ASTM F2519-05(2011)e1

(Test Method)Standard Test Method for Grease Particle Capture Efficiency of Commercial Kitchen Filters and Extractors

Standard Test Method for Grease Particle Capture Efficiency of Commercial Kitchen Filters and Extractors

SIGNIFICANCE AND USE

5.1 The pressure drop results can be added to the pressure drops of other components in an exhaust system to determine the total exhaust fan pressure requirement.

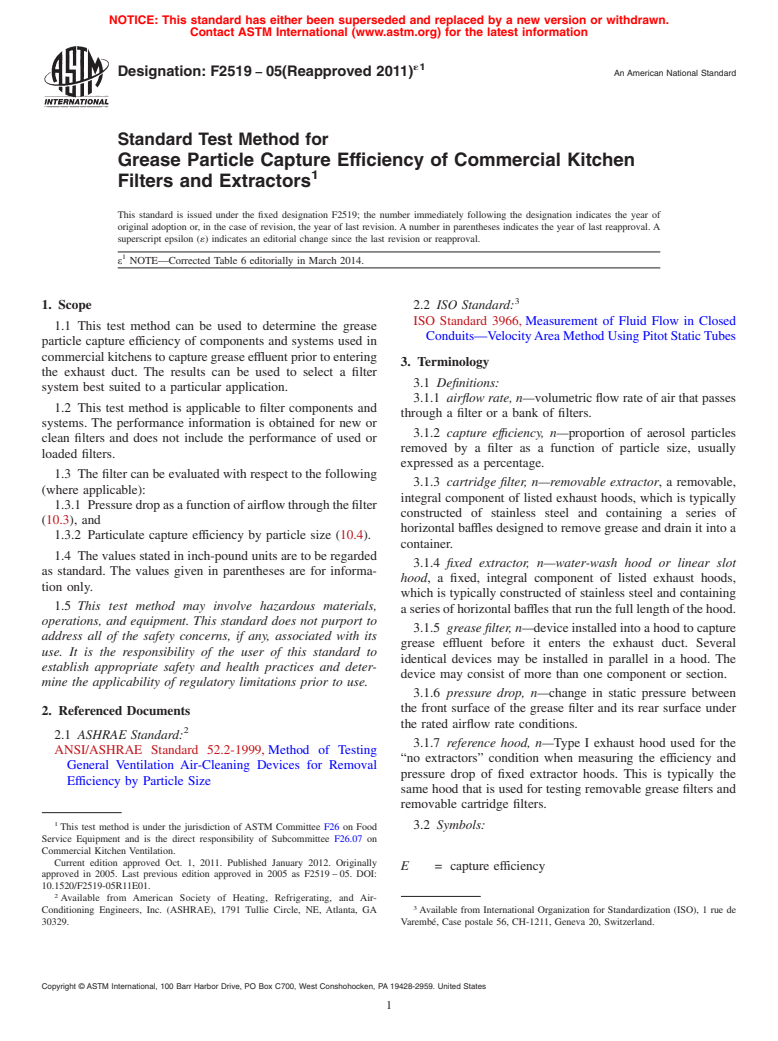

5.2 The particulate capture efficiency can be used with known particulate size emission data for a cooking appliance-food product combination to determine the total mass of grease particles captured by the filter, the total mass of grease particles that pass through the filter, and the particle size distribution of the grease particles that pass through the filter. Fig. 1 shows an example particle capture efficiency curve.

SCOPE

1.1 This test method can be used to determine the grease particle capture efficiency of components and systems used in commercial kitchens to capture grease effluent prior to entering the exhaust duct. The results can be used to select a filter system best suited to a particular application.

1.2 This test method is applicable to filter components and systems. The performance information is obtained for new or clean filters and does not include the performance of used or loaded filters.

1.3 The filter can be evaluated with respect to the following (where applicable):

1.3.1 Pressure drop as a function of airflow through the filter (10.3), and

1.3.2 Particulate capture efficiency by particle size (10.4).

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are for information only.

1.5 This test method may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F2519 − 05(Reapproved 2011) An American National Standard

Standard Test Method for

Grease Particle Capture Efficiency of Commercial Kitchen

Filters and Extractors

This standard is issued under the fixed designation F2519; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Corrected Table 6 editorially in March 2014.

1. Scope 2.2 ISO Standard:

ISO Standard 3966, Measurement of Fluid Flow in Closed

1.1 This test method can be used to determine the grease

Conduits—VelocityArea Method Using Pitot StaticTubes

particle capture efficiency of components and systems used in

commercial kitchens to capture grease effluent prior to entering

3. Terminology

the exhaust duct. The results can be used to select a filter

3.1 Definitions:

system best suited to a particular application.

3.1.1 airflow rate, n—volumetric flow rate of air that passes

1.2 This test method is applicable to filter components and

through a filter or a bank of filters.

systems. The performance information is obtained for new or

3.1.2 capture effıciency, n—proportion of aerosol particles

clean filters and does not include the performance of used or

removed by a filter as a function of particle size, usually

loaded filters.

expressed as a percentage.

1.3 The filter can be evaluated with respect to the following

3.1.3 cartridge filter, n—removable extractor, a removable,

(where applicable):

integral component of listed exhaust hoods, which is typically

1.3.1 Pressuredropasafunctionofairflowthroughthefilter

constructed of stainless steel and containing a series of

(10.3), and

horizontal baffles designed to remove grease and drain it into a

1.3.2 Particulate capture efficiency by particle size (10.4).

container.

1.4 The values stated in inch-pound units are to be regarded

3.1.4 fixed extractor, n—water-wash hood or linear slot

as standard. The values given in parentheses are for informa-

hood, a fixed, integral component of listed exhaust hoods,

tion only.

which is typically constructed of stainless steel and containing

1.5 This test method may involve hazardous materials,

aseriesofhorizontalbafflesthatrunthefulllengthofthehood.

operations, and equipment. This standard does not purport to

3.1.5 grease filter, n—device installed into a hood to capture

address all of the safety concerns, if any, associated with its

grease effluent before it enters the exhaust duct. Several

use. It is the responsibility of the user of this standard to

identical devices may be installed in parallel in a hood. The

establish appropriate safety and health practices and deter-

device may consist of more than one component or section.

mine the applicability of regulatory limitations prior to use.

3.1.6 pressure drop, n—change in static pressure between

the front surface of the grease filter and its rear surface under

2. Referenced Documents

the rated airflow rate conditions.

2.1 ASHRAE Standard:

3.1.7 reference hood, n—Type I exhaust hood used for the

ANSI/ASHRAE Standard 52.2-1999, Method of Testing

“no extractors” condition when measuring the efficiency and

General Ventilation Air-Cleaning Devices for Removal

pressure drop of fixed extractor hoods. This is typically the

Efficiency by Particle Size

same hood that is used for testing removable grease filters and

removable cartridge filters.

This test method is under the jurisdiction of ASTM Committee F26 on Food 3.2 Symbols:

Service Equipment and is the direct responsibility of Subcommittee F26.07 on

Commercial Kitchen Ventilation.

Current edition approved Oct. 1, 2011. Published January 2012. Originally

E = capture efficiency

approved in 2005. Last previous edition approved in 2005 as F2519 – 05. DOI:

10.1520/F2519-05R11E01.

Available from American Society of Heating, Refrigerating, and Air-

Conditioning Engineers, Inc. (ASHRAE), 1791 Tullie Circle, NE, Atlanta, GA Available from International Organization for Standardization (ISO), 1 rue de

30329. Varembé, Case postale 56, CH-1211, Geneva 20, Switzerland.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

F2519 − 05 (2011)

4.3 The total airflow rate through the exhaust system is set

n = number of sample sets

so that the volumetric flow rate through the filter under test is

P = penetration

equivalent 250 cfm per linear foot (width) of filter (based on

t = t distribution variable

T = sampling time external filter dimensions).

W = counts of each size range (or channel) with test

4.3.1 Performancemayalsobeevaluatedatotherairflowsin

device(s) installed

accordance with manufacturer recommendations (see Appen-

WO = counts of each size range (or channel) without test

dix X1).

device(s)

4.4 Balanced makeup air shall be provided at 75 6 5°F and

δ = standard deviation of a sample

50 6 20 % RH.

4.5 Particulate capture efficiency for removable grease filter

or removable cartridges is determined by comparing particle

3.3 Subscripts:

concentration versus size in the exhaust duct with and without

the filters installed.

b = background

4.5.1 Particulate capture efficiency for hoods with fixed

c = correlation

e = estimated extractorsisdeterminedbycomparingparticleconcentrationas

i = sample number a function of particle size in the exhaust duct with the fixed

lcl = lower confidence limit

extractor hood and the reference hood without the filters

n = number of sample sets

installed.

o = observed

4.5.2 The test aerosol is oleic acid that covers a size range

t = testing a filter

from 0.3 to 10 µm in diameter or as specified by the

ucl = upper confidence limit

manufacturer. Efficiency shall be reported as zero from 0.3 µm

w = with test device(s) installed

to the lower limit of the test conditions. Particulate concentra-

wo = without test device(s) installed

tion measurements (as a function of particle size) are taken in

the exhaust duct using an isokinetic sampling probe and an

4. Summary of Test Method

optical particle counter. The particulate capture efficiency is

4.1 There are three predominant classes of filters in kitchen determined by taking the difference between the particle

ventilation grease extraction systems: removable baffle filters, concentration with and without the filters installed at each

removable cartridge filters, and fixed extractors. particle size range set on the particle counter.

4.2 Removable baffle and cartridge filters to be tested are

5. Significance and Use

installed into the test system.

5.1 The pressure drop results can be added to the pressure

4.2.1 Identical filters to be tested are installed into a

drops of other components in an exhaust system to determine

standard 4-ft canopy hood connected to a nominal 12-in. round

the total exhaust fan pressure requirement.

duct exhaust system. The filters should fit tightly together and

into the opening and any bypasses larger than ⁄8-in. wide on 5.2 The particulate capture efficiency can be used with

the ends are sealed. known particulate size emission data for a cooking appliance-

food product combination to determine the total mass of grease

4.2.2 For fixed-extractor systems, a reference hood shall be

particlescapturedbythefilter,thetotalmassofgreaseparticles

used for testing conditions that call for no filters to be installed

that pass through the filter, and the particle size distribution of

in the hood. Testing requires switching between the reference

the grease particles that pass through the filter. Fig. 1 shows an

hood and the fixed extractor hood.

example particle capture efficiency curve.

4.2.3 A filter system to be used in a non-standard canopy

hood is installed at the height of actual application above the

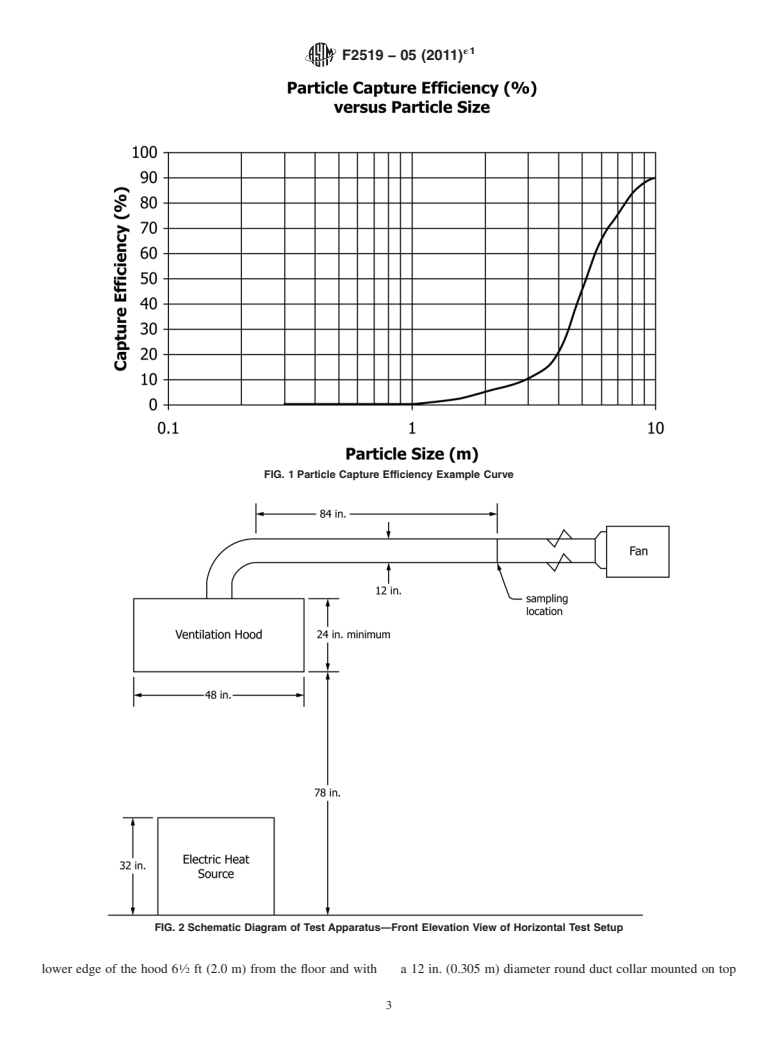

6. Apparatus

floor and connected to a nominal 12-in. round duct exhaust

6.1 Mandatory and Discretionary Requirements—Critical

system.

dimensions and arrangements of the test apparatus are shown

4.2.4 Thestaticpressuredropacrossthefiltersisrecordedat

in Figs. 2-5. Vertical ductwork may also be used with the same

the test airflow.

critical dimensions (duct diameter, length, and so forth). All

4.2.4.1 For removable baffle or cartridge filters, the net filter

dimensions shown are mandatory unless otherwise indicated.

pressure drop is determined by subtracting the pressure drop of

Units shown are in inches unless otherwise indicated. The

the hood when the filters are removed from the pressure drop

design of equipment not specified, including but not limited to

measured when the filters are installed. The total exhaust

exhaust fan, makeup air system, and external structural

volumetric flow rate must be equal in both pressure drop

supports, is discretionary, but the equipment must have ad-

measurements.

equate capacity to meet the requirements of this test method.

4.2.4.2 For fixed-extractor hood systems, the pressure drop

is determined by subtracting the pressure drop of the reference 6.2 Test Facility:

hood when the filters are removed from the pressure drop 6.2.1 Exhaust Hood:

measured on the fixed-extractor hood. The total exhaust 6.2.1.1 The test installation should have a canopy exhaust

volumetric flow rate must be equal in both pressure drop hoodwhichmeetstheserequirements:4ft(1.2m)inwidthand

measurements. depth, minimum 2 ft (0.61 m) in height, wall mounted with the

´1

F2519 − 05 (2011)

FIG. 1 Particle Capture Efficiency Example Curve

FIG. 2 Schematic Diagram of Test Apparatus—Front Elevation View of Horizontal Test Setup

lower edge of the hood 6 ⁄2 ft (2.0 m) from the floor and with a 12 in. (0.305 m) diameter round duct collar mounted on top

´1

F2519 − 05 (2011)

FIG. 3 Schematic Diagram of Test Apparatus—Front Elevation of

Vertical Test Setup

´1

F2519 − 05 (2011)

6.2.1.3 The typical reference hood will be a canopy exhaust

hood matching the one described in 6.2.1.1 and shown in Fig.

6. If the hood with fixed extractors cannot be built to match

6.2.1.1,thenthereferencehoodshallbebuilttomatchthehood

with fixed extractors.

6.2.1.4 To facilitate switching hoods, the lab may build

rolling stands for each reference hood and the current hood

being tested. These stands may be rolled in and out of the test

rig. Care should be taken to insure that both hoods are installed

in the same location at the same height (6 ⁄2 ft) each time.

6.2.1.5 The test apparatus shown in Figs. 2-5 is designed for

test filters with a nominal height of 20 in. It is permitted to test

a bank of several filters in parallel if the width of an individual

filtration device is less than 50 % of the width of the hood.

Spacers may be added symmetrically on both ends of the filter

FIG. 4 Schematic Diagram of Test Apparatus—Plan View

under test if the filter does not span the entire width of the

hood.

6.2.2 Round Exhaust Duct, 12 in. (0.305 m) in diameter,

connected to the duct collar on the top of the exhaust hood and

leading to an exhaust fan.All duct connections shall be sealed.

The duct may be horizontal or vertical. If horizontal, it must

have a 90-degree elbow configured as shown in Fig. 7. The

elbow must have a centerline duct radius of 14-in.

NOTE 1—The r/D ratio is 1.167 for this configuration.

6.2.2.1 The distance from the duct collar for a vertical

exhaust duct or from the end of the 90 degree elbow for a

horizontal exhaust duct to the sampling location shall be 84 in.

If a different sampling location is used, or a different exhaust

configuration is used, an aerosol uniformity test shall be

conducted.

6.2.2.2 The minimum distance from the sampling location

to the nearest duct fitting or fan inlet shall be 24 in.

6.2.3 Exhaust Fan, capable of moving 1000 ft /min (472

L/s) through the filters under test and the additional exhaust

system components at the test static pressure condition. The

fan shall have a variable frequency drive or other means to

control the airflow rate. The exhaust shall be discharged

outdoors.

6.2.4 MakeupAir System, a means for providing makeup air

at 75 6 5°F and 50 6 20 % relative humidity to match exhaust

rate without disturbing the airflow pattern near the exhaust

hood.

6.2.5 Heat Source, a uniform electric heat source with a

solid metal surface, a minimum 2 ft. deep by 3 ft. wide,

maintained at an average surface temperature of 375 6 5°F.

FIG. 5 Schematic Diagram of Test Apparatus—Side Elevation

NOTE 2—A commercial electric griddle with a rated input between 7

View

and 10 kW and been shown to work well as a heat source.

6.2.5.1 The cooking surface of the heat source shall be 32

in. (0.81 m) above the floor. The heat source shall be centered

in the center of the hood with the rear surface of the opening

under the hood from side to side and from front to back. Any

1.0 in. from the back side of the hood. If the hood is installed

air gap between the rear of the heat source and the back wall

at a different height, a distance of 46 in. must be maintained

shall be sealed with a horizontal sheet of stainless steel

between the appliance surface and bottom of the hood. The

positioned at the same height as the rear of the heat source.

hood shall contain means for securing grease filters under test

6.3 Instrumentation:

in a position typical in application.

6.2.1.2 Hoods with fixed extractors should be built to match 6.3.1 Flow Metering Station, installed in the exhaust duct

the description given in 6.2.1.1 as closely as possible without for measuring the airflow rate through the filters under test.

affecting the hood’s extraction efficiency. Options include a grid of local velocity measurements using

´1

F2519 − 05 (2011)

FIG. 6 Schematic Diagram of Reference Hood

made with and without the test filters installed to set the fan

speed for proper airflow rate at each test condition.

6.3.2 Barometer, for measuring absolute pressure of the air

entering the exhaust hood. The barometer shall have a resolu-

tion of 0.2 in. Hg (670 Pa).

6.3.3 Differential Pressure Gage,formeasuringthepressure

drop across the filters under test. The pressure gage shall have

a range from 0 to 5 in. water (0 to 2.5 kPa), and have an

accuracy of 1 % at full scale.

6.3.4 Temperature Sensors, industry standard Type T or K

thermocouples, one mounted at the inlet to the particle sam-

pling probe in the exhaust duct to measure the temperature of

the exhaust, the other located 6 ⁄2 ft from the floor and 6 ft in

FIG. 7 Schematic Diagram of 90-Degree Elbow to Connect the

front of the center of the exhaust hood with radiation shielding

Duct Collar on th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.