ASTM C196-00(2016)

(Specification)Standard Specification for Expanded or Exfoliated Vermiculite Thermal Insulating Cement

Standard Specification for Expanded or Exfoliated Vermiculite Thermal Insulating Cement

ABSTRACT

This specification covers expanded or exfoliated vermiculite thermal insulating material in the form of dry cement or plaster, intended to be mixed with a suitable proportion of water, applied as a plastic mass, and dried in place, for use as insulation on surfaces. The cement shall be composed predominantly of expanded or exfoliated vermiculite, with a suitable proportion of heat-resistant binder. The following requirements are employed for purposes of initial material or product qualification: consistency, compressive strength, linear shrinkage, apparent thermal conductivity, and dry adhesion to steel. The consistency of the material, dry converting capacity and volume change upon drying, compressive strength, linear shrinkage, apparent thermal conductivity, and dry adhesion to steel shall be tested to meet the requirements prescribed.

SCOPE

1.1 This specification covers expanded or exfoliated vermiculite thermal insulating material in the form of dry cement or plaster, intended to be mixed with a suitable proportion of water, applied as a plastic mass, and dried in place, for use as insulation on surfaces operating at temperatures between 100°F (38°C) and 1800°F (982°C). The cement shall not be used where it will be exposed to combustion conditions, such as the hot face lining of a furnace.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazards caveat pertains only to the test method portion, Section 10, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 When the installation or use of thermal insulation materials, accessories and systems, may pose safety or health problems, the manufacturer shall provide the user with appropriate current information regarding any known problems associated with the recommended use of the company's products. The manufacturer shall also recommend protective measures to be employed in the safe utilization of said products.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C196 −00 (Reapproved 2016)

Standard Specification for

Expanded or Exfoliated Vermiculite Thermal Insulating

Cement

This standard is issued under the fixed designation C196; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope C163 Practice for Mixing Thermal Insulating Cement

Samples

1.1 This specification covers expanded or exfoliated ver-

C166 Test Method for Covering Capacity and Volume

miculite thermal insulating material in the form of dry cement

Change Upon Drying of Thermal Insulating Cement

or plaster, intended to be mixed with a suitable proportion of

C168 Terminology Relating to Thermal Insulation

water, applied as a plastic mass, and dried in place, for use as

C177 Test Method for Steady-State Heat Flux Measure-

insulation on surfaces operating at temperatures between

ments and Thermal Transmission Properties by Means of

100°F (38°C) and 1800°F (982°C). The cement shall not be

the Guarded-Hot-Plate Apparatus

used where it will be exposed to combustion conditions, such

C353 Test Method forAdhesion of DriedThermal Insulating

as the hot face lining of a furnace.

or Finishing Cement (Withdrawn 2002)

1.2 The values stated in inch-pound units are to be regarded

C354 Test Method for Compressive Strength of Thermal

as standard. The values given in parentheses are mathematical

Insulating or Finishing Cement (Withdrawn 2002)

conversions to SI units that are provided for information only

C356 Test Method for Linear Shrinkage of Preformed High-

and are not considered standard.

Temperature Thermal Insulation Subjected to Soaking

1.3 The following safety hazards caveat pertains only to the

Heat

test method portion, Section 10, of this specification. This C390 Practice for Sampling and Acceptance of Thermal

standard does not purport to address all of the safety concerns,

Insulation Lots

if any, associated with its use. It is the responsibility of the user C405 Practice for Estimating Consistency of Wet-Mixed

of this standard to establish appropriate safety and health

Thermal Insulating Cement (Withdrawn 2006)

practices and determine the applicability of regulatory limita- C518 Test Method for Steady-State Thermal Transmission

tions prior to use. Properties by Means of the Heat Flow Meter Apparatus

1.4 When the installation or use of thermal insulation

C1058 Practice for Selecting Temperatures for Evaluating

materials, accessories and systems, may pose safety or health and Reporting Thermal Properties of Thermal Insulation

problems, the manufacturer shall provide the user with appro-

3. Terminology

priate current information regarding any known problems

associated with the recommended use of the company’s

3.1 Definitions:

products. The manufacturer shall also recommend protective

3.2 Terminology C168 shall be considered as applying to

measures to be employed in the safe utilization of said

the terms used in this specification.

products.

4. Materials and Manufacture

2. Referenced Documents

4.1 The cement shall be composed predominantly of ex-

2.1 ASTM Standards:

panded or exfoliated vermiculite, with a suitable proportion of

heat-resistant binder. Asbestos shall not be used as an ingredi-

ent or component part of the product.

This specification is under the jurisdiction of ASTM Committee C16 on

Thermal Insulation and is the direct responsibility of Subcommittee C16.20 on

Homogeneous Inorganic Thermal Insulations. 5. Other Requirements

Current edition approved March 1, 2016. Published March 2016. Originally

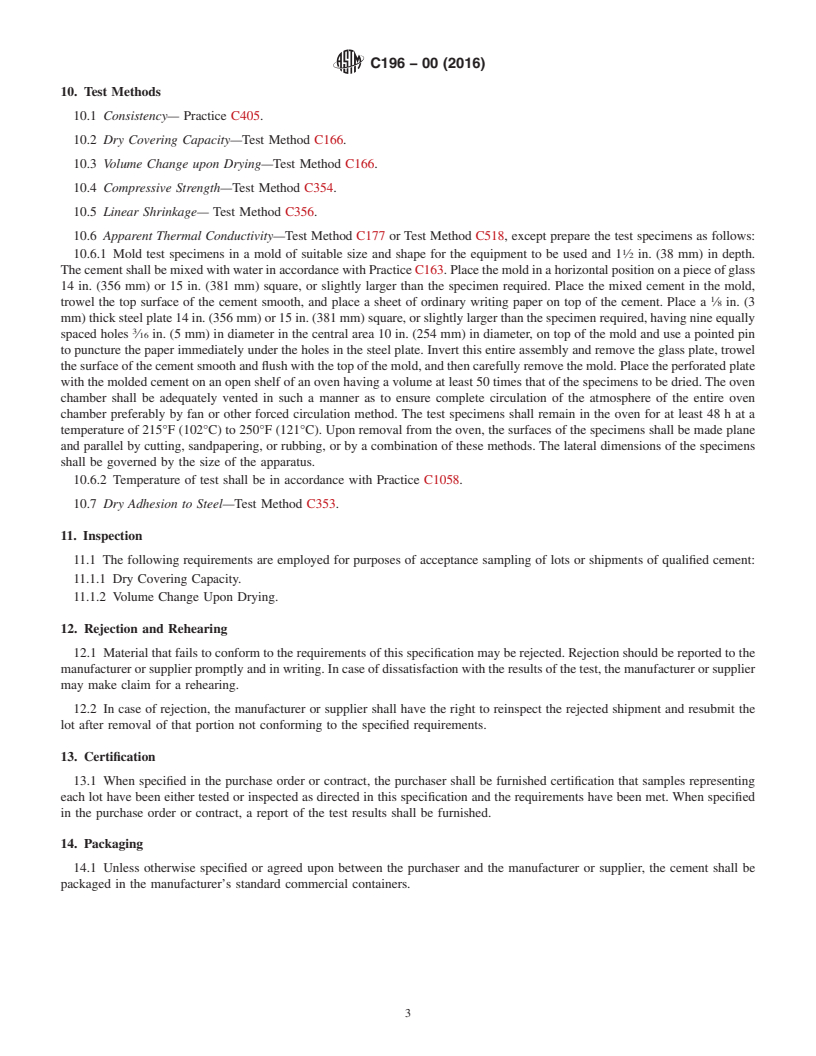

5.1 The cement shall conform to the requirements given in

approved in 1944. Last previous edition approved in 2010 as C196 – 00 (2010).

DOI: 10.1520/C0196-00R16. Table 1. Conformance shall be based on results of tests on

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C196−00 (2016)

TABLE 1 Other Requirements

9.2 The amount of water to be used in preparing samples for

Consistency all tests shall be that amount which results in the specified

Method A, % 35 to 45

consistency, determined in accordance with Practice C405.

Method B, in. (mm) 7 (178) to 9 (229)

Dry covering capacity, min, ft , 1 in. in thickness per 50 (26)

10. Test Methods

100 lb of dry cement (m , 1 cm. in thickness per

100 kg of dry cement)

10.1 Consistency— Practice C405.

Volume change upon drying, max,% 20

Compressive strength, min, psi (kPa) at 5 % defor- 5 (34.5)

10.2 Dry Covering Capacity—Test Method C166.

mation

Linear shrinkage max % 24 h at 1800°F (980°C) 5

10.3 Volume Change upon Drying—Test Method C166.

Apparent thermal conductivity, max, Btu·in./

h·ft ·°F (W/m·K)

10.4 Compressive Strength—Test Method C354.

At mean temperatures of:

10.5 Linear Shrinkage— Test Method C356.

200°F (95°C) 0.95 (0.137)

500°F (260°C) 1.10 (0.159)

10.6 Apparent Thermal Conductivity—Test Method C177 or

700°F (370°C) 1.20 (0.173)

Dry adhesion to steel, min, psi(kPa) 3.5 (24.2)

Test Method C518, except prepare the test specimens as

follows:

10.6.1 Mold test specimens in a mold of suitable size and

specimens first mixed with water, according to the ratio for

shape for the equipment to be used and 1 ⁄2 in. (38 mm) in

proper troweling consistency determined in accordance with

depth. The cement shall be mixed with water in accordance

Section 10.

with Practice C163. Place the mold in a horizontal position on

a piece of glass 14 in. (356 mm) or 15 in. (381 mm) square, or

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C196 − 00 (Reapproved 2010) C196 − 00 (Reapproved 2016)

Standard Specification for

Expanded or Exfoliated Vermiculite Thermal Insulating

Cement

This standard is issued under the fixed designation C196; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers expanded or exfoliated vermiculite thermal insulating material in the form of dry cement or plaster,

intended to be mixed with a suitable proportion of water, applied as a plastic mass, and dried in place, for use as insulation on

surfaces operating at temperatures between 100°F (38°C) and 1800°F (982°C). The cement shall not be used where it will be

exposed to combustion conditions, such as the hot face lining of a furnace.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 The following safety hazards caveat pertains only to the test method portion, Section 10, of this specification.This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 When the installation or use of thermal insulation materials, accessories and systems, may pose safety or health problems,

the manufacturer shall provide the user with appropriate current information regarding any known problems associated with the

recommended use of the company’s products. The manufacturer shall also recommend protective measures to be employed in the

safe utilization of said products.

2. Referenced Documents

2.1 ASTM Standards:

C163 Practice for Mixing Thermal Insulating Cement Samples

C166 Test Method for Covering Capacity and Volume Change Upon Drying of Thermal Insulating Cement

C168 Terminology Relating to Thermal Insulation

C177 Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the

Guarded-Hot-Plate Apparatus

C353 Test Method for Adhesion of Dried Thermal Insulating or Finishing Cement (Withdrawn 2002)

C354 Test Method for Compressive Strength of Thermal Insulating or Finishing Cement (Withdrawn 2002)

C356 Test Method for Linear Shrinkage of Preformed High-Temperature Thermal Insulation Subjected to Soaking Heat

C390 Practice for Sampling and Acceptance of Thermal Insulation Lots

C405 Practice for Estimating Consistency of Wet-Mixed Thermal Insulating Cement (Withdrawn 2006)

C518 Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus

C1058 Practice for Selecting Temperatures for Evaluating and Reporting Thermal Properties of Thermal Insulation

3. Terminology

3.1 Definitions:

3.2 Terminology C168 shall be considered as applying to the terms used in this specification.

This specification is under the jurisdiction of ASTM Committee C16 on Thermal Insulation and is the direct responsibility of Subcommittee C16.20 on Homogeneous

Inorganic Thermal Insulations.

Current edition approved Sept. 1, 2010March 1, 2016. Published January 2011March 2016. Originally approved in 1944. Last previous edition approved in 20052010 as

C196 – 00 (2010).(2005). DOI: 10.1520/C0196-00R10.10.1520/C0196-00R16.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C196 − 00 (2016)

4. Materials and Manufacture

4.1 The cement shall be composed predominantly of expanded or exfoliated vermiculite, with a suitable proportion of

heat-resistant binder. Asbestos shall not be used as an ingredient or component part of the product.

5. Other Requirements

5.1 The cement shall conform to the requirements given in Table 1. Conformance shall be based on results of tests on specimens

first mixed with water, according to the ratio for proper troweling consistency determined in accordance with Section 10.

6. Qualification Requirements

6.1 The following requirements are employed for purposes of initial material or product qualification:

6.1.1 Consistency,

6.1.2 Compressive strength,

6.1.3 Linear shrinkage,

6.1.4 Apparent thermal conductivity, and

6.1.5 Dry adhesion to steel.

7. Sampling

7.1 The cement shall be sampled, for the purpose of tests using one of the following procedures.

7.1.1 Inspection Requirements:

7.1.1.1 Use Practice C390. Each bag shall represent a unit.

7.1.1.2 In a single sampling plan by attributes the acceptability of a lot will be determined by the number of units of product

in the sample that do not conform to the specifications. The acceptable quality level (AQL) and limiting quality level (LQL) of

an acceptance sampling plan, expressed as percentages of the units nonconforming, are characteristics of the sampling plan and

are not to be viewed as product specifications.

7.1.2 Qualification Requirements:

7.1.2.1 Use the average of the test data from the number of test specimens required by the appropriate test method to represent

the average for the entire lot.

7.2 The specimen for test is to be taken from the middle of a bag, so as to be representative of material from the entire bag.

8. Number of Tests and Retests

8.1 If the average of the test data obtained using 7.1.2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.