ASTM D3511-07

(Test Method)Standard Test Method for Pilling Resistance and Other Related Surface Changes of Textile Fabrics: Brush Pilling Tester

Standard Test Method for Pilling Resistance and Other Related Surface Changes of Textile Fabrics: Brush Pilling Tester

SCOPE

1.1 This test method covers the determination of the propensity of a fabric to form pills from fuzz under test conditions intended to simulate normal wear using the brush pilling tester. This procedure is generally applicable to all types of apparel fabrics including both woven and knitted fabrics. Note 1For other test methods for the pilling resistance of textiles, refer to Test Methods D 3512, D 3514, and D 4970.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as the standard. Within the text, the inch-pound units are shown in parentheses. The values stated in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3511–07

Standard Test Method for

Pilling Resistance and Other Related Surface Changes of

1

Textile Fabrics: Brush Pilling Tester

This standard is issued under the fixed designation D 3511; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

3

1. Scope 2.2 ASTM Adjuncts:

ADJD3512 Set of 5 Photographic Standards for Random

1.1 This test method covers the determination of the pro-

Tumble Pilling Test

pensity of a fabric to form pills from fuzz under test conditions

intended to simulate normal wear using the brush pilling tester.

3. Terminology

This procedure is generally applicable to all types of apparel

3.1 Definitions:

fabrics including both woven and knitted fabrics.

3.1.1 fuzz, n—untangled fiber ends that protrude from the

NOTE 1—For other test methods for the pilling resistance of textiles,

surface of a yarn or fabric.

refer to Test Methods D 3512, D 3514, and D 4970.

3.1.2 pilling resistance, n—resistance to the formation of

1.2 The values stated in either SI units or inch-pound units

pills on the surface of a textile fabric.

are to be regarded separately as the standard. Within the text,

3.1.3 pills, n—bunches or balls of tangled fibers which are

the inch-pound units are shown in parentheses. The values

held to the surface of a fabric by one or more fibers.

stated in each system are not exact equivalents; therefore, each

3.1.4 For definitions of other textile terms used in this test

system shall be used independently of the other. Combining

method, refer to Terminology D 123.

values from the two systems may result in nonconformance

4. Summary of Test Method

with the specification.

1.3 This standard does not purport to address all of the

4.1 Pilling and other changes in surface appearance, such as

safety concerns, if any, associated with its use. It is the fuzzing, which occur in normal wear are simulated on labora-

responsibility of the user of this standard to establish appro-

tory testing machines. Fabrics are subjected to simulated wear

priate safety and health practices and determine the applica- conditions: first brushing the specimens to free fiber ends that

bility of regulatory limitations prior to use.

form fuzz on the surface of the fabric, then rubbing two of the

specimens together in circular motion to roll the fiber ends into

2. Referenced Documents

pills.Thedegreeoffabricpillingisevaluatedbycomparingthe

2

2.1 ASTM Standards:

tested specimens with visual standards, which may be actual

D 123 Terminology Relating to Textiles

fabrics or photographs of fabrics, showing a range of pilling

D 1776 Practice for Conditioning and Testing Textiles

resistance. The observed resistance to pilling is reported using

D 3512 Test Method for Pilling Resistance and Other Re-

an arbitrary rating scale.

lated Surface Changes of Textile Fabrics: Random Tumble

5. Significance and Use

Pilling Tester

D 3514 Test Method for Pilling Resistance and Other Re- 5.1 Acceptance Testing—This method of testing fabrics for

lated Surface Changes of Textile Fabrics: Elastomeric Pad

resistancetopillingisnotrecommendedforacceptancetesting.

D 4970 Test Method for Pilling Resistance and Other Re- If it is used for acceptance testing, it should be used with

lated Surface Changes of Textile Fabrics: Martindale

caution because interlaboratory data are not available. In some

Tester cases the purchaser and the supplier may have to test a

commercial shipment of one or more specific materials by the

best available method, even though the method has not been

recommended for acceptance testing.

1

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

5.1.1 If there are differences or practical significance be-

and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods,

Specific. tween reported test results for two laboratories (or more),

Current edition approved July 1, 2007. Published August 2007. Originally

comparative tests should be performed to determine if there is

approved in 1976. Last previous edition approved in 2005 as D 3511 – 05.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from ASTM Headquarters, 100 Barr Harbor Drive, West Consho-

the ASTM website. hocken, PA 19428. Request ADJD3512.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3511–07

a statistical bias betwee

...

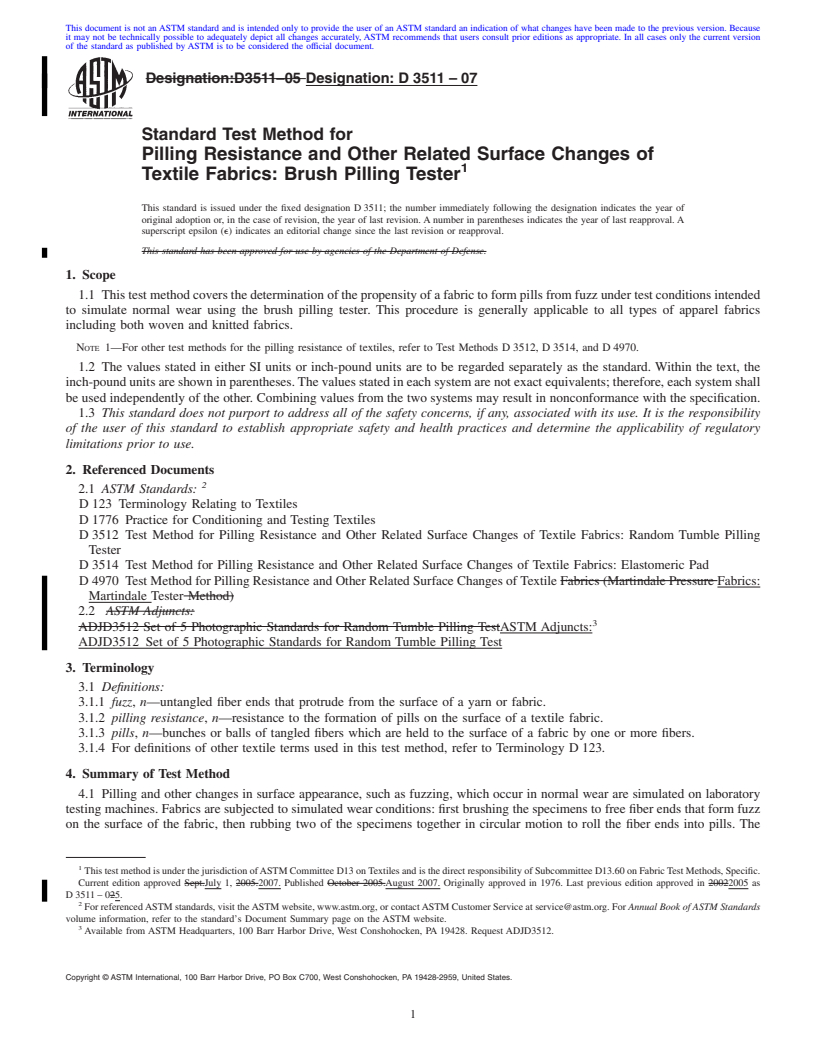

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D3511–05 Designation:D3511–07

Standard Test Method for

Pilling Resistance and Other Related Surface Changes of

1

Textile Fabrics: Brush Pilling Tester

This standard is issued under the fixed designation D 3511; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 Thistestmethodcoversthedeterminationofthepropensityofafabrictoformpillsfromfuzzundertestconditionsintended

to simulate normal wear using the brush pilling tester. This procedure is generally applicable to all types of apparel fabrics

including both woven and knitted fabrics.

NOTE 1—For other test methods for the pilling resistance of textiles, refer to Test Methods D 3512, D 3514, and D 4970.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as the standard. Within the text, the

inch-pound units are shown in parentheses.The values stated in each system are not exact equivalents; therefore, each system shall

be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 123 Terminology Relating to Textiles

D 1776 Practice for Conditioning and Testing Textiles

D 3512 Test Method for Pilling Resistance and Other Related Surface Changes of Textile Fabrics: Random Tumble Pilling

Tester

D 3514 Test Method for Pilling Resistance and Other Related Surface Changes of Textile Fabrics: Elastomeric Pad

D 4970 Test Method for Pilling Resistance and Other Related Surface Changes ofTextile Fabrics (Martindale Pressure Fabrics:

Martindale Tester Method)

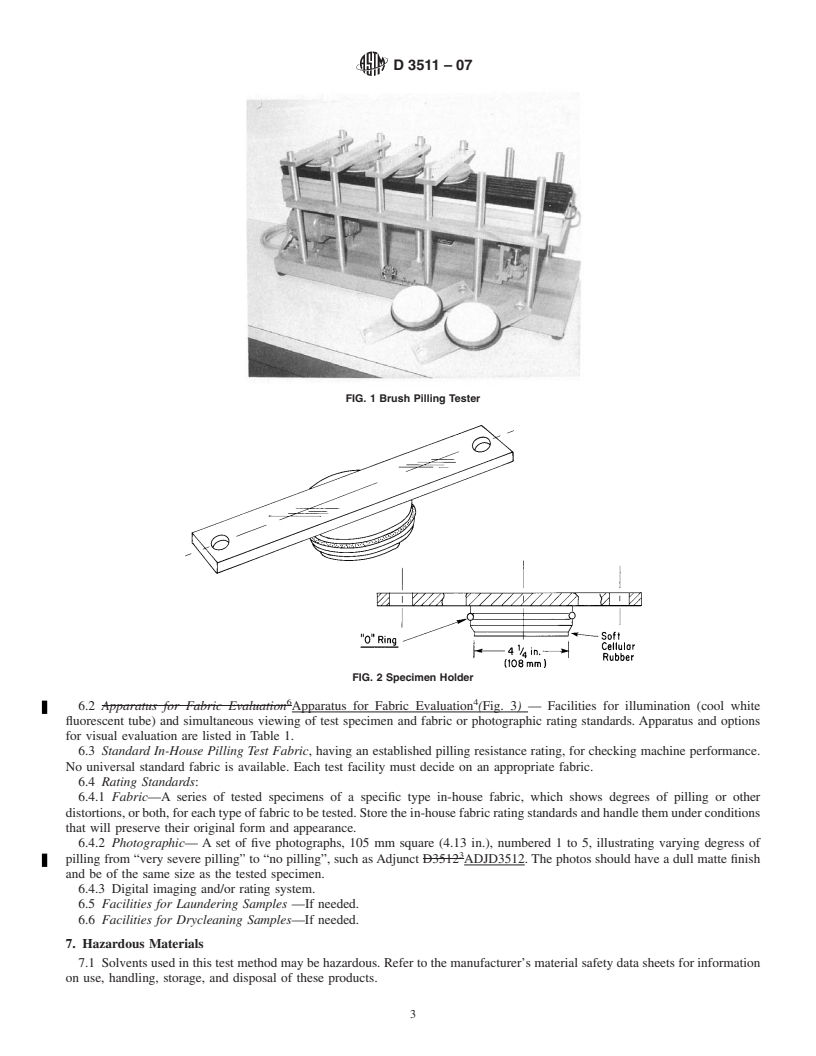

2.2 ASTM Adjuncts:

3

ADJD3512 Set of 5 Photographic Standards for Random Tumble Pilling TestASTM Adjuncts:

ADJD3512 Set of 5 Photographic Standards for Random Tumble Pilling Test

3. Terminology

3.1 Definitions:

3.1.1 fuzz, n—untangled fiber ends that protrude from the surface of a yarn or fabric.

3.1.2 pilling resistance, n—resistance to the formation of pills on the surface of a textile fabric.

3.1.3 pills, n—bunches or balls of tangled fibers which are held to the surface of a fabric by one or more fibers.

3.1.4 For definitions of other textile terms used in this test method, refer to Terminology D 123.

4. Summary of Test Method

4.1 Pilling and other changes in surface appearance, such as fuzzing, which occur in normal wear are simulated on laboratory

testing machines. Fabrics are subjected to simulated wear conditions: first brushing the specimens to free fiber ends that form fuzz

on the surface of the fabric, then rubbing two of the specimens together in circular motion to roll the fiber ends into pills. The

1

This test method is under the jurisdiction ofASTM Committee D13 onTextiles and is the direct responsibility of Subcommittee D13.60 on FabricTest Methods, Specific.

Current edition approved Sept.July 1, 2005.2007. Published October 2005.August 2007. Originally approved in 1976. Last previous edition approved in 20022005 as

D 3511 – 025.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from ASTM Headquarters, 100 Barr Harbor Drive, West Conshohocken, PA 19428. Request ADJD3512.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3511–07

degree of fabric pilling is evaluated by comparing the tested specimens with visual standards, which may be actual fabrics or

photographsoffabrics,showingarangeofpillingresistance.Theobservedresistancetopillingisreportedusinganarbitraryrating

scale.

5. Significance and Use

5.1 Acceptance Testing—This method of testing fabrics for resistance to pilling is not recommended for acceptance testing. If

it is used for acceptance testing, it should be use

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.