ASTM D2688-15e1

(Test Method)Standard Test Method for Corrosivity of Water in the Absence of Heat Transfer (Weight Loss Method)

Standard Test Method for Corrosivity of Water in the Absence of Heat Transfer (Weight Loss Method)

SIGNIFICANCE AND USE

4.1 Since the two tendencies are inseparable for a metal to corrode and for water and the materials it contains to promote or inhibit corrosion, the corrosiveness of a material or the corrosivity of water must be determined in relative, rather than absolute, terms. The tendency for a material to corrode is normally determined by measuring its rate of corrosion and comparing it with the corrosion rates of other materials in the same water environment. Conversely, the relative corrosivity of water may be determined by comparing the corrosion rate of a material in the water with the corrosion rates of the same material in other waters. Such tests are useful, for example, for evaluating the effects of corrosion inhibitors on the corrosivity of water. Although this test methods is intended to determine the corrosivity of water, it is equally useful for determining corrosiveness and corrosion rate of materials. Examples of systems in which this method may be used include but are not limited to open recirculating cooling water and closed chilled and hydronic heating systems.

SCOPE

1.1 This test method covers the determination of the corrosivity of water by evaluating pitting and by measuring the weight loss of metal specimens. Pitting is a form of localized corrosion: weight loss is a measure of the average corrosion rate. The rate of corrosion of a metal immersed in water is a function of the tendency for the metal to corrode and is also a function of the tendency for water and the materials it contains to promote (or inhibit) corrosion.

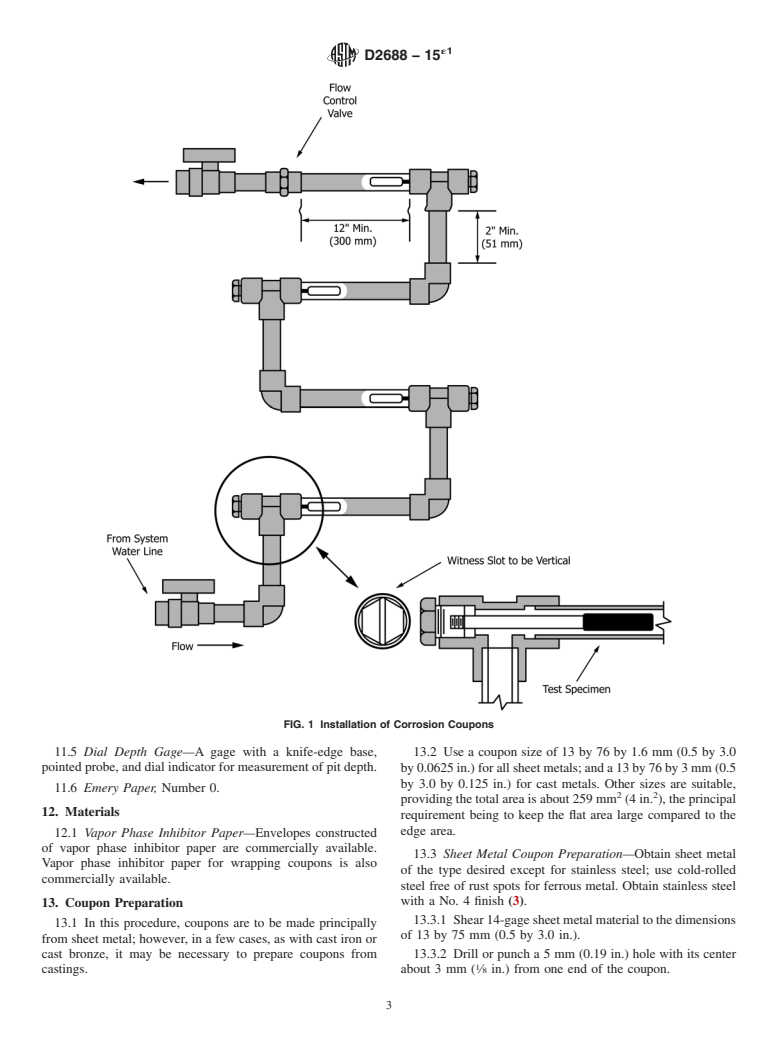

1.2 The test method employs flat, rectangular-shaped metal coupons which are mounted on pipe plugs and exposed to the water flowing in metal piping in municipal, building, and industrial water systems using a side stream corrosion specimen rack.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: D2688 − 15

Standard Test Method for

Corrosivity of Water in the Absence of Heat Transfer

1

(Weight Loss Method)

This standard is issued under the fixed designation D2688; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—An editorial correction was made to 13.3.2 in July 2016.

1. Scope 2. Referenced Documents

2

1.1 This test method covers the determination of the corro- 2.1 ASTM Standards:

sivity of water by evaluating pitting and by measuring the D1129Terminology Relating to Water

weight loss of metal specimens. Pitting is a form of localized D2331Practices for Preparation and Preliminary Testing of

corrosion: weight loss is a measure of the average corrosion Water-Formed Deposits

rate. The rate of corrosion of a metal immersed in water is a D2777Practice for Determination of Precision and Bias of

function of the tendency for the metal to corrode and is also a Applicable Test Methods of Committee D19 on Water

functionofthetendencyforwaterandthematerialsitcontains G1Practice for Preparing, Cleaning, and Evaluating Corro-

to promote (or inhibit) corrosion. sion Test Specimens

G16Guide for Applying Statistics to Analysis of Corrosion

1.2 The test method employs flat, rectangular-shaped metal

Data

coupons which are mounted on pipe plugs and exposed to the

water flowing in metal piping in municipal, building, and

3. Terminology

industrial water systems using a side stream corrosion speci-

3.1 Definitions—For definitions of terms used in this

men rack.

standard, refer to Terminology D1129.

1.3 The values stated in SI units are to be regarded as

standard. The values given in parentheses are mathematical

4. Significance and Use

conversions to inch-pound units that are provided for informa-

4.1 Since the two tendencies are inseparable for a metal to

tion only and are not considered standard.

corrode and for water and the materials it contains to promote

1.4 This standard does not purport to address all of the

or inhibit corrosion, the corrosiveness of a material or the

safety concerns, if any, associated with its use. It is the

corrosivity of water must be determined in relative, rather than

responsibility of the user of this standard to establish appro-

absolute, terms. The tendency for a material to corrode is

priate safety, health, and environmental practices and deter-

normally determined by measuring its rate of corrosion and

mine the applicability of regulatory limitations prior to use.

comparing it with the corrosion rates of other materials in the

1.5 This international standard was developed in accor-

same water environment. Conversely, the relative corrosivity

dance with internationally recognized principles on standard-

ofwatermaybedeterminedbycomparingthecorrosionrateof

ization established in the Decision on Principles for the

a material in the water with the corrosion rates of the same

Development of International Standards, Guides and Recom-

materialinotherwaters.Suchtestsareuseful,forexample,for

mendations issued by the World Trade Organization Technical

evaluating the effects of corrosion inhibitors on the corrosivity

Barriers to Trade (TBT) Committee.

of water. Although this test methods is intended to determine

the corrosivity of water, it is equally useful for determining

corrosiveness and corrosion rate of materials. Examples of

1

This test method is under the jurisdiction ofASTM Committee D19 on Water systems in which this method may be used include but are not

and is the direct responsibility of Subcommittee D19.03 on Sampling Water and

Water-Formed Deposits,Analysis of Water for Power Generation and Process Use,

2

On-Line Water Analysis, and Surveillance of Water. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved June 1, 2015. Published June 2015. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1969. Last previous edition approved in 2011 as D2688–11. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D2688-15E01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

D2688 − 15

limited to open recirculating cooling water and closed chilled most common constituents will be calcium, magnesium,

and hydronic heating systems. aluminum, zinc, co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.