ASTM A255-99

(Test Method)Standard Test Method for Determining Hardenability of Steel

Standard Test Method for Determining Hardenability of Steel

SCOPE

1.1 These test methods cover the identification and description of test methods for determining the hardenability of steels. The two test methods include the quantitative end-quench or Jominy Test and a method for calculating the hardenability of steel from the chemical composition based on the original work by M. A. Grossman.

1.2 The selection of the test method to be used for determining the hardenability of a given steel shall be agreed upon between the supplier and user. The Certified Material Test Report shall state the method of hardenability determination.

1.3 The calculation method described in these test methods is applicable only to the range of chemical compositions that follow: ElementRange, % Carbon0.10-0.70 Manganese0.50-1.65 Silicon0.15-0.60 Chromium1.35 max Nickel1.50 max Molybdenum0.55 max

1.4 Hardenability is a measure of the depth to which steel will harden when quenched from its austenitizing temperature (Table 1). It is measured quantitatively, usually by noting the extent or depth of hardening of a standard size and shape of test specimen in a standardized quench. In the end-quench test the depth of hardening is the distance along the specimen from the quenched end which correlates to a given hardness level.

1.5 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 255 – 99 An American National Standard

Standard Test Methods for

Determining Hardenability of Steel

This standard is issued under the fixed designation A 255; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

A

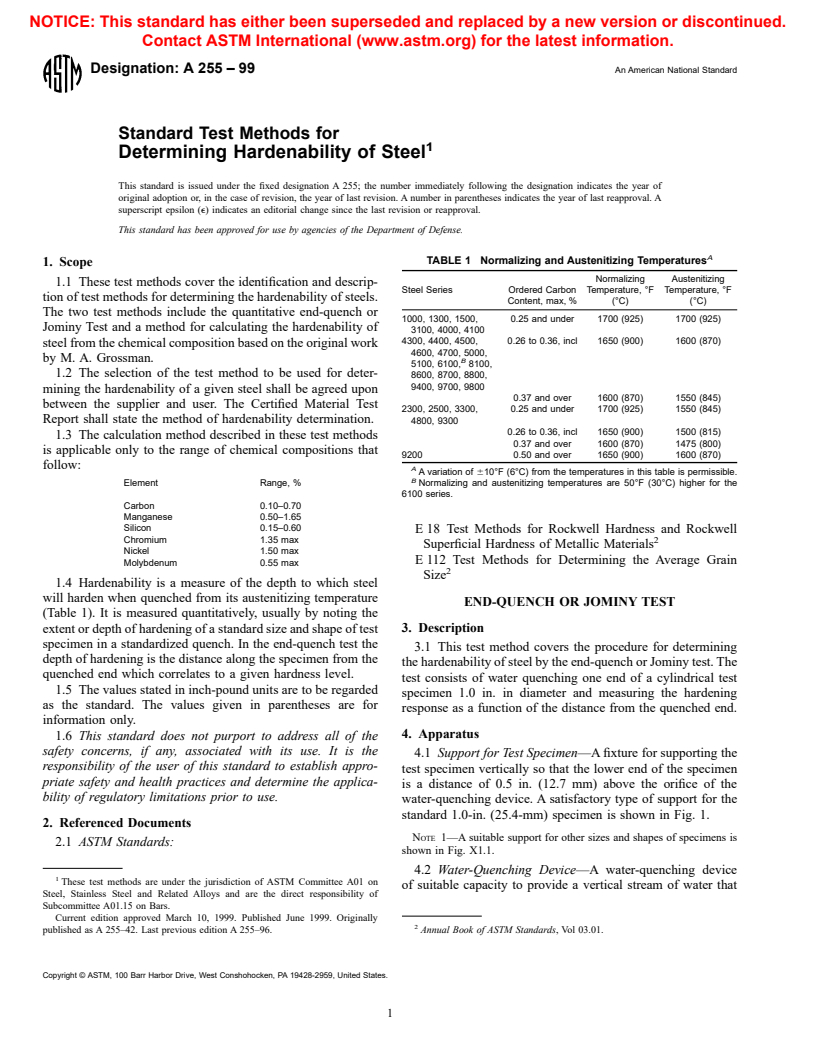

TABLE 1 Normalizing and Austenitizing Temperatures

1. Scope

Normalizing Austenitizing

1.1 These test methods cover the identification and descrip-

Steel Series Ordered Carbon Temperature, °F Temperature, °F

tion of test methods for determining the hardenability of steels.

Content, max, % (°C) (°C)

The two test methods include the quantitative end-quench or

1000, 1300, 1500, 0.25 and under 1700 (925) 1700 (925)

Jominy Test and a method for calculating the hardenability of

3100, 4000, 4100

4300, 4400, 4500, 0.26 to 0.36, incl 1650 (900) 1600 (870)

steel from the chemical composition based on the original work

4600, 4700, 5000,

by M. A. Grossman.

B

5100, 6100, 8100,

1.2 The selection of the test method to be used for deter- 8600, 8700, 8800,

9400, 9700, 9800

mining the hardenability of a given steel shall be agreed upon

0.37 and over 1600 (870) 1550 (845)

between the supplier and user. The Certified Material Test

2300, 2500, 3300, 0.25 and under 1700 (925) 1550 (845)

Report shall state the method of hardenability determination. 4800, 9300

0.26 to 0.36, incl 1650 (900) 1500 (815)

1.3 The calculation method described in these test methods

0.37 and over 1600 (870) 1475 (800)

is applicable only to the range of chemical compositions that

9200 0.50 and over 1650 (900) 1600 (870)

follow:

A

A variation of 610°F (6°C) from the temperatures in this table is permissible.

B

Element Range, % Normalizing and austenitizing temperatures are 50°F (30°C) higher for the

6100 series.

Carbon 0.10–0.70

Manganese 0.50–1.65

Silicon 0.15–0.60

E 18 Test Methods for Rockwell Hardness and Rockwell

Chromium 1.35 max 2

Superficial Hardness of Metallic Materials

Nickel 1.50 max

E 112 Test Methods for Determining the Average Grain

Molybdenum 0.55 max

Size

1.4 Hardenability is a measure of the depth to which steel

will harden when quenched from its austenitizing temperature

END-QUENCH OR JOMINY TEST

(Table 1). It is measured quantitatively, usually by noting the

3. Description

extent or depth of hardening of a standard size and shape of test

specimen in a standardized quench. In the end-quench test the

3.1 This test method covers the procedure for determining

depth of hardening is the distance along the specimen from the

the hardenability of steel by the end-quench or Jominy test. The

quenched end which correlates to a given hardness level.

test consists of water quenching one end of a cylindrical test

1.5 The values stated in inch-pound units are to be regarded

specimen 1.0 in. in diameter and measuring the hardening

as the standard. The values given in parentheses are for

response as a function of the distance from the quenched end.

information only.

4. Apparatus

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4.1 Support for Test Specimen—A fixture for supporting the

responsibility of the user of this standard to establish appro-

test specimen vertically so that the lower end of the specimen

priate safety and health practices and determine the applica-

is a distance of 0.5 in. (12.7 mm) above the orifice of the

bility of regulatory limitations prior to use.

water-quenching device. A satisfactory type of support for the

standard 1.0-in. (25.4-mm) specimen is shown in Fig. 1.

2. Referenced Documents

NOTE 1—A suitable support for other sizes and shapes of specimens is

2.1 ASTM Standards:

shown in Fig. X1.1.

4.2 Water-Quenching Device—A water-quenching device

These test methods are under the jurisdiction of ASTM Committee A01 on

of suitable capacity to provide a vertical stream of water that

Steel, Stainless Steel and Related Alloys and are the direct responsibility of

Subcommittee A01.15 on Bars.

Current edition approved March 10, 1999. Published June 1999. Originally

published as A 255–42. Last previous edition A 255–96. Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

A 255

FIG. 1 Test Specimen in Support for Water Quenching

can be controlled to a height of 2.5 in. (63.5 mm) when passing may be waived by agreement between the supplier and the

through an orifice 0.5 in. (12.7 mm) in diameter. A tank of user. The previous thermal history of the specimen tested shall

sufficient capacity to maintain the water temperature require- always be recorded.

ments of 6.3 with a small pump and control valves will be 5.2 Cast Specimens—A separately cast end-quench speci-

found satisfactory. The water-supply line shall also be provided men may be used for non-boron steels. Cast specimens are not

with a quick opening valve. suitable for boron steel grades due to erratic results. A graphite

or metal mold may be used to form an overlength specimen 1.0

5. Test Specimens

in. (25.4 mm) in diameter which shall be cut to the standard

specimen size. The mold may also be used to form a 1.25-in.

5.1 Wrought Specimens—End-quench specimens shall be

(31.8-mm) diameter specimen which shall be machined to the

prepared from rolled or forged stock and shall represent the full

cross section of the product. If negotiated between the supplier final specimen size. Cast tests need not be normalized.

and the user, the end-quench specimen may be prepared from

NOTE 2—Other sizes and shapes of test specimens are described in

a given location in a forged or rolled product or from a

Appendix X1.

continuous cast billet. The test specimen shall be 1.0 in. (25.4

6. Procedure

mm) in diameter by 4.0 in. (101.6 mm) in length, with means

for hanging it in a vertical position for end quenching. 6.1 Normalizing—The wrought product from which the

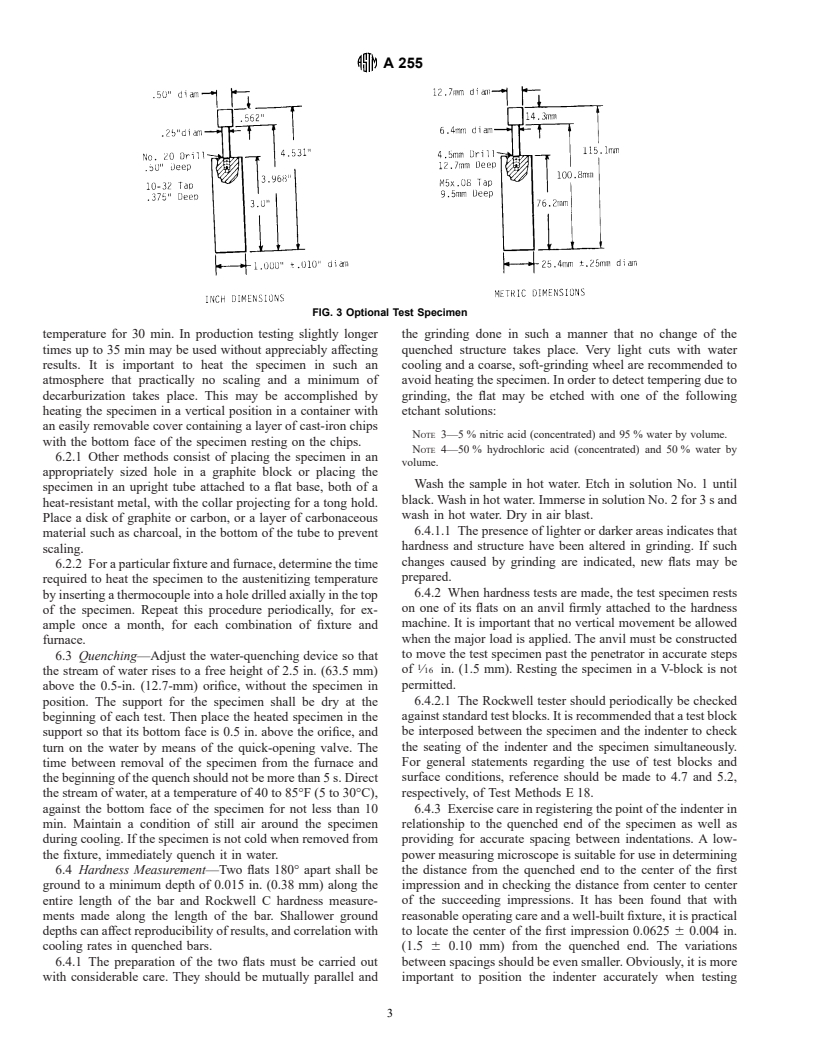

Dimensions of the preferred specimen and of an optional specimen is to be prepared shall be normalized to ensure proper

specimen (Note 2) are given in Fig. 2 and Fig. 3. The specimen hardening characteristics. The sample shall be held at the

shall be machined from a bar previously normalized in temperature listed in Table 1 for 1 h and cooled in air.

accordance with 6.1 and of such size as to permit the removal Tempering of the normalized sample to improve machinability

of all decarburization in machining to 1.0 in. round. The end of is permitted.

the specimen to be water cooled shall have a reasonably 6.2 Heating—Place the specimen in a furnace that is at the

smooth finish, preferably produced by grinding. Normalizing specified austenitizing temperature (Table 1) and hold at this

FIG. 2 Preferred Test Specimen

A 255

FIG. 3 Optional Test Specimen

temperature for 30 min. In production testing slightly longer the grinding done in such a manner that no change of the

times up to 35 min may be used without appreciably affecting quenched structure takes place. Very light cuts with water

results. It is important to heat the specimen in such an cooling and a coarse, soft-grinding wheel are recommended to

atmosphere that practically no scaling and a minimum of avoid heating the specimen. In order to detect tempering due to

decarburization takes place. This may be accomplished by grinding, the flat may be etched with one of the following

heating the specimen in a vertical position in a container with etchant solutions:

an easily removable cover containing a layer of cast-iron chips

NOTE 3—5 % nitric acid (concentrated) and 95 % water by volume.

with the bottom face of the specimen resting on the chips.

NOTE 4—50 % hydrochloric acid (concentrated) and 50 % water by

6.2.1 Other methods consist of placing the specimen in an

volume.

appropriately sized hole in a graphite block or placing the

Wash the sample in hot water. Etch in solution No. 1 until

specimen in an upright tube attached to a flat base, both of a

black. Wash in hot water. Immerse in solution No. 2 for3sand

heat-resistant metal, with the collar projecting for a tong hold.

wash in hot water. Dry in air blast.

Place a disk of graphite or carbon, or a layer of carbonaceous

6.4.1.1 The presence of lighter or darker areas indicates that

material such as charcoal, in the bottom of the tube to prevent

hardness and structure have been altered in grinding. If such

scaling.

changes caused by grinding are indicated, new flats may be

6.2.2 For a particular fixture and furnace, determine the time

prepared.

required to heat the specimen to the austenitizing temperature

6.4.2 When hardness tests are made, the test specimen rests

by inserting a thermocouple into a hole drilled axially in the top

on one of its flats on an anvil firmly attached to the hardness

of the specimen. Repeat this procedure periodically, for ex-

machine. It is important that no vertical movement be allowed

ample once a month, for each combination of fixture and

when the major load is applied. The anvil must be constructed

furnace.

to move the test specimen past the penetrator in accurate steps

6.3 Quenching—Adjust the water-quenching device so that

of ⁄16 in. (1.5 mm). Resting the specimen in a V-block is not

the stream of water rises to a free height of 2.5 in. (63.5 mm)

permitted.

above the 0.5-in. (12.7-mm) orifice, without the specimen in

6.4.2.1 The Rockwell tester should periodically be checked

position. The support for the specimen shall be dry at the

beginning of each test. Then place the heated specimen in the against standard test blocks. It is recommended that a test block

be interposed between the specimen and the indenter to check

support so that its bottom face is 0.5 in. above the orifice, and

turn on the water by means of the quick-opening valve. The the seating of the indenter and the specimen simultaneously.

For general statements regarding the use of test blocks and

time between removal of the specimen from the furnace and

surface conditions, reference should be made to 4.7 and 5.2,

the beginning of the quench should not be more than 5 s. Direct

respectively, of Test Methods E 18.

the stream of water, at a temperature of 40 to 85°F (5 to 30°C),

against the bottom face of the specimen for not less than 10 6.4.3 Exercise care in registering the point of the indenter in

relationship to the quenched end of the specimen as well as

min. Maintain a condition of still air around the specimen

during cooling. If the specimen is not cold when removed from providing for accurate spacing between indentations. A low-

the fixture, immediately quench it in water. power measuring microscope is suitable for use in determining

6.4 Hardness Measurement—Two flats 180° apart shall be the distance from the quenched end to the center of the first

ground to a minimum depth of 0.015 in. (0.38 mm) along the impression and in checking the distance from center to center

entire length of the bar and Rockwell C hardness measure- of the succeeding impressions. It has been found that with

ments made along the length of the bar. Shallower ground reasonable operating care and a well-built fixture, it is practical

depths can affect reproducibility of results, and correlation with to locate the center of the first impression 0.0625 6 0.004 in.

cooling rates in quenched bars. (1.5 6 0.10 mm) from the quenched end. The variations

6.4.1 The preparation of the two flats must be carried out between spacings should be even smaller. Obviously, it is more

with considerable care. They should be mutually parallel and important to position the indenter accurately when testing

A 255

low-hardenability steels than when testing high-hardenability 9.1.4 A prominent notation on the standard hardenability

steels. The positioning of the indenter should be checked with chart if any of the test specimens listed in Appendix X1 are

sufficient frequency to provide assurance that accuracy require- used.

ments are being met. In cases of lack of reproducibility or of

differences between laboratories, indenter spacing should be CALCULATION OF HARDENABILITY

measured immediately.

10. Introduction

6.4.4 Readings shall be taken in steps of ⁄16 in. (1.6 mm)

for the first 16 sixteenths (25.4 mm), then 18, 20, 22, 24, 28,

10.1 This method of Jominy Hardenability calculation from

and 32 sixteenths of an inch. Values below 20 HRC are not

the chemical ideal diameter (DI) on a steel is based on the

recorded because such values are not accurate. When a flat on

original work of M. A. Grossman and provides increased

which readings have been made is used as a base, the burrs

accuracy by refinement of the carbon multiplying factors and

around the indentation shall be removed by grinding unless a

the correlation of a boron factor (B.F.) with carbon and alloy

fixture is used which has been relieved to accommodate the

content. These refinements were based on analysis of thou-

irregularities due to the indentations.

sands of heats of boron and non-boron 1500, 4100, 5000, and

6.4.4.1 Hardness readings should preferably be made on

8600 series steels encompassing a range of compositions as

two flats 180° apart. Testing on two flats will assist in the

follows and a range of DI as contained in Tables 2-5. The

detection of errors in specimen preparation and hardness

accuracy of this test method and the techniques used to develop

measurement. If the two probes on opposite sides differ by

it have been documented. For comparison of this test method to

more than 4 HRC points at any one position, the test should be

others, or for steel compositions outside the mentioned grades,

repeated on new flats, 90° from the first two flats. If the retest

the user should refer to other articles concerned with calculat-

also has greater than 4 HRC points spread, a new specimen

ing hardenability.

should be tested.

Element Range, %

6.4.4.2 For reporting purposes, hardness readings should be

Carbon 0.10–0.70

recorded to the nearest integer, with 0.5 HRC values rounded

Manganese 0.50–1.65

to the next higher integer. Silicon 0.15–0.60

Chromium 1.35 max

7. Plotting Test Results

Nickel 1.50 max

Molybdenum 0.55 max

7.1 Test results should be plotted on a standard hardenabil-

ity chart prepared for this purpose, in which the ordinates

10.2 DI Calculation for Non-Boron Steels—This calcula-

represent HRC values and the abscissae represent the distance

tion relies on a series of hardenability factors (Table 6) for each

from the quen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.