ASTM B48-00(2011)

(Specification)Standard Specification for Soft Rectangular and Square Bare Copper Wire for Electrical Conductors

Standard Specification for Soft Rectangular and Square Bare Copper Wire for Electrical Conductors

ABSTRACT

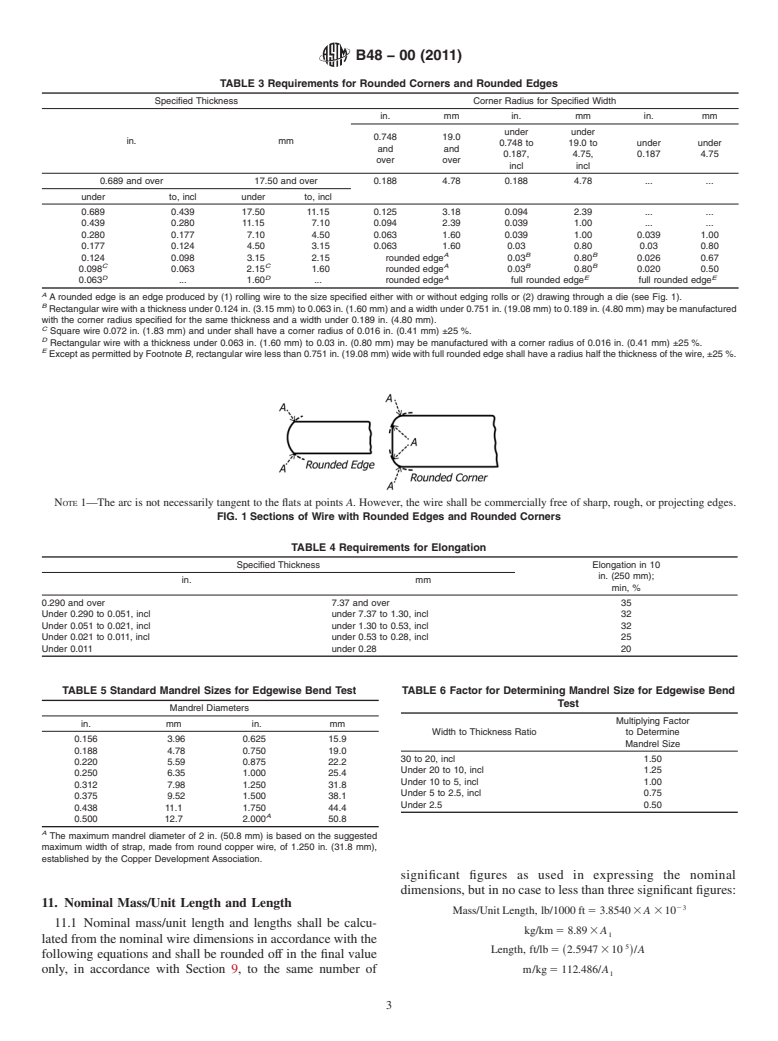

This specification covers soft or annealed bare copper wire, rectangular or square in shape with rounded corners. For the purpose of this specification, the wire shall be classified as Type A and Type B. The wire shall be annealed after the last drawing or rolling to size and shape, and shall be processed as to produce a uniformly soft product with a clean surface. The finished wire shall not contain joints except such as have passed through drawing dies. Necessary joints in the wire and rods prior to final drawing shall be made in accordance with good commercial practice. Material dimensions, such as thickness and width, shall not vary from that specified by more than the amounts prescribed. The wire shall conform to the requirements for rounded corners and rounded edges. The material shall undergo physical tests, and shall conform to the elongation and bending requirements. For the purpose of this specification, all wire dimensions and properties shall be considered ac occurring at the internationally standardized reference temperature. Nominal cross-sectional areas shall be calculated by subtracting the area reductions due to rounded corners or rounded edges. Nominal mass/unit length and lengths shall be calculated from the nominal wire dimensions in accordance with the following equations and shall be rounded off in the final value only. Electrical resistivity shall be determined on representative samples by resistance measurements. Tests to determine conformance to electrical resistance requirements shall be made on the uninsulated conductor.

SCOPE

1.1 This specification covers soft or annealed bare copper wire, rectangular or square in shape with rounded corners (Explanatory Note 1).

1.2 For the purpose of this specification, the wire is classified as follows:

1.2.1 Type A—For all applications except those involving edgewise bending.

1.2.2 Type B—For applications involving edgewise bending. Type B wire of thickness less than 0.020 in. (0.51 mm) or with a ratio of width to thickness greater than 30 to 1 is not contemplated in this specification.

1.3 Unless otherwise specified by the purchaser, Type A material shall be furnished.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard; except for Sections 12 and 13.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B48 −00(Reapproved 2011)

Standard Specification for

Soft Rectangular and Square Bare Copper Wire for

1

Electrical Conductors

This standard is issued under the fixed designation B48; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Other Documents:

3

NBS Handbook 100 Copper Wire Tables

1.1 This specification covers soft or annealed bare copper

wire, rectangular or square in shape with rounded corners

3. Ordering Information

(Explanatory Note 1).

3.1 Orders for material to this specification shall include the

1.2 For the purpose of this specification, the wire is classi-

following information:

fied as follows:

3.1.1 Quantity of each size;

1.2.1 Type A—For all applications except those involving

3.1.2 Type of wire (see 1.1, 1.2, and 1.3);

edgewise bending.

3.1.3 Wire size: thickness and width, in inches or millime-

1.2.2 Type B—Forapplicationsinvolvingedgewisebending.

tres (see 6.1);

Type B wire of thickness less than 0.020 in. (0.51 mm) or with

3.1.4 Type of copper, if special (see Section 4);

a ratio of width to thickness greater than 30 to 1 is not

3.1.5 Package size (see 16.1);

contemplated in this specification.

3.1.6 Special package marking, if required; and

3.1.7 Place of inspection. (see Section 15).

1.3 Unless otherwise specified by the purchaser, Type A

material shall be furnished.

4. Material

1.4 The values stated in inch-pound units are to be regarded

4.1 The material shall be copper of such quality and purity

as standard. The values given in parentheses are mathematical

that the finished product shall have the properties and charac-

conversions to SI units that are provided for information only

teristics prescribed in this specification.

and are not considered standard; except for Sections 12 and 13.

4.2 Specification B49 defines the materials suitable for use.

2. Referenced Documents

5. Manufacture

2

2.1 ASTM Standards:

5.1 The wire shall be annealed after the last drawing or

B49 Specification for Copper Rod for Electrical Purposes

rolling to size and shape, and shall be so processed as to

B193 Test Method for Resistivity of Electrical Conductor

produce a uniformly soft product with a clean surface.

Materials

B279 Test Method for Stiffness of Bare Soft Square and 5.2 The finished wire shall not contain joints except such as

Rectangular Copper andAluminumWire for MagnetWire have passed through drawing dies. Necessary joints in the wire

Fabrication and rods prior to final drawing shall be made in accordance

E8 Test Methods for Tension Testing of Metallic Materials

with good commercial practice.

E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications 6. Dimensions and Permissible Variations

6.1 The dimensions shall be expressed in decimal fractions

of an inch or in millimetres. Unless otherwise specified, it will

1

be assumed that the dimensions are in inches. (Explanatory

This specification is under the jurisdiction of ASTM Committee B01 on

Electrical Conductorsand is the direct responsibility of Subcommittee B01.04 on

Note 6, Explanatory Note 7, and Explanatory Note 8.)

Conductors of Copper and Copper Alloys.

6.2 The thickness shall not vary from that specified by more

Current edition approved April 1, 2011. Published September 2011. Originally

ε1

approved in 1968. Last previous edition approved in 2005 as B48 – 00(2005) .

than the amounts prescribed in Table 1.

DOI: 10.1520/B0048-00R11.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from National Institute of Standards and Technology (NIST), 100

the ASTM website. Bureau Dr., Stop 3460, Gaithersburg, MD 20899-3460.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

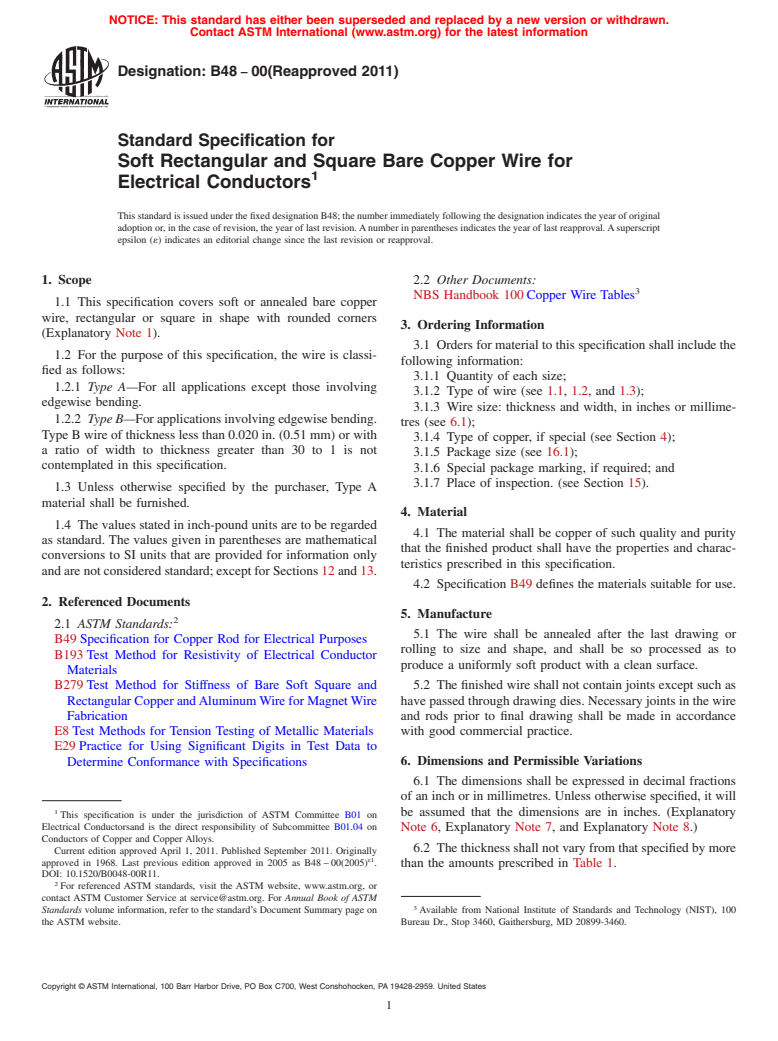

B48−00 (2011)

TABLE 1 Variation in Thickness

Width

Specified Thickness

Over 1,000 1.000 in. (25.4 mm) Under

in. (25.4 mm) to 0.492 in. (12.5 mm) 0.492 in. (12.5 mm)

Permissible Variation in Thickness, max, plus and minus

in. mm

in % mm in. % mm in. % mm

0.501 and over 12.73 and over . 1 . . 1 . . . .

under to, incl under to, incl

0.501 0.280 12.73 7.11 . 1 . . 1 . 0.003 . 0.076

0.280 0.201 7.11 5.11 0.003 . 0.08 . 1 . . 1 .

0.201 0.098 5.11 2.49 0.0025 . 0.064 . 1 . . 1 .

0.098 0.051 2.49 1.30 0.002 . 0.051 0.001 . 0.03 0.001 . 0.03

0.051 . 1.30 . 0.0015 . 0.038 0.001

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.