ASTM F2922-13e1

(Specification)Standard Specification for Polyethylene (PE) Corrugated Wall Stormwater Collection Chambers

Standard Specification for Polyethylene (PE) Corrugated Wall Stormwater Collection Chambers

ABSTRACT

This specification covers requirements, test methods, materials, and marking for polyethylene (PE), open bottom, buried arch-shaped chambers of corrugated wall construction used for collection, detention, and retention of stormwater runoff. These collection chambers can be used as commercial, residential, agricultural, and highway drainage, including installation under parking lots and roadways. This specification indicates the classifications, tolerances, and dimensions of the chambers. It also lists the test methods that examine the physical and mechanical properties of finished chambers.

SCOPE

1.1 This specification covers requirements, test methods, materials, and marking for polyethylene (PE), open bottom, buried arch-shaped chambers of corrugated wall construction used for collection, detention, and retention of stormwater runoff. Applications include commercial, residential, agricultural, and highway drainage, including installation under parking lots and roadways.

1.2 Chambers are produced in arch shapes with dimensions based on chamber rise, chamber span, and wall stiffness. Chambers are manufactured with integral feet that provide base support. Chambers may include perforations to enhance water flow. Chambers must meet test requirements for arch stiffness, flattening, and accelerated weathering.

1.3 Analysis and experience have shown that the successful performance of this product depends upon the type and depth of bedding and backfill, and care in installation. This specification includes requirements for the manufacturer to provide chamber installation instructions to the purchaser.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 The following safety hazards caveat pertains only to the test method portion, Section 6, of this specification:

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:F2922 −13

Standard Specification for

Polyethylene (PE) Corrugated Wall Stormwater Collection

1

Chambers

This standard is issued under the fixed designation F2922; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—5.3.8 and 5.3.9 were editorially corrected in December 2013.

1. Scope* 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This specification covers requirements, test methods,

D618 Practice for Conditioning Plastics for Testing

materials, and marking for polyethylene (PE), open bottom,

D1600 Terminology forAbbreviatedTerms Relating to Plas-

buried arch-shaped chambers of corrugated wall construction

tics

used for collection, detention, and retention of stormwater

D2122 Test Method for Determining Dimensions of Ther-

runoff. Applications include commercial, residential,

moplastic Pipe and Fittings

agricultural, and highway drainage, including installation un-

D2412 Test Method for Determination of External Loading

der parking lots and roadways.

Characteristics of Plastic Pipe by Parallel-Plate Loading

D2990 Test Methods for Tensile, Compressive, and Flexural

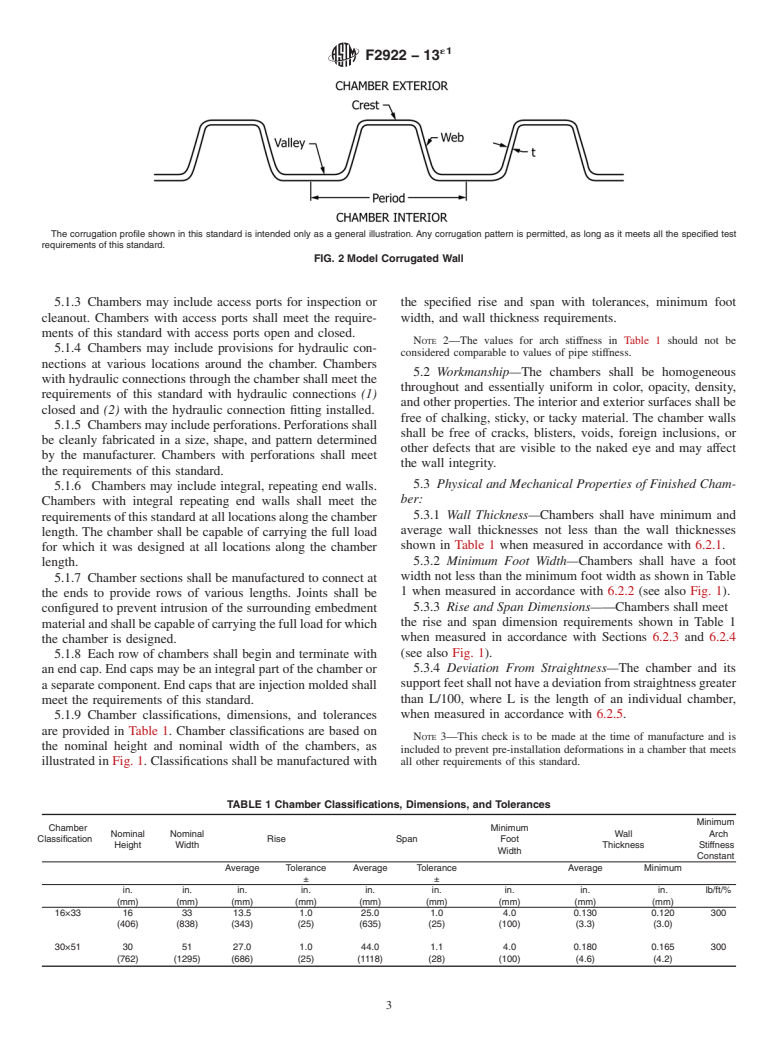

1.2 Chambers are produced in arch shapes with dimensions

Creep and Creep-Rupture of Plastics

based on chamber rise, chamber span, and wall stiffness.

D3350 Specification for Polyethylene Plastics Pipe and Fit-

Chambersaremanufacturedwithintegralfeetthatprovidebase

tings Materials

support. Chambers may include perforations to enhance water

D4329 Practice for Fluorescent Ultraviolet (UV) Lamp Ap-

flow. Chambers must meet test requirements for arch stiffness,

paratus Exposure of Plastics

flattening, and accelerated weathering.

D4703 Practice for Compression Molding Thermoplastic

1.3 Analysis and experience have shown that the successful

Materials into Test Specimens, Plaques, or Sheets

performance of this product depends upon the type and depth D6992 Test Method for Accelerated Tensile Creep and

of bedding and backfill, and care in installation. This specifi- Creep-Rupture of Geosynthetic Materials Based on Time-

Temperature Superposition Using the Stepped Isothermal

cation includes requirements for the manufacturer to provide

Method

chamber installation instructions to the purchaser.

F412 Terminology Relating to Plastic Piping Systems

1.4 The values stated in inch-pound units are to be regarded

F2136 Test Method for Notched, Constant Ligament-Stress

as standard. The values given in parentheses are mathematical

(NCLS) Test to Determine Slow-Crack-Growth Resis-

conversions to SI units that are provided for information only

tance of HDPE Resins or HDPE Corrugated Pipe

and are not considered standard.

F2787 Practice for Structural Design of Thermoplastic Cor-

rugated Wall Stormwater Collection Chambers

1.5 The following safety hazards caveat pertains only to the

test method portion, Section 6, of this specification:This

3. Terminology

standard does not purport to address all of the safety concerns,

3.1 Definitions—Definitions used in this specification are in

if any, associated with its use. It is the responsibility of the user

accordance with the definitions in Terminology F412, and

of this standard to establish appropriate safety and health

abbreviations are in accordance with Terminology D1600,

practices and determine the applicability of regulatory limita-

unless otherwise indicated.

tions prior to use.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 chamber—an arch-shaped structure manufactured of

thermoplastic with an open-bottom that is supported on feet

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.65 on Land

2

Drainage. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2013. Published December 2013. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ε1

approved in 2012. Last previous edition approved in 2012 as F2922-12 . DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F2922–13E01. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

F2922−13

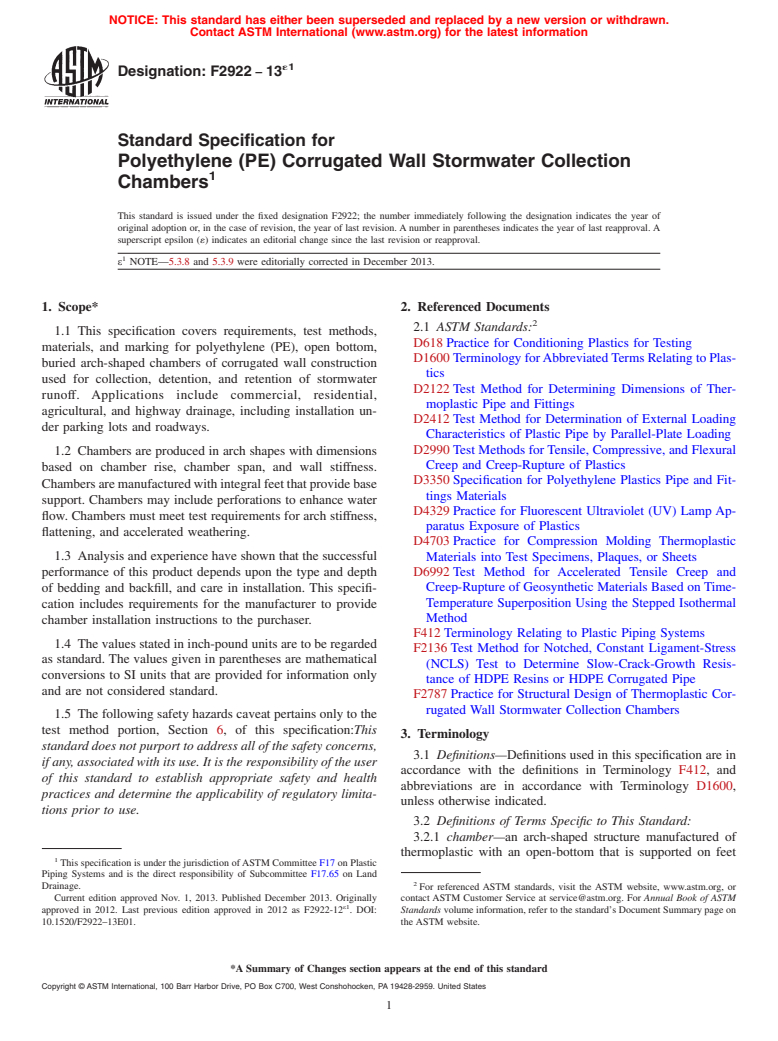

and may be joined into rows that begin with, and are termi- 3.2.14 valley—the element of a corrugated wall located at

nated by, end caps (see Fig. 1). the interior surface of the chamber wall, spanning between two

webs (see Fig. 2).

3.2.2 cham

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.