ASTM D3633/D3633M-12

(Test Method)Standard Test Method for Electrical Resistivity of Membrane-Pavement Systems

Standard Test Method for Electrical Resistivity of Membrane-Pavement Systems

SIGNIFICANCE AND USE

This test method for measuring the electrical resistivity of water-barrier membrane-pavement systems may be interpreted to indicate the effectiveness of such systems.

This test method is predicated on the fact that an electrical connection between the surface of the pavement and the reinforcing steel in the concrete pavement cannot be made through an impermeable water-barrier membrane.

This test method may be used for acceptance when the accepting agency specifies the minimum resistance value desired.

SCOPE

1.1 This test method covers the measurement of the electrical resistivity of water-barrier membrane-pavement systems when applied to concrete bridge decks.

1.2 Measurements shall be performed on the bituminous pavement surface covering the water-barrier membrane.

1.3 This test method utilizes a measure of electrical resistance between the saturated top surface of the water-barrier membrane and the reinforcing steel embedded in the concrete bridge deck.

1.4 The values measured represent the electrical resistance obtained with the equipment and procedures stated herein and do not necessarily agree or correlate with those using other equipment or procedures.

1.5 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3633/D3633M − 12

Standard Test Method for

1

Electrical Resistivity of Membrane-Pavement Systems

This standard is issued under the fixed designation D3633/D3633M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope ture Protection (Withdrawn 2004)

D4071PracticeforUseofPortlandCementConcreteBridge

1.1 This test method covers the measurement of the electri-

Deck Water Barrier Membrane Systems

cal resistivity of water-barrier membrane-pavement systems

E105Practice for Probability Sampling of Materials

when applied to concrete bridge decks.

3. Terminology

1.2 Measurements shall be performed on the bituminous

pavement surface covering the water-barrier membrane.

3.1 For definitions of terms used in this specification, refer

to Terminology D3743.

1.3 This test method utilizes a measure of electrical resis-

tance between the saturated top surface of the water-barrier

4. Significance and Use

membrane and the reinforcing steel embedded in the concrete

bridge deck.

4.1 This test method for measuring the electrical resistivity

of water-barrier membrane-pavement systems may be inter-

1.4 The values measured represent the electrical resistance

preted to indicate the effectiveness of such systems.

obtained with the equipment and procedures stated herein and

do not necessarily agree or correlate with those using other 4.2 This test method is predicated on the fact that an

equipment or procedures.

electrical connection between the surface of the pavement and

the reinforcing steel in the concrete pavement cannot be made

1.5 Units—The values stated in either SI units or inch-

through an impermeable water-barrier membrane.

pound units are to be regarded separately as standard. The

4.3 This test method may be used for acceptance when the

values stated in each system may not be exact equivalents;

therefore,eachsystemshallbeusedindependentlyoftheother. accepting agency specifies the minimum resistance value

desired.

Combining values from the two systems may result in noncon-

formance with the standard.

5. Apparatus

1.6 This standard does not purport to address all of the

5.1 Ohmmeter, dc, 20 000 Ω/V rating connected to a

safety concerns, if any, associated with its use. It is the

double-pole, double-throw switch box or ac ohmmeter (switch

responsibility of the user of this standard to establish appro-

box not required).

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

NOTE 1—When this test method is used for acceptance, the accepting

agency should specify the type of ohmmeter to be used.

2. Referenced Documents

5.2 InsulatedWire,No.18,Beldentestprobewireorequiva-

2

lent. Two spools, minimum 38 m [125 ft].

2.1 ASTM Standards:

1

C670Practice for Preparing Precision and Bias Statements

5.3 Copper Plate, 305 by 305 by 3.0 mm [12 by 12 by ⁄8

for Test Methods for Construction Materials

in.], with the means for connecting the ohmmeter lead and a

D3743Terminology Relating to Bridge Deck and Substruc-

wooden handle approximately 1 m [39 in.] in length.

5.4 Polyurethane Sponge, 305 by 305 by 13 mm [12 by 12

1

by ⁄2 in.], to be attached to the copper plate with rubber bands

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

or other suitable means. When assembled this apparatus is

and Paving Materials and is the direct responsibility of Subcommittee D04.32 on

called the probe.

Bridges and Structures.

Current edition approved June 1, 2012. Published July 2012 . Originally

5.5 Pressure Spray Can, 12-L [3-gal] capacity, with a hose

approved in 1977. Last previous edition approved in 2006 as D3633–98 (2006).

and spray nozzle.

DOI: 10.1520/D3633-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3633/D3633M − 12

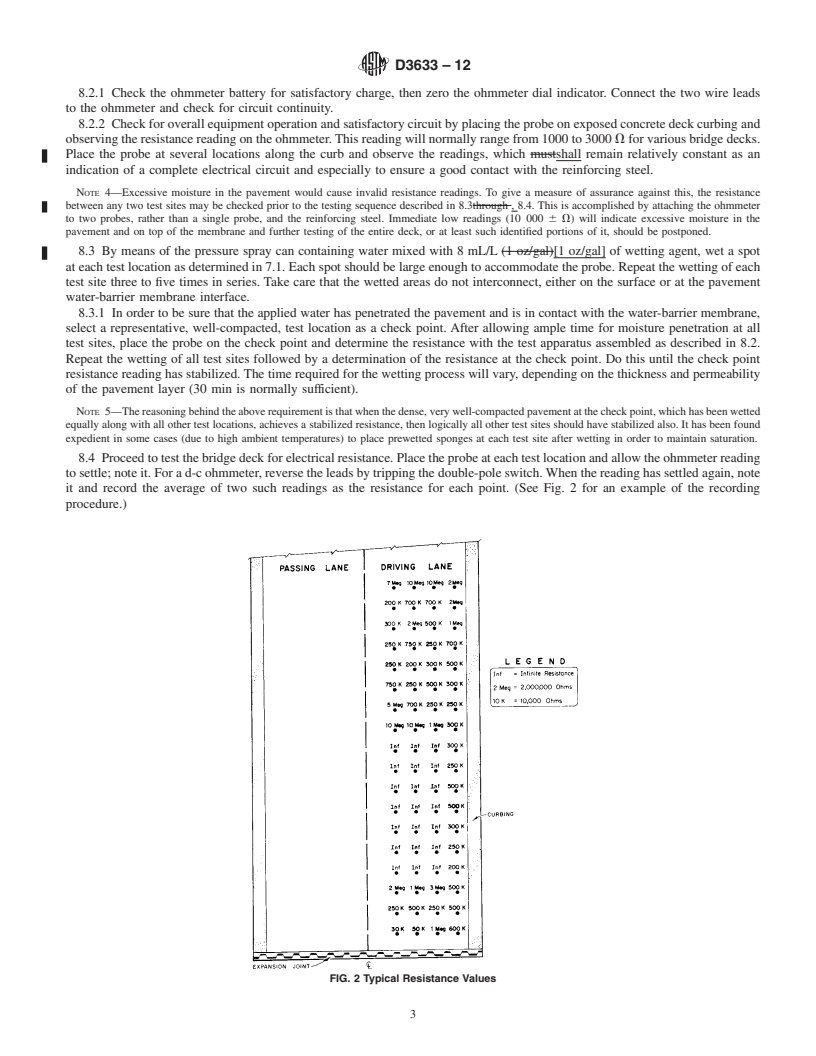

6. Reagent 8.2 Uncoil an ample length of wire to reach all areas to be

tested, attach the minus (−) jack of the ohmmeter to the

6.1 A wetting agent which, when added to the water, will

reinforcing steel and the plus (+) jack to the 305 by 305 by

break the surface tension and promote the penetration of the

1

3.0-mm [12 by 12 by ⁄8-in.] copper plate of the probe. Then

water thr

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D3633–98(Reapproved 2006) Designation: D3633 – 12

Standard Test Method for

1

Electrical Resistivity of Membrane-Pavement Systems

This standard is issued under the fixed designation D3633; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the measurement of the electrical resistivity of water-barrier membrane-pavement systems when

applied to concrete bridge decks.

1.2 Measurements shall be performed on the bituminous pavement surface covering the water-barrier membrane.

1.3 This test method utilizes a measure of electrical resistance between the saturated top surface of the water-barrier membrane

and the reinforcing steel embedded in the concrete bridge deck.

1.4 The values measured represent the electrical resistance obtained with the equipment and procedures stated herein and do

not necessarily agree or correlate with those using other equipment or procedures.

1.5The values stated in SI units are to be regarded as the standard.

1.5 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated

in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values

from the two systems may result in nonconformance with the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

D3743 Terminology Relating to Bridge Deck and Substructure Protection

D4071 Practice for Use of Portland Cement Concrete Bridge Deck Water Barrier Membrane Systems

E105 Practice for Probability Sampling of Materials

3. Terminology

3.1 For definitions of terms used in this specification, refer to Terminology D3743.

4. Significance and Use

4.1 This test method for measuring the electrical resistivity of water-barrier membrane-pavement systems may be interpreted

to indicate the effectiveness of such systems.

4.2 This test method is predicated on the fact that an electrical connection between the surface of the pavement and the

reinforcing steel in the concrete pavement cannot be made through an impermeable water-barrier membrane.

4.3 This test method may be used for acceptance when the accepting agency specifies the minimum resistance value desired.

5. Apparatus

5.1 Ohmmeter, dc, 20 000 V/V rating connected to a double-pole, double-throw switch box or ac ohmmeter (switch box not

required).

NOTE 1—When this test method is used for acceptance, the accepting agency should specify the type of ohmmeter to be used.

5.2 Insulated Wire, No. 18, Belden test probewire or equivalent. Two spools, minimum 38 m (125 ft). [125 ft].

1

This test method is under the jurisdiction ofASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.32 on Bridges

and Structures.

Current edition approved Dec. 1, 2006. Published December 2006. Originally approved in 1977. Last previous edition approved in 1998 as D3633–98. DOI:

10.1520/D3633-98R06.

Current edition approved June 1, 2012. Published July 2012 . Originally approved in 1977. Last previous edition approved in 2006 as D3633–98(2006). DOI:

10.1520/D3633-12.

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3633 – 12

1

5.3 Copper Plate, 305 by 305 by 3.0 mm (12[12 by 12 by ⁄8 in.),in.], with the means for connecting the ohmmeter lead and

a wooden handle approximately 1 m (39 in.)[39 in.] in length.

1

5.4 PolyurethaneSponge,305by305by13mm(12[12by12by ⁄2in.),in.],tobeattachedtothecopperplatewithrubberbands

or other suitable means. When assembled this apparatus is called the probe.

5.5 Pressure Spray Can, 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.