ASTM A859/A859M-04

(Specification)Standard Specification for Age-Hardening Alloy Steel Forgings for Pressure Vessel Components

Standard Specification for Age-Hardening Alloy Steel Forgings for Pressure Vessel Components

ABSTRACT

This specification covers the standard requirements for low-carbon age-hardened nickel-copper-chromium-molybdenum-columbium alloy steel forgings for pressure vessel components. Materials shall be manufactured to a killed fine austenitic grain size, by vacuum degas melting process. Heat treatment shall be conducted, according to class, by: normalizing and precipitation hardening (Grade A, Class 1); liquid quenching and precipitation hardening (Grade A, Class 2); or double liquid-quenching, tempering, double austenitizing, and precipitation hardening (Grade B). Heat and product analyses shall be used to evaluate the conformance of forgings to required chemical compositions. Tensile, notch toughness, and Charpy impact requirements shall be examined, for which one of four sampling methods may be employed. One tension test and one impact test (for three samples) shall be made for each forging. Dimensions and finishes of the forgings shall conform to that specified by the purchaser. Repair welding shall also be performed only if permitted by the purchaser.

SCOPE

1.1 This specification covers requirements for low-carbon age-hardening nickel-copper-chromium-molybdenum-columbium alloy steel forgings for pressure vessel components.

1.2 Forgings under this specification are available as Grades A or B. Grade A may be ordered in one or two classes as follows:

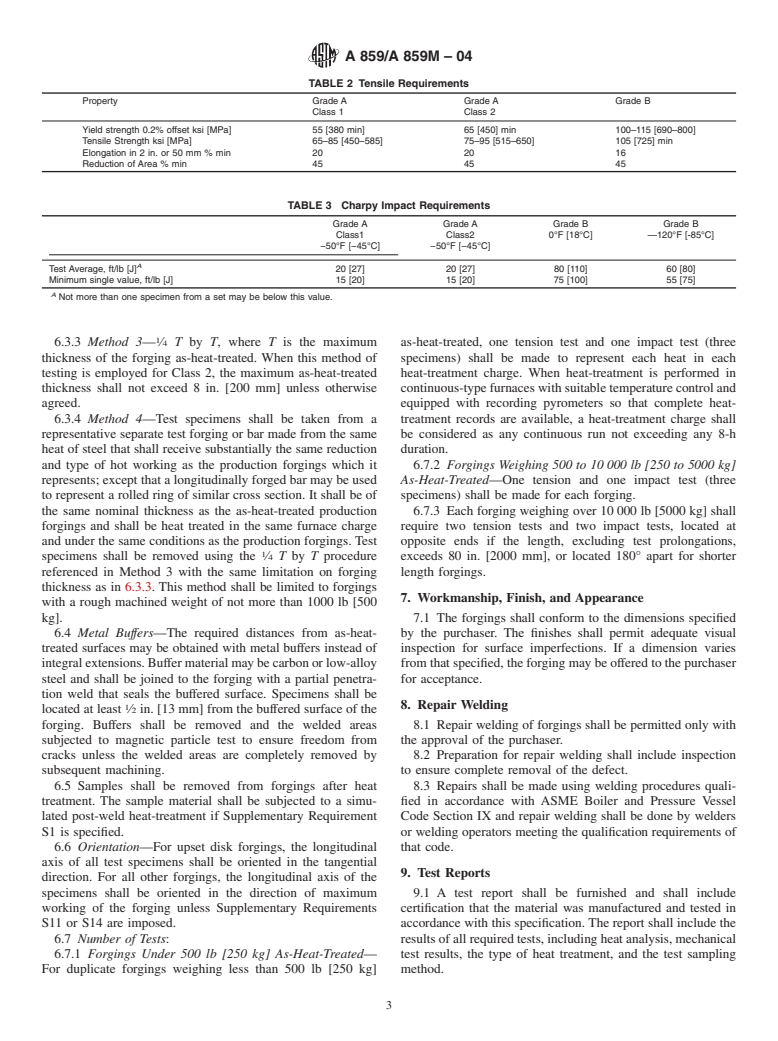

1.2.1 Grade A Class 1Normalized-and-precipitation-heat-treated, providing a minimum yield strength of 55 ksi [380 MPa] and a minimum tensile strength of 65 ksi [450 MPa].

1.2.2 Grade A Class 2Quenched-and-precipitation-heat-treated, providing a minimum yield strength of 65 ksi [450 MPa] and a minimum tensile strength of 75 ksi [MPa].

1.2.3 Grade A was the original steel composition in this specification.

1.3 Although the material is readily weldable, welding procedures are of fundamental importance and must be such as not to affect adversely the properties of the material, especially in the heat-affected zone. It is presupposed that welding procedures will be suitable for the material being welded.

1.4 Supplementary requirements, including those applicable in Specification A 788, are provided for use when additional testing or inspection is desired. These shall apply only when specified individually by the purchaser in the order.

1.5 The values stated in either inch-pound or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.6 This specification is expressed in both inch-pound and SI units. However, unless the order specifies the applicable "M" specification designation [SI units], the material shall be furnished to inch-pound units.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 859/A 859M – 04

Standard Specification for

Age-Hardening Alloy Steel Forgings for Pressure Vessel

1

Components

ThisstandardisissuedunderthefixeddesignationA859/A859M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

1.1 This specification covers requirements for low-carbon 2.1 ASTM Standards:

age-hardening nickel-copper-chromium-molybdenum-col- A275/A275M Test Method for Magnetic Particle Exami-

umbium alloy steel forgings for pressure vessel components. nation of Steel Forgings

1.2 ForgingsunderthisspecificationareavailableasGrades A370 TestMethodsandDefinitionsforMechanicalTesting

A or B. Grade A may be ordered in one or two classes as of Steel Products

follows: A 388/A 388M Practice for Ultrasonic Examination of

1.2.1 GradeAClass1—Normalized-and-precipitation-heat- Heavy Steel Forgings

treated, providing a minimum yield strength of 55 ksi [380 A788 Specification for Steel Forgings, General Require-

MPa] and a minimum tensile strength of 65 ksi [450 MPa]. ments

1.2.2 Grade A Class 2—Quenched-and-precipitation-heat- E208 Test Method for Conducting Drop-Weight Test to

treated, providing a minimum yield strength of 65 ksi [450 Determine Nil-DuctilityTransitionTemperature of Ferritic

MPa] and a minimum tensile strength of 75 ksi [MPa]. Steels

1.2.3 Grade A was the original steel composition in this E604 Test Method for Dynamic Tear Testing of Metallic

specification. Materials

1.3 Although the material is readily weldable, welding

proceduresareoffundamentalimportanceandmustbesuchas 2.2 ASME Standard:

3

nottoaffectadverselythepropertiesofthematerial,especially ASME Boiler and Pressure Vessel Code—Section IX,

in the heat-affected zone. It is presupposed that welding Welding Qualifications

procedures will be suitable for the material being welded.

3. Ordering Information and General Requirements

1.4 Supplementaryrequirements,includingthoseapplicable

3.1 In addition to the ordering information required by

in Specification A788, are provided for use when additional

testing or inspection is desired. These shall apply only when Specification A788, the purchaser shall include with the

inquiry and order a detailed drawing, sketch, or written

specified individually by the purchaser in the order.

1.5 The values stated in either inch-pound or SI units are to description of the forging and the method of selecting test

location (see 6.3). When appropriate, the areas of significant

beregardedseparatelyasstandard.Withinthetext,theSIunits

areshowninbrackets.Thevaluesstatedineachsystemarenot loading in the forging shall be designated.

3.2 Material supplied to this specification shall conform to

exact equivalents; therefore, each system must be used inde-

pendentlyoftheother.Combiningvaluesfromthetwosystems the requirements of Specification A788, which outlines addi-

tional ordering information, manufacturing requirements, test-

may result in nonconformance with the specification.

1.6 This specification is expressed in both inch-pound and ing and retesting methods and procedures, marking, certifica-

tion, product analysis variations, and additional supplementary

SI units. However, unless the order specifies the applicable

“M” specification designation [SI units], the material shall be requirements.

furnished to inch-pound units.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee Standards volume information, refer to the standard’s Document Summary page on

A01.06 on Steel Forgings and Billets. the ASTM website.

3

Current edition approved March 1, 2004. Published April 2004. Originally Available from American Society of Mechanical Engineers, 345 E. 47th St.,

approved in 1986. Last previous edition approved in 2002 as A859/A859M–02. New York, NY 10017.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 859/A 859M – 04

3.3 If the requirements of this specification are in conflict of Table 2. The largest obtainable tension test specimen as

with the requirements of SpecificationA788, the requirements specified in Test Methods and DefinitionsA370 shall be used.

of this specification shall prevail.

6.2 Notch Toughness Requirements:

6.2.1 For Grade A, Class 1 or 2 forgi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.