ASTM D6795-02(2007)

(Test Method)Standard Test Method for Measuring the Effect on Filterability of Engine Oils After Treatment with Water and Dry Ice and a Short (30-min) Heating Time

Standard Test Method for Measuring the Effect on Filterability of Engine Oils After Treatment with Water and Dry Ice and a Short (30-min) Heating Time

SIGNIFICANCE AND USE

It is normal for some of the combustion products of an internal combustion engine to penetrate into the engine lubricant and be retained in it.

When an engine is run for a period of time and then stored over a long period of time, the by-products of combustion may be retained in the oil in a liquefied state.

Under these circumstances, precipitates can form that impair the filterability of the oil the next time the engine is run.

This test method subjects the test oil and the new oil to the same treatments such that the loss of filterability can be determined.

Reference oils, on which the data obtained by this test method is known, are available.

This test method requires that a reference oil also be tested and results reported. Two oils are available, one known to give a low and one known to give a high data value for this test method.

Note 1—When the new oil test results are to be offered as candidate oil test results for a specification, such as Specification D 4485, the specification will state maximum allowable loss of filterability (flow reduction) of the test oil as compared to the new oil.

SCOPE

1.1 This test method covers the determination of the tendency of an oil to form a precipitate that can plug an oil filter. It simulates a problem that may be encountered in a new engine run for a short period of time, followed by a long period of storage with some water in the oil.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D6795–02 (Reapproved 2007)

Standard Test Method for

Measuring the Effect on Filterability of Engine Oils After

Treatment with Water and Dry Ice and a Short (30-min)

Heating Time

This standard is issued under the fixed designation D 6795; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Any properly equipped laboratory, without outside assistance, can use the procedure described in

this test method. However, theASTM Test Monitoring Center (TMC) provides reference oils and an

assessmentofthetestresultsobtainedonthoseoilsbythelaboratory(seeAnnexA1).Bythesemeans,

the laboratory will know whether their use of the test method gives results statistically similar to those

obtainedbyotherlaboratories.Furthermore,variousagenciesrequirethatalaboratoryutilizetheTMC

services in seeking qualification of oils against specifications. For example, the U.S. Army imposes

such a requirement in connection with several Army engine lubricating oil specifications.

Accordingly, this test method is written for use by laboratories that utilize the TMC services.

Laboratories that choose not to use those services may simply ignore those portions of the test method

that refer to the TMC.

This test method may be modified by means of information letters issued by the TMC. In addition,

the TMC may issue supplementary memoranda related to the test method (see Annex A1).

For other information, refer to the research report of this test method.

1. Scope 2. Referenced Documents

1.1 This test method covers the determination of the ten- 2.1 ASTM Standards:

dency of an oil to form a precipitate that can plug an oil filter. D 1193 Specification for Reagent Water

Itsimulatesaproblemthatmaybeencounteredinanewengine D 4057 Practice for Manual Sampling of Petroleum and

run for a short period of time, followed by a long period of Petroleum Products

storage with some water in the oil. D 4485 Specification for Performance of Engine Oils

1.2 This standard does not purport to address all of the D 5844 Test Method for Evaluation of Automotive Engine

safety concerns, if any, associated with its use. It is the Oils for Inhibition of Rusting (Sequence IID)

responsibility of the user of this standard to establish appro- D 5862 Test Method for Evaluation of Engine Oils in

priate safety and health practices and determine the applica- Two-Stroke Cycle Turbo-Supercharged 6V92TA Diesel

bility of regulatory limitations prior to use. Engine

E 344 Terminology Relating to Thermometry and Hydrom-

etry

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

3. Terminology

D02.B0 on Automotive Lubricants.

3.1 Definitions:

Current edition approved May 1, 2007. Published June 2007. Originally

approved in 2002. Last previous edition approved in 2002 as D 6795 – 02.

ASTM Test Monitoring Center, 6555 Penn Ave., Pittsburgh, PA 152006-4489.

This test method is supplemented by Information Letters and Memoranda issued by For referenced ASTM standards, visit the ASTM website, www.astm.org, or

theASTM Test Monitoring Center. Users of this test method can contact theASTM contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Test Monitoring Center to obtain the most recent of these. Standards volume information, refer to the standard’s Document Summary page on

Supporting data have been filed at ASTM International Headquarters and may the ASTM website.

be obtained by requesting Research Report RR: D02–1529. Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6795–02 (2007)

3.1.1 calibrate, v—to determine the indication or output of 5.6 This test method requires that a reference oil also be

a measuring device with respect to that of a standard. E 344 tested and results reported. Two oils are available, one known

3.1.2 calibration test, n—a test, using a coded reference oil, to give a low and one known to give a high data value for this

conducted as specified in the test method. test method.

3.1.2.1 Discussion—The test result is used to determine the

NOTE 1—Whenthenewoiltestresultsaretobeofferedascandidateoil

suitability of the testing facility/laboratory to conduct such

test results for a specification, such as Specification D 4485, the specifi-

tests on non-reference oils.

cation will state maximum allowable loss of filterability (flow reduction)

3.1.3 candidate oil, n—an oil that is intended to have the of the test oil as compared to the new oil.

performance characteristics necessary to satisfy a specification

6. Apparatus

and is tested against that specification. D 5844

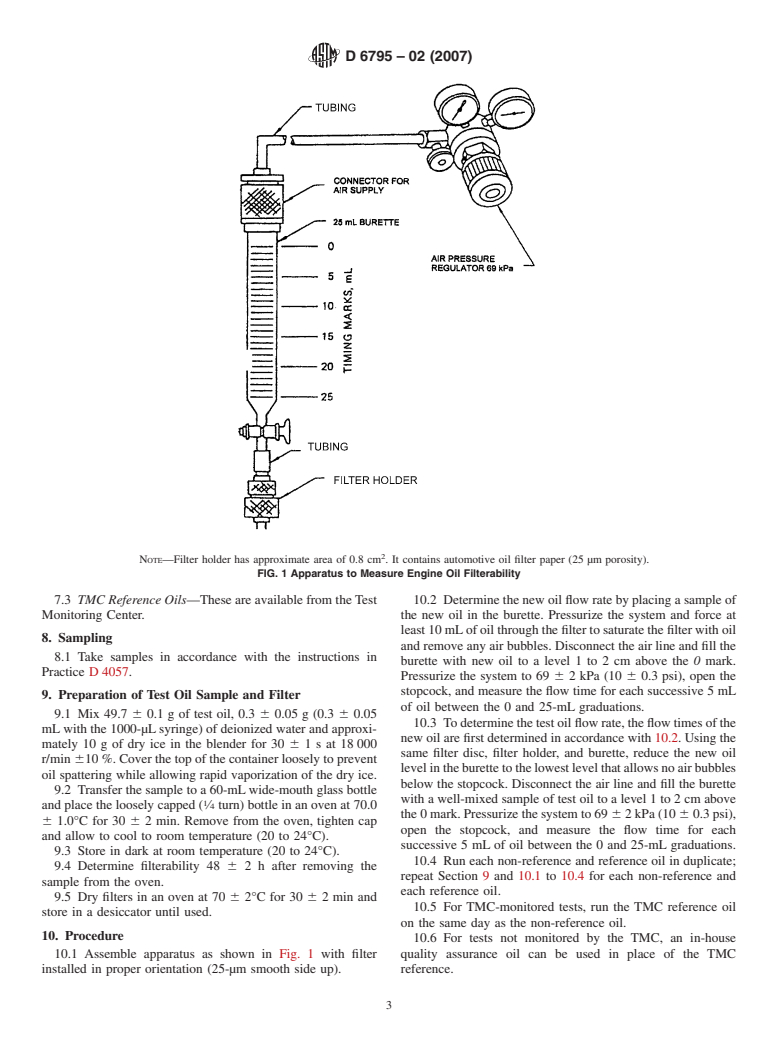

3.1.4 engine oil, n—a liquid that reduces friction or wear, or 6.1 Theapparatusconsistsofa25-mLburette,afilterholder

with 25-µm automotive oil filter paper, and a source of 69 6 2

both, between the moving parts within an engine; removes

heat, particularly from the underside of pistons; and serves as kPa (10 6 0.3 psi) air pressure. Discs of filter paper are cut to

fit the holder and installed (see Fig. 1).

a combustion gas sealant for the piston rings.

6.1.1 Burette (glass or plastic), 25 mL, with polytetrafluo-

3.1.4.1 Discussion—It may contain additives to enhance

roethylene (PTFE) stopcock and 1.8 6 0.1 mm burette tip

certain properties. Inhibition of engine rusting, deposit forma-

opening.

tion,valvetrainwear,oiloxidation,andfoamingareexamples.

6.1.2 Air Regulator, capable of regulating air to a pressure

D 5862

of 69 6 2 kPa (10 6 0.3 psi).

3.1.5 non-reference oil, n—any oil other than a reference

6.1.3 Filter Holder, with effective filter area approximately

oil–such as a research formulation, commercial oil, or candi-

0.8 cm .

date oil. D 5844

6.1.4 Automotive Oil Filter Paper, 25 mm, (25-µm poros-

3.1.6 reference oil, n—an oil of known performance char-

ity).

acteristics, used as a basis for comparison.

6.2 Blender, capable of 18 000 r/min. 610 % without the

3.1.6.1 Discussion—Reference oils are used to calibrate

container.

testing facilities, to compare the performance of other oils, or

6.2.1 Timer, capable of timing 30 61s.

to evaluate other materials (such as seals) that interact with

6.3 Container, 250 mL, with blade compatible with the

oils. D 5844

blender.

3.2 Definitions of Terms Specific to This Standard:

6.4 Syringe, 1000 µL.

3.2.1 effective filter area, n—that surface of a test filter that

6.5 Dry Ice (solid carbon dioxide).

can receive the material to be filtered.

6.6 Mechanical Convection Oven, capable of maintaining

3.2.2 new oil, n—an unused oil having the identical formu-

70 6 1°C.

lation and base stock as the test oil.

6.7 Sensors (or equivalent timing devices), capable of mea-

3.2.3 test oil, n—the new oil with water added and dry ice

suring sequential events to 1 s resolution.

added.

6.8 Glass Jars, 60 mL, with inert lined lids.

3.2.3.1 Discussion—A potential precipitate in the test oil is

induced by heating the oil and aging.

7. Reagents

7.1 Purity of Reagents—Use reagent grade chemicals in all

4. Summary of Test Method

tests. Unless otherwise indicated, it is intended that all reagents

4.1 The test oil is treated with deionized water and dry ice.

shall conform to the specifications of the Committee on

The sample is heated to 70°C for 30 min, followed by storage 7

AnalyticalReagentsoftheAmericanChemicalSociety, where

at room temperature. The sample is filtered and the flow rate is

such specifications are available. Other grades may be used,

calculated determining the engine oil filterability characteris-

provided it is first ascertained that the reagent is of sufficiently

tics.

high purity to permit its use without lessening the accuracy of

the determination.

5. Significance and Use

7.2 Purity of Water—Unless otherwise indicated, references

5.1 It is normal for some of the combustion products of an to water shall be understood to mean Specification D 1193

internal combustion engine to penetrate into the engine lubri- Type III deionized water or water of equivalent purity.

cant and be retained in it.

5.2 When an engine is run for a period of time and then

The sole source of supply of the automotive oil filter paper known to the

stored over a long period of time, the by-products of combus-

committee at this time is The Central Parts Distributor, OH Technologies Inc., P.O.

tion may be retained in the oil in a liquefied state. Box5039,Mentor,OH44061-5039.Ifyouareawareofalternativesuppliers,please

provide this information toASTM International Headquarters. Your comments will

5.3 Under these circumstances, precipitates can form that

receive careful consideration at a meeting of the responsible technical committee ,

impair the filterability of the oil the next time the engine is run.

which you may attend.

5.4 This test method subjects the test oil and the new oil to

Reagent Chemicals, American Chemical Society Specifications , American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

the same treatments such that the loss of filterability can be

listed by the American Chemical Society, see Analar Standards for Laboratory

determined.

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

5.5 Reference oils, on which the data obtained by this test

and National Formulary, U.S. Pharmacopeial Convention, Inc., (USPC), Rockville,

method is known, are available. MD.

D6795–02 (2007)

NOTE—Filter holder has approximate area of 0.8 cm . It contains automotive oil filter paper (25 µm porosity).

FIG. 1 Apparatus to Measure Engine Oil Filterability

7.3 TMC Reference Oils—These are available from the Test 10.2 Determine the new oil flow rate by placing a sample of

Monitoring Center. the new oil in the burette. Pressurize the system and force at

least10mLofoilthroughthefiltertosaturatethefilterwithoil

8. Sampling

and remove any air bubbles. Disconnect the air line and fill the

8.1 Take samples in accordance with the instructions in

burette with new oil to a level 1 to 2 cm above the 0 mark.

Practice D 4057.

Pressurize the system to 69 6 2 kPa (10 6 0.3 psi), open the

stopcock, and measure the flow time for each successive 5 mL

9. Preparation of Test Oil Sample and Filter

of oil between the 0 and 25-mL graduations.

9.1 Mix 49.7 6 0.1 g of test oil, 0.3 6 0.05 g (0.3 6 0.05

10.3 Todeterminethetestoilflowrate,theflowtimesofthe

mLwith the 1000-µLsyringe) of deionized water and approxi-

new oil are first determined in accordance with 10.2. Using the

mately 10 g of dry ice in the blender for 30 61sat18000

same filter disc, filter holder, and burette, reduce the new oil

r/min 610 %. Cover the top of the container loosely to prevent

levelintheburettetothelowestlevelthatallowsnoairbubbles

oil spattering while allowing rapid vaporization of the dry ice.

below the stopcock. Disconnect the air line and fill the burette

9.2 Transfer the sample to a 60-mLwide-mouth glass bottle

with a well-mixed sample of test oil to a level 1 to 2 cm above

and place the loosely capped ( ⁄4 turn) bottle in an oven at 70.0

the0mark.Pressurizethesystemto69 62kPa(10 60.3psi),

6 1.0°C for 30 6 2 min. Remove from the oven, tighten cap

open the stopcock, and measure the flow time for each

and allow to cool to room temperature (20 to 24°C).

successive 5 mL of oil between the 0 and 25-mL graduations.

9.3 Store in dark at room temperature (20 to 24°C).

10.4 Run each non-reference and reference oil in duplicate;

9.4 Determine filterability 48 6 2 h after removing the

repeat Section 9 and 10.1 to 10.4 for each non-reference and

sample from the oven.

each reference oil.

9.5 Dry filters in an oven at 70 6 2°C for 30 6 2 min and

10.5 For TMC-monitored tests, run the TMC reference oil

store in a desiccator until used.

on the same day as the non-reference oil.

10. Procedure

10.6 For tests not monitored by the TMC, an in-house

10.1 Assemble apparatus as shown in Fig. 1 with filter quality assurance oil can be used in place of the TMC

installed in proper orientation (25-µm smooth side up). reference.

D6795–02 (2007)

11. Calculation include any non-reference test data. Complete all of the

required blank fields on the forms.

11.1 Calculate the flow rate for the new oil and the test oil

12.1.4.2 Transmit reference test data to the TMC by elec-

for each 5-mL portion of oil using Eq 1:

tronic means or by telephone facsimile immediately upon

A

completion of the test analysis. Include all of the reporting

flow rate 5 (1)

B

forms in the transmission.

where:

NOTE 4—Specific protocols for the electronic transmission of test data

A = volume of oil, and

to the TMC are available from the TMC.

B = flow time.

12.1.5 Evaluation of Reference Test Oil Results—Upon

11.2 Calculate the percent change in flow rate of the test oil

receipt of the transmitted TMC reference oil test results, the

relative to the new oil with the final oil flow rates (between 20

TMC will review the test for operational adherence to the

and 25 mL measured with the same filter disc) using Eq 2:

published test method. If the test is found to be operationally

E 2 D

percent change in flow rate 5 3 100 (2) valid, the reference oil results will be evaluated using accep-

D

tance criteria established by the governing surveillance panel.

where: The reference oil acceptance criteria are subject to change at

D = final new oil flow rate, and the discretion of the surveillance panel.

E = final test oil flow rate.

12.1.5.1 If the transmitted test is found to be both opera-

tionally valid and statistically acceptable, the testing laboratory

12. TMC Reference Oil Testing will be notified of the acceptable status of the reference test.

The uncoded TMC reference oil identification will also be

12.1 Test a TMC-coded reference oil along with each batch

disclosed to the testing laboratory.

of non-reference oil tests. Run the reference oil simultaneously

12.1.5.2 In the event that a TMC reference oil test is found

with, and in the same batch as, the non-reference oils.

to be unacceptable, an explanation of the problem relating to

NOTE 2—AnnexA1 discusses the involvement of theASTMTMC with

the failure will be provided to the testing laboratory. If there is

respect to the reference test-monitoring program.

an obvious operational reason for the failed test, the problem

shall be corrected before requesting anotherTMC reference oil

12.1.1 Prior to conducting a reference oil test, procure a

supplyofr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.