ASTM D6663-08(2013)

(Specification)Standard Specification for Woven and Knitted Comforter and Accessory Products for Institutional and Household Use

Standard Specification for Woven and Knitted Comforter and Accessory Products for Institutional and Household Use

SCOPE

1.1 This specification covers the evaluation of specific performance characteristics of importance in woven and knit comforter and accessory products, except for pillows and window treatments, for use in institutional and household environments.

1.2 The following safety hazards caveat pertains only to the test methods described in this specification: This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6663 −08 (Reapproved 2013)

Standard Specification for

Woven and Knitted Comforter and Accessory Products for

Institutional and Household Use

This standard is issued under the fixed designation D6663; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D3787 Test Method for Bursting Strength of Textiles—

Constant-Rate-of-Traverse (CRT) Ball Burst Test

1.1 This specification covers the evaluation of specific

D3882 Test Method for Bow and Skew in Woven and

performance characteristics of importance in woven and knit

Knitted Fabrics

comforter and accessory products, except for pillows and

D5034 TestMethodforBreakingStrengthandElongationof

window treatments, for use in institutional and household

Textile Fabrics (Grab Test)

environments.

2.2 AATCC Standards:

1.2 The following safety hazards caveat pertains only to the

Test Method 8 Colorfastness to Crocking: AATCC Crock-

test methods described in this specification: This standard may

meter Method

involve hazardous materials, operations, and equipment. This

Test Method 15 Colorfastness to Perspiration

standard does not purport to address all of the safety concerns,

Test Method 16 Colorfastness to Light

if any, associated with its use. It is the responsibility of the user

Test Method 61 Colorfastness to Laundering, Home and

of this standard to establish appropriate safety and health

Commercial: Accelerated

practices and determine the applicability of regulatory limita-

Test Method 88B Appearance of Seams in Durable Press

tions prior to use.

Items After Repeated Home Launderings

Test Method 96 Dimensional Changes in Commercial Laun-

2. Referenced Documents

dering of Woven and Knitted Fabrics Except Wool

2.1 ASTM Standards: Test Method 116 Colorfastness to Crocking: Rotary Vertical

D123 Terminology Relating to Textiles

Crockmeter Method

D1230 Test Method for Flammability of Apparel Textiles Test Method 124 Appearance of Fabrics After Repeated

(Withdrawn 2010)

Home Laundering

D1776 Practice for Conditioning and Testing Textiles Test Method 132 Colorfastness to Drycleaning

D2905 Practice for Statements on Number of Specimens for

Test Method 135 Dimensional Changes in Automatic Home

Textiles (Withdrawn 2008) Laundering of Woven and Knit Fabrics

D3136 Terminology Relating to Care Labeling for Apparel,

Test Method 143 Appearance of Apparel and Other Textile

Textile, Home Furnishing, and Leather Products End Products After Repeated Home Launderings

D3512 TestMethodforPillingResistanceandOtherRelated

Evaluation Procedure 1 Gray Scale for Color Change

Surface Changes of Textile Fabrics: Random Tumble Evaluation Procedure 2 Gray Scale for Staining

Pilling Tester

2.3 Other Documents:

D3786 Test Method for Bursting Strength of Textile Glossary for AATCC Standard Terminology

Fabrics—Diaphragm Bursting Strength Tester Method

NOTE 1—Reference to test methods in this performance specification

give only the pertinent part of the designation ofASTM,AATCC, or other

test methods. The current edition of each test method shall prevail.

This specification is under the jurisdiction of ASTM Committee D13 on

3. Terminology

Textiles and is the direct responsibility of Subcommittee D13.63 on Home

Furnishings.

3.1 Definitions:

Current edition approved Oct. 1, 2013. Published October 2013. Originally

3.1.1 For definitions of other textile terms used in this

approved in 2001. Last previous edition approved in 2008 as D6663–08. DOI:

performance specification, refer to Terminology D123 and the

10.1520/D6663-08R13.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from American Association of Textile Chemists and Colorists

the ASTM website. (AATCC), P.O. Box 12215, Research Triangle Park, NC 27709, http://

The last approved version of this historical standard is referenced on www.aatcc.org.

www.astm.org. Available in the AATCC Technical Manual.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

D6663−08 (2013)

AATCC Glossary. For definitions of care labeling terms, refer 3.1.8 For definitions of other textile terms used in this

to Terminology D3136. specification, refer to Terminology D123 and the AATCC

Glossary. For definitions of care labeling terms, refer to

3.1.2 bedskirt, n—a decorative product which is positioned

Terminology D3136.

below the mattress and drapes to the floor; a dustruffle.

3.1.3 comforter, n—a bed covering assembly, consisting of

4. Significance and Use

an insulating filler secure between two layers of fabric,

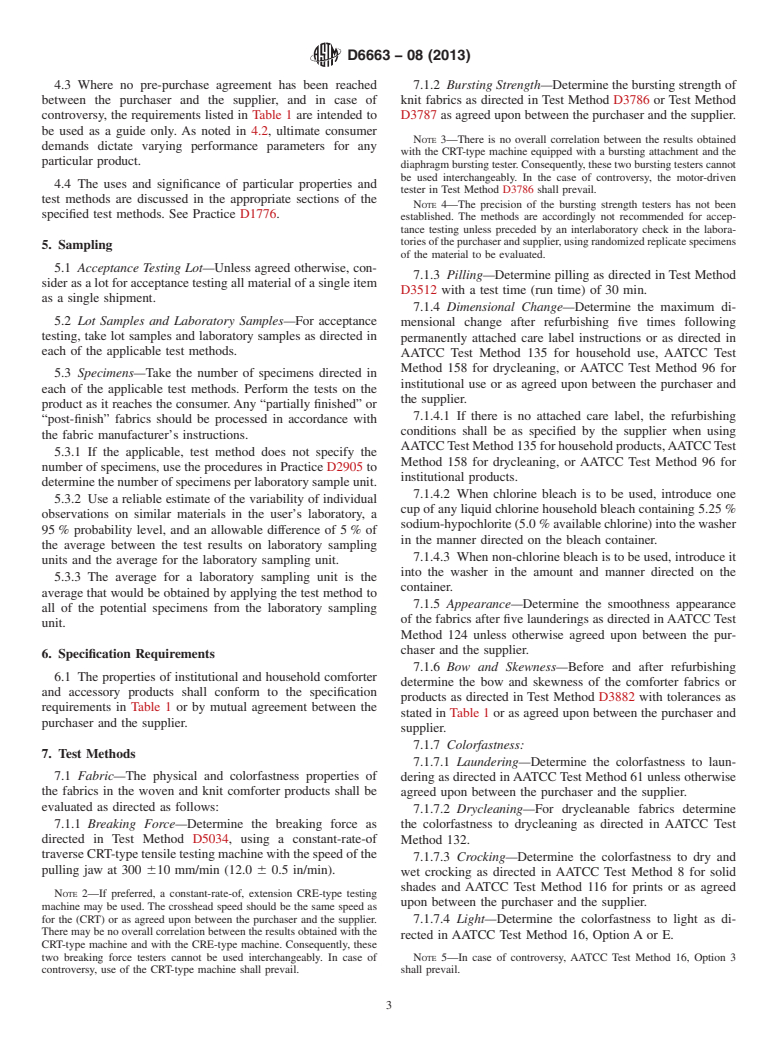

designed to reduce heat loss. 4.1 Upon mutual agreement between the purchaser and the

supplier, comforter and accessory products intended for this

3.1.4 comforter accessories, n—products which augment or

end use should meet all of the requirements listed in Table 1 of

enhance the decorative feature of the comforter.

this specification.

3.1.4.1 Discussion—Accessories can include pillowshams,

dustruffles, bedskirts, duvets, etc. but does not include pillows 4.2 It is recognized that, for purposes of fashion or

or window treatments. aesthetics, the ultimate consumer of articles made from these

fabrics may find acceptable products that do not conform to all

3.1.5 duvet, n—a decorative outercover in which a com-

of the requirements in Table 1. Therefore, one or more of the

forter is inserted.

requirements in Table 1 may be modified by mutual agreement

3.1.6 fill leakage, n—in comforters, either partial or total

between the purchaser and the supplier.

penetration of batting material through the outer or face fabric.

4.2.1 In such cases, any references to the specification shall

3.1.7 pillow sham, n—a decorative product which covers a specify that: “This product meets ASTM Specification XXXX

bed pillow. except for the following characteristic(s).”

TABLE 1 Specification Requirements

Characteristics Requirements Section

Woven Comforter Knitted Comforter

andAccessories andAccessories

Breaking Force

(CRT) Type Machine—Each

A

Direction 133 N (30 lbf) Min NA 7.1.1

A

Bursting Strength NA 155 kPa (35 psi) Min 7.1.2

Pilling 4.0 Min 4.0 Min 7.1.3

Dimensional Change to: 7.1.4

Laundering—Each Direction 3.0% Max 5.0% Max

Dry Cleaning—Each Direction 3.0% Max 5.0% Max

Refurbishing

Appearance (Fabric) 7.2.1

B B

Polyester/Cotton SA3.0 Min SA3.0 Min

B B

100% Cotton SA2.2 Min SA2.2 Min

Bow and Skewness 7.1.7

Fabric Weave 3.0% Max 3.0% Max

Pattern Print Acceptable Acceptable

Colorfastness to:

Laundering: 7.1.7.1

C C

Alteration in Shade Class 4 Min Class 4 Min

D D

Staining Class 3 Min Class 3 Min

C C

Dry Cleaning - (Shade Change) Class 4 Min Class 4 Min 7.1.7.2

Crocking 7.1.7.3

D D

Dry Class 4 Min Class 4 Min

D D

Wet Class3Min Class 3 Min

Light (20AATCC FU) 7.1.7.4

A C C

Xenon-Arc Step 4 Min Step 4 Min

Perspiration 7.1.7.5

C C

Alteration in Shade Class 4 Min Class 4 Min

D D

Staining Class 3 Min Class 3 Min

Flammability (Product) Class 1 Class 1 7.1.7.6

Refurbishing Acceptable Acceptable 7.2.1

Appearance (Product)

Fill Leakage (Product) Acceptable Acceptable 7.2.2

A

Thereismorethanonestandardmethodthatcanbeusedtomeasurebreakingforce,burstingforce,tearresistance,andlightfastness.Thesemethodscannotbeused

interchangeably because there may be no overall correlation between them. See Notes 2-5.

B

ClassincolorfastnessandSAratingisbaledonanumericalscaleof5.0fornegligiblecolorchange,colortransfer,orwrinklingto1.0forvaryseverecolorchange,color

transfer or wrinkling. The numerical rating in Table 1 or higher is acceptable.

C

AATCC Gray Scale for Color Change.

D

AATCC Gray Scale for Staining.

D6663−08 (2013)

4.3 Where no pre-purchase agreement has been reached 7.1.2 Bursting Strength—Determine the bursting strength of

between the purchaser and the supplier, and in case of knit fabrics as directed in Test Method D3786 or Test Method

controversy, the requirements listed in Table 1 are intended to D3787 as agreed upon between the purchaser and the supplier.

be used as a guide only. As noted in 4.2, ultimate consumer

NOTE 3—There is no overall correlation between the r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.