4 Normal induction and hysteresis properties may be determined over the flux density range from essentially zero to intrinsic saturation for most materials.

1.5 Recommendations of the useful magnetic field strength range for each of the permeameters are shown in Table 1 . Also, see Sections 3 and 4 for general limitations relative to the use of permeameters.

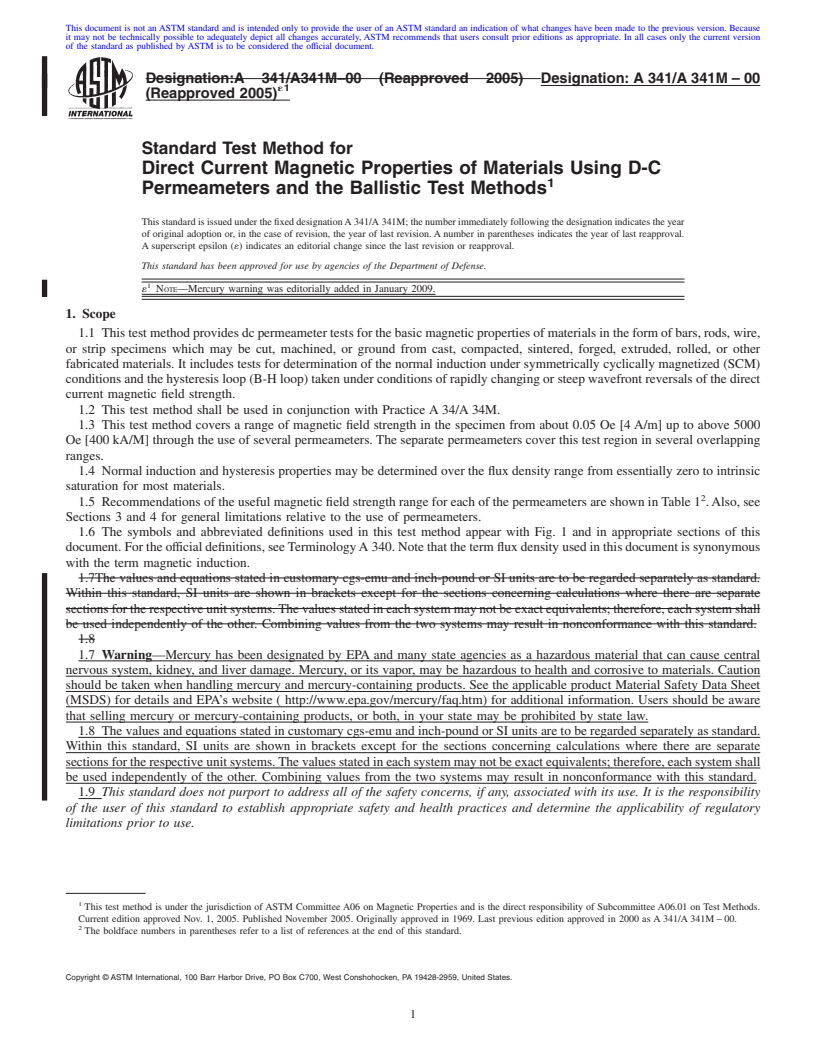

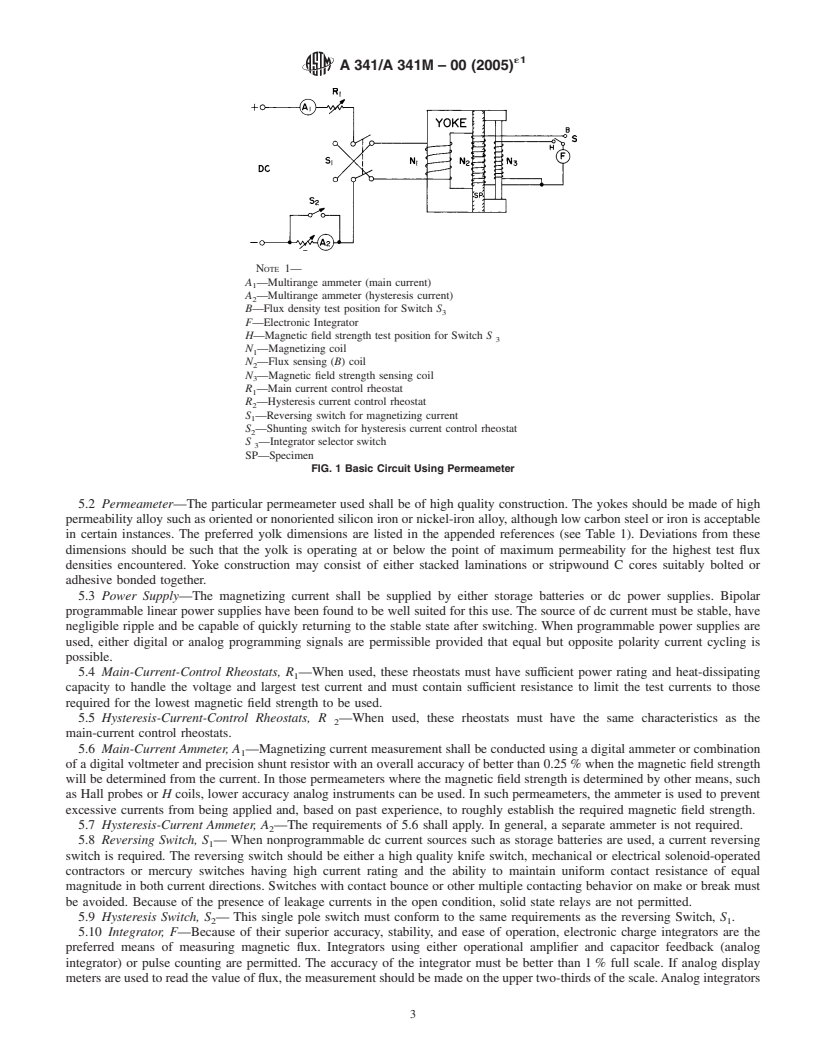

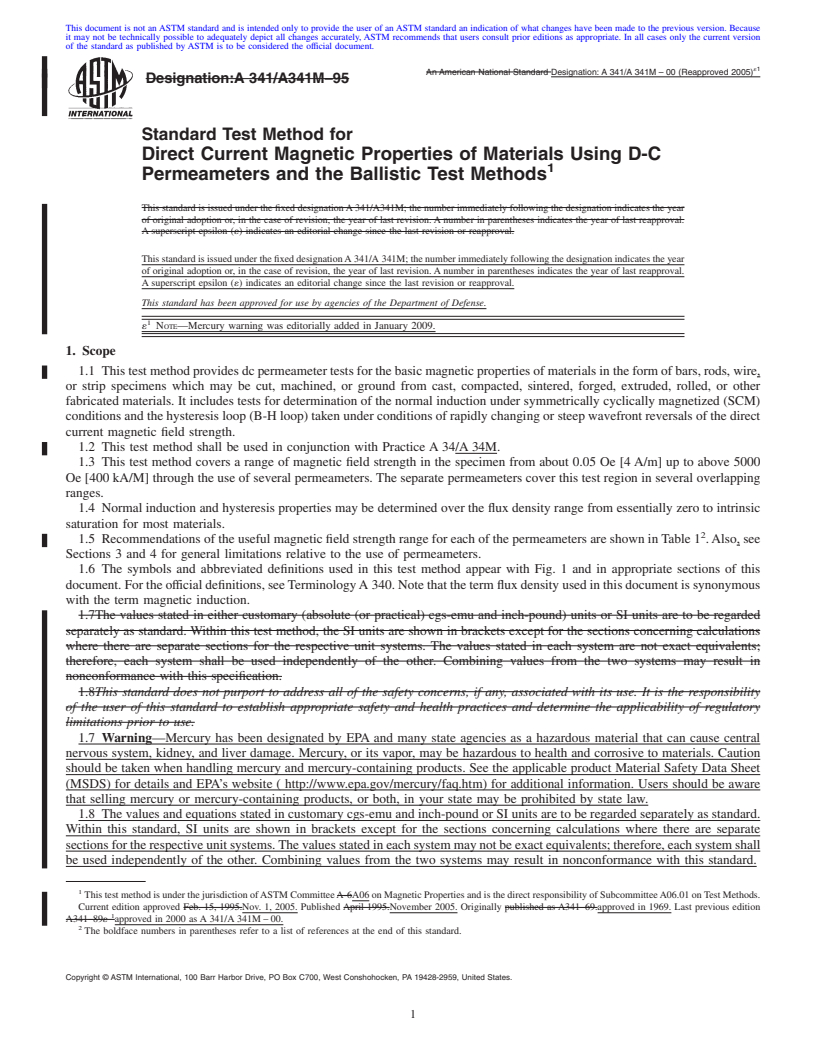

1.6 The symbols and abbreviated definitions used in this test method appear with Fig. 1 and in appropriate sections of this document. For the official definitions, see Terminology A 340. Note that the term flux density used in this document is synonymous with the term magnetic induction.

1.7 Warning—Mercury has been designated by EPA and many state agencies as a hazardous material that can cause central nervous system, kidney, and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury-containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s website (http://www.epa.gov/mercury/faq.htm) for additional information. Users should be aware that selling mercury or mercury-containing products, or both, in your state may be prohibited by state law.

1.8 The values and equations stated in customary cgs-emu and inch-pound or SI units are to be regarded separately as standard. Within this standard, SI units are shown in brackets except for the sections concerning calculations where there are separate sections for the respective unit systems. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with this standard.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

TABLE 1 Permeameters PermeameterUseful Magnetic Field Strength RangeAH Measuring

DeviceB Reluct...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:A341/A341M–00 (Reapproved 2005)

Standard Test Method for

Direct Current Magnetic Properties of Materials Using D-C

Permeameters and the Ballistic Test Methods

This standard is issued under the fixed designationA341/A341M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

´ NOTE—Mercury warning was editorially added in January 2009.

1. Scope central nervous system, kidney, and liver damage. Mercury, or

its vapor, may be hazardous to health and corrosive to

1.1 This test method provides dc permeameter tests for the

materials.Cautionshouldbetakenwhenhandlingmercuryand

basicmagneticpropertiesofmaterialsintheformofbars,rods,

mercury-containing products. See the applicable product Ma-

wire, or strip specimens which may be cut, machined, or

terial Safety Data Sheet (MSDS) for details and EPA’s website

ground from cast, compacted, sintered, forged, extruded,

(http://www.epa.gov/mercury/faq.htm) for additional informa-

rolled, or other fabricated materials. It includes tests for

tion. Users should be aware that selling mercury or mercury-

determination of the normal induction under symmetrically

containingproducts,orboth,inyourstatemaybeprohibitedby

cyclically magnetized (SCM) conditions and the hysteresis

state law.

loop (B-H loop) taken under conditions of rapidly changing or

1.8 The values and equations stated in customary cgs-emu

steep wavefront reversals of the direct current magnetic field

and inch-pound or SI units are to be regarded separately as

strength.

standard. Within this standard, SI units are shown in brackets

1.2 This test method shall be used in conjunction with

except for the sections concerning calculations where there are

Practice A34/A34M.

separate sections for the respective unit systems. The values

1.3 This test method covers a range of magnetic field

stated in each system may not be exact equivalents; therefore,

strength in the specimen from about 0.05 Oe [4 A/m] up to

each system shall be used independently of the other. Combin-

above 5000 Oe [400 kA/M] through the use of several

ingvaluesfromthetwosystemsmayresultinnonconformance

permeameters. The separate permeameters cover this test

with this standard.

region in several overlapping ranges.

1.9 This standard does not purport to address all of the

1.4 Normal induction and hysteresis properties may be

safety concerns, if any, associated with its use. It is the

determined over the flux density range from essentially zero to

responsibility of the user of this standard to establish appro-

intrinsic saturation for most materials.

priate safety and health practices and determine the applica-

1.5 Recommendations of the useful magnetic field strength

2 bility of regulatory limitations prior to use.

range for each of the permeameters are shown in Table 1 .

Also,seeSections3and4forgenerallimitationsrelativetothe

2. Referenced Documents

use of permeameters.

2.1 ASTM Standards:

1.6 Thesymbolsandabbreviateddefinitionsusedinthistest

A34/A34M Practice for Sampling and Procurement Testing

method appear with Fig. 1 and in appropriate sections of this

of Magnetic Materials

document. For the official definitions, see Terminology A340.

A340 Terminology of Symbols and Definitions Relating to

Note that the term flux density used in this document is

Magnetic Testing

synonymous with the term magnetic induction.

A596/A596M Test Method for Direct-Current Magnetic

1.7 Warning—Mercury has been designated by EPA and

Properties of Materials Using the Ballistic Method and

many state agencies as a hazardous material that can cause

Ring Specimens

2.2 IEC Standard:

This test method is under the jurisdiction of ASTM Committee A06 on Publication 60404-4, Ed. 2.0 Magnetic Materials – Part 4:

MagneticPropertiesandisthedirectresponsibilityofSubcommitteeA06.01onTest

Methods.

Current edition approved Nov. 1, 2005. Published November 2005. Originally

approved in 1969. Last previous edition approved in 2000 as A341/A341M–00. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

DOI: 10.1520/A0341_A0341M-00R05E01. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The boldface numbers in parentheses refer to a list of references at the end of Standards volume information, refer to the standard’s Document Summary page on

this standard. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

A341/A341M–00 (2005)

TABLE 1 Permeameters

A

Magnetizing Coil

Useful Magnetic Field Strength Range

H Measuring Reluctance

Permeameter Surrounds References

B

Device Compensation

Oe kA/m Specimen

Babbit 40/1000 3.2/80 I, HC yes yes (1,2)

Burroughs 0.1/300 0.008/24 I yes yes (1,3,4,5)

C

Fahy Simplex 0.1/300 0.008/24 HC no no (1,4,5,6,7)

Fahy Simplex

100/2500 8/200 HC no no (1,3)

C

Super H adapter

Full range 0.05/1400 0.004/112 HC yes yes (1,8)

High H 100/5000 8/400 FC yes no (1,5,7,9)

Iliovici 0.5/500 0.04/400 I, HC yes yes (4,10,11)

IEC Type A 0.1/2500 0.008/200 HC, HP no yes IEC 60404-4

IEC Type B 0.1/630 0.008/50 RCC no no IEC 60404-4

Isthmus 100/20 000+ 8/1600+ HC, HP no no (1,4,12,13)

MH 0.1/300 0.008/24 FC yes yes (1,6,14)

NPL 0.5/2500 0.04/200 I, HC yes yes (15)

Saturation 100/4000 8/320 HC no yes (5,16,17)

A

Although the permeameters are capable of being used at the lower end of the measurement range, the measurement accuracy is reduced.

B

I—magnetizing current; HC—fixed H coil; FC—flip coil; HP—Hall probe; RCC—Rogowski-Chattock coil.

C

Fahy permeameters require a standard of known magnetic properties for calibration of the H coil.

ring test methods. Refer to Test Method A596/A596M for

further details on ring test methods. However, when testing

certainshapesasbarsorwhenmagneticfieldstrengthinexcess

of200Oe[15.9ormorekA/m]arerequired,permeametersare

the only practical means of measuring magnetic properties.

3.2 Thistestmethodissuitableforspecificationacceptance,

service evaluation, research and development and design.

3.3 When the test specimen is fabricated from a larger

sampleandisinthesameconditionasthelargersample,itmay

not exhibit magnetic properties representative of the original

sample. In such instances the test results, when viewed in

context of past performance history, will be useful for judging

NOTE 1—

the suitability of the material for the intended application.

A —Multirange ammeter (main current)

A —Multirange ammeter (hysteresis current)

4. Interferences

B—Flux density test position for Switch S

4.1 In general, permeameters do not maintain a uniform

F—Electronic Integrator

H—Magnetic field strength test position for Switch S

magneticfieldineithertheaxialorradialdirectionsaroundthe

N —Magnetizing coil

1 test specimen. The field gradients in both of these directions

N —Flux sensing (B) coil

willdifferinthevariouspermeameters.AlsotheH-sensingand

N —Magnetic field strength sensing coil

B-sensing coils of the different permeameters are not identical

R —Main current control rheostat

in area, in turns, or in length or identically located. Although

R —Hysteresis current control rheostat

test specimens are prepared to have uniform physical cross

S —Reversing switch for magnetizing current

S —Shunting switch for hysteresis current control rheostat section, they may have undetected nonuniform magnetic prop-

S —Integrator selector switch

erties radially or axially along the specimen length adjacent to

SP—Specimen

the H or B coils. Some permeameters may also introduce

FIG. 1 Basic Circuit Using Permeameter

clamping strains into the test specimen. For the above reasons

test results obtained on a test specimen with one type per-

Methods of Measurement of D.C. Magnetic Properties of

meameter may not agree closely with those obtained on the

Iron and Steel, IEC, 1995

same test specimen using another type of permeameter.

2.3 Other Documents:

5 5. Apparatus

NIST Circular No. 74, pg. 269

NIST Scientific Paper 117, SPBTA 5.1 Because of the differences in physical construction of

the various permeameters listed in Table 1, no standard list of

3. Significance and Use

components is given. When used with a particular type of

3.1 Permeameters require the use of yokes to complete the permeameter, the components should conform to the general

magnetic circuit and are therefore inherently less accurate than requirementslistedbelow.Abasicschematicofapermeameter

is shown in Fig. 1.

5.2 Permeameter—The particular permeameter used shall

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

be of high quality construction. The yokes should be made of

4th Floor, New York, NY 10036.

high permeability alloy such as oriented or nonoriented silicon

Available from National Institute of Standards and Technology (NIST), 100

Bureau Dr., Stop 3460, Gaithersburg, MD 20899-3460. iron or nickel-iron alloy, although low carbon steel or iron is

´1

A341/A341M–00 (2005)

TABLE 2 Number of Test Strips

acceptable in certain instances. The preferred yolk dimensions

are listed in the appended references (see Table 1). Deviations Nominal Thickness Gage Number of

in. mm Number Strips

fromthesedimensionsshouldbesuchthattheyolkisoperating

0.0100 to 0.0250 0.254 to 0.635 32 to 24, incl 12

at or below the point of maximum permeability for the highest

0.0280 to 0.0435 0.711 to 1.105 23 to 19, incl 8

test flux densities encountered. Yoke construction may consist 0.0500 and over 1.27 and over 18 and thicker 4

of either stacked laminations or stripwound C cores suitably

bolted or adhesive bonded together.

measurement should be made on the upper two-thirds of the

5.3 Power Supply—The magnetizing current shall be sup-

scale. Analog integrators must have drift adjust circuitry and

plied by either storage batteries or dc power supplies. Bipolar

−6

thedriftshouldnotexceed100Maxwell-turns[10 Wb-turns]

programmable linear power supplies have been found to be

per minute on the most sensitive range. It is also desirable that

wellsuitedforthisuse.Thesourceofdccurrentmustbestable,

theintegratorhaveappropriatescalingcircuitrytopermitdirect

have negligible ripple and be capable of quickly returning to

reading of either flux (f) or flux density (B). Ballistic galva-

the stable state after switching. When programmable power

nometersormovingcoilfluxmetersarepermittedprovidedthe

suppliesareused,eitherdigitaloranalogprogrammingsignals

1% full-scale accuracy requirement is met. Such devices

are permissible provided that equal but opposite polarity

requireadditionalcircuitrynotshowninFig.1.Detailsmaybe

current cycling is possible.

found in the appropriate references appended to this test

5.4 Main-Current-Control Rheostats, R —When used,

method.

these rheostats must have sufficient power rating and heat-

5.11 B Coils—Prewound fixed flux sensing coils are often

dissipating capacity to handle the voltage and largest test

used. When used, the cross-sectional area enclosed by the

current and must contain sufficient resistance to limit the test

secondary winding and number of turns must be known to be

currentstothoserequiredforthelowestmagneticfieldstrength

better than 0.5%.

to be used.

5.12 Magnetic Field Strength Measuring Devices—Certain

5.5 Hysteresis-Current-Control Rheostats, R —When used,

permeameters do not or cannot use the magnetizing current to

these rheostats must have the same characteristics as the

determine the magnetic field strength accurately. Such per-

main-current control rheostats.

meameters instead use stationary H coils, flip coils, or Hall

5.6 Main-Current Ammeter, A —Magnetizing current mea-

probes. When such devices are used, they shall be capable of

surement shall be conducted using a digital ammeter or

determiningtheapparentmagneticfieldstrengthtoaccuracyof

combination of a digital voltmeter and precision shunt resistor

1.0% or better.

with an overall accuracy of better than 0.25% when the

magnetic field strength will be determined from the current. In

6. Test Specimens

those permeameters where the magnetic field strength is

6.1 Test specimen area shall normally be determined from

determined by other means, such as Hall probes or H coils,

mass, length, and density as indicated in 9.1 and 10.1. When

lower accuracy analog instruments can be used. In such

thetestspecimenismachinedorgroundtohaveaverysmooth

permeameters, the ammeter is used to prevent excessive

surface, the physical dimensions obtained from micrometer

currents from being applied and, based on past experience, to

measurements may be used to calculate the cross-sectional

roughly establish the required magnetic field strength.

area.

5.7 Hysteresis-Current Ammeter, A —The requirements of

6.2 Test specimens in bar form may be of round, square, or

5.6 shall apply. In general, a separate ammeter is not required.

rectangular cross-sectional shape. In some permeameters the

5.8 Reversing Switch, S —When nonprogrammable dc cur-

1 bar specimen may be a half round or any shape having a

rent sources such as storage batteries are used, a current

uniform cross-sectional area. Certain permeameters must have

reversing switch is required. The reversing switch should be

a good magnetic joint between the ends of the test specimen

either a high quality knife switch, mechanical or electrical

and the permeameter yoke or pole faces. Pole shoes may be

solenoid-operatedcontractorsormercuryswitcheshavinghigh

necessary to create this joint. Generally, to achieve a good

current rating and the ability to maintain uniform contact

magnetic joint, the test specimen must be of square or

resistance of equal magnitude in both current directions.

rectangular cross section and must be machined or ground to

Switches with contact bounce or other multiple contacting

have straight and parallel surfaces. For permeameters using

behavior on make or break must be avoided. Because of the

specimens butted to pole pieces, the specimen ends must be

presence of leakage currents in the open condition, solid state

smooth and parallel.

relays are not permitted.

6.3 When the material is in flat-rolled form and is to be

5.9 Hysteresis Switch, S —This single pole switch must

evaluated as half transverse-half longitudinal, the specimen

conform to the same requirements as the reversing Switch, S .

shall be sheared to have strips in multiples of four in accor-

5.10 Integrator, F—Because of their superior accuracy, dance with Table 2. When material is to be eval

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A 341/A341M–00 (Reapproved 2005) Designation:A341/A341M–00

´1

(Reapproved 2005)

Standard Test Method for

Direct Current Magnetic Properties of Materials Using D-C

Permeameters and the Ballistic Test Methods

ThisstandardisissuedunderthefixeddesignationA341/A341M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

´ NOTE—Mercury warning was editorially added in January 2009.

1. Scope

1.1 Thistestmethodprovidesdcpermeametertestsforthebasicmagneticpropertiesofmaterialsintheformofbars,rods,wire,

or strip specimens which may be cut, machined, or ground from cast, compacted, sintered, forged, extruded, rolled, or other

fabricatedmaterials.Itincludestestsfordeterminationofthenormalinductionundersymmetricallycyclicallymagnetized(SCM)

conditionsandthehysteresisloop(B-Hloop)takenunderconditionsofrapidlychangingorsteepwavefrontreversalsofthedirect

current magnetic field strength.

1.2 This test method shall be used in conjunction with Practice A34/A34M.

1.3 This test method covers a range of magnetic field strength in the specimen from about 0.05 Oe [4A/m] up to above 5000

Oe [400 kA/M] through the use of several permeameters.The separate permeameters cover this test region in several overlapping

ranges.

1.4 Normal induction and hysteresis properties may be determined over the flux density range from essentially zero to intrinsic

saturation for most materials.

1.5 RecommendationsoftheusefulmagneticfieldstrengthrangeforeachofthepermeametersareshowninTable1 .Also,see

Sections 3 and 4 for general limitations relative to the use of permeameters.

1.6 The symbols and abbreviated definitions used in this test method appear with Fig. 1 and in appropriate sections of this

document.Fortheofficialdefinitions,seeTerminologyA340.Notethatthetermfluxdensityusedinthisdocumentissynonymous

with the term magnetic induction.

1.7The values and equations stated in customary cgs-emu and inch-pound or SI units are to be regarded separately as standard.

Within this standard, SI units are shown in brackets except for the sections concerning calculations where there are separate

sectionsfortherespectiveunitsystems.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshall

be used independently of the other. Combining values from the two systems may result in nonconformance with this standard.

1.8

1.7 Warning—Mercury has been designated by EPA and many state agencies as a hazardous material that can cause central

nervous system, kidney, and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution

should be taken when handling mercury and mercury-containing products. See the applicable product Material Safety Data Sheet

(MSDS) for details and EPA’s website ( http://www.epa.gov/mercury/faq.htm) for additional information. Users should be aware

that selling mercury or mercury-containing products, or both, in your state may be prohibited by state law.

1.8 Thevaluesandequationsstatedincustomarycgs-emuandinch-poundorSIunitsaretoberegardedseparatelyasstandard.

Within this standard, SI units are shown in brackets except for the sections concerning calculations where there are separate

sectionsfortherespectiveunitsystems.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshall

be used independently of the other. Combining values from the two systems may result in nonconformance with this standard.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

This test method is under the jurisdiction ofASTM CommitteeA06 on Magnetic Properties and is the direct responsibility of SubcommitteeA06.01 on Test Methods.

Current edition approved Nov. 1, 2005. Published November 2005. Originally approved in 1969. Last previous edition approved in 2000 as A341/A341M–00.

The boldface numbers in parentheses refer to a list of references at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

A341/A341M–00 (2005)

2. Referenced Documents

2.1 ASTM Standards:

A34/A34M Practice for Sampling and Procurement Testing of Magnetic Materials

A340 Terminology of Symbols and Definitions Relating to Magnetic Testing

A596/A596M Test Method for Direct-Current Magnetic Properties of Materials Using the Ballistic Method and Ring

Specimens

2.2 IEC Standard:

Publication 60404-4, Ed. 2.0 Magnetic Materials – Part 4: Methods of Measurement of D.C. Magnetic Properties of Iron and

Steel, IEC, 1995

2.3 Other Documents:

NIST Circular No. 74, pg. 269

NIST Scientific Paper 117, SPBTA

3. Significance and Use

3.1 Permeameters require the use of yokes to complete the magnetic circuit and are therefore inherently less accurate than ring

test methods. Refer to Test MethodA596/A596M for further details on ring test methods. However, when testing certain shapes

asbarsorwhenmagneticfieldstrengthinexcessof200Oe[15.9ormorekA/m]arerequired,permeametersaretheonlypractical

means of measuring magnetic properties.

3.2 This test method is suitable for specification acceptance, service evaluation, research and development and design.

3.3 When the test specimen is fabricated from a larger sample and is in the same condition as the larger sample, it may not

exhibitmagneticpropertiesrepresentativeoftheoriginalsample.Insuchinstancesthetestresults,whenviewedincontextofpast

performance history, will be useful for judging the suitability of the material for the intended application.

4. Interferences

4.1 In general, permeameters do not maintain a uniform magnetic field in either the axial or radial directions around the test

specimen.Thefieldgradientsinbothofthesedirectionswilldifferinthevariouspermeameters.AlsotheH-sensingand B-sensing

coils of the different permeameters are not identical in area, in turns, or in length or identically located.Although test specimens

arepreparedtohaveuniform physical cross section, theymayhaveundetectednonuniformmagneticpropertiesradiallyoraxially

along the specimen length adjacent to the H or B coils. Some permeameters may also introduce clamping strains into the test

specimen. For the above reasons test results obtained on a test specimen with one type permeameter may not agree closely with

those obtained on the same test specimen using another type of permeameter.

5. Apparatus

5.1 Because of the differences in physical construction of the various permeameters listed in Table 1, no standard list of

components is given. When used with a particular type of permeameter, the components should conform to the general

requirements listed below. A basic schematic of a permeameter is shown in Fig. 1.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036.

Available from National Institute of Standards and Technology (NIST), 100 Bureau Dr., Stop 3460, Gaithersburg, MD 20899-3460.

TABLE 1 Permeameters

A

Magnetizing Coil

Useful Magnetic Field Strength Range

H Measuring Reluctance

Permeameter Surrounds References

B

Device Compensation

Oe kA/m Specimen

Babbit 40/1000 3.2/80 I, HC yes yes (1,2)

Burroughs 0.1/300 0.008/24 I yes yes (1,3,4,5)

C

Fahy Simplex 0.1/300 0.008/24 HC no no (1,4,5,6,7)

Fahy Simplex

100/2500 8/200 HC no no (1,3)

C

Super H adapter

Full range 0.05/1400 0.004/112 HC yes yes (1,8)

High H 100/5000 8/400 FC yes no (1,5,7,9)

Iliovici 0.5/500 0.04/400 I, HC yes yes (4,10,11)

IEC Type A 0.1/2500 0.008/200 HC, HP no yes IEC 60404-4

IEC Type B 0.1/630 0.008/50 RCC no no IEC 60404-4

Isthmus 100/20 000+ 8/1600+ HC, HP no no (1,4,12,13)

MH 0.1/300 0.008/24 FC yes yes (1,6,14)

NPL 0.5/2500 0.04/200 I, HC yes yes (15)

Saturation 100/4000 8/320 HC no yes (5,16,17)

A

Although the permeameters are capable of being used at the lower end of the measurement range, the measurement accuracy is reduced.

B

I—magnetizing current; HC—fixed H coil; FC—flip coil; HP—Hall probe; RCC—Rogowski-Chattock coil.

C

Fahy permeameters require a standard of known magnetic properties for calibration of the H coil.

´1

A341/A341M–00 (2005)

NOTE 1—

A —Multirange ammeter (main current)

A —Multirange ammeter (hysteresis current)

B—Flux density test position for Switch S

F—Electronic Integrator

H—Magnetic field strength test position for Switch S

N —Magnetizing coil

N —Flux sensing (B) coil

N —Magnetic field strength sensing coil

R —Main current control rheostat

R —Hysteresis current control rheostat

S —Reversing switch for magnetizing current

S —Shunting switch for hysteresis current control rheostat

S —Integrator selector switch

SP—Specimen

FIG. 1 Basic Circuit Using Permeameter

5.2 Permeameter—The particular permeameter used shall be of high quality construction. The yokes should be made of high

permeability alloy such as oriented or nonoriented silicon iron or nickel-iron alloy, although low carbon steel or iron is acceptable

in certain instances. The preferred yolk dimensions are listed in the appended references (see Table 1). Deviations from these

dimensions should be such that the yolk is operating at or below the point of maximum permeability for the highest test flux

densities encountered. Yoke construction may consist of either stacked laminations or stripwound C cores suitably bolted or

adhesive bonded together.

5.3 Power Supply—The magnetizing current shall be supplied by either storage batteries or dc power supplies. Bipolar

programmable linear power supplies have been found to be well suited for this use.The source of dc current must be stable, have

negligible ripple and be capable of quickly returning to the stable state after switching. When programmable power supplies are

used, either digital or analog programming signals are permissible provided that equal but opposite polarity current cycling is

possible.

5.4 Main-Current-Control Rheostats, R —When used, these rheostats must have sufficient power rating and heat-dissipating

capacity to handle the voltage and largest test current and must contain sufficient resistance to limit the test currents to those

required for the lowest magnetic field strength to be used.

5.5 Hysteresis-Current-Control Rheostats, R —When used, these rheostats must have the same characteristics as the

main-current control rheostats.

5.6 Main-Current Ammeter, A —Magnetizing current measurement shall be conducted using a digital ammeter or combination

of a digital voltmeter and precision shunt resistor with an overall accuracy of better than 0.25% when the magnetic field strength

will be determined from the current. In those permeameters where the magnetic field strength is determined by other means, such

as Hall probes or H coils, lower accuracy analog instruments can be used. In such permeameters, the ammeter is used to prevent

excessive currents from being applied and, based on past experience, to roughly establish the required magnetic field strength.

5.7 Hysteresis-Current Ammeter, A —The requirements of 5.6 shall apply. In general, a separate ammeter is not required.

5.8 Reversing Switch, S — When nonprogrammable dc current sources such as storage batteries are used, a current reversing

switch is required. The reversing switch should be either a high quality knife switch, mechanical or electrical solenoid-operated

contractors or mercury switches having high current rating and the ability to maintain uniform contact resistance of equal

magnitude in both current directions. Switches with contact bounce or other multiple contacting behavior on make or break must

be avoided. Because of the presence of leakage currents in the open condition, solid state relays are not permitted.

5.9 Hysteresis Switch, S — This single pole switch must conform to the same requirements as the reversing Switch, S .

2 1

5.10 Integrator, F—Because of their superior accuracy, stability, and ease of operation, electronic charge integrators are the

preferred means of measuring magnetic flux. Integrators using either operational amplifier and capacitor feedback (analog

integrator) or pulse counting are permitted. The accuracy of the integrator must be better than 1% full scale. If analog display

metersareusedtoreadthevalueofflux,themeasurementshouldbemadeontheuppertwo-thirdsofthescale.Analogintegrators

´1

A341/A341M–00 (2005)

−6

musthavedriftadjustcircuitryandthedriftshouldnotexceed100Maxwell-turns[10 Wb-turns]perminuteonthemostsensitive

range. It is also desirable that the integrator have appropriate scaling circuitry to permit direct reading of either flux (f)orflux

density (B). Ballistic galvanometers or moving coil fluxmeters are permitted provided the 1% full-scale accuracy requirement is

met. Such devices require additional circuitry not shown in Fig. 1. Details may be found in the appropriate references appended

to this test method.

5.11 B Coils—Prewoundfixedfluxsensingcoilsareoftenused.Whenused,thecross-sectionalareaenclosedbythesecondary

winding and number of turns must be known to be better than 0.5%.

5.12 Magnetic Field Strength Measuring Devices—Certain permeameters do not or cannot use the magnetizing current to

determinethemagneticfieldstrengthaccurately.SuchpermeametersinsteadusestationaryHcoils,flipcoils,orHallprobes.When

such devices are used, they shall be capable of determining the apparent magnetic field strength to accuracy of 1.0% or better.

6. Test Specimens

6.1 Testspecimenareashallnormallybedeterminedfrommass,length,anddensityasindicatedin9.1and10.1.Whenthetest

specimenismachinedorgroundtohaveaverysmoothsurface,thephysicaldimensionsobtainedfrommicrometermeasurements

may be used to calculate the cross-sectional area.

6.2 Test specimens in bar form may be of round, squ

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

An American National Standard Designation: A 341/A 341M – 00 (Reapproved 2005)

Designation:A 341/A341M–95

Standard Test Method for

Direct Current Magnetic Properties of Materials Using D-C

Permeameters and the Ballistic Test Methods

ThisstandardisissuedunderthefixeddesignationA341/A341M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ThisstandardisissuedunderthefixeddesignationA341/A341M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

´ NOTE—Mercury warning was editorially added in January 2009.

1. Scope

1.1 Thistestmethodprovidesdcpermeametertestsforthebasicmagneticpropertiesofmaterialsintheformofbars,rods,wire,

or strip specimens which may be cut, machined, or ground from cast, compacted, sintered, forged, extruded, rolled, or other

fabricatedmaterials.Itincludestestsfordeterminationofthenormalinductionundersymmetricallycyclicallymagnetized(SCM)

conditionsandthehysteresisloop(B-Hloop)takenunderconditionsofrapidlychangingorsteepwavefrontreversalsofthedirect

current magnetic field strength.

1.2 This test method shall be used in conjunction with Practice A34/A34M.

1.3 This test method covers a range of magnetic field strength in the specimen from about 0.05 Oe [4A/m] up to above 5000

Oe [400 kA/M] through the use of several permeameters.The separate permeameters cover this test region in several overlapping

ranges.

1.4 Normal induction and hysteresis properties may be determined over the flux density range from essentially zero to intrinsic

saturation for most materials.

1.5 RecommendationsoftheusefulmagneticfieldstrengthrangeforeachofthepermeametersareshowninTable1 .Also,see

Sections 3 and 4 for general limitations relative to the use of permeameters.

1.6 The symbols and abbreviated definitions used in this test method appear with Fig. 1 and in appropriate sections of this

document.Fortheofficialdefinitions,seeTerminologyA340.Notethatthetermfluxdensityusedinthisdocumentissynonymous

with the term magnetic induction.

1.7The values stated in either customary (absolute (or practical) cgs-emu and inch-pound) units or SI units are to be regarded

separately as standard. Within this test method, the SI units are shown in brackets except for the sections concerning calculations

where there are separate sections for the respective unit systems. The values stated in each system are not exact equivalents;

therefore, each system shall be used independently of the other. Combining values from the two systems may result in

nonconformance with this specification.

1.8This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.7 Warning—Mercury has been designated by EPA and many state agencies as a hazardous material that can cause central

nervous system, kidney, and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution

should be taken when handling mercury and mercury-containing products. See the applicable product Material Safety Data Sheet

(MSDS) for details and EPA’s website ( http://www.epa.gov/mercury/faq.htm) for additional information. Users should be aware

that selling mercury or mercury-containing products, or both, in your state may be prohibited by state law.

1.8 Thevaluesandequationsstatedincustomarycgs-emuandinch-poundorSIunitsaretoberegardedseparatelyasstandard.

Within this standard, SI units are shown in brackets except for the sections concerning calculations where there are separate

sectionsfortherespectiveunitsystems.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshall

be used independently of the other. Combining values from the two systems may result in nonconformance with this standard.

ThistestmethodisunderthejurisdictionofASTMCommitteeA-6A06onMagneticPropertiesandisthedirectresponsibilityofSubcommitteeA06.01onTestMethods.

Current edition approved Feb. 15, 1995.Nov. 1, 2005. Published April 1995.November 2005. Originally published as A341–69.approved in 1969. Last previous edition

A341–89´ approved in 2000 asA341/A341M–00.

The boldface numbers in parentheses refer to a list of references at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

A341/A341M–00 (2005)

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

A34PracticeforProcurement,TestingandSamplingofMagneticMaterials 34/A34M PracticeforSamplingandProcurement

Testing of Magnetic Materials

A340 Terminology of Symbols and Definitions Relating to Magnetic Testing Testing

A596Test Method for Direct Current Magnetic Properties of Materials Using the Ballistic Method and Ring Specimens

A773Test Method for dc Magnetic Properties of Materials Using Ring and Permeameter Procedures with dc Electronic

Hysteresigraphs 596/A596M Test Method for Direct-Current Magnetic Properties of Materials Using the Ballistic Method

and Ring Specimens

2.2 IEC Standard:

Publication404-4MagneticMaterialsPart4:MethodsofMeasurementoftheD-CMagneticPropertiesofSolidSteel,IEC,1982.

Publication 60404-4, Ed. 2.0 Magnetic Materials – Part 4: Methods of Measurement of D.C. Magnetic Properties of Iron and

Steel, IEC, 1995

2.3 Other Documents:Other Documents:

NIST Circular No. 74, pg. 269

NISTCircular No. 74, pg. 269.

NISTScientific Paper 117, SPBTA

NIST Scientific Paper 117, SPBTA

Annual Book of ASTM Standards, Vol 03.04.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute, 11 Institute (ANSI), 25 W. 42nd43rd St., 13th4th Floor, New York, NY 10036.

Available from National Institute of Standards and Technology, (NIST), Gaithersburg, MD 20899.

Available from National Institute of Standards and Technology (NIST), 100 Bureau Dr., Stop 3460, Gaithersburg, MD 20899-3460.

TABLE 1 Permeameters

Useful Magnetizingc Foield Strcength

Magnetizing Coils

A

H Measuring Reluctance

Range

Permeameter Surrounds References

B

Device Comp.ensation

Specimen

Oersteds kA/M

m

Babbit 40/1 000 3 200/80 000 I, HC yes yes (1,2)

Babbit 40/1000 3.2/80 I, HC yes yes (1,2)

Burroughs 0.1/300 8/24 000 I yes yes (1,3,4,5)

Burroughs 0.1/300 0.008/24 I yes yes (1,3,4,5)

C

Fahy Simplex 0.1/300 8/24 000 HC no no (1,4,5,6,7)

C

Fahy Simplex 0.1/300 0.008/24 HC no no (1,4,5,6,7)

Fahy Simplex

100/2 500 8 000/200 000 HC no no (1,3)

C

Super H Adapter

Fahy Simplex

100/2500 8/200 HC no no (1,3)

C

Super H adapter

Full Range 0.05/1 400 4/1 100 HC yes yes (1,8)

Full range 0.05/1400 0.004/112 HC yes yes (1,8)

D

High H 100/5 000 8 000/400 000 FC yes no (1,5,7,9)

High H 100/5000 8/400 FC yes no (1,5,7,9)

D

Iliovici 0.5/500 40/400 000 I, HC yes yes (4,10,11)

Iliovici 0.5/500 0.04/400 I, HC yes yes (4,10,11)

Isthmus 100/20 000 + 8 000/1 600 000 + HC, HP no yes IEC 60404-4

IEC Type A 0.1/2500 0.008/200 HC, HP no yes IEC 60404-4

IEC Type B 0.1/630 0.008/50 RCC no no IEC 60404-4

Isthmus 100/20 000+ 8/1600+ HC, HP no no (1,4,12,13)

D

MH 0.1/300 8/2 400 FC yes yes (1,6,14)

MH 0.1/300 0.008/24 FC yes yes (1,6,14)

D

NPL 0.5/2 500 40/200 000 I, HC yes yes (15)

NPL 0.5/2500 0.04/200 I, HC yes yes (15)

Saturation 100/4 000 8 000/400 000 HC no yes (5,16,17)

Saturation 100/4000 8/320 HC no yes (5,16,17)

A

Although the permeameters are capable of being used at the lower end of the measurement range, the measurement accuracy is reduced. Best overall accuracy is

obtained for a combination of high flux density and high magnetic field strength such as is encountered in the testing of permanent magnet materials.

B

I—magnetizing current; HC—fixed H-coil; FC—flip coil; HP—Hall P probe; RCC—Rogowski-Chattock coil.

C

Fahy permeameters require a standard of known magnetic properties for calibration of the H-coil.

D

These permeameters are recommended by the International Electrotechnical Commission.

´1

A341/A341M–00 (2005)

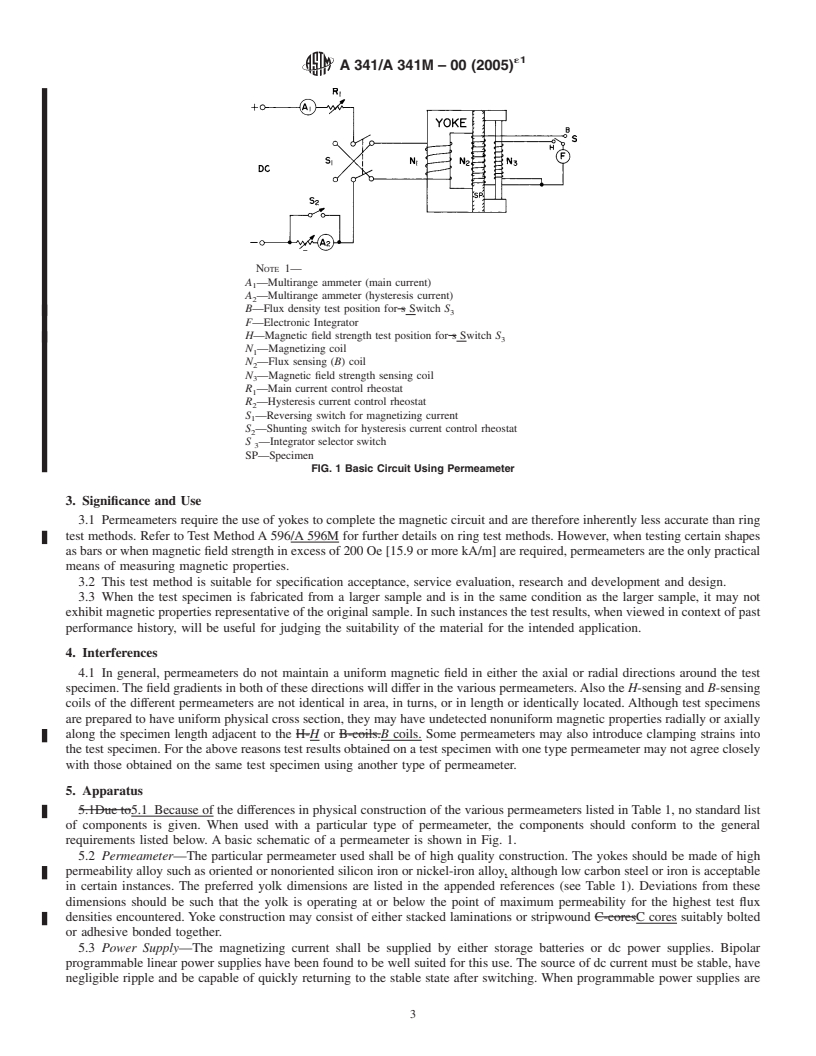

NOTE 1—

A —Multirange ammeter (main current)

A —Multirange ammeter (hysteresis current)

B—Flux density test position for s Switch S

F—Electronic Integrator

H—Magnetic field strength test position for s Switch S

N —Magnetizing coil

N —Flux sensing (B) coil

N —Magnetic field strength sensing coil

R —Main current control rheostat

R —Hysteresis current control rheostat

S —Reversing switch for magnetizing current

S —Shunting switch for hysteresis current control rheostat

S —Integrator selector switch

SP—Specimen

FIG. 1 Basic Circuit Using Permeameter

3. Significance and Use

3.1 Permeameters require the use of yokes to complete the magnetic circuit and are therefore inherently less accurate than ring

test methods. Refer to Test MethodA596/A596M for further details on ring test methods. However, when testing certain shapes

asbarsorwhenmagneticfieldstrengthinexcessof200Oe[15.9ormorekA/m]arerequired,permeametersaretheonlypractical

means of measuring magnetic properties.

3.2 This test method is suitable for specification acceptance, service evaluation, research and development and design.

3.3 When the test specimen is fabricated from a larger sample and is in the same condition as the larger sample, it may not

exhibitmagneticpropertiesrepresentativeoftheoriginalsample.Insuchinstancesthetestresults,whenviewedincontextofpast

performance history, will be useful for judging the suitability of the material for the intended application.

4. Interferences

4.1 In general, permeameters do not maintain a uniform magnetic field in either the axial or radial directions around the test

specimen.Thefieldgradientsinbothofthesedirectionswilldifferinthevariouspermeameters.AlsotheH-sensingandB-sensing

coils of the different permeameters are not identical in area, in turns, or in length or identically located.Although test specimens

are prepared to have uniform physical cross section, they may have undetected nonuniform magnetic properties radially or axially

along the specimen length adjacent to the H-H or B-coils.B coils. Some permeameters may also introduce clamping strains into

thetestspecimen.Fortheabovereasonstestresultsobtainedonatestspecimenwithonetypepermeametermaynotagreeclosely

with those obtained on the same test specimen using another type of permeameter.

5. Apparatus

5.1Due to5.1 Because of the differences in physical construction of the various permeameters listed inTable 1, no standard list

of components is given. When used with a particular type of permeameter, the components should conform to the general

requirements listed below. A basic schematic of a permeameter is shown in Fig. 1.

5.2 Permeameter—The particular permeameter used shall be of high quality construction. The yokes should be made of high

permeability alloy such as oriented or nonoriented silicon iron or nickel-iron alloy, although low carbon steel or iron is acceptable

in certain instances. The preferred yolk dimensions are listed in the appended references (see Table 1). Deviations from these

dimensions should be such that the yolk is operating at or below the point of maximum permeability for the highest test flux

densities encountered.Yoke construction may consist of either stacked laminations or stripwound C-coresC cores suitably bolted

or adhesive bonded together.

5.3 Power Supply—The magnetizing current shall be supplied by either storage batteries or dc power supplies. Bipolar

programmable linear power supplies have been found to be well suited for this use.The source of dc current must be stable, have

negligible ripple and be capable of quickly returning to the stable state after switching. When programmable power supplies are

´1

A341/A341M–00 (2005)

used, either digital or analog programming signals are permissible provided that equal but opposite polarity current cycling is

possible.

5.4 Main-Current-Control Rheostats, R —When used, these rheostats must have sufficient power rating and heat-dissipating

capacity to handle the voltage and largest test current and must contain sufficient resistance to limit the test currents to those

required for the lowest magnetic field strength to be used.

5.5 Hysteresis-Current-Control Rheostats, R —When used, these rheostats must have the same characteristics as the

main-current control rheostats.

5.6 Main-Current Ammeter, A —Magnetizing current measurement shall be conducted using a digital ammeter or combination

of a digital voltmeter and precision shunt resistor with an overall accuracy of better than 0.25% when the magnetic field strength

will be determined from the current. In those permeameters where the magnetic field strength is determined by other means, such

as Hall probes or H-coils,H coils, lower accuracy analog instruments can be used. In such permeameters, the ammeter is used to

prevent excessive currents from being applied and, based on past experience, to roughly establish the required magnetic field

strength.

5.7 Hysteresis-Current-Ammeter, A —The requirements of 5.6 shall apply. In general, a separate

Hysteresis-Current Ammeter, A

ammeter is not required.

5.8 Reversing Switch, S — When nonprogrammable dc current sources such as storage batteries are used, a current reversing

switch is required. The reversing switch should be either a high quality knife switch, mechanical or electrical solenoid-operated

contractors or mercury switches having hig

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.