ASTM E382-20

(Test Method)Standard Test Method for Determination of Crushing Strength of Iron Ore Pellets and Direct-Reduced Iron

Standard Test Method for Determination of Crushing Strength of Iron Ore Pellets and Direct-Reduced Iron

SIGNIFICANCE AND USE

5.1 The crushing strength aids the pellet producer in the determination of quality problems associated with the production of pellets.

5.2 The crushing strength is often used by the pellet consumer as a quality indicator for performance in the blast furnace and gas-based direct reduction plants.

SCOPE

1.1 This test method describes a method for determining the crushing strength of fired iron ore pellets and direct-reduced iron. Cylindrical agglomerates and briquettes are not covered by this test method.

1.2 The values as stated in SI units are to be regarded as the standards. The values in parentheses are given for information only.

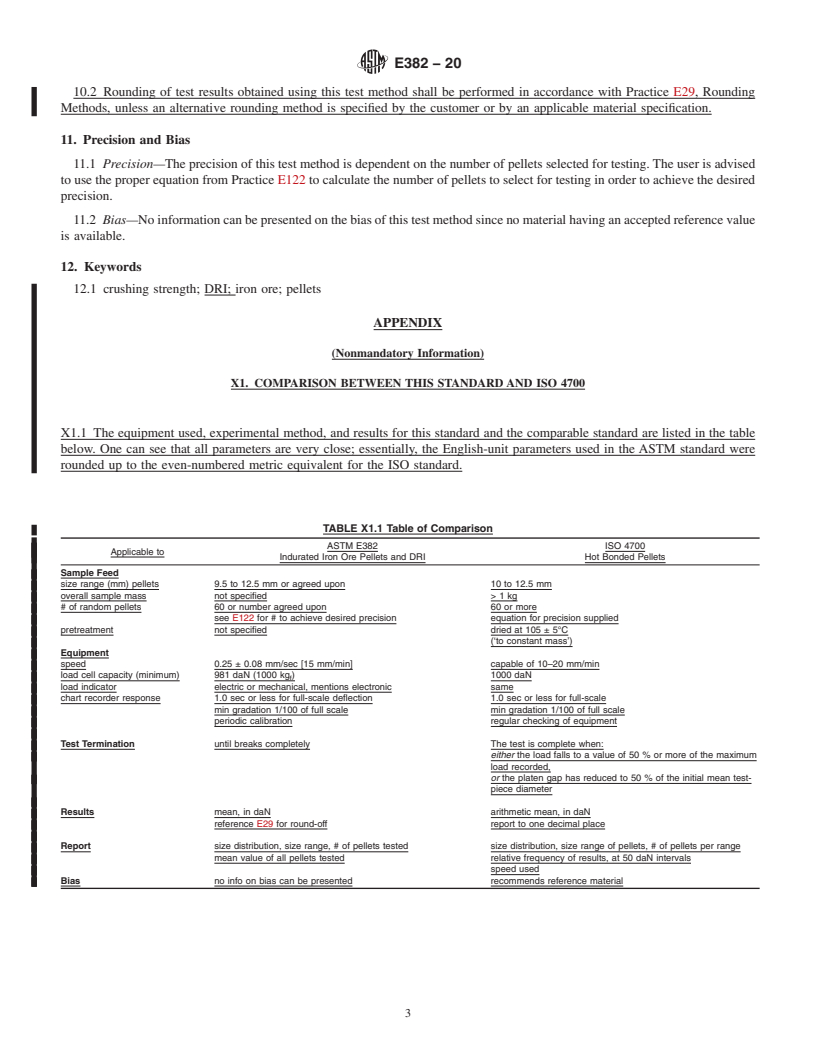

1.3 Results given by this test should be similar to those from ISO 4700 (see Appendix X1 for details).

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E382 − 20

Standard Test Method for

Determination of Crushing Strength of Iron Ore Pellets and

1

Direct-Reduced Iron

This standard is issued under the fixed designation E382; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Specified Precision, the Average for a Characteristic of a

Lot or Process

1.1 This test method describes a method for determining the

E135 Terminology Relating to Analytical Chemistry for

crushing strength of fired iron ore pellets and direct-reduced

Metals, Ores, and Related Materials

iron. Cylindrical agglomerates and briquettes are not covered

E389 TestMethodforParticleSizeorScreenAnalysisatNo.

by this test method.

4 (4.75-mm) Sieve and Coarser for Metal-Bearing Ores

1.2 The values as stated in SI units are to be regarded as the

and Related Materials

standards. The values in parentheses are given for information

E877 Practice for Sampling and Sample Preparation of Iron

only.

Ores and Related Materials for Determination of Chemi-

cal Composition and Physical Properties

1.3 Resultsgivenbythistestshouldbesimilartothosefrom

3

ISO 4700 (see Appendix X1 for details). 2.2 ISO Standards:

ISO 4700 Iron ore pellets for blast furnace and direct

1.4 This standard does not purport to address all of the

reduction feedstocks—Determination of the crushing

safety concerns, if any, associated with its use. It is the

strength

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

3. Terminology

mine the applicability of regulatory limitations prior to use.

3.1 Definitions—For definitions of terms used in this test

1.5 This international standard was developed in accor-

method, refer to Terminology E135.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

3.2 Definitions of Terms Specific to This Standard:

Development of International Standards, Guides and Recom-

3.2.1 crushing strength, n—average compressive load

mendations issued by the World Trade Organization Technical

needed to break the pellets in the test sample completely.

Barriers to Trade (TBT) Committee.

4. Summary of Test Method

2. Referenced Documents

4.1 A load is applied on a single pellet at a specified speed

2

of the compressive platen until the pellet is broken. This

2.1 ASTM Standards:

procedure is repeated on all pellets of the test sample.

E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications 4.2 This test method assumes that individual samples are

E50 Practices for Apparatus, Reagents, and Safety Consid-

essentially brittle; that is, at some level of applied force, the

erations for Chemical Analysis of Metals, Ores, and sample will break into two or more pieces. There are

Related Materials

circumstances, however, when pellets are more ductile (for

E122 Practice for Calculating Sample Size to Estimate,With example, green pellets that have not yet been fired), and the

sample may deform and not break. This test method does not

apply to such pellets; refer to ISO 4700 for analytical methods

to deal with ductile samples.

1

This test method is under the jurisdiction of ASTM Committee E01 on

Analytical Chemistry for Metals, Ores, and Related Materials and is the direct

5. Significance and Use

responsibility of Subcommittee E01.02 on Ores, Concentrates, and Related Metal-

lurgical Materials.

5.1 The crushing strength aids the pellet producer in the

Current edition approved April 15, 2020. Published August 2020. Originally

determination of quality problems associated with the produc-

approved in 1968. Last previous edition approved in 2012 as E382 – 12. DOI:

10.1520/E0382-20.

tion of pellets.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E382 − 20

5.2 The crushing strength is often used by the pellet 8. Sampling and Sample Preparation

consumer as a quality indicator for performance in the bl

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E382 − 12 E382 − 20

Standard Test Method for

Determination of Crushing Strength of Iron Ore Pellets and

1

Direct-Reduced Iron

This standard is issued under the fixed designation E382; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method describes a method for determining the crushing strength of fired iron ore pellets. Cylindrical agglomerates,

briquettes, and reduced pellets pellets and direct-reduced iron. Cylindrical agglomerates and briquettes are not covered by this test

method.

1.2 The values as stated in SI units are to be regarded as the standards. The values in parentheses are given for information only.

1.3 Results given by this test should be similar to those from ISO 4700 (see Appendix X1 for details).

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E50 Practices for Apparatus, Reagents, and Safety Considerations for Chemical Analysis of Metals, Ores, and Related Materials

E122 Practice for Calculating Sample Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or

Process

E135 Terminology Relating to Analytical Chemistry for Metals, Ores, and Related Materials

E389 Test Method for Particle Size or Screen Analysis at No. 4 (4.75-mm) Sieve and Coarser for Metal-Bearing Ores and

Related Materials

E877 Practice for Sampling and Sample Preparation of Iron Ores and Related Materials for Determination of Chemical

Composition and Physical Properties

3

2.2 ISO Standards:

ISO 4700 Iron ore pellets for blast furnace and direct reduction feedstocks—Determination of the crushing strength

3. Terminology

3.1 Definitions—For definitions of terms used in this test method, refer to Terminology E135.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 crushing strength, n—average compressive load needed to break the pellets in the test sample completely.

4. Summary of Test Method

4.1 A load is applied on a single pellet at a specified speed of the compressive platen until the pellet is broken. This procedure

is repeated on all pellets of the test sample.

1

This test method is under the jurisdiction of ASTM Committee E01 on Analytical Chemistry for Metals, Ores, and Related Materials and is the direct responsibility of

Subcommittee E01.02 on Ores, Concentrates, and Related Metallurgical Materials.

Current edition approved June 1, 2012April 15, 2020. Published July 2012August 2020. Originally approved in 1968. Last previous edition approved in 20072012 as

E382 – 07.E382 – 12. DOI: 10.1520/E0382-12.10.1520/E0382-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E382 − 20

4.2 This test method assumes that individual samples are essentially brittle; that is, at some level of applied force, the sample

will break into two or more pieces. There are circumstances, however, when pellets are more ductile (for example, green pellets

that have not yet been fired), and the sample may deform and not break. This test method does not apply to such pellets; refer to

ISO 4700 for analytical methods to deal with ductile samples.

5. Significance and Use

5.1 The crushin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.