ASTM C1382-16(2023)

(Test Method)Standard Test Method for Determining Tensile Adhesion Properties of Sealants When Used in Exterior Insulation and Finish Systems (EIFS) Joints

Standard Test Method for Determining Tensile Adhesion Properties of Sealants When Used in Exterior Insulation and Finish Systems (EIFS) Joints

SIGNIFICANCE AND USE

5.1 EIFS are barrier-type systems that must be weatherproofed to prevent the passage of moisture, air, dust, heat, and cold from entering a structure.

5.2 This test method is intended to determine the adhesion properties of the sealant with the EIFS substrate as determined by its tensile adhesive properties for dry, wet, frozen, heat-aged, and artificial weather-aged conditions.

SCOPE

1.1 This test method describes a laboratory procedure for measuring tensile adhesion properties of sealants to exterior insulation and finish systems (EIFS) under dry, wet, frozen, heat-aged, and artificial weather-aged conditions.

1.2 The committee with jurisdiction over this standard is not aware of any comparable standards published by other organizations.

1.3 The values stated in SI units are to be regarded as the standard. The inch-pound values given in parentheses are provided for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1382 − 16 (Reapproved 2023)

Standard Test Method for

Determining Tensile Adhesion Properties of Sealants When

Used in Exterior Insulation and Finish Systems (EIFS)

Joints

This standard is issued under the fixed designation C1382; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C1442 Practice for Conducting Tests on Sealants Using

Artificial Weathering Apparatus

1.1 This test method describes a laboratory procedure for

E177 Practice for Use of the Terms Precision and Bias in

measuring tensile adhesion properties of sealants to exterior

ASTM Test Methods

insulation and finish systems (EIFS) under dry, wet, frozen,

E691 Practice for Conducting an Interlaboratory Study to

heat-aged, and artificial weather-aged conditions.

Determine the Precision of a Test Method

1.2 Thecommitteewithjurisdictionoverthisstandardisnot

E2110 Terminology for Exterior Insulation and Finish Sys-

aware of any comparable standards published by other orga-

tems (EIFS)

nizations.

G113 Terminology Relating to Natural andArtificial Weath-

ering Tests of Nonmetallic Materials

1.3 The values stated in SI units are to be regarded as the

standard. The inch-pound values given in parentheses are G151 Practice for Exposing Nonmetallic Materials inAccel-

erated Test Devices that Use Laboratory Light Sources

provided for information only.

G154 Practice for Operating Fluorescent Ultraviolet (UV)

1.4 This standard does not purport to address all of the

Lamp Apparatus for Exposure of Nonmetallic Materials

safety concerns, if any, associated with its use. It is the

G155 Practice for Operating XenonArc LampApparatus for

responsibility of the user of this standard to establish appro-

Exposure of Materials

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

3. Terminology

1.5 This international standard was developed in accor-

3.1 Definitions:

dance with internationally recognized principles on standard-

3.1.1 Refer to Terminology C717 for definitions of terms

ization established in the Decision on Principles for the

used in this test method, including but not limited to the

Development of International Standards, Guides and Recom-

following: adhesion failure, cohesive failure, primer, sealant,

mendations issued by the World Trade Organization Technical

standard conditions, and substrate.

Barriers to Trade (TBT) Committee.

3.1.2 Refer to Terminology G113 for definitions of terms

relating to natural and artificial weathering.

2. Referenced Documents

3.2 Description of Terms Specific to This Standard—refer to

2.1 ASTM Standards:

Terminology E2110 for definitions of the following terms used

C717 Terminology of Building Seals and Sealants

in this test method: base coat, EIFS, and finish coat.

C1135 Test Method for Determining TensileAdhesion Prop-

erties of Structural Sealants

4. Summary of Test Method

4.1 This test method is a modification of Test Method

ThistestmethodisunderthejurisdictionofASTMCommitteeC24onBuilding

C1135. Preliminary testing using Test Method C794 may be

Seals and Sealants and is the direct responsibility of Subcommittee C24.30 on

helpful as a screen test to determine dry adhesion capabilities

Adhesion.

and priming requirements before proceeding with this test.

Current edition approved Jan. 1, 2023. Published January 2023. Originally

This test is performed after the specimen assemblies are

approved in 1997. Last previous edition approved in 2016 as C1382 – 16. DOI:

10.1520/C1382-16R23.

subjected to a variety of conditions that artificially accelerate

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

the effect of weathering impact on the sealant-to-EIFS bond.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The conditioning employed in this test does not necessarily

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. address all field conditions.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1382 − 16 (2023)

5. Significance and Use 7. Test Specimens

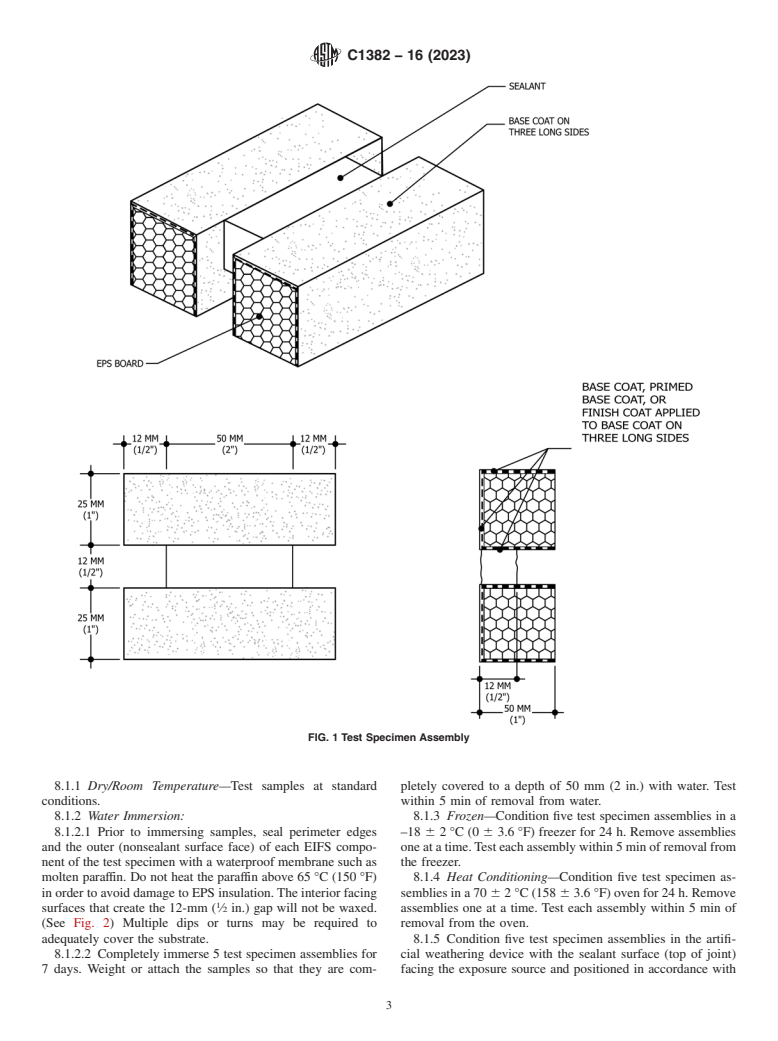

5.1 EIFS are barrier-type systems that must be weather- 7.1 Two (2) EIFS samples are required for each test speci-

proofed to prevent the passage of moisture, air, dust, heat, and men assembly as shown in Fig. 1. The EIFS sample size shall

cold from entering a structure. be determined by the size of the test machine grips, yet they

must be a minimum of 25 by 75 mm (1 by 3 in.). It may be

5.2 This test method is intended to determine the adhesion

necessary to cut the EIFS substrate into rectangles appropri-

properties of the sealant with the EIFS substrate as determined

ately sized for the test. If cutting is required, the EIFS must be

by its tensile adhesive properties for dry, wet, frozen, heat-

configured such that three of the four long ends of the EIFS

aged, and artificial weather-aged conditions.

substrate will be coated with EIFS base coat, primed base coat,

or finish coat. The remaining long end and two short ends will

6. Apparatus and Materials

be uncoated EPS board with cut edges of the EIFS coating

6.1 Tensile Testing Machine—Capable of producing a ten-

visible. In all cases, the sealant should be applied to the EIFS

sile load on the specimen at the rate of 506 5 mm (2.0 6 0.20

base coat, primed base coat, or finish coat on a long side at the

in.)/min., and with a recording chart to show stress/strain

edge where a coated surface continues around the corner. The

values (tensile modulus).

sealant should not be applied on the edge where coating stops

6.1.1 Fixed Member—A fixed or essentially stationary

and EPS board is exposed on the adjoining corner.

member carrying one grip.

7.2 The EIF system being tested must be applied over

6.1.2 Movable Member—A movable member carrying a

minimum 25 mm (1 in.) insulation board with coating thick-

second grip.

ness consistent with the EIFS manufacturer’s requirements and

6.1.3 Grips—The grips should be suitable to firmly grasp

allowed to cure 28 days minimum at standard conditions.

the test fixture that holds the test specimen and should be

Select surface to be tested (for example, EIFS primer, base

designed to eliminate eccentric specimen loading. Specimen

coat, finish coat, etc.).

loading should be perpendicular to the substrate/sealant inter-

faces. For alignment purposes, each grip shall have a swivel or NOTE 1—Five test specimen assemblies per condition should be

prepared for each sealant and substrate system being tested for a total of

universal joint at the end nearest to the specimen.

25 specimens per sealant/EIFS substrate combination. It may be beneficial

6.1.4 Grip Fixture—A fixture capable of being held by the

to prepare up to five extra specimen assemblies in the event one or more

grips and furnishing a tensile force to the sealant specimen.

samples is unusable.

6.2 Spatulas—For use in applying sealant.

7.3 Prior to assembling the test specimens, clean the sur-

faces to be sealed with a clean, dry, lint-free cloth or soft,

6.3 Caulking Gun—For extruding sealant from cartridges,

nonmetallic bristle brush.

when applicable.

7.4 Prime surfaces (if applicable) to be sealed with appro-

6.4 Primer, if applicable.

priate primer as recommended by the sealant manufacturer. Do

6.5 Sealant.

notallowprimertocontactEPSinsulation.Allowprimertodry

6.6 Spacer—One piece of spacer made from polytetrafluo-

as specified by sealant manufacturer.

rethylene (PTFE) or a suitable rigid material shall be used to

7.5 Provide a 12 mm (; ⁄2 in.) spacer to form a sealant

which the test sealant will not bond.

cavity centered on the test specimen measuring 12 by 12 by 50

1 1

6.7 Knife, with sharp razor-type blade.

mm ( ⁄2 by ⁄2 by 2 in.) between the test samples. (See Fig. 1.)

6.8 Masking Tape.

7.6 Sandwich the spacer between the two test samples and

secure them together with clamps or mechanical devices.

6.9 EIFS substrates, as identified in 10.1.5.

7.7 Fill each set of five test specimen assemblies with the

6.10 Rigid substrate, for applying EIFS coating in the peel

sealant being tested and immediately strike off any excess

adhesion test.

sealant.

6.11 Waterproof membrane, such as molten paraffin.

7.8 Identify each of the five test specimens.

6.12 Freezer, –1862°C(0 6 3.6 °F).

7.9 Cure specimens under one of the following cycles:

6.13 Oven, 70 6 2 °C (158 6 3.6 °F).

7.9.1 Cureatstandardconditionsforaminimumof21days.

6.14 Exposure Apparatus—Choice of type of apparatus 7.9.2 Alternately, cure for a total of 21 days as follows: (a)

shall be by mutual agreement among the interested parties. 7 days at standard conditions above; (b) 7 days at 38 62°C

Because of differences in test conditions, test results may differ (100 6 3.6 °F) and 95 % relative humidity; (c) 7 days at

with the type of apparatus used. Consult Practices G154 and standard conditions.

G155 for differences in the spectral power distributions of the 7.9.3 The sealant manufacturer may request conditions

exposure sources and Practice C1442 for the differences in test other than those specified provided the temperature does not

exceed 50 °C (122 °F).

parameters in the two types of apparatus specified.

6.14.1 Fluorescent UV/Condensation Apparatus, as de-

8. Conditioning

scribed in Practice C1442, Section 7.3.

6.14.2 Xenon Arc Light Apparatus, as described in Practice 8.1 Following completion of cure as outlined in 7.9, test

C1442, Section 7.2. samples under the following conditions:

C1382 − 16 (2023)

FIG. 1 Test Specimen Assembly

8.1.1 Dry/Room Temperature—Test samples at standard pletely covered to a depth of 50 mm (2 in.) with water. Test

conditions. within 5 min of removal from water.

8.1.2 Water Immersion: 8.1.3 Frozen—Condition five test specimen assemblies in a

8.1.2.1 Prior to immersing samples, seal perimeter edges –18 62°C(0 6 3.6 °F) freezer for 24 h. Remove assemblies

and the outer (nonsealant surface face) of each EIFS compo- oneatatime.Testeachassemblywithin5minofremovalfrom

nent of the test specimen with a waterproof membrane such as the freezer.

molten paraffin. Do not heat the paraffin above 65 °C (150 °F) 8.1.4 Heat Conditioning—Condition five test specimen as-

in order to avoid damage to EPS insulation.The interior facing semblies in a 70 6 2 °C (158 6 3.6 °F) oven for 24 h. Remove

surfaces that create the 12-mm ( ⁄2 in.) gap will not be waxed. assemblies one at a time. Test each assembly within 5 min of

(See Fig. 2) Multiple dips or turns may be required to removal from the oven.

adequately cover the substrate. 8.1.5 Condition five test specimen assemblies in the artifi-

8.1.2.2 Completely immerse 5 test specimen assemblies for cial weathering device with the sealant surface (top of joint)

7 days. Weight or attach the samples so that they are com- facing the exposure source and positioned in accordance with

C1382 − 16 (2023)

FIG. 2 Test Specimen Assembly of Water Immersion Samples

the manufacturer’s recommendations for specimen mounting. exposure chamber. If the specimens do not completely fill the

Specimens should be confined to an exposure area in which the

racks,filltheemptyspaceswithblankmetalpanelstomaintain

irradiance is at least 90 % of the irradiance at the center of the

the test conditions within the chamber.

exposure area. Unless it is known that irradiance uniformity

8.1.5.1 Operate the fluorescent UV device in accordance

meets this requirement, use one of the procedures described in

with the procedure in Practice C1442, Section 7.3. Position the

Practice G151, Section 5.1.4 to ensure equal radiant exposure

assemblies as shown in Fig. 3 and expose for 2500 h.

on all specimens or compensation for differences within the

C1382 − 16 (2023)

FIG. 3 Position of Test Specimens for UV/Condensation Exposure

C1382 − 16 (2023)

8.1.5.2 Operate the xenon arc device in accordance with the 10.1.6.2 The percentage loss in bond and cohesion for each

procedure in Practice C1442, Section 7.2. The exposed face of sample tested. Note failure mode,

the assemblies is positioned in accordance with the manufac- 10.1.6.3 Variation, if any, from the test procedure,

turer’s recommendations for specimen mounting. Expose for 10.1.7 Freezer temperature,

2500hwhenoperatedatanirradiancelevelof0.51W/(m .nm) 10.1.8 Type, manufacturer and model of artificial weather-

at 340 nm. (At an irradiance level of 0.35 W/(m .nm) at 340 ing apparatus used, and

nm,exposefor3643h.SeeAnnexA1.2.1inPracticeC1442for 10.1.9 Irradiance level and actual time (number of hours) in

the formula to calculate exposure time at other irradiance weathering apparatus.

levels.)

11. Precision and Bias

NOTE 2—The test cycles have been used by historical convention and

11.1 The precision of this test method is based on an

may not adequately simulate the effects of outdoor exposure of sealants.

interlaboratory study of Test Method C1382 conducted in

Other cycles can be used by mutual agreement of all concernced parties.

NOTE 3—Refer to Practice G151 for full cautionary guidance regarding

1996. Each of four laboratories tested three different sealants

laboratory weathering of nonmetallic materials.

and three primers under varying environmental conditions.

8.1.5.3 After exposure, condition samples in laboratory for

Every “test result” represents an individual determination.

16 h minimum at standard conditions.

Each participating laboratory was instructed to submit five

replicate test results for one, two, or three different sealant

9. Procedure

primer combinations. Except for the limited number of report-

9.1 Measure and record the initial distance between the inglaboratories,PracticeE691wasfollowedforthedesignand

analysis of the data; the details are given in ASTM Research

EIFS substrates prior to loading.

Report No. C24-1059.

9.2 Place the test specimen assembly in the grips of the

11.1.1 Repeatability Limit (r)—Two test results obtained

tensile test machine and test at a rate of 50 mm 6 5 mm (2.0

within one laboratory shall be judged not equivalent if they

6 0.20 in.)/min.

differ by more than the “r” value for that material; “r”isthe

9.3 Record the tensile load at 10, 2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.