ASTM D5163-04

(Guide)Standard Guide for Establishing Procedures to Monitor the Performance of Service Level I Coatings in an Operating Nuclear Power Plant

Standard Guide for Establishing Procedures to Monitor the Performance of Service Level I Coatings in an Operating Nuclear Power Plant

SCOPE

1.1 This guide covers procedures for establishing a program to monitor Coating Service Level I coating systems in operating nuclear power plants. Monitoring is an on going process of evaluating the condition of the in-service coating systems.

1.2 It is the intent of this guide to provide a recommended basis for establishing a coatings monitoring program, not to mandate a singular basis for all programs. Variations or simplifications of the program described in this guide may be appropriate for each operating nuclear power plant depending on their licensing commitments. Similar guidelines are applicable for Service Level III and other areas outside containment.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5163 – 04

Standard Guide for

Establishing Procedures to Monitor the Performance of

Service Level I Coatings in an Operating Nuclear Power

1

Plant

This standard is issued under the fixed designation D 5163; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 4538 Terminology Relating to Protective Coating and

Lining Work for Power Generation Facilities

1.1 This guide covers procedures for establishing a program

D 4541 Test Method for Pull-Off Strength of Coatings

to monitor Coating Service Level I coating systems in operat-

2

Using Portable Adhesion Testers

ing nuclear power plants. Monitoring is an on going process of

D 5144 Guide for Use of Protective Coating Standards in

evaluating the condition of the in-service coating systems.

Nuclear Power Plants

1.2 It is the intent of this guide to provide a recommended

D 5162 Practice for Discontinuity (Holiday) Testing of

basis for establishing a coatings monitoring program, not to

Nonconductive Protective Coating on Metallic Substrates

mandate a singular basis for all programs. Variations or

D 6677 Test Method for Evaluating Adhesion by Knife

simplifications of the program described in this guide may be

F 1130 Practice for Inspecting the Coating System of a Ship

appropriate for each operating nuclear power plant depending

F 1131 Practice for Inspecting the Coating System of a

on their licensing commitments. Similar guidelines are appli-

Ship’s Tanks and Voids

cable for Service Level III and other areas outside containment.

F 1132 Practice for Inspecting the Coating System of a

1.3 This standard does not purport to address all of the

Ship’s Decks and Deck Machinery

safety concerns, if any, associated with its use. It is the

F 1133 Practice for Inspecting the Coating System of a

responsibility of the user of this standard to establish appro-

Ship’s Underwater Hull and Boottop During Drydocking

priate safety and health practices and determine the applica-

2.2 ANSI Standard:

bility of regulatory limitations prior to use.

N45.2.6—Qualification of Inspection, Examination, and

4

2. Referenced Documents

Testing Personnel for Nuclear Power Plants

2

2.1 ASTM Standards:

2.3 SSPC Standard:

D 610 Test Method for Evaluating Degree of Rusting on

SSPC-PA2—Measurement of Dry Paint Thickness With

Painted Steel Surfaces

5

Magnetic Gages

D 714 Test Method for Evaluating Degree of Blistering of

SSPC VIS 2 —Standard Method of Evaluating Degree of

Paints

5

Rusting on Painted Steel Surfaces

D 1186 Test Methods for Nondestructive Measurement of

2.4 USNRC NUREG:

Dry Film Thickness of Nonmagnetic Coatings Applied to

NUREG 1801, Vol 2, April 2001 Generic Aging Lessons

a Ferrous Base

Learned (GALL) Report, Section SI.S8 – Protective

D 3359 Test Methods for Measuring Adhesion by Tape Test

6

Coatings Monitoring and Maintenance Program

D 4121 Practice for Photographic Documentation of Coat-

3

ing and Lining Failures and Defects

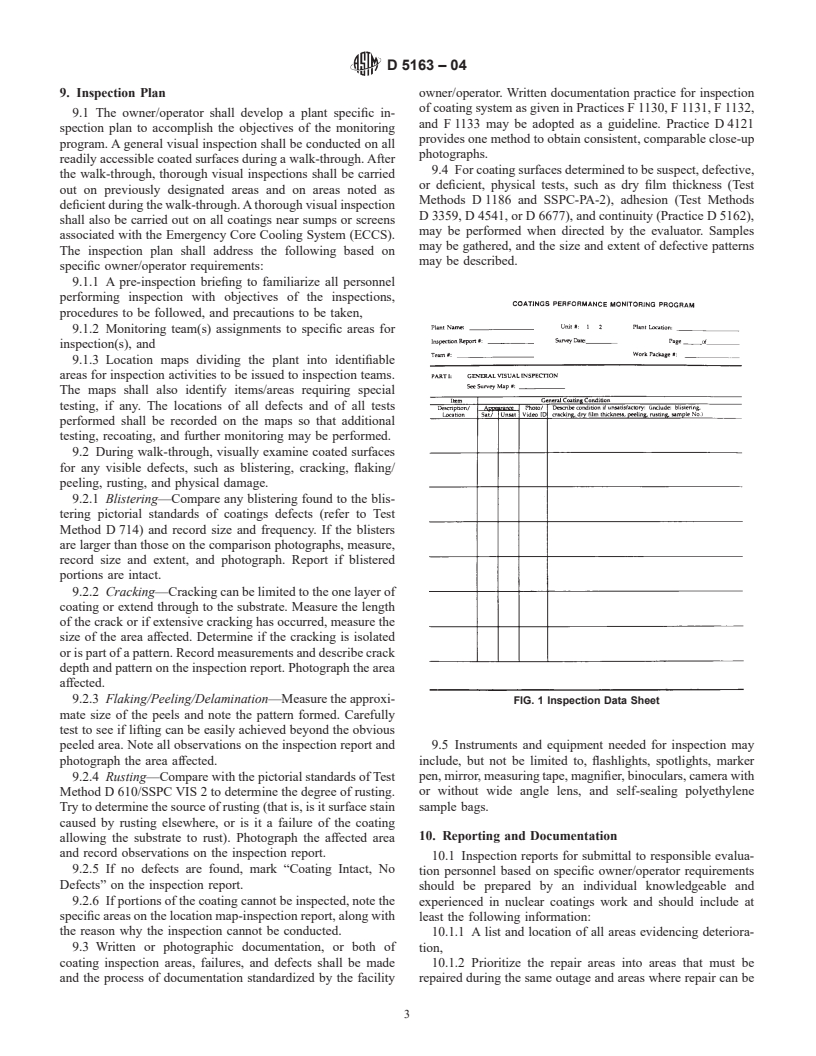

3. Significance and Use

D 4537 Guide for Establishing Procedures to Qualify and

3.1 Establishment of an in-service coatings monitoring pro-

Certify Personnel Performing Coating Work Inspection in

2

gram permits planning and prioritization of coatings mainte-

Nuclear Facilities

nance work as needed to maintain coating integrity and

performance in nuclear Service Level I coating systems. For

1

This guide is under the jurisdiction of ASTM Committee D33 on Protective

Coating and Lining Work for Power Generation Facilities and is the direct

responsibility of Subcommittee D33.04 on Quality Systems and Inspection.

4

Current edition approved Jan. 1, 2004. Published February 2004. Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 4th Floor, New York, NY 10036.

5

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from SSPC: The Society for Protective Coatings, 40 24th St., 6th

Standards volume information, refer to the standard’s Document Summary page on Floor, Pittsburgh, PA 15222-4656.

6

the ASTM website. Available from U.S. Nuclear Regulatory Commission (NRC), PDR, 01F13,

3

Withdrawn. Washington DC 20555.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5163–04

additional information on nuclear maintenance coating work, shutdown frequency. Any change in service criteria or modi-

refer to ASTM Manual on Maintenance Coatings for Nuclear fications of the physical design must be identified and dat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.