ASTM D4009-92(2023)

(Guide)Standard Guide for Foam Stability of Hand Dishwashing Detergents

Standard Guide for Foam Stability of Hand Dishwashing Detergents

SIGNIFICANCE AND USE

3.1 The guide, as now constituted, is not suitable for ranking of hand dishwashing products, since no basis is available at this time for correlation of the foam stability of these products using any particular food soil or combination of soils with consumers' ranking of performance.

3.2 The relative foam stability ranking of hand dishwashing detergent products will vary greatly depending on the type of food soils used in the test. Therefore, selection of the standard food soil to be used in a test shall be made by agreement between the interested parties on the basis of experience.

3.3 This laboratory screening guide includes flexibility in several areas so as to allow its use by the maximum number of laboratories, without purchase of significant additional equipment. It should be recognized, therefore, that differences in specific equipment may result in a reduced level of interlaboratory and inter-operator precision, and such results must be evaluated with caution.

SCOPE

1.1 This guide provides guidelines for several techniques of measuring the foam stability of light-duty hand dishwashing detergent products in the presence of artificially applied test-food soils. It is intended as a laboratory screening test to aid in the formulation of products, for quality control and as a basis between the formulator and supplier in standardizing foam stability of the detergents.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4009 − 92 (Reapproved 2023)

Standard Guide for

Foam Stability of Hand Dishwashing Detergents

This standard is issued under the fixed designation D4009; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope using any particular food soil or combination of soils with

consumers’ ranking of performance.

1.1 This guide provides guidelines for several techniques of

measuring the foam stability of light-duty hand dishwashing 3.2 The relative foam stability ranking of hand dishwashing

detergent products in the presence of artificially applied test- detergent products will vary greatly depending on the type of

food soils. It is intended as a laboratory screening test to aid in food soils used in the test. Therefore, selection of the standard

the formulation of products, for quality control and as a basis food soil to be used in a test shall be made by agreement

between the formulator and supplier in standardizing foam between the interested parties on the basis of experience.

stability of the detergents.

3.3 This laboratory screening guide includes flexibility in

1.2 This standard does not purport to address all of the

several areas so as to allow its use by the maximum number of

safety concerns, if any, associated with its use. It is the

laboratories, without purchase of significant additional equip-

responsibility of the user of this standard to establish appro-

ment. It should be recognized, therefore, that differences in

priate safety and health practices and determine the applica-

specific equipment may result in a reduced level of interlabo-

bility of regulatory limitations prior to use.This standard does

ratory and inter-operator precision, and such results must be

not purport to address all of the safety concerns, if any,

evaluated with caution.

associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety, health, and environ- 4. Recommended Conditions

mental practices and determine the applicability of regulatory

4.1 Water Hardness—If only one test is to be made, hard

limitations prior to use.

water (150 ppm, about 9 grains per gallon (gpg)) is suggested.

1.3 This international standard was developed in accor-

To produce a more complete picture of product foam stability,

dance with internationally recognized principles on standard-

test at two or three additional hardness levels: soft water

ization established in the Decision on Principles for the

(35 ppm, 2 gpg); moderately hard water (100 ppm, 6 gpg); or

Development of International Standards, Guides and Recom-

very hard water (260 ppm, 15 gpg).

mendations issued by the World Trade Organization Technical

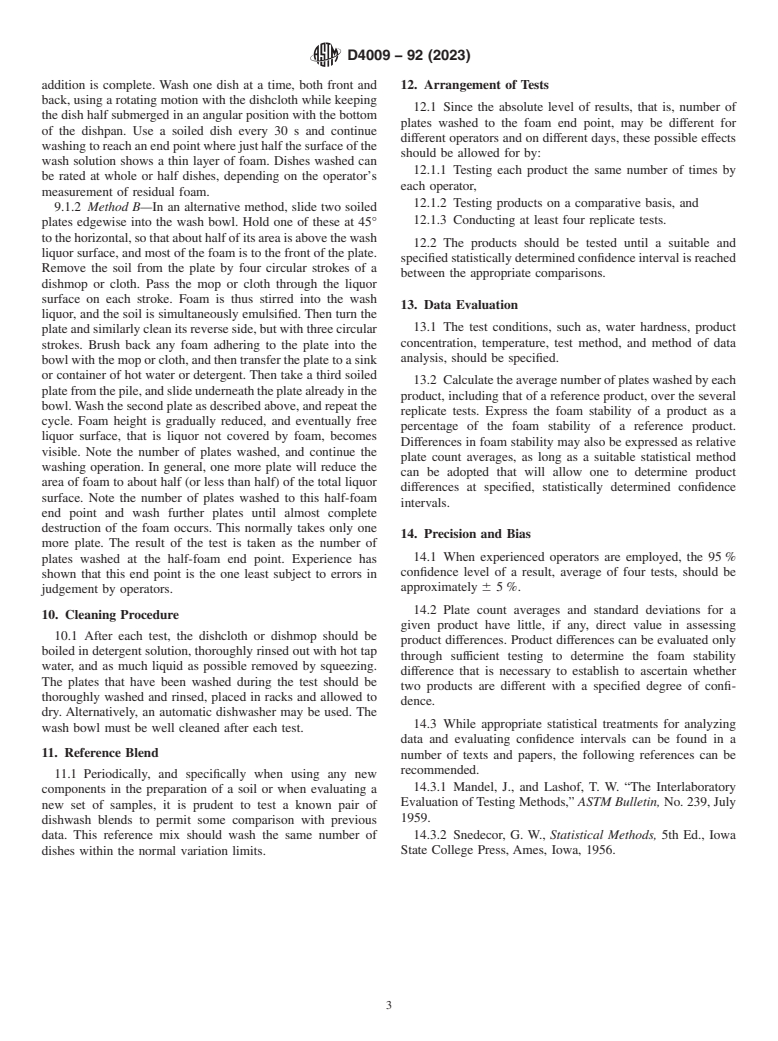

4.1.1 Calcium/Magnesium Ratio (as CaCo )—It is sug-

Barriers to Trade (TBT) Committee.

gested that this ratio be adjusted for different water hardness as

follows:

2. Summary of Guide

Water Hardness Range, Calcium/Magnesium

2.1 Soiled dinner plates are washed by hand in solutions of ppm (gpg) Ratio

0 to 60 (0 to 3.5) 4:1

hand dishwashing detergents under standardized conditions

61 to 120 (3.6 to 7.0) 3:1

until an end point of near-disappearance of the foam is reached,

121 and over (7.1 and over) 2:1

after which the number of plates washed is compared to the

4.2 Water Temperature—The water temperature at the start

number of plates washed using a standard product.

of the test should be adjusted to 47 °C (117 °F).

3. Significance and Use

5. Materials

3.1 The guide, as now constituted, is not suitable for ranking

5.1 Plain White Glazed Dinner Plates in Sound Condition—

of hand dishwashing products, since no basis is available at this

200 mm to 230 mm (8 in. to 9 in.) in diameter, with 160 mm to

time for correlation of the foam stability of these products

1 1

165 mm (6 ⁄4 in. to 6 ⁄2 in.) indented bottom.

5.2 Dishpan (conventional)—Bottom diameter = 280 mm

(11 in.), top diameter = 370 mm (14 ⁄2 in.), depth = 140 mm (5

This guide is under the jurisdiction of ASTM Committee D12 on Soaps and

⁄2 in.). Sheet metal or plastic are suitable materials.

Other Detergents and is the direct responsibility of Subcommittee D12.16 on Hard

Surface Cleaning.

5.3 Dishcloth (any conventional brand), Dish Mop, or

Current edition approved July 1, 2023. Published August 2023. Originally

Disposable Dishcloths—Enough clean dish cloths (or dish

approved in 1981. Last previous edition approved in 2017 as D4009 – 92 (2017).

DOI: 10.1520/D4009-92R23. mops) should be available to ensure the use of a fresh cloth (or

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4009 − 92 (2023)

dish mop) for each test run in one day. A new disposable cloth tity prepared should be sufficient for one day’s work only, soil

should be used for each wash. being made up fresh daily. Approximately 450 g of shortening

and 150 g of egg powder make sufficient soil for about 500

5.4 Any suitable reservoir of 4 L capacity, that can be

plates.

readily loaded with test water and that can deliver its contents

through a 9.5 mm ( ⁄8 in.) (inside diameter) drainage tip.

7. Preparation of Soiled Plates

Preferably, this drainage tube is an open-shut style to permit

7.1 Wash the plates thoroughly, by usual hand methods or in

full flow immediately upon opening.

an automatic dishwasher, before starting the test and between

test soilings/washings to provide clean dry plates.

6. Standard Soils

7.2 Place on a balance, the beaker containing the selected

6.1 Four soils, representative of those commonly used for

soil, A, B, or C. Set to weigh 6.0 g 6 0.1 g light. Use a spatula

hand dishwashing tests, are described below. Other soil com-

or spoon to remove 6.0 g soil for application to a plate.

positions may be used.

Alternatively, weigh each plate, tare, and then add soil to 6.0 g

6.1.1 Soil A:

6 0.1 g.

wt %

Lard (not hydrogenated) 18.3

7.3 Transfer Soil A or B most readily, with a small spatula.

Wesson oil 9.2

Scrape all soil from the spatula on the edge of the plate. Soil C,

Corn oil 9.2

Oleic acid (USP) 4.2

a liquid at 42 °C (108 °F), can be added from a small spoon or

Salt 0.4

by using an automatic pipet syringe by Manostat set to deliver

Gelatin 0.4

6.0 g.

Flour 41.6

Water 16.7

7.4 For Soil D use a press-down cream dispenser with

100.0

adjustable plunger to deliver 2 g 6 0.03 g of soil to each plate.

6.1.1.1 Prepare this mixture on the day prior to use. Discard

7.5 Use one’s finger to spread the soil over the surface of the

any soil more than one day old. Prepare as follows: Weigh the

plate. Disposable gloves are recommended for this procedure.

lard, vegetable oil, corn oil, and oleic acid into a beaker and

Soiled plates are then stacked in convenient sized piles

warm to 38 °C (100 °F). Add the salt, gelatin, and flour while

(20 plates to 25 plates). The top plate of each pile may be

mixing with a spatula. Store at 3 °C to 6 °C (38 °F to 42 °F)

inverted to prevent drying out of soil. After soiling the last

overnight. The following day, just prior to use and without

plate of each stack, the residual soil on the finger is removed by

heating, blend in the water with a large 200 mm (8 in.) spatula.

wiping on the sides of the stacked, soiled plates.

Apply soil at room temperature. A bright dye may be added to

aid visual inspection.

7.6 Wash Soils A, B or D the same day as soiling. Test wash

6.1.2 Soil B:

Soil C the day after soiling.

Flour 50 %

7.7 Keep soil well mixed by frequent stirring and keep soil

Shortening 48 %

covered. Do not use excess soil or soiled dishes beyond the

Oleic acid (USP) 2 %

time schedule, as noted.

6.1.2.1 Warm the shortening with oleic acid to 38 °C

(100 °F). Slowly add flour while mixing with a spatula and

8. Preparation of Dishwash Solution

warming to 49 °C (120 °F). Hold soil temperature at 49 °C 6

8.1 The standard concentration is 0.10 % product. The

1.5 °C (120 °F 6 3 °F) while soiling dishes.

standard temperature is

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.