ASTM F1108-21

(Specification)Standard Specification for Titanium-6Aluminum-4Vanadium Alloy Castings for Surgical Implants (UNS R56406)

Standard Specification for Titanium-6Aluminum-4Vanadium Alloy Castings for Surgical Implants (UNS R56406)

ABSTRACT

This specification covers the chemical, mechanical, and metallurgical requirements for cast titanium-6aluminum-4vanadium alloy (UNS R56406). Castings conforming to this specification shall be produced by vacuum investment casting. Castings covered by this specification shall be in the annealed and hot isostatically pressed condition. Product castings shall conform to the requirements prescribed. Material supplied under this specification shall conform to the mechanical property requirements prescribed. Chemical analysis, product analysis, tension tests, fluorescent penetrant examination, and radiographic examination shall be performed to meet the specified requirements.

SCOPE

1.1 This specification covers the chemical, mechanical, and metallurgical requirements for cast titanium-6aluminum-4vanadium alloy (UNS R56406).

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F1108 −21

Standard Specification for

Titanium-6Aluminum-4Vanadium Alloy Castings for Surgical

1

Implants (UNS R56406)

This standard is issued under the fixed designation F1108; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E539Test Method for Analysis of Titanium Alloys by

WavelengthDispersiveX-RayFluorescenceSpectrometry

1.1 This specification covers the chemical, mechanical, and

E1409TestMethodforDeterminationofOxygenandNitro-

metallurgical requirements for cast titanium-6aluminum-

gen in Titanium and TitaniumAlloys by Inert Gas Fusion

4vanadium alloy (UNS R56406).

E1447Test Method for Determination of Hydrogen in Tita-

1.2 Units—The values stated in either SI units or inch-

nium and Titanium Alloys by Inert Gas Fusion Thermal

pound units are to be regarded separately as standard. The

Conductivity/Infrared Detection Method

values stated in each system are not necessarily exact equiva-

E2994Test Method for Analysis of Titanium and Titanium

lents; therefore, to ensure conformance with the standard, each

AlloysbySparkAtomicEmissionSpectrometryandGlow

system shall be used independently of the other, and values

Discharge Atomic Emission Spectrometry (Performance-

from the two systems shall not be combined.

Based Method)

1.3 This standard does not purport to address all of the F136 Specification for Wrought Titanium-6Aluminum-

safety concerns, if any, associated with its use. It is the

4VanadiumELI(ExtraLowInterstitial)AlloyforSurgical

responsibility of the user of this standard to establish appro- Implant Applications (UNS R56401)

priate safety, health, and environmental practices and deter-

F601Practice for Fluorescent Penetrant Inspection of Me-

mine the applicability of regulatory limitations prior to use. tallic Surgical Implants

1.4 This international standard was developed in accor-

F629Practice for Radiography of Cast Metallic Surgical

dance with internationally recognized principles on standard- Implants

ization established in the Decision on Principles for the

IEEE/ASTM SI 10American National Standard for Metric

Development of International Standards, Guides and Recom- Practice

3

mendations issued by the World Trade Organization Technical

2.2 ISO Standards:

Barriers to Trade (TBT) Committee.

ISO 6892Metallic Materials—Tensile Testing at Ambient

Temperature

2. Referenced Documents

ISO 9001Quality Management Systems—Requirements

2

ISO 13485 Medical Devices—Quality Management

2.1 ASTM Standards:

Systems—Requirements for Regulatory Purposes

B600Guide for Descaling and Cleaning Titanium and Tita-

4

2.3 Aerospace Material Specification:

nium Alloy Surfaces

AMS 2249Chemical Check Analysis Limits, Titanium and

E3Guide for Preparation of Metallographic Specimens

Titanium Alloys

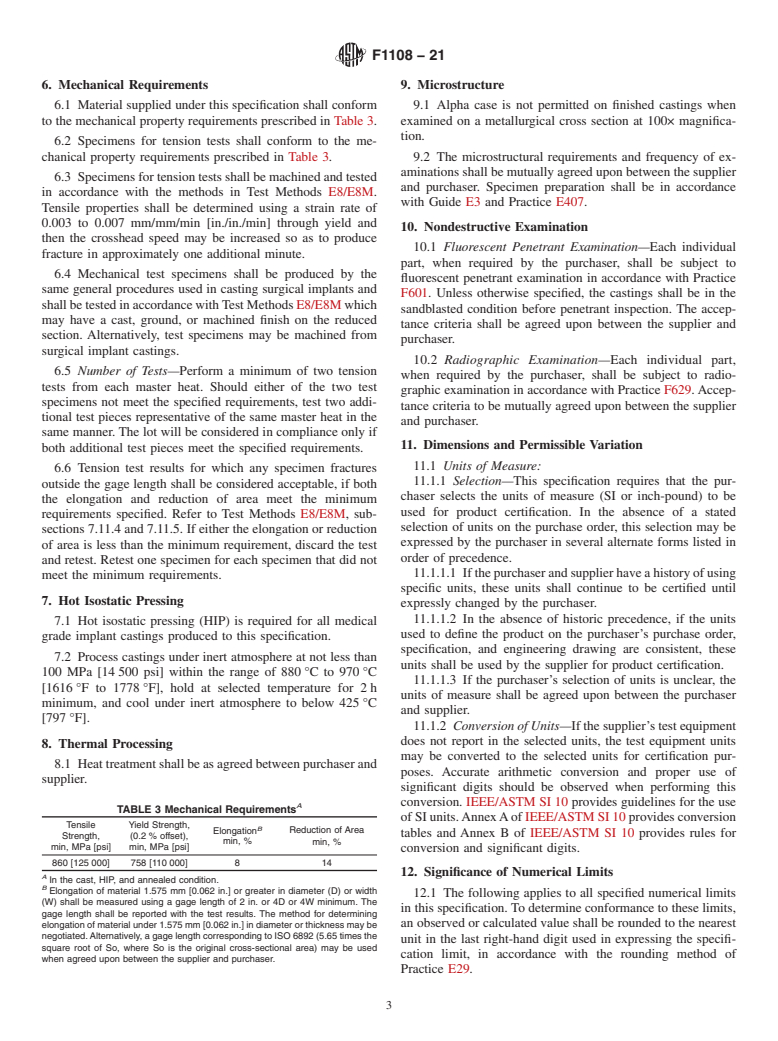

E8/E8MTest Methods for Tension Testing of Metallic Ma-

4

terials 2.4 Society of Automotive Engineers:

SAE J1086Practice for Numbering Metals and Alloys

E29Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications (UNS)

E407Practice for Microetching Metals and Alloys

3. Ordering Information

3.1 Inquiriesandordersformaterialunderthisspecification

1

This specification is under the jurisdiction of ASTM Committee F04 on

shall include the following information:

Medical and Surgical Materials and Devices and is the direct responsibility of

3.1.1 Quantity,

Subcommittee F04.12 on Metallurgical Materials.

3.1.2 ASTM designation and issue date,

Current edition approved Sept. 15, 2021. Published September 2021. Originally

approved in 1988. Last previous edition approved in 2014 as F1108–14. DOI:

10.1520/F1108-21.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1108−21

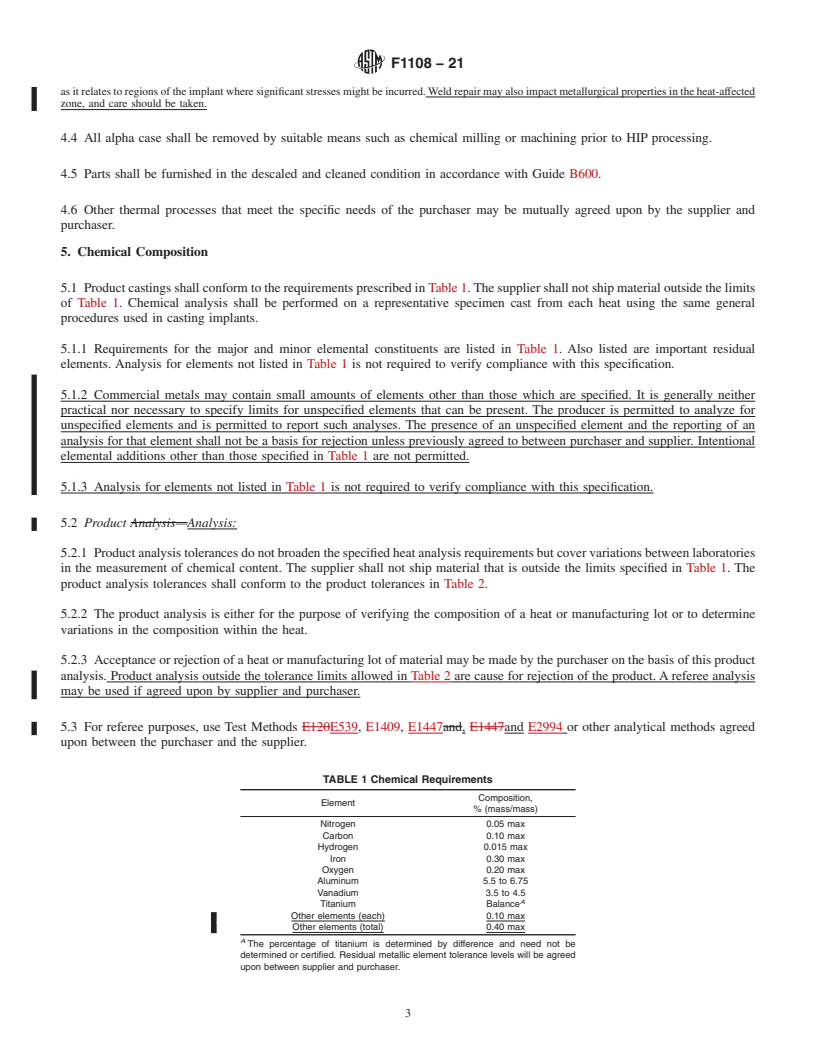

3.1.3 Applicable dimensions or drawing number, 5.1.1 Requirements for the major and mi

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1108 − 14 F1108 − 21

Standard Specification for

Titanium-6Aluminum-4Vanadium Alloy Castings for Surgical

1

Implants (UNS R56406)

This standard is issued under the fixed designation F1108; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers the chemical, mechanical, and metallurgical requirements for cast titanium-6aluminum-4vanadium

alloy (UNS R56406).

1.2 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in

each system mayare not benecessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be

used independently of the other. Combiningother, and values from the two systems may result in nonconformance with the

standard.shall not be combined.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

B600 Guide for Descaling and Cleaning Titanium and Titanium Alloy Surfaces

E3 Guide for Preparation of Metallographic Specimens

E8E8/E8M Test Methods for Tension Testing of Metallic Materials [Metric] E0008_E0008M

3

E120 Test Methods for Chemical Analysis of Titanium and Titanium Alloys (Withdrawn 2003)

E165E29 Practice for Liquid Penetrant Testing for General IndustryUsing Significant Digits in Test Data to Determine

Conformance with Specifications

E407 Practice for Microetching Metals and Alloys

E539 Test Method for Analysis of Titanium Alloys by Wavelength Dispersive X-Ray Fluorescence Spectrometry

E1409 Test Method for Determination of Oxygen and Nitrogen in Titanium and Titanium Alloys by Inert Gas Fusion

E1447 Test Method for Determination of Hydrogen in Titanium and Titanium Alloys by Inert Gas Fusion Thermal

Conductivity/Infrared Detection Method

E2994 Test Method for Analysis of Titanium and Titanium Alloys by Spark Atomic Emission Spectrometry and Glow Discharge

Atomic Emission Spectrometry (Performance-Based Method)

1

This specification is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.12 on Metallurgical Materials.

Current edition approved Nov. 1, 2014Sept. 15, 2021. Published January 2015September 2021. Originally approved in 1988. Last previous edition approved in 20092014

as F1108 – 04 (2009).F1108 – 14. DOI: 10.1520/F1108-14. 10.1520/F1108-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1108 − 21

F136 Specification for Wrought Titanium-6Aluminum-4Vanadium ELI (Extra Low Interstitial) Alloy for Surgical Implant

Applications (UNS R56401)

F601 Practice for Fluorescent Penetrant Inspection of Metallic Surgical Implants

F629 Practice for Radiography of Cast Metallic Surgical Implants

IEEE/ASTM SI 10 American National Standard for Use of the International System of Units (SI): The Modern Metric

SystemMetric Practice

3

2.2 ISO Standard:Standards:

ISO 6892 Metallic Materials—Tensile Testing at Ambient Temperature

ISO 9001 Quality management systems -- RequirementsManagement Systems—Requirements

ISO 13485 Medical devices -- Quality management systems -- Requirements for regulatory purposesDevices—Quality

Management Systems—Requirements for Regulatory Purposes

4

2.3 Aerospace Material Specification:

AMS 2249 Chemical Check Analysis Limi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.