ASTM A681-07

(Specification)Standard Specification for Tool Steels Alloy

Standard Specification for Tool Steels Alloy

SCOPE

1.1 This specification covers the chemical, mechanical, and physical requirements for available wrought alloy tool steel products.

1.2 These products, which include hot or cold finished bar, plate, sheet, strip, rod, wire, or forgings, are normally fabricated into tools, dies, or fixtures. The selection of a material for a particular application will depend upon design, service conditions, and desired properties.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 681 – 07

Standard Specification for

1

Tool Steels Alloy

This standard is issued under the fixed designation A 681; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope MIL-STD-163 Steel Mill Products, Preparation for Ship-

4

ment and Storage

1.1 This specification covers the chemical, mechanical, and

2.3 Federal Standards:

physical requirements for available wrought alloy tool steel

4

Fed. Std. No. 123 Marking and Shipment (CivilAgencies)

products.

Fed. Std. No. 183 Continuous Identification Marking of

1.2 These products, which include hot or cold finished bar,

4

Iron and Steel Products

plate, sheet, strip, rod, wire, or forgings, are normally fabri-

2.4 Other Standards:

catedintotools,dies,orfixtures.Theselectionofamaterialfor

SAE J1086 Recommended Practice for Numbering Metals

a particular application will depend upon design, service

5

and Alloys (UNS)

conditions, and desired properties.

1.3 The values stated in inch-pound units are to be regarded

3. Classification

as standard. The values given in parentheses are mathematical

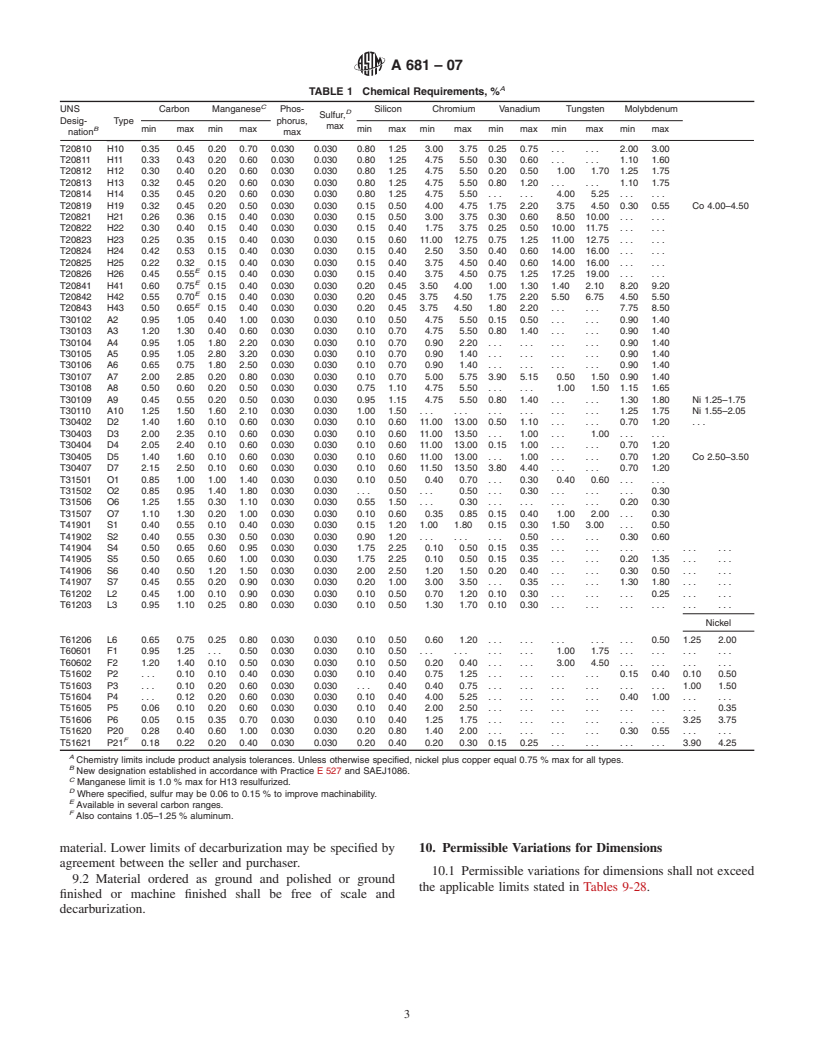

3.1 Material in accordance with this specification is classi-

conversions to SI units that are provided for information only

fied by chemical composition. Types correspond to respective

and are not considered standard.

AISI designations.

2. Referenced Documents 3.1.1 Hot Work Tool Steels, Identification H:

2

3.1.1.1 Types H10 to H19 are characterized by a controlled

2.1 ASTM Standards:

chromium content along with other alloying elements.The first

A 370 Test Methods and Definitions for MechanicalTesting

four, containing molybdenum, offer excellent toughness and

of Steel Products

high hardenability and are frequently used in cold work

A 561 Practice for Macroetch Testing of Tool Steel Bars

applications requiring toughness at relatively high hardness

A 600 Specification for Tool Steel High Speed

levels.

A 700 Practices for Packaging, Marking, and Loading

3.1.1.2 Types H21 to H26 are characterized by a controlled

Methods for Steel Products for Shipment

tungsten content along with other alloying elements. These

E3 Guide for Preparation of Metallographic Specimens

steels offer greater resistance to the softening effect of elevated

E30 Test Methods for Chemical Analysis of Steel, Cast

3

service temperatures but exhibit a lower degree of toughness.

Iron, Open-Hearth Iron, and Wrought Iron

3.1.1.3 Types H41 to H43 are low-carbon modifications of

E45 Test Methods for Determining the Inclusion Content

molybdenum high speed tool steels (Note 1) and have charac-

of Steel

teristics similar to the tungsten types.

E59 PracticeforSamplingSteelandIronforDetermination

3

of Chemical Composition

NOTE 1—High-speed tool steels are covered in Specification A 600.

E 527 Practice for Numbering Metals and Alloys (UNS)

3.1.2 Cold Work Tool Steels, Identification A—Types A2 to

2.2 Military Standard:

A10 cover a wide range of carbon and alloy contents but all

have high hardenability and may be hardened in air. The low

carbon Types A8 and A9 have less wear resistance but offer

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, greater toughness than others in this group.TypeA7, with high

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

carbon and vanadium, offers exceptional wear resistance but at

A01.29 on Tool Steels.

a very low level of toughness.

Current edition approved Sept. 1, 2007. Published September 2007. Originally

approved in 1973. Last previous edition approved in 2004 as A 681 – 94 (2004).

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from the Standardization Documents, Order Desk, Bldg. 4, Section

Standards volume information, refer to the standard’s Document Summary page on D 700 Robbins Ave. Philadelphia, PA 19111-5094 Attn: NPODS.

5

the ASTM website. Available from the Society ofAutomotive Engineers, 400 Commonwelth drive,

3

Withdrawn. Warrendale, PA 15096.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 681–07

3.1.3 Cold Work Tool Steels, Identification D—Types D2 to drilling parallel to the axis of the bar or forging at any point

D7 are characterized by high carbon and high chromium midway between the center and surface in accordance with the

contents and exhibit high resistance to abrasion. The type

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.