ASTM F2229-20

(Specification)Standard Specification for Wrought, Nitrogen Strengthened 23Manganese-21Chromium-1Molybdenum Low-Nickel Stainless Steel Alloy Bar and Wire for Surgical Implants (UNS S29108)

Standard Specification for Wrought, Nitrogen Strengthened 23Manganese-21Chromium-1Molybdenum Low-Nickel Stainless Steel Alloy Bar and Wire for Surgical Implants (UNS S29108)

ABSTRACT

This specification covers the chemical, mechanical, and metallurgical requirements for wrought, nitrogen strengthened manganese-chromium-molybdenum low-nickel stainless steel alloy bars and wires used for surgical implants. All bars and wires should be furnished as specified in either annealed or cold-worked condition and in cold-drawn, pickled, ground and polished, ground, or any other specified finish. The products should conform to the required chemical composition, microcleanliness, purity, surface finish, tensile properties, and hardness and should pass the intergranular corrosion susceptibility test. Both wires and bars must have a homogenous microstructure and with grain sizes within the specified range.

SCOPE

1.1 This specification covers the chemical, mechanical, and metallurgical requirements for wrought nitrogen strengthened 23manganese-21chromium-1molybdenum low-nickel stainless steel alloy bar and wire for surgical implants.

1.2 The SI units in this standard are the primary units. The values stated in either primary SI units or secondary inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2229 −20

Standard Specification for

Wrought, Nitrogen Strengthened 23Manganese-

21Chromium-1Molybdenum Low-Nickel Stainless Steel Alloy

1

Bar and Wire for Surgical Implants (UNS S29108)

This standard is issued under the fixed designation F2229; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E8/E8MTest Methods for Tension Testing of Metallic Ma-

terials

1.1 This specification covers the chemical, mechanical, and

E10Test Method for Brinell Hardness of Metallic Materials

metallurgical requirements for wrought nitrogen strengthened

E18Test Methods for Rockwell Hardness of Metallic Ma-

23manganese-21chromium-1molybdenum low-nickel stainless

terials

steel alloy bar and wire for surgical implants.

E29Practice for Using Significant Digits in Test Data to

1.2 The SI units in this standard are the primary units. The

Determine Conformance with Specifications

values stated in either primary SI units or secondary inch-

E45Test Methods for Determining the Inclusion Content of

pound units are to be regarded separately as standard. The

Steel

values stated in each system may not be exact equivalents;

E112Test Methods for Determining Average Grain Size

therefore,eachsystemshallbeusedindependentlyoftheother.

E354 Test Methods for Chemical Analysis of High-

Combiningvaluesfromthetwosystemsmayresultinnoncon-

Temperature,Electrical,Magnetic,andOtherSimilarIron,

formance with the standard.

Nickel, and Cobalt Alloys

1.3 This international standard was developed in accor- E407Practice for Microetching Metals and Alloys

dance with internationally recognized principles on standard-

F138Specification for Wrought 18Chromium-14Nickel-

ization established in the Decision on Principles for the 2.5MolybdenumStainlessSteelBarandWireforSurgical

Development of International Standards, Guides and Recom-

Implants (UNS S31673)

mendations issued by the World Trade Organization Technical F746Test Method for Pitting or Crevice Corrosion of

Barriers to Trade (TBT) Committee. Metallic Surgical Implant Materials

F748PracticeforSelectingGenericBiologicalTestMethods

2. Referenced Documents

for Materials and Devices

2

F1314Specification for Wrought Nitrogen Strengthened 22

2.1 ASTM Standards:

Chromium–13 Nickel–5 Manganese–2.5 Molybdenum

A262Practices for Detecting Susceptibility to Intergranular

Stainless Steel Alloy Bar and Wire for Surgical Implants

Attack in Austenitic Stainless Steels

(UNS S20910)

A484/A484MSpecification for General Requirements for

F1586Specification for Wrought Nitrogen Strengthened

Stainless Steel Bars, Billets, and Forgings

21Chromium—10Nickel—3Manganese—

A555/A555MSpecification for General Requirements for

2.5Molybdenum Stainless Steel Alloy Bar for Surgical

Stainless Steel Wire and Wire Rods

Implants (UNS S31675)

A751Test Methods, Practices, and Terminology for Chemi-

IEEE/ASTM SI 10American National Standard for Metric

cal Analysis of Steel Products

Practice

3

2.2 Aerospace Material Specification:

1 AMS2248Chemical CheckAnalysis Limits, Corrosion and

This specification is under the jurisdiction of ASTM Committee F04 on

Heat Resistant Steels and Alloys, Maraging and Other

Medical and Surgical Materials and Devicesand is the direct responsibility of

Subcommittee F04.12 on Metallurgical Materials.

Highly-Alloyed Steels, and Iron Alloys

Current edition approved Nov. 15, 2020. Published November 2020. Originally

AMS 2630Inspection, Ultrasonic Product over 12.7 mm

approved in 2002. Last previous edition approved in 2012 as F2229–12. DOI:

[0.5 in.] Thick

10.1520/F2229-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2229−20

4

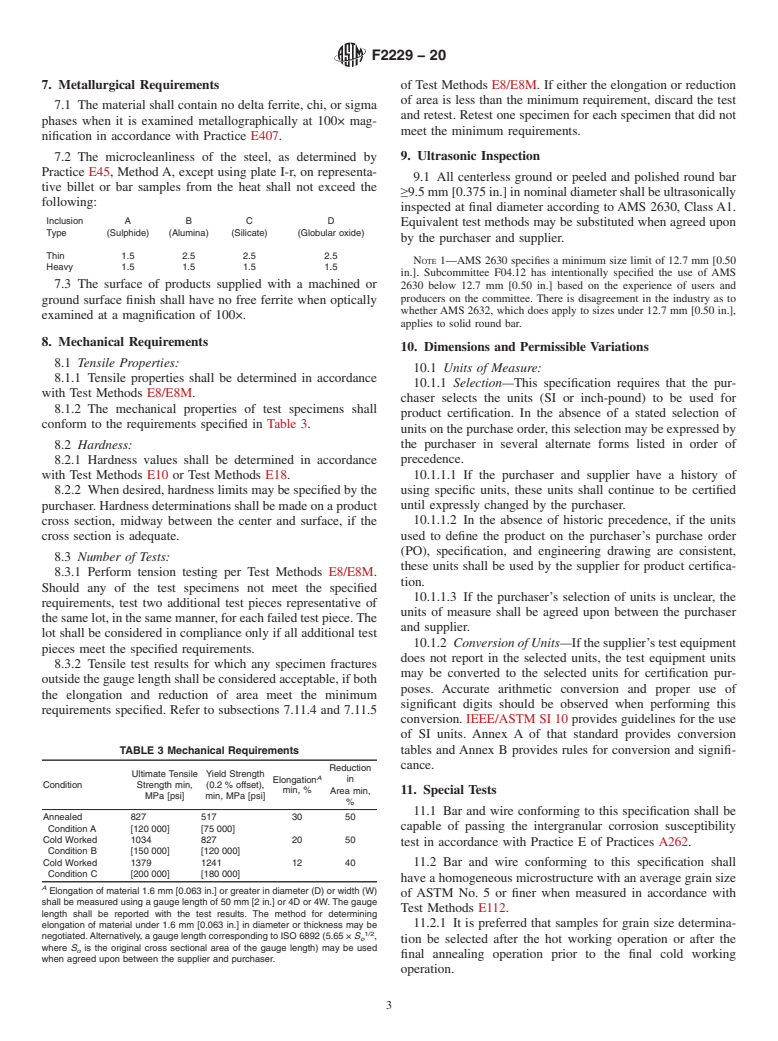

TABLE 1 Chemical Composition

2.3 ISO Standards:

ISO6892Metallic Materials Tensile Testing at Ambient Composition,

Element

% (mass/mass)

Temperature

Carbon 0.08 max

ISO9001Quality Management Systems—Requirements

Manganese 21.00 to 24.00

Phosphorus 0.03 max

3. Terminology Sulfur 0.01 max

Silicon 0.75 max

3.1 Definitions of Terms Specific to This Standard:

Chromium 19.00 to 23.00

Nickel 0.05 max

3.1.1 bar—roundbarandflatsfrom4.75mm[0.1875in

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2229 − 12 F2229 − 20

Standard Specification for

Wrought, Nitrogen Strengthened 23Manganese-

21Chromium-1Molybdenum Low-Nickel Stainless Steel Alloy

1

Bar and Wire for Surgical Implants (UNS S29108)

This standard is issued under the fixed designation F2229; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers the chemical, mechanical, and metallurgical requirements for wrought nitrogen strengthened

23manganese-21chromium-1molybdenum low-nickel stainless steel alloy bar and wire for surgical implants.

1.2 The SI units in this standard are the primary units. The values stated in either primary SI units or secondary inch-pound units

are to be regarded separately as standard. The values stated in each system aremay not necessarilybe exact equivalents; therefore,

to ensure conformance with the standard, each system shall be used independently of the other, andother. Combining values from

the two systems shall not be combined.may result in nonconformance with the standard.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

A484/A484M Specification for General Requirements for Stainless Steel Bars, Billets, and Forgings

A555/A555M Specification for General Requirements for Stainless Steel Wire and Wire Rods

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

E8/E8M Test Methods for Tension Testing of Metallic Materials

E10 Test Method for Brinell Hardness of Metallic Materials

E18 Test Methods for Rockwell Hardness of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E45 Test Methods for Determining the Inclusion Content of Steel

E112 Test Methods for Determining Average Grain Size

E354 Test Methods for Chemical Analysis of High-Temperature, Electrical, Magnetic, and Other Similar Iron, Nickel, and

Cobalt Alloys

E407 Practice for Microetching Metals and Alloys

1

This specification is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devicesand is the direct responsibility of Subcommittee

F04.12 on Metallurgical Materials.

Current edition approved Oct. 1, 2012Nov. 15, 2020. Published October 2012November 2020. Originally approved in 2002. Last previous edition approved in 20072012

as F2229 – 07.F2229 – 12. DOI: 10.1520/F2229-12.10.1520/F2229-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2229 − 20

F138 Specification for Wrought 18Chromium-14Nickel-2.5Molybdenum Stainless Steel Bar and Wire for Surgical Implants

(UNS S31673)

F746 Test Method for Pitting or Crevice Corrosion of Metallic Surgical Implant Materials

F748 Practice for Selecting Generic Biological Test Methods for Materials and Devices

F1314 Specification for Wrought Nitrogen Strengthened 22 Chromium–13 Nickel–5 Manganese–2.5 Molybdenum Stainless

Steel Alloy Bar and Wire for Surgical Implants (UNS S20910)

F1586 Specification for Wrought Nitrogen Strengthened 21Chromium—10Nickel—3Manganese—2.5Molybdenum Stainless

Steel Alloy Bar for Surgical Implants (UNS S31675)

IEEE/ASTM SI 10 American National Standard for Metric Practice

3

2.2 Aerospace Material Specification:

AMS 2248 Chemical Check Analysis Limits, Corrosion and Heat Resistant Steels and Alloys, Maraging and Other

Highly-Alloyed Steels, and Iron Alloys

AMS 2630 Inspection, Ultrasonic Product over 0.5 Inch (12.7 mm)12.7 mm [0.5 in.] Thick

4

2.3 ISO Standards:

ISO 6892 Metallic Materials Tensile Testing

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.