ASTM E2898-13

(Guide)Standard Guide for Risk-Based Validation of Analytical Methods for PAT Applications

Standard Guide for Risk-Based Validation of Analytical Methods for PAT Applications

SIGNIFICANCE AND USE

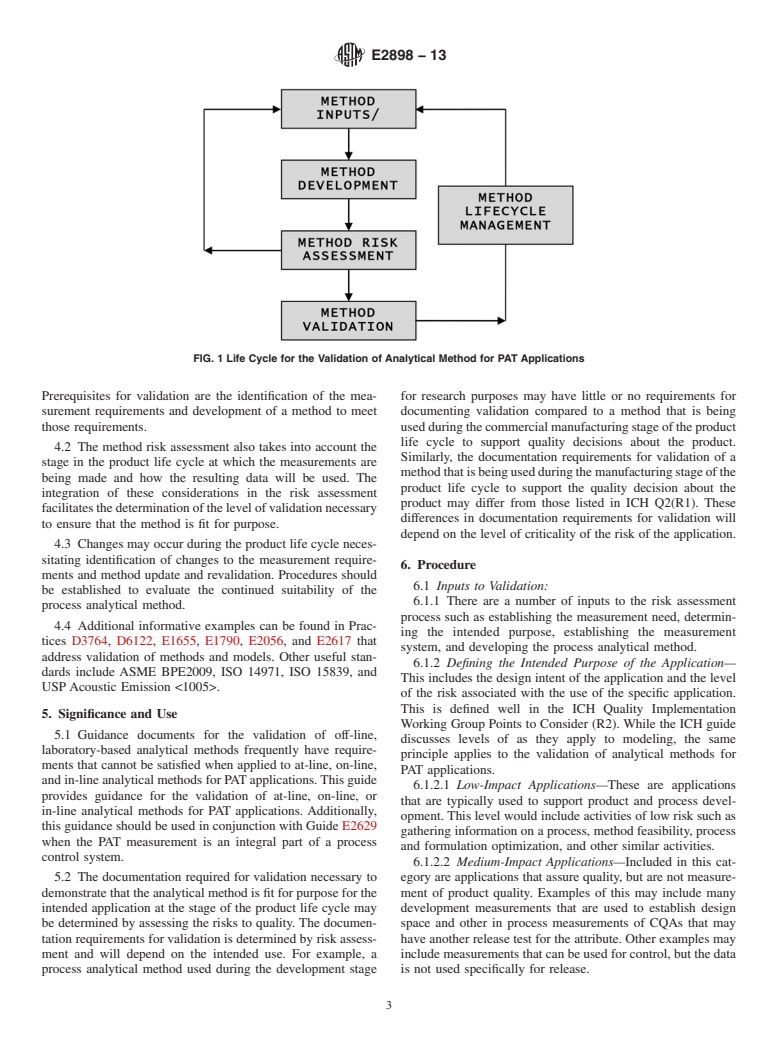

4.1 This guide supports the principles of Guide E2500 and extends these principles to validation of analytical methods for PAT applications. The ongoing process of method validation is graphically represented in Fig. 1, which shows the life cycle of the validation of analytical methods for PAT applications. Prerequisites for validation are the identification of the measurement requirements and development of a method to meet those requirements.

4.2 The method risk assessment also takes into account the stage in the product life cycle at which the measurements are being made and how the resulting data will be used. The integration of these considerations in the risk assessment facilitates the determination of the level of validation necessary to ensure that the method is fit for purpose.

4.3 Changes may occur during the product life cycle necessitating identification of changes to the measurement requirements and method update and revalidation. Procedures should be established to evaluate the continued suitability of the process analytical method.

4.4 Additional informative examples can be found in Practices D3764, D6122, E1655, E1790, E2056, and E2617 that address validation of methods and models. Other useful standards include ASME BPE2009, ISO 14971, ISO 15839, and USP Acoustic Emission .

SCOPE

1.1 This guide provides an overview to the risk-based validation of process analytical methods under a process analytical technology (PAT) paradigm for pharmaceuticals and biopharmaceuticals and as such includes guidance on assessing risk to product quality from inappropriate method validation.

1.2 This guide builds on existing standards on the topic of validation concentrating on applying such standards to analytical methods for on-line analysis. In particular, it addresses the validation of at-line, on-line, or in-line PAT measurements and covers both API and Drug Product (DP) measurements.

1.3 The definitions of International Conference on Harmonization (ICH) validation parameters (such as specificity, precision, repeatability, etc.) apply; however, the method of demonstrating the validation parameters may vary from that described in ICH and is discussed.

1.4 As consistent with the U.S. Food and Drug Administration (FDA) process validation guidance, this document also briefly covers ongoing assurance that the method remains in a validated state during routine use.

1.5 Equipment and instrument qualification are out of the scope of this guide but will be referenced as inputs to validation of analytical methods for PAT applications.

1.6 The validation of multivariate prediction models is out of scope but will be referenced as inputs to validation of analytical methods for PAT applications.

1.7 Microbiological methods are out of scope.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2898 − 13

StandardGuide for

Risk-Based Validation of Analytical Methods for PAT

Applications

This standard is issued under the fixed designation E2898; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This guide provides an overview to the risk-based 2.1 ASTM Standards:

validation of process analytical methods under a process

D3764 Practice forValidation of the Performance of Process

analytical technology (PAT) paradigm for pharmaceuticals and

Stream Analyzer Systems

biopharmaceuticalsandassuchincludesguidanceonassessing D6122 Practice for Validation of the Performance of Multi-

risk to product quality from inappropriate method validation.

variate Online,At-Line, and Laboratory Infrared Spectro-

photometer Based Analyzer Systems

1.2 This guide builds on existing standards on the topic of

E1655 Practices for Infrared Multivariate Quantitative

validation concentrating on applying such standards to analyti-

Analysis

cal methods for on-line analysis. In particular, it addresses the

E1790 Practice for Near Infrared Qualitative Analysis

validation of at-line, on-line, or in-line PAT measurements and

E2056 Practice for Qualifying Spectrometers and Spectro-

covers both API and Drug Product (DP) measurements.

photometers for Use in Multivariate Analyses, Calibrated

1.3 The definitions of International Conference on Harmo-

Using Surrogate Mixtures

nization (ICH) validation parameters (such as specificity,

E2476 Guide for Risk Assessment and Risk Control as it

precision, repeatability, etc.) apply; however, the method of

Impacts the Design, Development, and Operation of PAT

demonstrating the validation parameters may vary from that

Processes for Pharmaceutical Manufacture

described in ICH and is discussed.

E2500 Guide for Specification, Design, and Verification of

Pharmaceutical and Biopharmaceutical Manufacturing

1.4 As consistent with the U.S. Food and DrugAdministra-

Systems and Equipment

tion (FDA) process validation guidance, this document also

E2617 Practice for Validation of Empirically Derived Mul-

briefly covers ongoing assurance that the method remains in a

tivariate Calibrations

validated state during routine use.

E2629 Guide for Verification of ProcessAnalytical Technol-

1.5 Equipment and instrument qualification are out of the

ogy (PAT) Enabled Control Systems

scope of this guide but will be referenced as inputs to

2.2 ICH Standards:

validation of analytical methods for PAT applications.

Q2(R1) Guidance on Validation of Analytical Procedures:

1.6 The validation of multivariate prediction models is out

Text and Methodology

of scope but will be referenced as inputs to validation of

Q7 Good Manufacturing Practice Guide for Active Pharma-

analytical methods for PAT applications.

ceutical Ingredients

Q9 Quality Risk

1.7 Microbiological methods are out of scope.

ICH Quality Implementation Working Group Points to

1.8 This standard does not purport to address all of the

Consider (R2) ICH-Endorsed Guide for ICH Q8/Q9/Q10

safety concerns, if any, associated with its use. It is the

Implementation dated 6 December 2011

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

This guide is under the jurisdiction of ASTM Committee E55 on Manufacture the ASTM website.

of Pharmaceutical Products and is the direct responsibility of Subcommittee E55.01 Available from International Conference on Harmonisation of Technical

on PAT System Management, Implementation and Practice. Requirements for Registration of Pharmaceuticals for Human Use (ICH), ICH

Current edition approved Nov. 1, 2013. Published December 2013. DOI: Secretariat, c/o IFPMA, 15 ch. Louis-Dunant, P.O. Box 195, 1211 Geneva 20,

10.1520/E2898-13. Switzerland, http://www.ich.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2898 − 13

2.3 Other Standards: 3.1.10.1 Discussion—Qualification is part of validation, but

ASME BPE2009 BioProcessing Equipment Standard the individual qualification steps alone do not constitute

FDA Guidance for Industry Process Validation: General process validation. FDA/ICH Q7A

Principles and Practices

3.1.11 qualitative, adj—type of method whereby a classifi-

ISO 14971 Medical Devices—Application of Risk Manage-

cation (such as pass/fail) is generated for the attribute or

ment to Medical Devices

parameter measured.

ISO 15839 Water Quality—On-line Sensors/Analysing

3.1.11.1 Discussion—The method output may be descrip-

Equipment for Water—Specifications and Performance

tive rather than numerical.

Tests

3.1.12 quantitative, adj—type of method whereby a numeri-

ISO/IEC Guide 51 Safety Aspects—Guidelines for Their

6 cal value or result is generated for the attribute or parameter

Inclusion in Standards

measured.

USP Acoustic Emission <1005>

3.1.13 reference sample, n—substanceofestablishedquality

3. Terminology

used as a reference standard for the method validation.

3.1 Definitions: 3.1.13.1 Discussion—The reference sample may be a refer-

3.1.1 acceptance criteria, n—criteria that a system or com- ence standard (primary or secondary) and may be commercial

ponentshallsatisfytobeacceptedbyauserorotherauthorized or development material for which the value of its relevant

entity. parameter or attribute has been established. E1655

3.1.2 at-line measurements, n—measurement in which the 3.1.14 risk, n—combination of the probability of occurrence

sample is removed, isolated from, and analyzed in close

of harm and the severity of that harm. ISO/IEC Guide 51,

proximity to the process stream. ICH Q9

3.1.3 categorical data, n—measurement output that has

3.1.15 risk analysis, n—the estimation of the risk associated

distinct and predetermined output options (for example, pass/

with the identified hazard. ICH Q9

fail, 1/0, red/yellow/green, and on/off) and is typically nonnu-

3.1.16 risk assessment, n—a systematic process of organiz-

meric in nature.

ing information to support a risk decision to be made within a

3.1.4 continuous data, n—numerical information or output

risk management process. Consisting of identification hazards

having any values within a given range.

and the analysis and evaluation of risks associated with

exposure to those hazards. ICH Q9, ISO 14971

3.1.5 discrete data, n—numerical information for which a

limited set of values are allowed within a given range.

3.1.17 verification, n—systematic approach to demonstrate

that manufacturing systems, acting singly or in combination,

3.1.6 in-line measurements, n—measurement in which the

are fit for intended use, have been properly installed, and are

sample is not removed from the process stream, which may be

operating correctly.

either invasive or noninvasive.

3.1.7 off-line measurements, n—measurement in which the

3.1.17.1 Discussion—This is an umbrella term that encom-

sample is removed, isolated from, and analyzed in an area

passes all types of approaches to assuring systems are fit for

remote from the manufacturing process.

use such as qualification, commissioning and qualification,

verification, system validation, or other validation. There is

3.1.8 on-line measurements, n—measurement in which the

sample is diverted from the manufacturing process and may be recognition that the word verification is used in conjunction

with validating process systems and that the word validation is

returned to the process stream.

used for analytical methods.

3.1.9 process analytical technology (PAT) application,

3.2 Acronyms:

n—the installation/utilization of a measurement system, for

3.2.1 ICH—International Conference on Harmonization of

designing, analyzing, and controlling manufacturing through

Technical Requirements for Registration of Pharmaceuticals

timely measurements (that is, during processing) of critical

for Human Use

quality and performance attributes of raw and in-process

materials and processes, with the goal of ensuring final product 3.2.2 LOD—limit of detection

quality.

3.2.3 LOQ—limit of quantification

3.1.10 qualification, n—action of proving and documenting

3.2.4 PAT—process analytical technology

that equipment or ancillary systems are properly installed,

3.2.5 RTRT —real time release testing

work correctly, and are fit for their intended purpose.

3.2.6 DOE—design of experiments

Available from American Society of Mechanical Engineers (ASME), ASME

International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

4. Significance and Use

www.asme.org.

4.1 This guide supports the principles of Guide E2500 and

Available from Food and Drug Administration (FDA), 10903 New Hampshire

Ave., Silver Spring, MD 20993-0002, http://www.fda.gov.

extends these principles to validation of analytical methods for

Available from International Organization for Standardization (ISO), 1, ch. de

PAT applications. The ongoing process of method validation is

la Voie-Creuse, CP 56, CH-1211 Geneva 20, Switzerland, http://www.iso.org.

graphically represented in Fig. 1, which shows the life cycle of

Available from U.S. Pharmacopeia (USP), 12601 Twinbrook Pkwy., Rockville,

MD 20852-1790, http://www.usp.org. the validation of analytical methods for PAT applications.

E2898 − 13

FIG. 1 Life Cycle for the Validation of Analytical Method for PAT Applications

Prerequisites for validation are the identification of the mea- for research purposes may have little or no requirements for

surement requirements and development of a method to meet documenting validation compared to a method that is being

those requirements. usedduringthecommercialmanufacturingstageoftheproduct

life cycle to support quality decisions about the product.

4.2 The method risk assessment also takes into account the

Similarly, the documentation requirements for validation of a

stage in the product life cycle at which the measurements are

methodthatisbeingusedduringthemanufacturingstageofthe

being made and how the resulting data will be used. The

product life cycle to support the quality decision about the

integration of these considerations in the risk assessment

product may differ from those listed in ICH Q2(R1). These

facilitatesthedeterminationofthelevelofvalidationnecessary

differences in documentation requirements for validation will

to ensure that the method is fit for purpose.

depend on the level of criticality of the risk of the application.

4.3 Changes may occur during the product life cycle neces-

sitating identification of changes to the measurement require-

6. Procedure

ments and method update and revalidation. Procedures should

6.1 Inputs to Validation:

be established to evaluate the continued suitability of the

6.1.1 There are a number of inputs to the risk assessment

process analytical method.

process such as establishing the measurement need, determin-

4.4 Additional informative examples can be found in Prac-

ing the intended purpose, establishing the measurement

tices D3764, D6122, E1655, E1790, E2056, and E2617 that

system, and developing the process analytical method.

address validation of methods and models. Other useful stan-

6.1.2 Defining the Intended Purpose of the Application—

dards include ASME BPE2009, ISO 14971, ISO 15839, and

This includes the design intent of the application and the level

USP Acoustic Emission <1005>.

of the risk associated with the use of the specific application.

This is defined well in the ICH Quality Implementation

5. Significance and Use

Working Group Points to Consider (R2). While the ICH guide

5.1 Guidance documents for the validation of off-line,

discusses levels of as they apply to modeling, the same

laboratory-based analytical methods frequently have require-

principle applies to the validation of analytical methods for

ments that cannot be satisfied when applied to at-line, on-line,

PAT applications.

and in-line analytical methods for PATapplications.This guide

6.1.2.1 Low-Impact Applications—These are applications

provides guidance for the validation of at-line, on-line, or

that are typically used to support product and process devel-

in-line analytical methods for PAT applications. Additionally,

opment. This level would include activities of low risk such as

this guidance should be used in conjunction with Guide E2629

gathering information on a process, method feasibility, process

when the PAT measurement is an integral part of a process

and formulation optimization, and other similar activities.

control system.

6.1.2.2 Medium-Impact Applications—Included in this cat-

5.2 The documentation required for validation necessary to egory are applications that assure quality, but are not measure-

demonstrate that the analytical method is fit for purpose for the ment of product quality. Examples of this may include many

intended application at the stage of the product life cycle may development measurements that are used to establish design

be determined by assessing the risks to quality. The documen- space and other in process measurements of CQAs that may

tation requirements for validation is determined by risk assess- have another release test for the attribute. Other examples may

ment and will depend on the intended use. For example, a include measurements that can be used for control, but the data

process analytical method used during the development stage is not used specifically for release.

E2898 − 13

6.1.2.3 High Impact Applications—These are applications information purposes, where as much more extensive docu-

that fall into the Real Time Release Testing (RTRT) category. mentation may be required to demonstrate validation of high

This is the application that incorporates the measurement to

level applications during the development stage of the life

insure product quality by control of the process or is a cycle. During the development stage of the product life cycle,

substitute for a specification test such as product assay or is

the impact to product quality will typically come from the fact

replacement for dissolution.

thatmeasurementdatageneratedbythemethodmaybeusedto

6.1.3 Establishing the PAT Measurement System— make decisions concerning the design of the p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.