ASTM B888-98

(Specification)Standard Specification for Copper Alloy Strip for Use in the Manufacture of Electrical Connectors or Spring Contacts

Standard Specification for Copper Alloy Strip for Use in the Manufacture of Electrical Connectors or Spring Contacts

SCOPE

1.1 This specification covers the requirements for copper alloy strip for use in the manufacture of electrical connectors or spring contacts produced from one of the following Copper Alloy UNS Nos. C14530, C15100, C15500, C19400, C19500, C19700, C23000, C26000, C42200, C42500, C51000, C51100, C52100, C63800, C65400, C68800, C70250, C70260, C75200, and C76200.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 888 – 98

Standard Specification for

Copper Alloy Strip for Use in the Manufacture of Electrical

Connectors or Spring Contacts

This standard is issued under the fixed designation B 888; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope B 601 Practice for Temper Designations for Copper and

Copper Alloys—Wrought and Cast

1.1 This specification covers the requirements for copper

B 768 Specification for Copper-Cobalt-Beryllium Alloy

alloy strip for use in the manufacture of electrical connectors or

Strip and Sheet

spring contacts produced from one of the following Copper

B 820 Test Method for Bend Test for Formability of Copper

Alloy UNS Nos. : C14530, C15100, C15500, C19400,

Alloy Spring Material

C19500, C19700, C23000, C26000, C42200, C42500,

B 846 Terminology for Copper and Copper Alloys

C51000, C51100, C52100, C63800, C65400, C68800, C70250,

E 8 Test Methods for Tension Testing of Metallic Materials

C70260, C75200, and C76200.

E 8M Test Methods for Tension Testing of Metallic Mate-

1.2 The requirements for the other copper alloys such as

rials [Metric]

beryllium copper UNS C17000, C17200, C17400, C17410,

E 54 Test Methods for Chemical Analysis of Special

C17500, and C17510 shall be as prescribed in the current

Brasses and Bronzes

edition of Standards B 194, B 768 and B 534.

E 62 Test Methods for Chemical Analysis of Copper and

1.3 The values stated in either inch-pound units or SI units

Copper Alloys (Photometric Method)

are to be regarded separately as standard. The values stated in

E 75 Test Methods for Chemical Analysis of Copper-Nickel

each system may not be exact equivalents; therefore, each

and Copper-Nickel-Zinc Alloys

system shall be used independently of the other. Combining

E 478 Test Methods for Chemical Analysis of Copper

values from the two systems may result in noncompliance with

Alloys

this specification.

E 527 Test Practice for Numbering Metals and Alloys

2. Referenced Documents (UNS)

2.2 ISO Standards:

2.1 ASTM Standards:

ISO 4744 Copper and Copper Alloys—Determination of

B 193 Test Method for Resistivity of Electrical Conductor

Chromium Content - Flame Atomic Absorption Spectro-

Material

metric Method

B 194 Specification for Copper-Beryllium Alloy Plate,

ISO 7602 Copper and Copper Alloys—Determination of

Sheet, Strip, and Rolled Bar

Tellurium Content

B 248 Specification for General Requirements for Wrought

Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled

3. Terminology

Bar

3.1 Definitions—For definition of terms used in this speci-

B 248M Specification for General Requirements for

fication, refer to Terminology B 846.

Wrought Copper and Copper-Alloy Plate, Sheet, Strip, and

Rolled Bar [Metric]

4. General Requirements

B 534 Specification for Copper-Cobalt-Beryllium Alloy and

4.1 For product furnished under this specification in English

Copper-Nickel-Beryllium Alloy Plate, Sheet, Strip, and

4 units, the following sections of Specification B 248 must

Rolled Bar

constitute a part of this specification. For product furnished

under this specification in the SI units, the following sections

of Specification B 248M must constitute a part of this specifi-

This standard is under the jurisdiction of Committee B-5 on Copper and is the

cation.

direct responsibility of Subcommittee B05.01 on Plate, Sheet, and Strip.

Current edition approved May 10, 1998. Published September 1998.

The UNS system for copper and copper alloys (see Practice E 527) is a simple

expansion of the former standard designation system accomplished by the addition Annual Book of ASTM Standards, Vol 03.01.

of a prefix “c” and a suffix “00.” The suffix can be used to accommodate Annual Book of ASTM Standards, Vol 03.05.

composition variations of the base alloy. Annual Book of ASTM Standards, Vol 01.01.

3 8

Annual Book of ASTM Standards, Vol 02.03. Available from American National Standards Institute, 11 W. 42nd St., New

Annual Book of ASTM Standards, Vol 02.01. York, NY 10036-8002.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B888–98

4.1.1 Terminology, 6.2.1 Type of edge: slit, sheared, sawed, square corners,

4.1.2 Materials and Manufacture, rounded corners, rounded edges, or full-rounded edges (Sec-

4.1.3 Dimensions, Weights, and Permissible Variations, tion 11),

4.1.4 Workmanship, Finish, and Appearance, 6.2.2 Width and straightness tolerances, slit-metal toler-

4.1.5 Sampling,

ances, square-sheared metal tolerances, sawed metal toler-

4.1.6 Number of Tests and Retests, ances, straightened or edge-rolled metal tolerances (Section

4.1.7 Specimen Preparation,

11),

4.1.8 Test Methods,

6.2.3 Identification marking (Section 22),

4.1.9 Significance of Numerical Limits,

6.2.4 Certification (Section 20),

4.1.10 Certification,

6.2.5 Mill test report (Section 21), and

4.1.11 Test Reports, and

6.2.6 How packaged: coil wound in traverse or pancake

4.1.12 Packaging and Package Marking.

style (Section 22).

4.2 In the event of a conflict between this specification and

6.2.6.1 Number of strip lengths per coil,

Specification B 248 or B 248M, the requirements of this

6.2.6.2 Size and weight of each coil, and

specification shall take precedence.

6.2.7 The electrical resistivity or any other physical and

electrical properties (See Table X1.1).

5. Classification

5.1 Product produced to this specification is classified as

7. Materials and Manufacture

strip material to be used for spring contact or electrical and

7.1 Material—The material of manufacture shall be a cast

electronic connector applications only.

bar, slab, cake, billet, or other form of the composition given in

6. Ordering Information

Table 1 for the specified alloy, suitable for processing into the

product prescribed in this specification.

6.1 Contract or purchase orders for product under this

specification should include the following information: 7.2 Manufacture—The product shall be produced by either

hot- or cold-working operation. It shall be finished, unless

6.1.1 ASTM designation and year of issue,

6.1.2 UNS alloy designation, otherwise specified, by such hot working, cold working,

annealing, or heat treatment as may be necessary to meet the

6.1.3 Dimensions, for example, thickness, width,

6.1.4 Quantity, and properties specified in Table 2.

6.1.5 Temper (Section 8). 7.3 Edges—The edges shall be slit or rolled edges as

6.2 The following options are available under this specifi- specified by the buyer. Slit edges shall be furnished unless

cation and shall be specified in the contract or purchase order otherwise specified or agreed upon between the purchaser and

when required: supplier or manufacturer.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B888–98

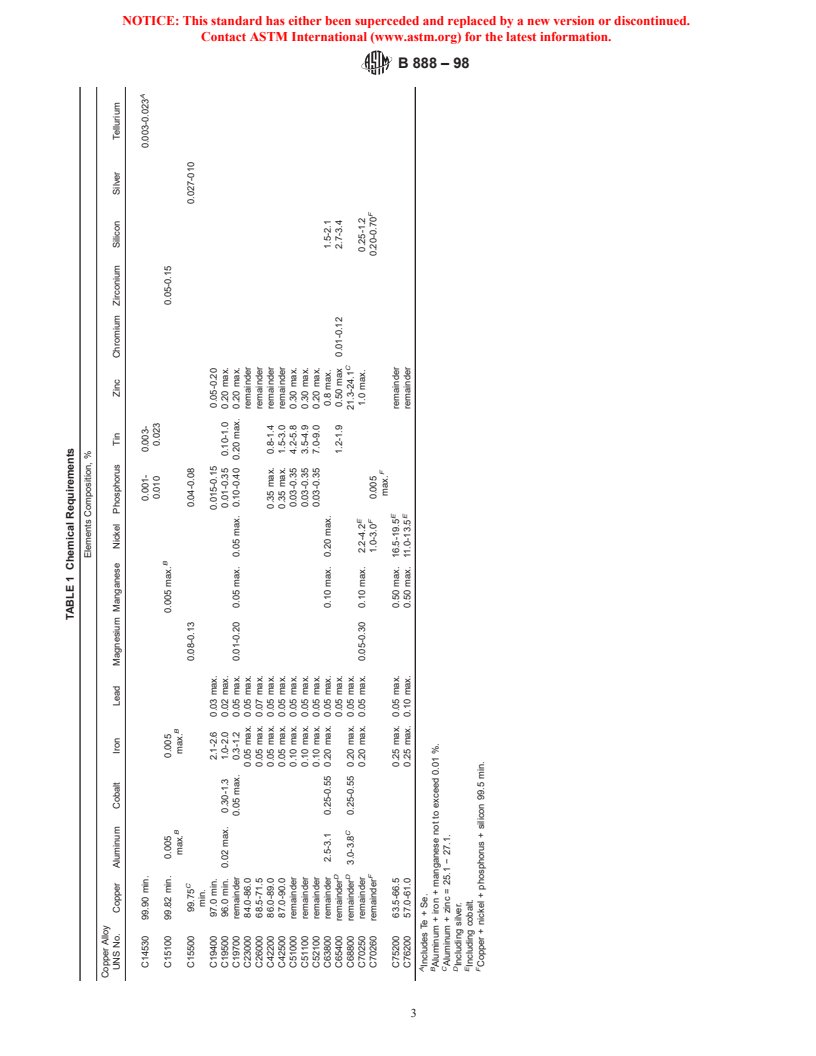

TABLE 1 Chemical Requirements

Elements Composition, %

Copper Alloy

UNS No. Copper Aluminum Cobalt Iron Lead Magnesium Manganese Nickel Phosphorus Tin Zinc Chromium Zirconium Silicon Silver Tellurium

A

C14530 99.90 min. 0.001- 0.003- 0.003-0.023

0.010 0.023

B

C15100 99.82 min. 0.005 0.005 0.005 max. 0.05-0.15

B B

max. max.

C

C15500 99.75 0.08-0.13 0.04-0.08 0.027-010

min.

C19400 97.0 min. 2.1-2.6 0.03 max. 0.015-0.15 0.05-0.20

C19500 96.0 min. 0.02 max. 0.30-1.3 1.0-2.0 0.02 max. 0.01-0.35 0.10-1.0 0.20 max.

C19700 remainder 0.05 max. 0.3-1.2 0.05 max. 0.01-0.20 0.05 max. 0.05 max. 0.10-0.40 0.20 max. 0.20 max.

C23000 84.0-86.0 0.05 max. 0.05 max. remainder

C26000 68.5-71.5 0.05 max. 0.07 max. remainder

C42200 86.0-89.0 0.05 max. 0.05 max. 0.35 max. 0.8-1.4 remainder

C42500 87.0-90.0 0.05 max. 0.05 max. 0.35 max. 1.5-3.0 remainder

C51000 remainder 0.10 max. 0.05 max. 0.03-0.35 4.2-5.8 0.30 max.

C51100 remainder 0.10 max. 0.05 max. 0.03-0.35 3.5-4.9 0.30 max.

C52100 remainder 0.10 max. 0.05 max. 0.03-0.35 7.0-9.0 0.20 max.

C63800 remainder 2.5-3.1 0.25-0.55 0.20 max. 0.05 max. 0.10 max. 0.20 max. 0.8 max. 1.5-2.1

D

C65400 remainder 0.05 max. 1.2-1.9 0.50 max 0.01-0.12 2.7-3.4

D C C

C68800 remainder 3.0-3.8 0.25-0.55 0.20 max. 0.05 max. 21.3-24.1

E

C70250 remainder 0.20 max. 0.05 max. 0.05-0.30 0.10 max. 2.2-4.2 1.0 max. 0.25-1.2

F F F

C70260 remainder 1.0-3.0 0.005 0.20-0.70

F

max.

E

C75200 63.5-66.5 0.25 max. 0.05 max. 0.50 max. 16.5-19.5 remainder

E

C76200 57.0-61.0 0.25 max. 0.10 max. 0.50 max. 11.0-13.5 remainder

A

Includes Te + Se.

B

Aluminum + iron + manganese not to exceed 0.01 %.

C

Aluminum + zinc = 25.1 − 27.1.

D

Including silver.

E

Including cobalt.

F

Copper + nickel + phosphorus + silicon 99.5 min.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B888–98

TABLE 2 Mechanical Requirements

Yield Strength

Yield Strength

Temper Designation Tensile Strength, ksi Tensile Strength, MPa (0.2 % Offset), Elongation, %

(0.2 % Offset), ksi

MPa

Standard Former Min. Max. Min. Max. Min. Min. Min.

Copper Alloy UNS NO. C14530

H01 ⁄4 hard 35 45 240 310 26 180 7

H02 ⁄2 hard 40 50 275 345 33 230 5

H03 ⁄4 hard 44 54 305 370 39 270 3

H04 hard 47 57 325 395 43 295 2

H06 extra hard 50 60 345 415 47 325 1

H08 spring 54 64 370 440 51 350 1

H10 extra spring 58 . . . 400 . . . 56 385 . . .

Copper Alloy UNS NO. C15100

O61 annealed 37 42 255 290 9 60 35

H01 ⁄4 hard 40 45 275 310 26 180 11

H02 ⁄2 hard 43 51 295 350 35 240 3

H03 ⁄4 hard 47 56 325 385 45 310 1

H04 hard 53 62 365 425 51 350 1

H06 extra hard 59 65 405 450 57 395 1

H08 spring 64 71 440 490 62 425 1

Copper Alloy UNS NO. C15500

O61 annealed 34 43 235 295 15 105 30

H02 ⁄2 hard 45 55 310 380 38 260 13

H04 hard 56 64 385 440 50 345 6

H06 extra hard 63 72 435 495 56 385 5

H08 spring 65 73 450 505 60 415 4

H10 extra spring 68 75 470 515 63 435 3

Copper Alloy UNS NO. C19400

O61 annealed 40 63 275 435 16 110 10

H02 ⁄2 hard 53 63 365 435 36 250 6

H04 full hard 60 70 415 485 53 365 3

H06 extra hard 67 73 460 505 64 440 2

H08 spring hard 70 76 485 525 67 460 2

H10 extra spring 73 80 505 550 70 485 1

Copper Alloy UNS NO. C19500

O61 annealed 50 60 345 415 21 145 22

H01 ⁄4 hard 60 72 415 495 45 310 5

H02 ⁄2 hard 68 78 470 540 66 455 3

H03 ⁄4 hard 75 85 515 585 72 495 2

H04 full hard 82 90 565 620 79 545 2

H08 spring 88 97 605 670 85 585 1

Copper Alloy UNS NO. C19700

O61 annealed 43 53 295 365 16 110 20

H02 ⁄2 hard 53 63 365 435 36 250 6

H04 full hard 60 70 415 485 53 365 2

H06 extra hard 67 73 460 505 64 440 2

H08 spring hard 70 76 485 525 67 460 2

H10 extra spring 73 80 505 550 70 485 1

Copper Alloy UNS NO. C23000

O61 annealed 39 47 270 325 8 55 43

H01 ⁄4 hard 44 54 305 370 23 160 15

H02 ⁄2 hard 51 61 350 420 43 295 8

H03 ⁄4 hard 57 67 395 460 51 350 4

H04 hard 63 72 435 495 57 395 4

H06 extra hard 72 80 495 550 65 450 3

H08 spring 78 86 540 595 69 475 3

H10 extra spring 82 90 565 620 73 505 2

Copper Alloy UNS NO. C26000

O61 annealed 45 61 310 420 10 70 40

H01 ⁄4 hard 49 59 340 405 21 145 34

H02 ⁄2 hard 57 67 395 460 42 290 19

H03 ⁄4 hard 64 74 440 510 55 380 8

H04 hard 71 81 490 560 67 460 6

H06 extra hard 83 92 570 635 79 545 2

H08 spring 91 100 625 690 82 565 1

H10 extra spring 95 104 655 715 86 595 1

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B888–98

TABLE 2 Continued

Yield Strength

Yield Strength

Temper Designation Tensile Strength, ksi Tensile Strength, MPa (0.2 % Offset), Elongation, %

(0.2 % Offset), ksi

MPa

Standard Former Min. Max. Min. Max. Min. Min. Min.

Copper Alloy UNS NO. C42200

O61 annealed 41 49 285 340 12 85 43

H01 ⁄4 hard 47 57 325 395 21 145 17

H02 ⁄2 hard 54 65 370 450 48 330 6

H03 ⁄4 hard 60 72 415 495 58 400 4

H04 hard 67 79 460 545 67 460 3

H06 extra hard 75 85 515 585 72 495 2

H08 spring 82 92 565 635 77 530 2

H10 extra spring 88 . . . 605 . . . 82 565 1

Copper Alloy UNS NO. C42500

O61 annealed 41 47 285 325 13 90 47

H01 ⁄4 hard 49 59 340 405 20 140 24

H02 ⁄2 hard 57 69 395 475 51 350 13

H03 ⁄4 hard 62 74 425 510 58 400 10

H04 hard 70 82 485 565 66 455 6

H06 extra hard 76 88 525 605 73 505 5

H08 spring 84 94 580 650 81 560 3

H10 extra spring 92 . . . 635 . . . 87 600 . . .

Copper Alloy UNS NO. C51000

O61 annealed 46 56 315 385 19 130 48

H01 ⁄4 hard 49 61 340 420 22 150 32

H02 ⁄2 hard 58 73 400 505 47 325 10

H03 ⁄4 hard 68 79 470 545 61 420 10

H04 hard 76 91 525 625 74 510 9

H06 extra hard 88 103 605 710 85 585 2

H08 spring 95 110 655 760 92 635 1

H10 extra spring 100 114 690 785 98 675 1

Copper Alloy UNS NO. C51100

O61 annealed 46 54 315 370 16 110 45

H01 ⁄4 hard 46 58 315 400 20 140 25

H02 ⁄2 hard 55 70 380 485 42 290 12

H03 ⁄4 hard 67 82 460 565 64 440 6

H04 hard 72 87 495 600 70 485 2

H06 extra hard 84 99 580 685 81 560 1

H08 spring 91 105 625 725 88 605 1

H10 extra spring 96 109 660 750 92 635 1

Copper Alloy UNS NO. C52100

O61 annealed 56 65 385 450 23 160 60

H01 ⁄4 hard 63 75 435 515 35 240 40

H02 ⁄2 hard 69 84 475 580 51 350 25

H03 ⁄4 hard 80 92 550 635 70 485 18

H04 hard 85 100 585 690 78 540 12

H06 extra hard 97 112 670 770 92 635 10

H08 spring 105 119 725 820 100 690 3

H10 extra spring 110 122 760 840 105 725 2

Copper Alloy UNS NO. C63800

O61 annealed 77 87 530 600 45 310 27

H01 ⁄4 hard 90 102 620 705 75 515 12

H02 ⁄2 hard 100 112 690 770 87 600 7

H03 ⁄4 hard 105 117 725 805 93 640 5

H04 hard 114 126 785 870 102 705 3

H06 extra hard 118 130 815 895 106 730 2

H08 spring 123 134 850 925 111 765 2

H10 extra spring 130 . . . . . . . . . 119 820 . . .

Copper Alloy UNS NO. C65400

H01 ⁄4 hard 75 90 515 620 45 310 21

H02 ⁄2 hard 86 101 595 695 66 455 11

H03 ⁄4 hard 97 112 670 770 82 565 6

H04 hard 108 120 745 825 94 650 3

H06 extra hard 116 126 800 870 102 705 2

H08 spring 124 133 855 915 112 770 2

H10 extra spring 131 140 905 965 118 815 1

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B888–98

TABLE 2 Continued

Yield Strength

Yield Strength

Temper Desig

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.