ASTM D61-15

(Test Method)Standard Test Method for Softening Point of Pitches (Cube-in-Water Method)

Standard Test Method for Softening Point of Pitches (Cube-in-Water Method)

SIGNIFICANCE AND USE

5.1 Pitch does not go through a solid-liquid phase change when heated, and therefore it does not have a true melting point. As the temperature rises, pitch softens and becomes less viscous. The softening point is arbitrarily defined and shall be established by a closely controlled method which shall be carefully followed if test results are to be reproducible.

5.2 This test is useful in determining the consistency of pitch as one element in establishing the uniformity of shipments or sources of supply.

SCOPE

1.1 This test method covers the determination of the softening point of pitches below 176 °F (80 °C). Pitches of higher softening point should be tested by Test Method D2319 or Test Method D3104.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D61 − 15

Standard Test Method for

1

Softening Point of Pitches (Cube-in-Water Method)

This standard is issued under the fixed designation D61; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3.1.1 Digital Contact Thermometer (DCT), n—an electronic

device consisting of a digital display and associated tempera-

1.1 This test method covers the determination of the soft-

ture sensing probe.

ening point of pitches below 176 °F (80 °C). Pitches of higher

3.1.1.1 Discussion—This device consists of a temperature

softening point should be tested by Test Method D2319 or Test

sensor connected to a measuring instrument; this instrument

Method D3104.

measures the temperature-dependent quantity of the sensor,

1.2 The values stated in inch-pound units are to be regarded

computes the temperature from the measured quantity, and

as standard. The values given in parentheses are mathematical

provides a digital output or display, or both, of the temperature.

conversions to SI units that are provided for information only

The temperature sensing probe is in contact with the material

and are not considered standard.

whose temperature is being measured. This device is some-

1.3 This standard does not purport to address all of the

times referred to as a digital thermometer.

safety concerns, if any, associated with its use. It is the

NOTE 1—Portable electronic thermometers (PET) is an acronym some-

responsibility of the user of this standard to establish appro-

times used to refer to a subset of the devices covered by this definition.

priate safety and health practices and determine the applica-

4. Summary of Test Method

bility of regulatory limitations prior to use.

4.1 Two cubes of pitch, supported on wire hooks, are heated

2. Referenced Documents at a controlled rate in water in a glass container. The softening

2

point is defined as the mean of the temperatures at which the

2.1 ASTM Standards:

cubes sag downwards a distance of 25 mm.

D140 Practice for Sampling Bituminous Materials

D2319 Test Method for Softening Point of Pitch (Cube-in-

5. Significance and Use

Air Method)

5.1 Pitch does not go through a solid-liquid phase change

D3104 Test Method for Softening Point of Pitches (Mettler

when heated, and therefore it does not have a true melting

Softening Point Method)

point.As the temperature rises, pitch softens and becomes less

E1 Specification for ASTM Liquid-in-Glass Thermometers

viscous. The softening point is arbitrarily defined and shall be

E563 Practice for Preparation and Use of an Ice-Point Bath

established by a closely controlled method which shall be

as a Reference Temperature

carefully followed if test results are to be reproducible.

E1137 SpecificationforIndustrialPlatinumResistanceTher-

5.2 This test is useful in determining the consistency of

mometers

pitch as one element in establishing the uniformity of ship-

E2251 Specification for Liquid-in-Glass ASTM Thermom-

ments or sources of supply.

eters with Low-Hazard Precision Liquids

E2877 Guide for Digital Contact Thermometers

6. Apparatus

1

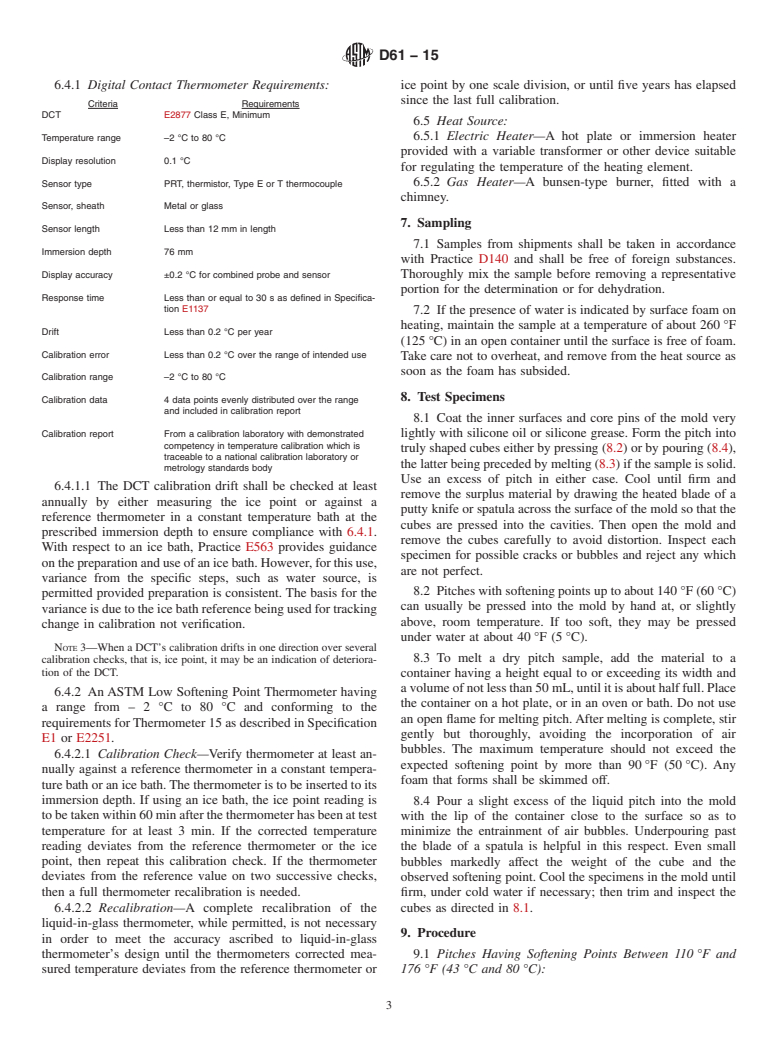

6.1 Mold—A mold suitable for forming two ⁄2 in.

3. Terminology

(12.7 mm) cubes of pitch, having cylindrical core pins 12

3.1 Definitions:

gauge (2.05 mm) in diameter located in the base plate of the

assembly to produce accurately centered suspension holes in

the cubes. (See Fig. 1.)

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricantsand is the direct responsibility of 6.2 Hooks—Two L-shaped hooks, made of 12 gauge

SubcommitteeD02.05onPropertiesofFuels,PetroleumCokeandCarbonMaterial.

(2.05 mm) copper wire. The foot of the hook shall be 1 in.

Current edition approved July 1, 2015. Published July 2015. Originally approved

(25 mm) long and at a right angle to the upright portion for

in 1919. Last previous edition approved in 2010 as D61 – 75 (2010). DOI:

insertion into the center hole of the pitch cube.

10.1520/D0061-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.3 Container—A glass vessel that can be heated, not less

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

than85 mmindiameterand105 mmdeep.(Astandard600 mL

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. low-form beaker meets these requirements).

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D61 − 75 (Reapproved 2010) D61 − 15

Standard Test Method for

1

Softening Point of Pitches (Cube-in-Water Method)

This standard is issued under the fixed designation D61; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method covers the determination of the softening point of pitches below 176°F (80°C).176 °F (80 °C). Pitches of

higher softening point should be tested by Test Method D2319 or Test Method D3104.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D140 Practice for Sampling Bituminous Materials

D2319 Test Method for Softening Point of Pitch (Cube-in-Air Method)

D3104 Test Method for Softening Point of Pitches (Mettler Softening Point Method)

E1 Specification for ASTM Liquid-in-Glass Thermometers

E563 Practice for Preparation and Use of an Ice-Point Bath as a Reference Temperature

E1137 Specification for Industrial Platinum Resistance Thermometers

E2251 Specification for Liquid-in-Glass ASTM Thermometers with Low-Hazard Precision Liquids

E2877 Guide for Digital Contact Thermometers

3. Terminology

3.1 Definitions:

3.1.1 Digital Contact Thermometer (DCT), n—an electronic device consisting of a digital display and associated temperature

sensing probe.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products Products, Liquid Fuels, and Lubricantsand is the direct responsibility of

Subcommittee D02.05 on Properties of Fuels, Petroleum Coke and Carbon Material.

Current edition approved Feb. 15, 2010July 1, 2015. Published March 2010July 2015. Originally approved in 1919. Last previous edition approved in 20042010 as

D61–75(2004).D61 – 75 (2010). DOI: 10.1520/D0061-75R10.10.1520/D0061-15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.1.1.1 Discussion—

This device consists of a temperature sensor connected to a measuring instrument; this instrument measures the temperature-

dependent quantity of the sensor, computes the temperature from the measured quantity, and provides a digital output or display,

or both, of the temperature. The temperature sensing probe is in contact with the material whose temperature is being measured.

This device is sometimes referred to as a digital thermometer.

NOTE 1—Portable electronic thermometers (PET) is an acronym sometimes used to refer to a subset of the devices covered by this definition.

4. Summary of Test Method

4.1 Two cubes of pitch, supported on wire hooks, are heated at a controlled rate in water in a glass container. The softening point

is defined as the mean of the temperatures at which the cubes sag downwards a distance of 25 mm.25 mm.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D61 − 15

5. Significance and Use

5.1 Pitch does not go through a solid-liquid phase change when heated, and therefore it does not have a true melting point. As

the temperature rises, pitch softens and becomes less viscous. The softening point is arbitrarily defined and shall be established

by a closely controlled method which shall be carefully followed if test results are to be reproducible.

5.2 This test is useful in determining the consistency of pitch as one element in establishing the uniformity of shipments or

sources of supply.

6. Apparatus

1

6.1 Mold—A mold suitable for forming two ⁄2-in. (12.7-mm) in. (12.7 mm) cubes of pitch, having cylindrical core pins 12

gauge (2.05 mm) (2.05 mm) in diameter located in the base plate of the assembly to produc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.