ASTM A977/A977M-07(2020)

(Test Method)Standard Test Method for Magnetic Properties of High-Coercivity Permanent Magnet Materials Using Hysteresigraphs

Standard Test Method for Magnetic Properties of High-Coercivity Permanent Magnet Materials Using Hysteresigraphs

SIGNIFICANCE AND USE

4.1 This test method is suitable for magnet specification, acceptance, service evaluation, quality control in magnet production, research and development, and design.

4.2 When a test specimen is cut or fabricated from a larger magnet, the magnetic properties measured on it are not necessarily exactly those of the original sample, even if the material is in the same condition. In such instances, the test results must be viewed in context of part performance history.

4.3 Tests performed in general conformity to this test method and even on the same specimen, but using different test systems, may not yield identical results. The main source of discrepancies are variations between the different test systems in the geometry of the region surrounding the sample, such as, size and shape of the electromagnet pole caps (see Annex A1 and Appendix X1), air gaps at the specimen end faces, and especially the size and location of the measuring devices for H and B or for their corresponding flux values (Hall-effect probes, inductive sensing coils). Also important is the method of B calibration, for example, a volt-second calibration of the fluxmeter alone versus an overall system calibration using a physical reference sample. The method of B and H sensing should be indicated in test reports (see Section 9).

SCOPE

1.1 This test method covers how to determine the magnetic characteristics of magnetically hard materials (permanent magnets), particularly their initial magnetization, demagnetization, and recoil curves, and such quantities as the residual induction, coercive field strength, knee field, energy product, and recoil permeability. This test method is suitable for all materials processed into bulk magnets by any common fabrication technique (casting, sintering, rolling, molding, and so forth), but not for thin films or for magnets that are very small or of unusual shape. Uniformity of composition, structure, and properties throughout the magnet volume is necessary to obtain repeatable results. Particular attention is paid to the problems posed by modern materials combining very high coercivity with high saturation induction, such as the rare-earth magnets, for which older test methods (see Test Method A341/A341M) are unsuitable. An applicable international standard is IEC Publication 60404-5.

1.2 The magnetic system (circuit) in a device or machine generally comprises flux-conducting and nonmagnetic structural members with air gaps in addition to the permanent magnet. The system behavior depends on properties and geometry of all these components and on the operating temperature. This test method describes only how to measure the properties of the permanent magnet material. The basic test method incorporates the magnetic specimen in a magnetic circuit with a closed flux path. Test methods using ring samples or frames composed entirely of the magnetic material to be characterized, as commonly used for magnetically soft materials, are not applicable to permanent magnets.

1.3 This test method shall be used in conjunction with Practice A34/A34M.

1.4 The values and equations stated in customary (cgs-emu or inch-pound) or SI units are to be regarded separately as standard. Within this test method, SI units are shown in brackets except for the sections concerning calculations where there are separate sections for the respective unit systems. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with this test method.

1.5 The names and symbols of magnetic quantities used in this test method, summarized in Table 1, are those generally accepted by the industry.

1.6 This test method is useful for magnet materials having Hci values between about 100 Oe and 35 kOe [8 kA/m and 2.8 MA/m], and Br values in the approximate range from 500 G to 20 kG [50 mT to...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A977/A977M − 07 (Reapproved 2020)

Standard Test Method for

Magnetic Properties of High-Coercivity Permanent Magnet

Materials Using Hysteresigraphs

This standard is issued under the fixed designationA977/A977M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope brackets except for the sections concerning calculations where

there are separate sections for the respective unit systems. The

1.1 This test method covers how to determine the magnetic

values stated in each system may not be exact equivalents;

characteristics of magnetically hard materials (permanent

therefore,eachsystemshallbeusedindependentlyoftheother.

magnets), particularly their initial magnetization,

Combining values from the two systems may result in noncon-

demagnetization, and recoil curves, and such quantities as the

formance with this test method.

residual induction, coercive field strength, knee field, energy

product, and recoil permeability. This test method is suitable 1.5 The names and symbols of magnetic quantities used in

for all materials processed into bulk magnets by any common this test method, summarized in Table 1, are those generally

fabrication technique (casting, sintering, rolling, molding, and accepted by the industry.

so forth), but not for thin films or for magnets that are very

1.6 This test method is useful for magnet materials having

small or of unusual shape. Uniformity of composition,

H values between about 100 Oe and 35 kOe [8 kA/m and 2.8

ci

structure, and properties throughout the magnet volume is

MA/m], and B values in the approximate range from 500 G to

r

necessary to obtain repeatable results. Particular attention is

20 kG [50 mT to 2 T]. High-coercivity rare-earth magnet test

paid to the problems posed by modern materials combining

specimens may require much higher magnetizing fields than

very high coercivity with high saturation induction, such as the

iron-core electromagnets can produce. Such samples must be

rare-earth magnets, for which older test methods (see Test

premagnetized externally and transferred into the measuring

Method A341/A341M) are unsuitable. An applicable interna-

yoke. Typical values of the magnetizing fields, H , required

mag

tional standard is IEC Publication 60404-5.

for saturating magnet materials are shown in Table A2.1.

1.2 The magnetic system (circuit) in a device or machine

1.7 This standard does not purport to address all of the

generally comprises flux-conducting and nonmagnetic struc-

safety concerns, if any, associated with its use. It is the

tural members with air gaps in addition to the permanent

responsibility of the user of this standard to establish appro-

magnet. The system behavior depends on properties and

priate safety, health, and environmental practices and deter-

geometry of all these components and on the operating

mine the applicability of regulatory limitations prior to use.

temperature. This test method describes only how to measure

1.8 This international standard was developed in accor-

the properties of the permanent magnet material.The basic test

dance with internationally recognized principles on standard-

method incorporates the magnetic specimen in a magnetic

ization established in the Decision on Principles for the

circuitwithaclosedfluxpath.Testmethodsusingringsamples

Development of International Standards, Guides and Recom-

or frames composed entirely of the magnetic material to be

mendations issued by the World Trade Organization Technical

characterized, as commonly used for magnetically soft

Barriers to Trade (TBT) Committee.

materials, are not applicable to permanent magnets.

2. Referenced Documents

1.3 This test method shall be used in conjunction with

Practice A34/A34M.

2.1 ASTM Standards:

A34/A34M Practice for Sampling and Procurement Testing

1.4 The values and equations stated in customary (cgs-emu

of Magnetic Materials

or inch-pound) or SI units are to be regarded separately as

A340 Terminology of Symbols and Definitions Relating to

standard. Within this test method, SI units are shown in

Magnetic Testing

This test method is under the jurisdiction of ASTM Committee A06 on

MagneticPropertiesandisthedirectresponsibilityofSubcommitteeA06.01onTest

Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

CurrenteditionapprovedJune1,2020.PublishedJuly2020.Originallyapproved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 1997. Last previous edition approved in 2013 as A977/A977M – 07 (2013). DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/A0977_A0977M-07R20. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A977/A977M − 07 (2020)

TABLE 1 Symbols, Quantities, and Units

4.3 Tests performed in general conformity to this test

methodandevenonthesamespecimen,butusingdifferenttest

NOTE 1—IEC nomenclature calls B “remanence,” when B represents

r r

systems, may not yield identical results. The main source of

the B at H = 0 of the outermost hysteresis loop, and it calls B “remanent

r

magnetic induction” for B at H = 0 at smaller loops.

discrepancies are variations between the different test systems

Customary in the geometry of the region surrounding the sample, such as,

Symbol Quantity SI Unit

cgs-emu

size and shape of the electromagnet pole caps (see Annex A1

2 2

A Cross section of search coil [m]cm

t

and Appendix X1), air gaps at the specimen end faces, and

B Magnetic induction at BH [T] G

d max

especially the size and location of the measuring devices for H

B Magnetic induction at low point of [T] G

rec

recoil loop and B or for their corresponding flux values (Hall-effect

B Magnetic induction at remanence [T] G

r

probes, inductive sensing coils). Also important is the method

d Diameter of pole piece [m] cm

l

of B calibration, for example, a volt-second calibration of the

d Diameter of homogeneous field [m] cm

H Magnetic field strength at BH [A/m] Oe

fluxmeter alone versus an overall system calibration using a

d max

H Magnetic field strength at low [A/m] Oe

p

physical reference sample. The method of B and H sensing

point of

should be indicated in test reports (see Section 9).

recoil loop

l Distance between pole faces [m] cm

l Length of test sample [m] cm

r

5. Measuring Methods and Apparatus

N Number of turns of test coil

e Voltage induced in test coil V V

5.1 Measuring Flux and Induction (Flux Density):

d Total air gap between test [m] cm

5.1.1 In the preferred B-measuring method, the total flux is

sample and

pole faces measured with a sensing coil (search coil) that surrounds the

µ A constant with value µ =4π

0 0

test specimen and is wound as closely as possible to the

-7

specimen surface. Its winding length should be no more than a

H/m

µ Recoil permability

third of the specimen length, preferably less than one fifth, and

rec

must be centered on the specimen. The leads shall be twisted

tightly.Asthefluxchangesinresponsetosweepingtheapplied

field, H, the total flux is measured by taking the time integral

A341/A341M Test Method for Direct Current Magnetic of the voltage induced in this coil. This measurement is taken

Properties of Soft Magnetic Materials Using D-C Per- with a fluxmeter. Modern hysteresigraphs use electronic inte-

meameters and the Point by Point (Ballistic)Test Methods grating fluxmeters that allow convenient continuous integra-

E177 Practice for Use of the Terms Precision and Bias in tion and direct graphic recording of magnetization curves. If

ASTM Test Methods the signal is large enough, high-speed voltage sampling at the

coil and digital integration is also possible.

2.2 Magnetic Materials Procedure Association Standard:

5.1.2 The magnetic induction B is determined by dividing

MMPANo. 0100–00 Standard Specifications for Permanent

the total flux by the area-turns product NA of the B-sensing

Magnet Materials

coil. For permanent magnets in general, and especially for

2.3 International Electrotechnical Commission Document:

high-coercivitymaterials,anair-fluxcorrectionisrequired(see

Publication 60404-5 Magnetic Materials– Part 5: Permanent

5.1.5).

Magnet (Magnetically Hard) Materials – Methods of

5.1.3 Thetotalerrorofmeasuring Bshallbenotgreaterthan

Measurement of Magnetic Properties

62%.

5.1.4 The change of magnetic induction, ∆ B = B – B,in

2 1

3. Terminology

thetimeintervalbetweenthetimes t and t isgivenasfollows:

1 2

3.1 Basic magnetic units are defined in Terminology A340

t

and MMPA No. 0100–00. Additional definitions with symbols ∆ B 5 10 /AN edt customary units (1)

~ ! * ~ !

t

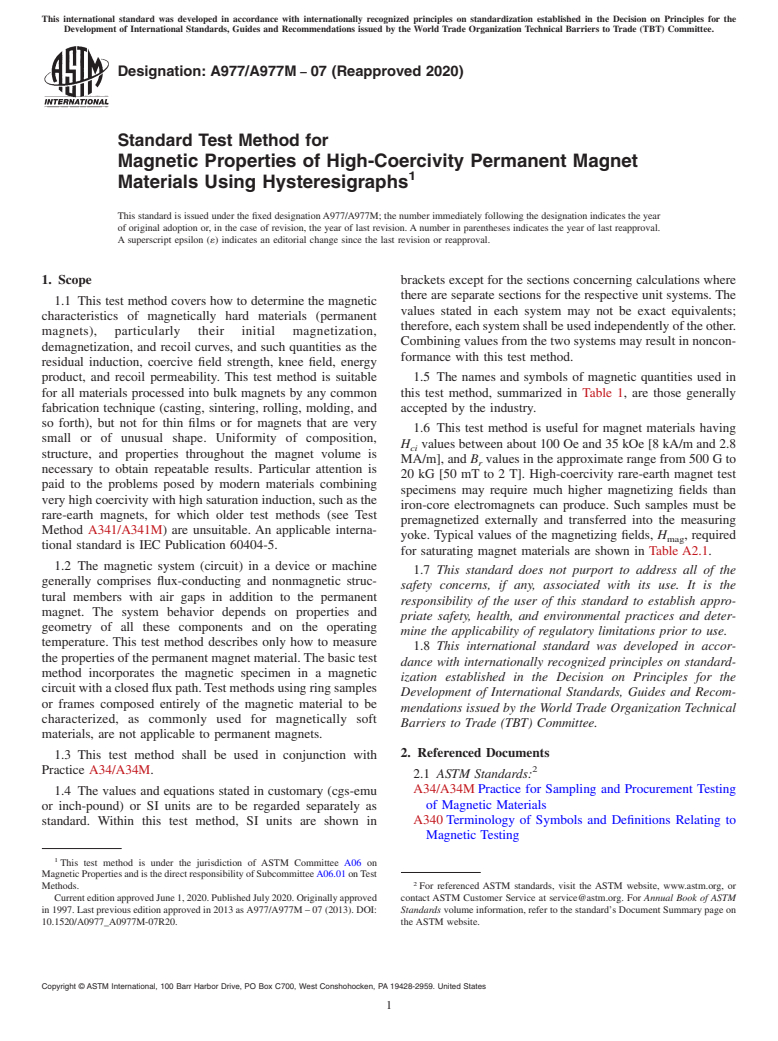

and units are given in Table 1 and Figs. 1-3 of this test method.

t

∆ B 5 1/AN edt SI units (2)

~ ! * ~ !

t

4. Significance and Use

where:

4.1 This test method is suitable for magnet specification,

B = magnetic induction, G [T];

acceptance, service evaluation, quality control in magnet

2 2

A = cross-sectional area of the test specimen, cm [m ];

production, research and development, and design.

N = number of turns on the B-sensing coil;

e = voltage induced in the coil, V;

4.2 When a test specimen is cut or fabricated from a larger

t = time, s; and

magnet, the magnetic properties measured on it are not

t

*

edt = voltage integral = flux, V-s [Weber].

necessarily exactly those of the original sample, even if the t

material is in the same condition. In such instances, the test

5.1.5 The change in the magnetic induction shall be cor-

results must be viewed in context of part performance history.

rectedtotakeintoaccounttheairfluxoutsidethetestspecimen

that is linked by the sensing coil. The corrected change, B ,

corr

is given as follows:

Available from Magnetic Materials ProducersAssociation, 8 S. MichiganAve.,

t

Suite 1000, Chicago, IL 60603.

∆ B 5 ~10 /AN! edt 2 ∆ H ~A 2 A!/A ~customary units!

*

corr t

4 t

Available from International Electrotechnical Commission (IEC), 3 rue de

Varembé, P.O. Box 131, CH-1211, Geneva 20, Switzerland. (3)

A977/A977M − 07 (2020)

FIG. 1 Normal and Intrinsic Hysteresis Loops and Initial Magnetization Curves for Permanent Magnet Materials Illustrating Two Ex-

tremes of Virgin Sample Behavior

t

5.2 Determining Intrinsic Induction :

∆B 5 ~1/AN! edt 2 µ ∆H ~A 2 A!/A ~SI units! (4)

*

corr 0 t

t

5.2.1 For high-coercivity magnets, it is more convenient to

where:

sense directly an electrical signal proportional to the intrinsic

A = average cross-sectional area of the sensing coil, induction, derive the average B by dividing this flux by the

i

2 2

cm [m ];

area-turns product of the surrounding B coil, and to plot B

i

∆ H = change in field from t until t , Oe [A/m]; and

1 2 versus H. B then is obtained by mathematical or electronic

-7

µ = magnetic constant [4π 10 H/m].

addition of H to B.

A977/A977M − 07 (2020)

t

∆ B 5 ~10 / AN! * edt ~customary units! (5)

i

t

t

∆B 5 ~1/AN! * edt ~SI units! (6)

i

t

where:

B = intrinsic induction, G [T];

i

2 2

A = cross section of the test specimen, cm [m ]; and

N = number of turns on Coil 1 containing the test specimen.

5.2.3 The two-sensing-coil device shall lie totally within the

homogeneous field defined by Eq A1.1 and Eq A1.2. Test

specimens of lower-coercivity magnets having a range of

cross-sectional areas and shapes can then be measured with the

samecoildevice.Anarrangementofside-by-sidecoilsofequal

size is useful. Serious errors, however, are incurred when

measuring B this way on high-B or high/coercivity magnets,

i r

or both, at applied fields of about 10 kOe or more. The errors

are most severe for test specimens of short pole-to-pole length.

Local pole-piece saturation causes strong field inhomogene-

ities. The specimen then must fill the cross section of Coil 1,

FIG. 2 Normal and Intrinsic Demagnetization Curves with Sym-

bols for Special Points of Interest and Definition of Salient Prop-

andCoil2mustbeathinandflatcoil,oracoaxialannularcoil,

erties. Illustration of Maximum Energy Product, Coercive Fields,

either centered on the specimen or in close proximity to its

and Definition of Knee Field

surface (see 5.3).

5.2.4 The total error of measuring B shall be not greater

i

than 62%.

5.3 Measuring the Magnetic Field Strength:

5.3.1 For correct magnetization curves, one should know

the magnetic field strength, H, inside the test specimen,

averaged over the specimen volume if H is not uniform. But

this inner field cannot be measured. At the surface of the test

specimen, H is equal to the local field strength just inside the

specimen in those locations (and only there) where the H

vectorisparalleltothesidesurfaceofthespecimen.Therefore,

a magnetic field strength sensor of small dimensions relative to

the specimen is placed near the specimen surface and sym-

metrical with respect to the end faces, covering the shortest

possible center portion of the specimen length. It shall be so

oriented that it correctly measures the tangential field compo-

nent.

5.3.2 To determine the magnetic field strength, a flat surface

coil, a tightly fitted annular coil, a magnetic potentiometer, or

FIG. 3 Normal and Intrinsic Demagnetization Curves with Sym-

a Hall probe is used together with suitable instruments. The

bols for Special Points of Interest and Definition of Salient Prop-

dimensions of the magnetic field sensor and its location shall

erties. Illustration of Recoil Loop. Recoil Permeability is Defined

be such that it is within an area of limited diameter around the

as µ = ∆B/∆H

rec

test specimen (see Annex A1).

5.3.3 The provisions of 5.3.2 are adequate for measure-

ments on magnets having low-to-moderate intrinsic coercivity,

such as Alnico and bonded ferrites. For high-coercivity, dense

5.2.2 The change of intrinsic induction in the test specimen

ferrites and especially for most rare earth-transition metal

can be determined by integrating the voltage induced in a

materials, it is essential for accurate measurement to use thin

device comprising two sensing coils, both subject to the same

flat or radially thin annular H-sensing coils of short length

applied field H, where the test specimen is contained in only

(<1/5 to 1/3 of the specimen length), centered on the specimen

one of the coils (Coil 1). If each individual coil has the same

and placed as close as possible to the specimen surfac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.