ASTM D3826-98(2013)

(Practice)Standard Practice for Determining Degradation End Point in Degradable Polyethylene and Polypropylene Using a Tensile Test

Standard Practice for Determining Degradation End Point in Degradable Polyethylene and Polypropylene Using a Tensile Test

SIGNIFICANCE AND USE

4.1 The tensile elongation property determined by this practice is of value for the characterization of degradable materials. The tensile elongation property may vary with specimen thickness, method of preparation, speed of testing, type of grips used, and manner of measuring test extension. Consequently, where precise comparative results are desired, these factors must be carefully controlled.

4.2 The tensile elongation property may be utilized to provide data for research and development and engineering design as well as quality control specifications. However, data from such tests cannot be considered significant for applications differing widely from the load-time scale of the test employed.

4.3 Materials that fail by tearing give anomalous data that cannot be compared with those from normal failure.

4.4 Before proceeding with this test method, reference should be made to the specifications of the material being tested. Any test specimen preparation, conditioning, dimensions, or testing parameters or a combination thereof, covered in the material specifications shall take precedence over those mentioned in this test method. If there are no material specifications, then the default conditions apply.

SCOPE

1.1 This practice covers the determination of a degradation-end point (a brittle point) for degradable polyethylene/polypropylene films and sheeting less than 1.0 mm (0.04 in.) thick. This practice is not intended for determination of the rate of degree of degradation of a polyethylene/polypropylene film or sheet, but rather, to assess when in the course of its degradation under some condition, a brittle point is reached. If one wishes to monitor tensile elongation during the degradation process (such as when the tensile elongation is significantly greater than 5 %), Test Method D882 is recommended. This practice should not be considered the only way of determining a degradation-end point.

1.2 Tensile properties of plastics 1.0 mm (0.04 in.) or greater in thickness shall be determined in accordance with Test Method D638.

1.3 Use a static weighing-constant rate of grip separation test. This procedure employs a constant rate of separation of the grips holding the sample and a static load cell. Note 1—This procedure is based on the use of grip separation as a measure of extension; however, the desirability of using extension indicators accurate to ±1.0 % or better as specified in Test Method D638 is recognized, and a provision for the use of such instrumentation is incorporated in the procedure.

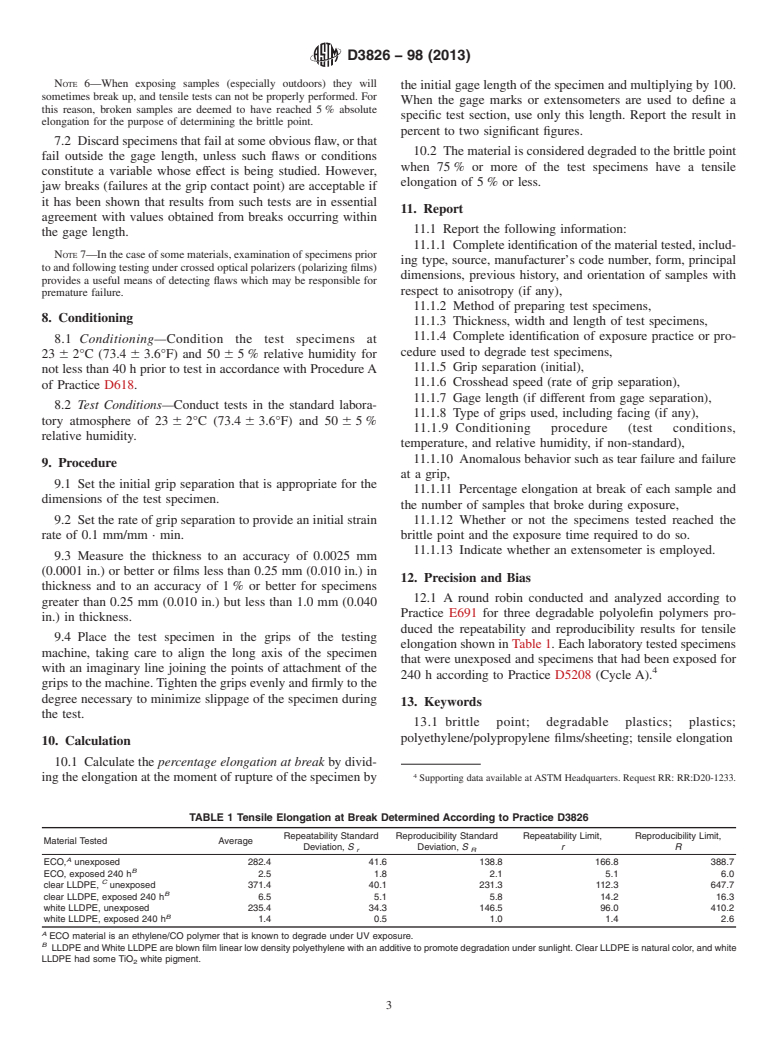

1.4 This procedure has been successful for determining the degradation end point of ethylene-carbon-monoxide copolymers and has screened successfully two other additive-type polyethylenes in a round robin test.

1.5 The values stated in SI units are to be regarded as the standard. The values in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.7 There is no equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3826 − 98 (Reapproved 2013)

Standard Practice for

Determining Degradation End Point in Degradable

Polyethylene and Polypropylene Using a Tensile Test

This standard is issued under the fixed designation D3826; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 There is no equivalent ISO standard.

1.1 This practice covers the determination of a degradation-

2. Referenced Documents

end point (a brittle point) for degradable polyethylene/

polypropylene films and sheeting less than 1.0 mm (0.04 in.)

2.1 ASTM Standards:

thick.This practice is not intended for determination of the rate

D374 Test Methods for Thickness of Solid Electrical Insu-

of degree of degradation of a polyethylene/polypropylene film

lation (Withdrawn 2013)

or sheet, but rather, to assess when in the course of its

D618 Practice for Conditioning Plastics for Testing

degradation under some condition, a brittle point is reached. If

D638 Test Method for Tensile Properties of Plastics

one wishes to monitor tensile elongation during the degrada-

D882 Test Method for Tensile Properties of Thin Plastic

tion process (such as when the tensile elongation is signifi-

Sheeting

cantly greater than 5 %), Test Method D882 is recommended.

D5208 Practice for Fluorescent Ultraviolet (UV) Exposure

This practice should not be considered the only way of

of Photodegradable Plastics

determining a degradation-end point.

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.2 Tensile properties of plastics 1.0 mm (0.04 in.) or

greater in thickness shall be determined in accordance with

3. Terminology

Test Method D638.

3.1 Definitions:

1.3 Use a static weighing-constant rate of grip separation

test. This procedure employs a constant rate of separation of

3.1.1 Definitions of terms and symbols relating to tension

the grips holding the sample and a static load cell. testing of plastics appear in the Annex to Test Method D638.

3.1.2 line grips, n—in tensile testing machines, grips having

NOTE 1—This procedure is based on the use of grip separation as a

measure of extension; however, the desirability of using extension faces designed to concentrate the entire gripping force along a

indicators accurate to 61.0 % or better as specified in Test Method D638

single line perpendicular to the direction of testing stress.

is recognized, and a provision for the use of such instrumentation is

3.1.3 tear failure, n—in tensile testing of films, a failure

incorporated in the procedure.

characterized by fracture initiating at one edge of the specimen

1.4 This procedure has been successful for determining the

and progressing across the specimen at a rate slow enough to

degradation end point of ethylene-carbon-monoxide copoly-

produce an anomalous load-deformation curve.

mers and has screened successfully two other additive-type

polyethylenes in a round robin test. 3.2 Definitions of Terms Specific to This Standard:

3.2.1 film, n—for the purpose of this practice, a piece of

1.5 The values stated in SI units are to be regarded as the

material not exceeding 0.250 mm (0.01 in.) in thickness.

standard. The values in parentheses are for information only.

1.6 This standard does not purport to address all of the 3.2.2 brittle point, n—in degradable polyethylene/

polypropylene film, that point in the history of a material when

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 75 % of the specimens tested have a tensile elongation at break

of 5 % or less.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1 2

This practice is under the jurisdiction ofASTM Committee D20 on Plastics and For referenced ASTM standards, visit the ASTM website, www.astm.org, or

isthedirectresponsibilityofSubcommitteeD20.96onEnvironmentallyDegradable contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Plastics and Biobased Products. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Feb. 1, 2013. Published February 2013. Originally the ASTM website.

approved in 1991. Last previous edition approved in 2008 as D3826 – 98 (2008). The last approved version of this historical standard is referenced on

DOI: 10.1520/D3826-98R13. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3826 − 98 (2013)

4. Significance and Use the specimens to the proper width and producing straight,

clean, parallel edges with no visible imperfections. A device

4.1 The tensile elongation property determined by this

consisting of two parallel knives mounted firmly against a

practice is of value for the characterization of degradable

precision-ground base shear-block (similar to a paper cutter)

materials. The tensile elongation property may vary with

has proved satisfactory. The use of striking dies is not

specimen thickness, method of preparation, speed of testing,

recommended because poor and inconsistent specimen edges

type of grips used, and manner of measuring test extension.

maybeproduced.Itisimperativethatthecuttingedgesbekept

Consequently, where precise comparative results are desired,

sharp and free from visible scratches or nicks.

these factors must be carefully controlled.

5.6 Extension Indicators—Ifemployed,extensionindicators

4.2 The tensile elongation property may be utilized to

shall conform to requirements specified in Test Method D638.

provide data for research and development and engineering

In addition, such apparatus shall be so designed as to minimize

design as well as quality control specifications. However, data

stressonthespecimenatthecontactpointsofthespecimenand

from such tests cannot be considered significant for applica-

the indicator.

tions differing widely from the load-time scale of the test

employed.

NOTE 3—A high-response speed in the recording system is desirable,

particularly when relatively high strain rates are employed for rigid

4.3 Materials that fail by tearing give anomalous data that

materials. The speed of pen response for recorders is supplied by

cannot be compared with those from normal failure.

manufacturers of this equipment. Take care to conduct tests at conditions

suchthatresponsetime(abilityofrecordertofollowactualload)produces

4.4 Before proceeding with this test method, reference

less than 2 % error.

should be made to the specifications of the material being

tested. Any test specimen preparation, conditioning,

6. Test Specimen

dimensions, or testing parameters or a combination thereof,

6.1 Cut test specimens prior to exposure. Take utmost care

covered in the material specifications shall take precedence

in cutting specimens to prevent nicks and tears that are likely

over those mentioned in this test method. If there are no

to cause premature failures (see Note 4). The edges shall be

material specifications, then the default conditions apply.

parallel to within 5 % of the width over the length of the

specimen between the grips.

5. Apparatus

NOTE 4—A microscopic examination of the specimen may be used to

5.1 Testing Machines:

detect flaws due to sample or specimen preparation.

5.1.1 Use a testing machine of the constant rate-of-jaw-

6.2 Prepare the test specimen with uniform width and

separation type. The machine shall be equipped with a weigh-

length. Examples of typical lengths and widths are:

ing system that moves a maximum distance of 2 % of the

specimen extension within the range being measured. Also,

Width, mm Length, mm

there should be a device for recording the tensile load and the

13 (0.5 in.) 152 (6 in.)

amount of separation of the grips; both of these measuring

25 (1.0 in.) 102 (4 in.)

systems shall be accurate to 62 %. The rate of separation of

the grips shall be uniform and capable of adjustment from

approximately 1.3 to 500 mm/min (0.05 to 20 in./min) in

6.2.1 The test specimen thickness is contingent upon the

increments necessary to produce the strain rates specified in

thickness of the end-use application. The test specimen thick-

9.2.

ness should be the same as that for the specific end-use

5.2 Grips—Use a grip

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.