ASTM F560-04

(Specification)Standard Specification for Unalloyed Tantalum for Surgical Implant Applications (UNS R05200, UNS R05400)

Standard Specification for Unalloyed Tantalum for Surgical Implant Applications (UNS R05200, UNS R05400)

SCOPE

1.1 This specification covers the chemical, mechanical, and metallurgical requirements for unalloyed tantalum plate, sheet, strip, rod, and wire used in the manufacture of surgical implants.

1.2 The values stated in inch-pound units are to be regarded as the standard. The SI equivalents in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F 560 – 04

Standard Specification for

Unalloyed Tantalum for Surgical Implant Applications

1

(UNS R05200, UNS R05400)

This standard is issued under the fixed designation F 560; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 3. General Requirements for Delivery

1.1 This specification covers the chemical, mechanical, and 3.1 In addition to the requirements of this specification, all

metallurgical requirements for unalloyed tantalum plate, sheet, requirements of the current editions of Specifications B 364,

strip, rod, and wire used in the manufacture of surgical B 365, and B 708 shall apply.

implants. 3.2 In the case where a conflict exists between this specifi-

1.2 The values stated in inch-pound units are to be regarded cation and those listed in 2.1, 2.2, and 3.1, this specification

as the standard. The SI equivalents in parentheses are for shall take precedence.

information only.

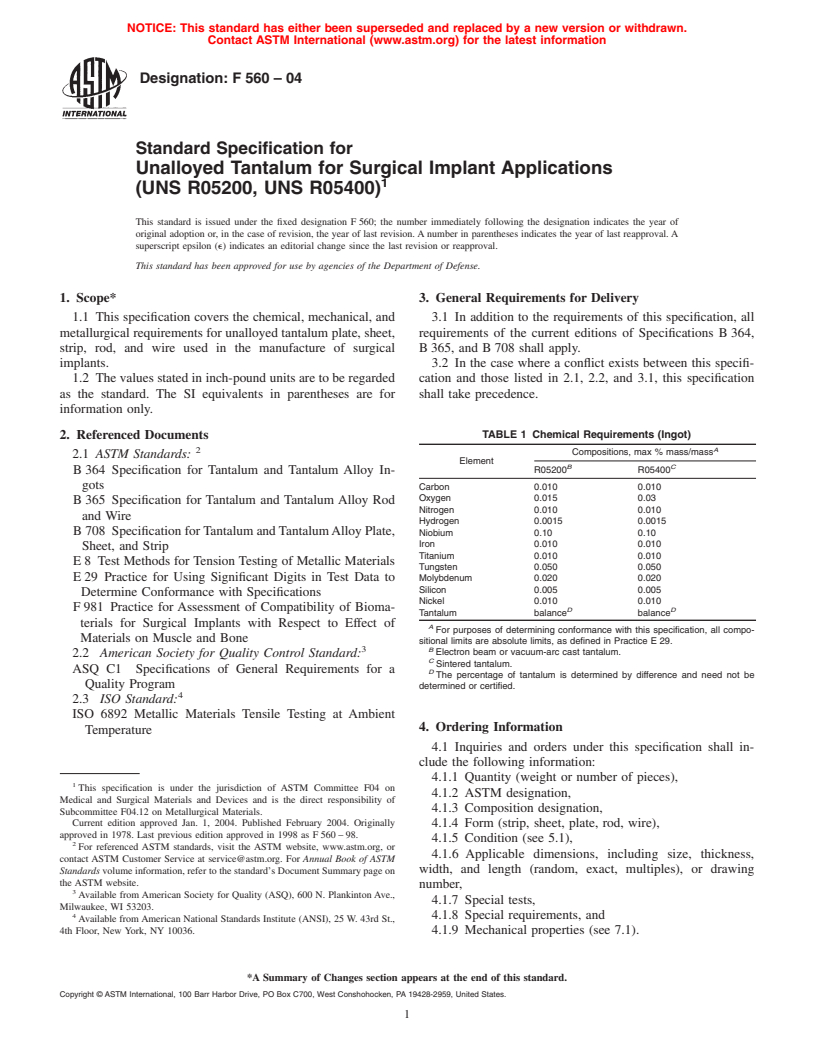

TABLE 1 Chemical Requirements (Ingot)

2. Referenced Documents

A

2

Compositions, max % mass/mass

2.1 ASTM Standards:

Element

B C

R05200 R05400

B 364 Specification for Tantalum and Tantalum Alloy In-

gots

Carbon 0.010 0.010

Oxygen 0.015 0.03

B 365 Specification for Tantalum and Tantalum Alloy Rod

Nitrogen 0.010 0.010

and Wire

Hydrogen 0.0015 0.0015

B 708 Specification forTantalum andTantalumAlloy Plate, Niobium 0.10 0.10

Iron 0.010 0.010

Sheet, and Strip

Titanium 0.010 0.010

E 8 Test Methods for Tension Testing of Metallic Materials

Tungsten 0.050 0.050

E 29 Practice for Using Significant Digits in Test Data to

Molybdenum 0.020 0.020

Silicon 0.005 0.005

Determine Conformance with Specifications

Nickel 0.010 0.010

F 981 Practice for Assessment of Compatibility of Bioma- D D

Tantalum balance balance

terials for Surgical Implants with Respect to Effect of

A

For purposes of determining conformance with this specification, all compo-

Materials on Muscle and Bone

sitional limits are absolute limits, as defined in Practice E 29.

B

3

Electron beam or vacuum-arc cast tantalum.

2.2 American Society for Quality Control Standard:

C

Sintered tantalum.

ASQ C1 Specifications of General Requirements for a

D

The percentage of tantalum is determined by difference and need not be

Quality Program

determined or certified.

4

2.3 ISO Standard:

ISO 6892 Metallic Materials Tensile Testing at Ambient

4. Ordering Information

Temperature

4.1 Inquiries and orders under this specification shall in-

clude the following information:

4.1.1 Quantity (weight or number of pieces),

1

This specification is under the jurisdiction of ASTM Committee F04 on

4.1.2 ASTM designation,

Medical and Surgical Materials and Devices and is the direct responsibility of

4.1.3 Composition designation,

Subcommittee F04.12 on Metallurgical Materials.

Current edition approved Jan. 1, 2004. Published February 2004. Originally

4.1.4 Form (strip, sheet, plate, rod, wire),

approved in 1978. Last previous edition approved in 1998 as F 560 – 98.

4.1.5 Condition (see 5.1),

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.1.6 Applicable dimensions, including size, thickness,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

width, and length (random, exact, multiples), or drawing

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

number,

3

Available from American Society for Quality (ASQ), 600 N. Plankinton Ave.,

4.1.7 Special tests,

Milwaukee, WI 53203.

4

4.1.8 Special requirements, and

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036. 4.1.9 Mechanical properties (see 7.1).

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F560–04

TABLE 2 Mechanical Properties, Flat Mill Products

A

Ultimate Tensile Yield Strength, Elongation

Condition Thickness, in. (mm) Strength, min, psi (0.2% offset) min, in 1 inch (25.4 mm),

(MPa) psi (MPa) min,%

Cold worked all 75 000 (517) 50 000 (345) 2

Stress relieved 0.0051 to 0.010 55 000 (379) 35 000 (241) 5

(0.13 to 0.26)

over 0.010 to 0.020 55 000 (379) 35 000 (241) 10

(0.26 to 0.51)

over 0.020( 0.51) 55 000 (379) 35 000 (241) 10

Annealed 0.0051 to 0.010 30 000 (207) 20 000 (138) 20

(0.13 to 0.26)

over 0.010 to 0.020 30 000 (207) 20 000 (138) 25

(0.26 to 0.51)

over 0.020 (0.51) 30 000 (207) 20 000 (138) 30

A

Elongation of materi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.